Updating of CNC programs for improving accuracy of roll-bending forming

2015-11-03SergeiBelykh

Sergei V.Belykh

(Aviation Technology Komsomolsk-on-Amur State Technical University, Komsomolsk-on-Amur 6810132, Russia)

Updating of CNC programs for improving accuracy of roll-bending forming

Sergei V.Belykh

(Aviation Technology Komsomolsk-on-Amur State Technical University, Komsomolsk-on-Amur 6810132, Russia)

The work on correcting control programs for the NC roll bevel-bending machine ГМС-1 is a continuation of a complex of works on designing software. This paper covers possible reasons for the occurrence of finished extruded section-shaped piece deviations from its electronic analogue in computer-aided bending by rolling on a NC roll machine. A mathematical description for the procedure of correcting NC programs according to component results is presented. A design of a checking device providing optimal quality and accuracy of finished part geometrical measurements is proposed.

NC; roll bending; pre-stressed state; numerical analysis

CLC:TG174.4

Aricle ID:2095-7262(2015)05-0570-03 Document code:A

0 Introduction

When automating elasto-plastic deformation processes, many development engineers run into a serious of processing problems. Whatever the accuracy of mathematical models of deformation process-ses is, the accurate manufacture of parts fully corresponding to their electronic models or standard samples, as a rule, is impossible. This is primarily due to the fact that, depending on a batch of work parts, a supplier and conditions of manufacture, storage and shipment of work parts as well as parameters of metal thermal treatment, if any in accordance to the manufacturing process, work part parameters may be inconsistent with tabled values used in designing NC programs. Variations in work-part cross-sectional geometrical parameters within tolerance limits according to reference books and classifications can markedly affect the results of a deformation process[1]. Variations in material mechanical characteristics can cause even greater errors and, for revealing actual parameters of a material, at least one work part from the batch should to be sent to a metrological examination, which may be a problem in conditions of the present-day production and cause an increase in time for a process design. The severity of taking into account for all mentioned above features hardly hinders the process of production automation in the filed of material deformation.

Similar problems have occurred in designing software for the roll machine ΓCM-1 for bending extruded products. A part made with an NC program designed with using tabled cross-sectional geometrical parameters and characteristics of a material may be inconsistent with its actual shape specified in detailed engineering drawings. To solve the above-mentioned problem, it has been decided to use a system of NC program correction according to the first component results.

1 Cross-sectional geometrical parameters

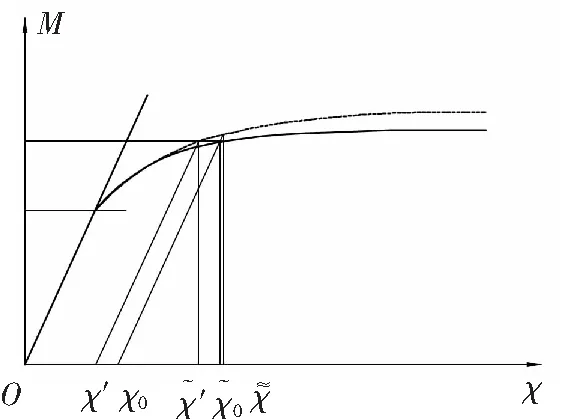

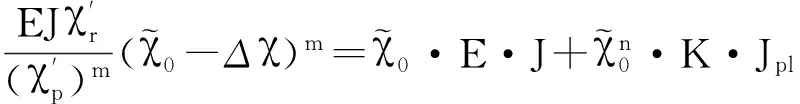

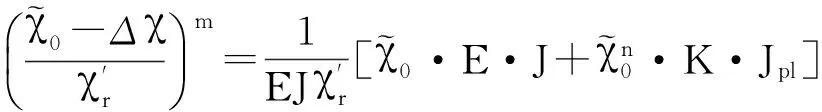

Let us assume that, for some normalized work part with certain cross-sectional geometrical parameters and made of a material with required mechanical characteristics, there is a dependenceM(χ) charac-terizing values of a bending force and a resultant curvature. For the case of elasto-plastic work of a material, this dependence is defined by the following expression[2-3]:

Mz=χ·E·J+χn·K·Jpl.

(1)

Atthegivendegreeofstress-strainedstateafterrelievinganactiveload,amaterialelasticrestitution[4-5]takesplaceandtheresidualcurvatureinacross-sectionisdefinedbythefollowingexpression[2-3]:

(2)

Arealworkpartmaygenerallydifferfromanormalizedonewithaveragedcharacteristicstakenfromareferencebookorclassificationbothovergeometricalparametersandmechanicalcharacteristicsofitsmaterial.Asaconsequence,thestiffnesscharacteristics[EJ]=f(χ)ofarealworkpartandnormalizedonewillbedifferent.Accordingly,thecurvatureofarealworkpartafterelasticrestitutionwilldifferfromtheratedonebysomevalueΔχwhichisfindfromthecomponentresults:

Δχ=χ0-χ′,

(3)

whereχ0istheexpectancecurvaturevalueafterspringbackandχ′istheactualcurvaturevalueafterspringback.

Δχ=0orχ0=χ′.

(4)

2 Cross-sectional model

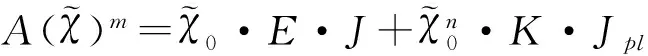

Adeviationofthegeneralizedstiffnesscharacteristic[EJ]=f(χ)ofarealworkpartwillbeconsiderednotgreatandthedependenceM(χ)forarealworkpartbesimilartoananalogdependenceforanormalizedworkpart.

Let,byananalogywiththedependenceσ-εintheformofalinearpowerfunctionforelasto-plasticworkofamaterial[2-6],theM(χ)functionapproximationalsoberepresentedasalinearpowerfunction.Assumingequalstiffnesscross-sectionalcharacteristicsintheelasticdeformationzoneforarealworkpartandnormalizedone(Fig.1)

[EJ]r=EJ,

weobtain

(5)

Fig. 1 M(χ) dependence approximation

WefindthevaluesAandmfromthelinearfunctionM=A(χ′)mgoingthroughtwopoints:

(1)thepointofchangingelasticstrainsinthecross-sectionbeingconsideredintoplasticones:

(6)

Taking,asaninitiationofplasticstrains,thecurvature,atwhichplasticstrainsoccurinthelayerfarthestremovedfromtheneutralcross-sectionalline,wewrite:

Thevalueh1-ynisfindfromthemodelforacomplexcross-section(Fig.2).

Fig. 2Elasto-plasticbendforacompound-sectioncomponent

or, taking into account (3),

(7)

ExpressingAfrom(6)andsubstitutingitinto(7),weobtain

(8)

Thelinearpowerdependencedescribedbyexpressions(5)and(8)characterizesthebehaviorofarealworkpartunderdeformation.

Accordingto(5),asthebendingforceMinsomesectionofarealworkpartisachieved,thecurvaturethereinforelasto-plasticloadingisdefinedas

(9)

Afterelasticrestitutionwithrelievinganactiveload,thecurvaturewillchangebythevalue

And the residual curvature is equal to

(10)

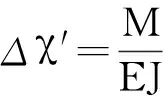

TocorrectanNCprogram,werecalculatetheinitialworkpartcurvaturesobtainedininvestigatingtheworkpartgeometryinthebendingplaneintonewvaluescorrespondingtotherealbehavioroftheworkpartunderdeformationwithconsiderationforitsactualstiffnesscharacteristics.

ThecorrectedbythismeansNCprogramwillgivefarmoreaccu-rateresults,whichmakesitpossibletoreduceaninfluenceofparame-tersneglectedindesigningandtolessenlaborinputinfinishingworkswhichareinevitableinmakingcomplexhigh-precisionparts.

Forcheckingafinishedpartgeometrydeviationfromitselectronicanalogueonecanuseacheckingdevicewhichconsistsinasetoflongitudinalmembers(gages)mountedatthesamebasealongthelengthofthepartandtherebyformingthepart-surfacegeneratinglineattheprescribedpoints(Fig.3).

Fig. 3 A checking device

3 Conclusion

Theuseofthiskindofcheckingdevicewillmakeitpossibletopreventshapedeformationsbygravity,whichisinevitablewithothermethodsofchecking,thusimprovingaccuracyofasubsequentNCprogram

correction. The readjustability of the device allows to check a wide range of standard parts at low expenses. The deviation may be measured both on coordinate-measuring machines and multi-purpose inspection tools. The selection of a measuring way and a tool depends on a required accuracy of measurements.

[1]Вдовин С И. Методы расчета и проектирования на ЭВМ процессов штамповки листовых и профильных заготовок [M].С И Вдовин - М: Машиностроение, 1988.

[2]Выгодский М Я, Справочник по высшей математике[M].М Я Выгодский- М: Наука, 865-872 .

[3]Белых С В, Станкевич А В, Кривенок А А. Особенности автоматизированного изготовления стрингеров летательного аппарата с использованием роликового оборудования оснащенного ЧПУ [J]. Авиационная промышленность 2009:30-44.

[4]Феоктистов С И, Белых С В, Кривенок А А. Перевалов. Аппроксимация геометрии контура дугами при контроле точности изготовления деталей летательных аппаратов[M].С И Феоктистов, - Комсомольск-на-Амуре: КнАГТУ, 2010:150-156.

[5]Феоктистов С И. Автоматизация проектирования технологичес-ких процессов оснастки заготовительно-штамповочного производства авиационной промышленности[M]. Владивосток: Дальнаука, 2001.

[6]Белых С В, Феоктистов С И, Станкевич А В.Аппроксимация геометрии контура дугами при контроле точности изготовления деталей летательных аппаратов[J].Ученые записки Комсомольского-на-Амуре государственного технического университета,2010:9-15.

(编辑李德根)

2015-01-06;修改日期:2015-07-06

Sergei V. Belykh(1978-),男,阿穆尔共青城人,副教授,工学博士,研究方向:数控加工,E-mail:belykhsv@knastu.ru。

提高成形轧辊挠度的CNC程序校正研究

Sergei V.Belykh

(阿穆尔共青城国立技术大学 飞行器制造系, 阿穆尔共青城 6810132, 俄罗斯 )

针对数控滚机床ГМС-1工序校正控制程序设计复杂的问题,分析发生挤压块偏离其弯曲数控滚轧机的原因,给出辊轧过程的数学描述。结果表明:校正的数控程序能够根据组件检查设备的状态,可以提高零件的几何精度。

NC; 轧辊挠度; 预应力状态; 数值分析

TG174.4

10.3969/j.issn.2095-7262.2015.05.021