Study on parameters optimization in resistance spot welding of stainless steel with rectangular electrodes*

2015-10-31ZhangXiaoqiXuGuochengWangChunshengandLiuJing

Zhang Xiaoqi,Xu Guocheng,Wang Chunsheng and Liu Jing

张小奇,徐国成,王春生,刘 静**

Study on parameters optimization in resistance spot welding of stainless steel with rectangular electrodes*

Zhang Xiaoqi,Xu Guocheng,Wang Chunsheng and Liu Jing

张小奇,徐国成,王春生,刘 静**

By means of the quadratic regression orthogonal combination design,a mathematical model of the relationship between the quality of spot welds and the welding parameters,including welding current,welding time and electrode force,is established.The influences of welding parameters on long-axis dimension of the nugget and shearing resistance of spot welds are studied and the welding parameters are optimized.The results show that the regression equation obtained can realize the accurate prediction of long-axis dimension of the nugget and shearing resistance of spot welds.

rectangular electrodes,resistance spot welding,parameter optimization

0 Introduction

Resistance spot weldingis animportantjoining process for fabricating sheet metal assemblies and is widely used in automobile body manufacturing and rail vehicle body manufacturing[1-2].Improving the quality of spot welding is of far-reaching significance to guarantee the assembly quality,the connection strength and sealing performance of the automobile body.The conventional electrodes can be divided into the cone type ones and the spherical ones,both of which produce around welding spot and the welding spot has limited effective connection length.The weld spacing used in production must exceed a certain value to avoid shunt current,which lowers strength of welded joint and gas tightness of welded structure.Therefore the conventional electrodes are not suitable for production which has the high requirement of strength and gas tightness.The conventional seam welding cannot satisfy the need of joint in small-scale because of restrictions of the configuration although continuous welding can be realized;the arc welding cannot satisfy the need of welding deformation although continuous welding can be realized.Therefore,under the premise of ensuring the strength of the joint,the end of the electrode is processed into a rectangle,which can extend the effective length of the connection joints,realize the welding of special structure and improve the welding efficiency and the gas tightness of welded structure[3].

The welding parameters are important factors affecting the quality of spot welding joint,including welding current,welding time and electrode force.The reasonable choice of welding parameters is necessary.The resistance spot welding with rectangular electrodes is new process without mature welding process specification.It is necessary to optimize the welding parameters and to study the influence of welding parameters on welding quality[4-5].

In order to obtain higher shearing resistance of spot welds and longer long-axis dimension of the nugget,a mathematical model of the relationship between the quality of spot welds and the welding parameters,including welding current,welding time and electrode force,is established by means of the quadratic regression orthogonalcombination design.The mathematical model can realize the accurate prediction of long-axis dimension of the nugget and shearing resistance of spot welds,and it can provide the theoretic foundation for application of resistance spot welding with rectangular electrodes.

1 Experimental conditions

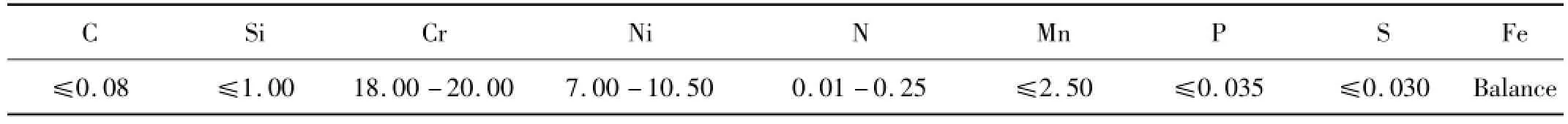

The material used in this research was SUS304 austenitic stainless steel,0.9 mm in thickness.The chemical composition and mechanical properties are shown in Table 1 and Table 2,respectively.

Table 1 Chemical composition of SUS304 austenitic stainless steel(wt.%)

Table 2 Mechanical properties of SUS304 stainless steel

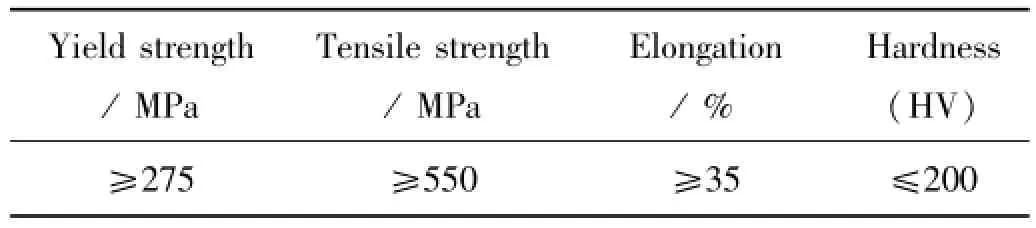

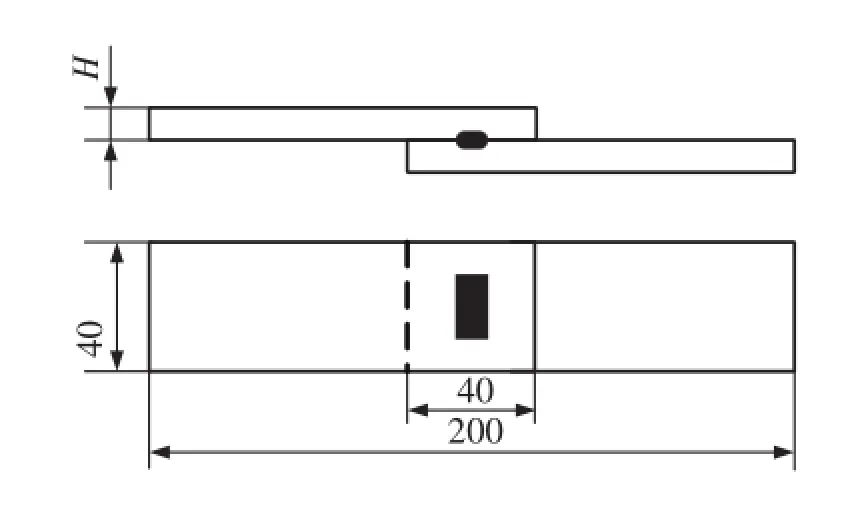

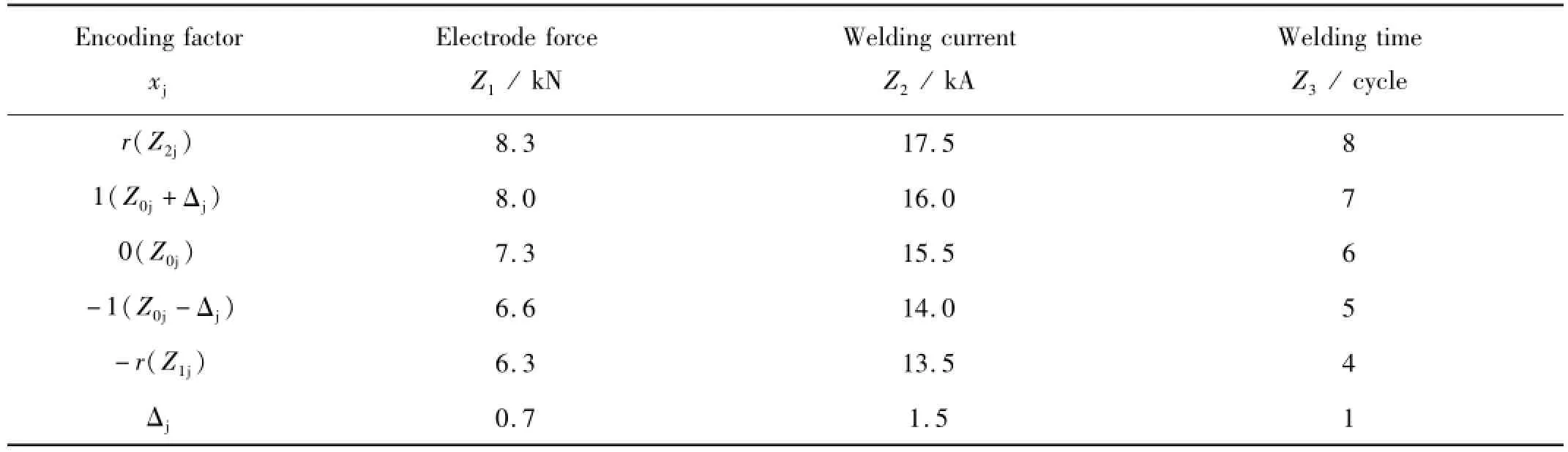

The end of lower electrode used in this study is rectangular and the end of upper ones is the plane.As far as possible to achieve the maximum length and width ratio of the rectangular electrode end face if conditions permit.The size and structure of rectangular electrode are shown in Fig.1,B is the width of rectangular electrode tip,L is the length of rectangular electrode tip,H is the thickness of specimen,B is 5 mm and L is 18 mm in this paper.The size and assembly method of welded specimen are shown in Fig.2.

Fig.1 The assembly drawing of rectangular electrode and specimen

Fig.2 Shape and size of specimen

2 Experiment scheme

Regression design is a branch of the field of experimental optimization,which is a method of modern modeling.By means of the quadratic regression orthogonal composite design process with three factors,which realize the orthogonal of test scheme,the optimization of resistance spot welding parameters with rectangular electrode for stainless steel can be realized.

2.1The selection principle of welding parameters variation range

The resistance spot welding with rectangular electrode belongs to the category of resistance spot welding from the perspective of working mechanism,although the shape of electrode has changed,so welding parameters are still an important factor in its quality.The welding parameters of spot welding with rectangular electrode were chosen which based on ordinary electrode[6].In choosing welding parameters with rectangular electrode,the fundamental principle is that the current density remains the same value between resistance spot welding with rectangular electrode and conventional electrodes,although the contact area be-tween electrode tip and workpiece increases.The chosen welding parameters should be adjusted because of the changed radiating condition resulted from the change of shape and size of electrode tip.

The effective connection length of spot welded joint was prolonged by the change of electrode shape.Therefore,the long-axis dimension of the nuggetin terms of y1is one of the important factors to measure the quality of welded joint,and the shearing resistance of spot weldsin terms of y2is another one.The long-axis dimension of the nugget and the shearing resistance of spot welds are used as the evaluating indicator in this paper.

2.2Test coding of nature factorsand the scheme design

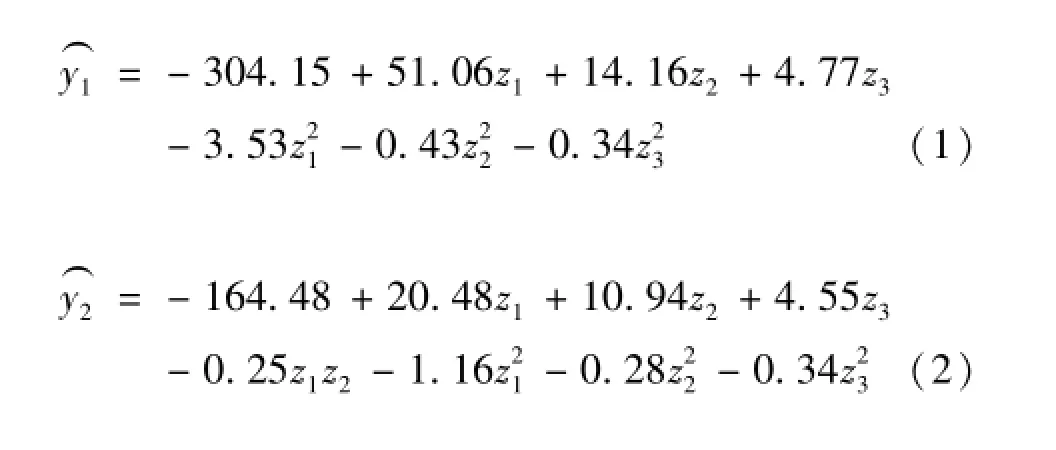

Electrode force(Z1),welding current(Z2)and welding time(Z3)were selected as nature factor,according to the characteristics of resistance spot welding and the selection principles of welding parameters.The variation range of electrode force is 6.3-8.3 kN,welding current is 13.5-17.5 kA,welding time is 4-8 cycle.

In the optimization design,due to the natural factors are three,so the choice of as the orthogonal table.The number of center points is 3,by looking-up the table,the length of the arm is 1.353,and the factor level and coding of this paper are shown in Table 3,which,Xjis the factor level,Zjis welding parameters.In this paper,one degree term and interaction item have a total of six.Therefore,the number ofcomprehensive test is 8 and the number of non-linear relationship test is 6.Then orthogonal combination designs a total of 17 times test.

Table 3 Level of nature factors and its coding

3 Experiment results and analysis

3.1Mathematical model

The purpose by using of rectangular electrode is to prolong the effective connection length and to increase the stopping property also,and then the optimization is mainly used to predict and inspect long-axis dimension of the nugget and shearing resistance of spot weld.A mathematical model of the relationship between the quality of spot welds and the welding parameters,including welding current,welding time and electrode force,is established in the optimum design.The mathematical model is tested though the significance test and lack-of-fit test.

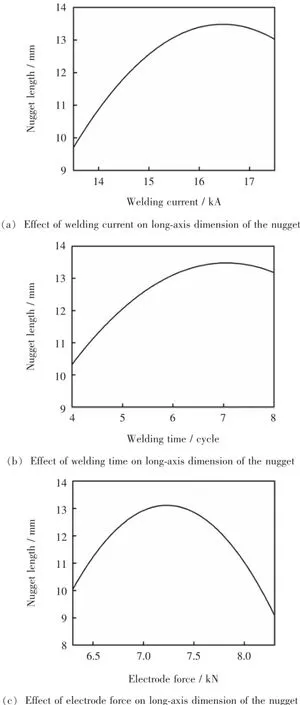

Eq.(1)is the mathematical model between the longaxis dimension of the nugget and the welding parameters,including welding current,welding time and electrode force,and Eq.(2)is the mathematical model between the shearing resistance of spot weld and the welding parameters.

The significance level of regression equation is 0.01 both of Eq.(1)and Eq.(2).Then it is showed that the fitting is good of regression equation.The square of lack of fit deviance is caused by experimental error.The equation is optimum regression equation.

3.2Analysis and discussion

3.2.1Effect of welding parameters on long-axis dimension of the nugget

According to the results of statistical test and the regression equation,the influence order of each nature factor on long-axis dimension of the nugget is welding current,welding time and electrode force.The effect of the interaction among nature factors on long-axis dimension of the nugget is not significant and can be neglected.

The effect of welding current,electrode force and welding time on long-axis dimension of the nugget are shown in Fig.3.The long-axis dimension of the nugget increases with increasing welding current below welding current of 16 kA,when the other welding conditions are kept constant.When the welding current value is more than 16 kA,the growth rate of the nugget size reduces gradually. When the current value reaches 17 kA,the splash occurs due to the intense heating.Thus,long-axis dimension of the nugget slightly decreases.The law of the change of the nugget described above is basically the same as that of the actual welding.

The long-axis dimension of the nugget increases with increasing welding time when the welding time is less than 7 cycle.The growth of long-axis dimension of the nugget reduces gradually when the welding time is more than 7 cycle,and it is similar to the actual welding.Now,the heating rate of heat source increases moderately,the heat production and the heat dissipation reach equilibrium,the nugget size reaches a saturation value.The splash cannot occurs due to the increase of nugget size.The effect of welding time on nugget size is similar to welding current.

The long-axis dimension of the nugget increases with increasing electrode force when the electrode force is less than 7.3 kN.When the electrode force is more than 7.3 kN,the long-axis dimension of the nugget decreases rapidly with increasing electrode force.The detection results show that excessive electrode force leads to the heating decreased decrease of heat and the heat dissipation enhancement in weld zone,and the rapid decrease of nugget size by using these parameters.

Fig.3 Effect of welding current,welding time,electrode force on long-axis dimension of the nugget

3.2.2 Effect of welding parameters on shearing resistance of spot welds

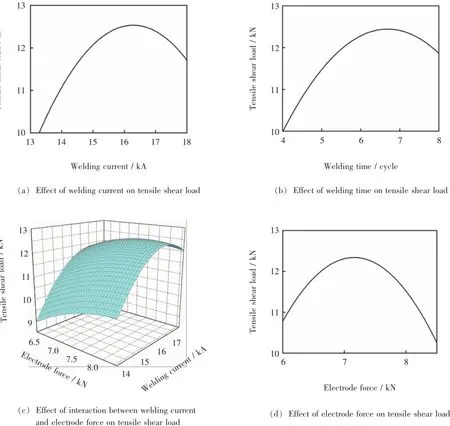

According to the regression equation and the results of statistical calculation,the influence order of each nature factor and its interaction on joint strength is welding current,welding time,the interaction between welding current and electrode force,the last one is electrode force. The other factors on joint strength can be neglected.The changing trend of the shearing resistance of spot welds which is affected by welding parameters above is shown in Fig.4.

Fig.4 Effect of welding parameter on tensile shear load

The shearing resistance of spot welds is sensitive to welding current,and the tensile shear load increases with increasing welding current while given conditions were kept constant as above,the maximum is 12.52 kN.The high shearing resistance of spot welds cannot be obtained while the welding current is more than 16.8 kA or less than 14.7 kA for energy deficiency and fast heating. When the welding current reaches 17.5 kA,the splash oc-curs due to the intense heating,and the shearing resistance of spot welds decreases.

The effect of welding time on shearing resistance of spot welds is like that on the long-axis dimension of the nugget.The shearing resistance of spot welds increase with increasing welding time,but the growth rate of the nugget size reduces increasingly beyond 7 cycle,for the balance of heat production and loss of heat in weld zone.

When welding,no splash is a main characteristic of the interaction between welding current and electrode force.The effect of interaction between welding current and electrode force on shearing resistance of spot welds can be characterized by 3D surface with 7 cycle welding time,as shown in Fig.4c.The shearing resistance of spot welds increases with increasing electrode force when the welding current is less than 16.5 kA,and decreases with increasing welding current when the welding current is more than 16.5 kA.But the growth rate of tensile shear load with lower electrode forceis higher than the growth rate with higher electrode force.

The shearing resistance of spot welds increases with increasing electrode force when the electrode force is less than 7.3 kN.The joint strength and nugget size decrease rapidly when the electrode force is more than 7.3 kN.The increasing of contact area is the primary cause,which lead to the decreasing of heating and the increasing of heat dissipation in weld zone.

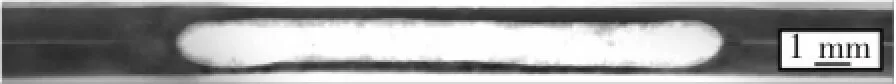

With long-axis dimension of the nugget and shearing resistance of spot welds as evaluating indicator,the optimum welding parameters were obtained by MATLAB in this paper,with electrode force 7.15 kN,welding current 16.43 kA and welding time 7 cycle,now the long-axis dimension of the nugget is 13.77 mm,and the tensile shear load is 12.63 kN by calculation,and the measured value is 14.0 mm and 11.83 kN,the error between measured value and predictive value is 1.65%and 6.7%respectively. The nugget section in long-axis dimension is shown in Fig.5.

Fig.5 The nugget section in long-axis dimension

4 Conclusions

By means of the quadratic regression orthogonal combination design,a mathematical model of the relationship between the quality of spot welds and the welding parameters,including welding current,welding time and electrode force,is established.The regression equation fitted well.Parameters optimization and experimental analysis results show that:(1)The influence of welding current on the long-axis dimension of the nugget is the most significant,followed by the electrode force and welding time;(2)The shearing resistance of spot welds is influenced by the change of welding current and electrode force,and also influenced by the interaction between them.High shearing resistance of spot welds can be obtained by taking large welding current and electrode force;(3)The optimum parameters are electrode force 7.15 kN,welding current 16.43 kA,welding time 7 cycle,under these conditions,the measured values of long-axis dimension of the nugget and shearing resistance of spot welds are in good agreement with the predicted values.

[1] Li Y B,Li Y,Lou M,et al.Light weighting of car body and its challenges to joining technologies.Journal of Mechanical Engineering,2012,48(18):44-54.(in Chinese)

[2] Du B G.Investigation of welding technology of stainless steel sheet for urban rail vehicle.Dalian:Dalian Jiaotong University,2007.(in Chinese)

[3] Zhang X Q,Xu G C,Wang C S,et al.The numerical simulation of the temperature field during resistance spot welding with rectangular electrode.Transactions of the China Welding Institution,2009,30(4):101-104.(in Chinese)

[4] Zhou M,Zhang H,Hu S J.Relationships between quality and attributes of spot welds.Welding Journal.2003,82(4):72s-77s.

[5] Luo Y,Pi F X,Xiong C Z,et al.Nonlinear multiple regression model of resistance spot welding for galvanized steel sheet.Transactions of the China Welding Institution,2010,31(4):89-92.(in Chinese)

[6] Zhao X H.Pressure welding.Beijing:China Machine Press,1997.(in Chinese)

*This work was supported by Scientific Research Project Fund of Jilin Provincial Education Department(Grant No.2013488).

**Zhang Xiaoqi,College of Engineering,Changchun Normal University,Changchun,130032. Xu Guocheng,College of Materials Science and Engineering,Jilin University,Changchun,130025. Liu Jing,Key Laboratory of Bionic Engineering of Ministry of Education,Jilin University,Changchun,130025. Wang Chunsheng,Changchun Railway Vehicles Corporation,Changchun,130062.Liu Jing,Corresponding author,E-mail:39088985@qq.com

猜你喜欢

杂志排行

China Welding的其它文章

- New filler metal systems for the brazing of titanium alloys

- Effect of gallium addition on microstructure and properties of Ag-Cu-Zn-Sn alloys*

- Influence of Mn on wettability and microstructure of low-silver lead-free solders*

- Plastic characterization and performance of SnAgCuBiNi/Cu lead-free BGA solder joints*

- Macrostructures and mechanical properties of ultrasonic-assisted friction stir welding joint of 2024-T3 aluminium alloy

- Influences of acoustic field parameters on welding arc behavior in ultrasonic-MIG welding*