A new heat transfer correlation for flow boiling in helically coiled tubes

2015-07-25JiCuilianHanJitianLiuXiaopengShaoLiChenChangnian

Ji CuilianHan JitianLiu XiaopengShao LiChen Changnian

(1School of Energy and Power Engineering,Shandong University,Jinan 250061,China)

(2Municipal and Environmental Engineering Department,Shandong Urban Construction Vocational College,Jinan 250103,China)

A new heat transfer correlation for flow boiling in helically coiled tubes

Ji Cuilian1,2Han Jitian1Liu Xiaopeng2Shao Li1Chen Changnian1

(1School of Energy and Power Engineering,Shandong University,Jinan 250061,China)

(2Municipal and Environmental Engineering Department,Shandong Urban Construction Vocational College,Jinan 250103,China)

Based on the superposition principle of the nucleate boiling and convective heat transfer terms,a new correlation is developed for flow boiling heat transfer characteristics in helically coiled tubes.The effects of the geometric and system parameters on heat transfer characteristics in helically coiled tubes are investigated by collecting large amounts of experimental data and analyzing the heat transfermechanisms.The existing correlations are divided into two categories,and they are calculated w ith the experimental data.The Dnfactor is introduced to take into account the effect of a complex geometrical structure on flow boiling heat transfer.A new correlation is developed for predicting the flow boiling heat transfer coefficients in the helically coiled tubes,which is validated by the experimental data of R134a flow boiling heat transfer in them;and the average relative error and rootmean square error of the new correlation are calculated.The results show that the new correlation agrees well w ith the experimental data,indicating that the new correlation can be used for predicting flow boiling heat transfer characteristics in the helically coiled tubes.

helically coiled tube;flow boiling;heat transfer coefficient correlation;heat transfer

H elical-coiled tubes are extensively used in the nuclear,petrochem ical,refrigeration and heat pump systems,and many others,due to high efficiency in heat transfer and compactness in volume.Many researchers investigated flow boiling heat transfer characteristics in the helically coiled tubes by experiments,numerical simulations,theoretical exploration and mechanism analysis,obtained a variety of data of engineering applications,and developed a series of correlations for flow boiling heat transfer coefficients.Those correlations can be mainly classified into two categories.One is the empirical heat transfer coefficient correlations including the boiling number based on the experimental results.They do not have universal significance,andmay only be applied to operating statesw ith the same conditions[14].The other category is based on themechanism of flow boiling heat transfer,which consists of an explicit convection item and boiling item.They are generally not dependent on the boiling number and_ have clear physicalmeaning and w ide applicable ranges[58].Apparently,a certain progress has been achieved in the study of flow boiling heat transfer in the helically coiled tubes.However,the fundamental basis of the phenomena is very incomplete and the correlations of engineering applications are still lacking due to the complexity of flow boiling phenomena and the lim itation in the current research expertise.

Accordingly,it is important to develop new correlations for heat transfer coefficients of flow boiling heat transfer in the helically coiled tubes.Chen’s[5]correlation based on the mechanism of nucleate and convective heat transfer isw idely used to correlate flow boiling heat transfer coefficients in straight tubes.However,it cannot predict the flow boiling heat transfer characteristics in the helically coiled tubes and other complex geometrical tubes.Therefore,the main objective of this study is to develop a new heat transfer coefficient correlation for flow boiling in the helically coiled tubes based on the Chen’s superposition principle of nucleate and convective heat transfer.The Dnfactor is introduced to take into account the geometrical parameter effect of complex tubes on flow boiling heat transfer in the helically coiled tubes,and the regression method is used to obtain the index of the Dn.The prediction accuracy of the developed correlation is further evaluated by the experimental data of flow boiling heat transfer.

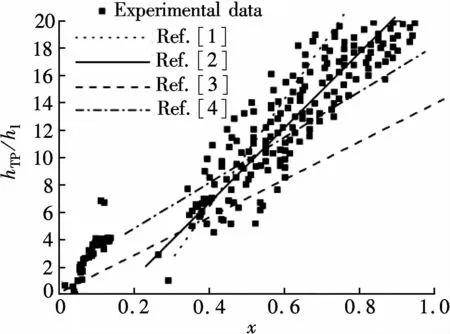

1 Assessment of Existing Correlations

A bank of experimental data was collected for flow boiling heat transfer in tubes,including 1 152 data_ po_ints from different sources and nine different fluids[13,916].The predictive capability of those correlations is determ ined as illustrated in Fig.1 by testing the correlations in Refs.[1- 4]against the data available in Refs.[11-13].In Fig.1,hTPis the flow boiling heat transfer coefficient,and hlis the liquid phase heat transfer coefficient.As shown in Fig.1,the prediction values of correlation in Ref.[1]are slightly higher than the experimental ones,while the prediction ones of correlation in Ref.[4]are lower than the experimental data.The differences are partially attributed to the experimental conditions,which mainly include the test section geometry parameters,system parameters and test fluids.Correlation in Ref.[4]is obtained by fitting the experimental data in the circular tubes.The heat transfer coefficients in the circular tubes are lower than those in the helically coiled tubes.

Fig.1 Comparison of correlations in Refs.[1- 4]

Using the experimental data in Refs.[1- 2,9],the comparison of prediction accuracy of correlations in Refs.[5- 8]is shown in Fig.2.The predicting values of correlation in Ref.[6]are close to the experimental values while the ones of correlation in Ref.[5]deviate from the experimental data,which is primarily attributed to the effect of geometric parameters of the helically coiled tubes on the heat transfer characteristics.The secondary flow generated by the centrifugal forces in the helically coiled tubes enhances the heat transfer in comparison w ith that in straight tubes.Therefore,the correlation based on the straight tubes needs to be modified for applying to the prediction of flow boiling heat transfer in the helically coiled tubes.

Fig.2 Comparison of correlations in Refs.[5- 8]

It is evident from the above discussion that the existing correlations cannot well predict the boiling heat transfer characteristics for the helically coiled tubes.Therefore,a new correlation is developed for flow boiling heat transfer characteristics in the helically coiled tubes using Chen’s[5]methodology for correlating flow boiling heat transfer.

2 Correlation Development

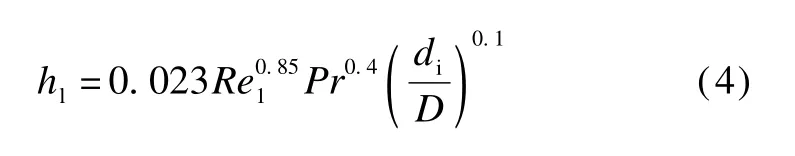

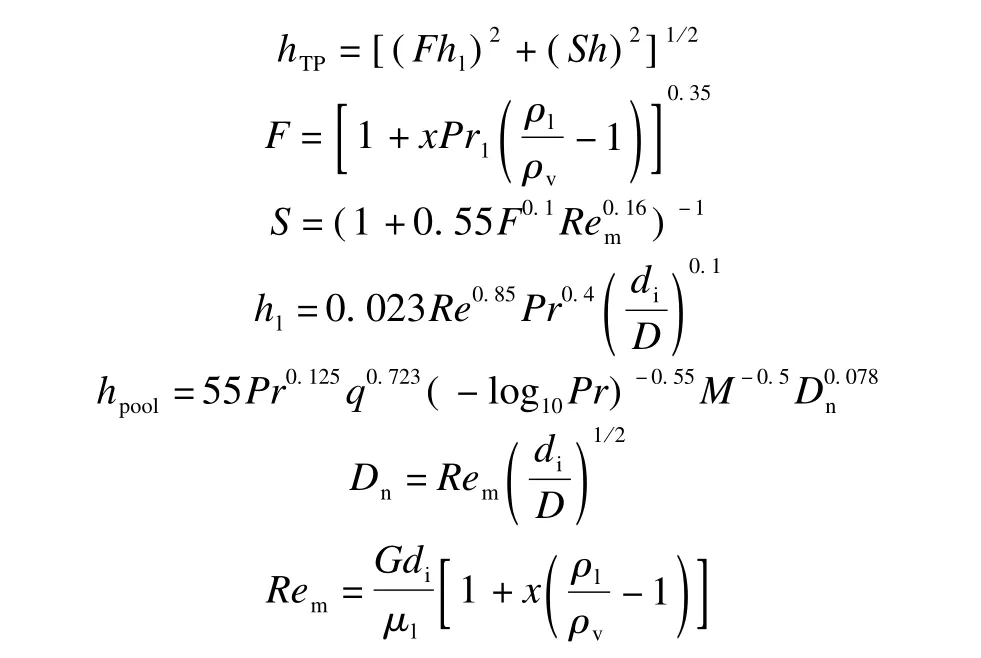

Follow ing Chen’s[5]superposition method of nucleate boiling and convective heat transfer,the flow boiling heat transfer coefficient correlation for flow boiling heat transfer coefficients in the helically coiled tubes can be expressed as

where(Fhl)nis the forced convective contribution;F is the forced convective heat transfer enhancement factor;(Shpool)nis the nucleate boiling contribution.

The value of F is always greater than 1 because the fluid velocities in two-phase flows are much higher than those in single-phase liquid-only flows.According to the forced convection heat transfer mechanism,superheated liquid vapor layers in flow boiling are thinner than those in pool boiling.Therefore,the suppression factor S is always less than 1.S is assumed to be a function of the two-phase flow m ixture Reynolds number Rem.The follow ing formula proposed by Liu et al.[6]is used to calculate F and S:

where Pr is the Prandtl Number;x is the vapor quality;ρlis the liquid density,kg/m3;ρvis the vapor density,kg/m3;Relis the Reynolds number.

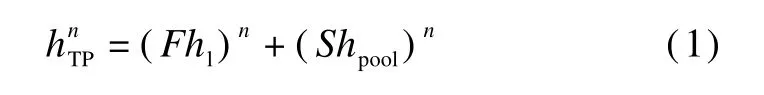

There are many available methods to calculate hlin the literature.The follow ing correlation w ith high precision is used to calculate the average heat transfer coefficient in the helically coiled tubes:

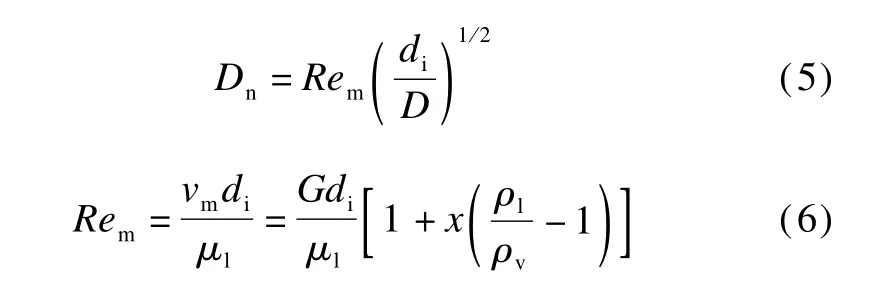

where diis the inner diameter,mm;D is the helical diameter,mm.The flow boiling heat transfer phenomenon in the helically coiled tubes ismore complex than that in straight tubes due to the secondary flow resulting from the centrifugal force[14].Therefore,the Dnfactor is introduced to take into account the comprehensive influence of the geometric parameters of the helically coiled tube on flow boiling heat transfer,which include the tube diameter,helical tube diameter,and helical pitch.

where vmis the two-phase mixture velocity;μlis the viscosity;G is themass flux.

The correlation for pool boiling is an appropriate choice for hpoolsince it is verified that the correlation provides good prediction for experimental heat transfer coefficientsin a variety of channels[17].Introducing the two-phase Dean number Dninto the correlation,the pool boiling heat transfer coefficient used for correlating flow boiling heat transfer coefficients in the helically coiled tubes is as follows:

where q is the heat flux,kW/m2;M is the molecular mass of the fluid,kg/kmol;c1,c2and c3are the constants determ ined by experiments.Through themultivariate nonlinear regression analysis on the experimental data,the values of c1,c2and c3are obtained,being 0.125,0.723,and 0.078,respectively.

The index n is equal to 2 in Eq.(1).Therefore,the flow boiling heat transfer coefficient can be calculated using Eq.(1)togetherw ith Eqs.(2)to(7).The correlation is verified by experimental data in Refs.[15- 16, 18].The predictive capability of the new correlation is illustrated in Fig.3.It can be seen that the prediction values of the new correlation are in good agreementw ith the experimental data.

Fig.3 Comparison of prediction values and experimental data

As shown in Fig.4,the statistical results indicate that the maximum deviation is 23.6%,w ith 93.2%of the experimental data distributing in±20%error range of the new correlation.

Fig.4 Prediction errors of new correlation

The developed correlation for flow boiling heat transfer coefficients in the helically coiled tubes can be summarized as follows:

Parameter ranges in the correlation are as follows:500 mm<L<7 070 mm;3.0 mm<di<15.0 mm;100 mm<D<400 mm;35 mm<Pt<120 mm;100 kg/(m2· s)<G<400 kg/(m2·s);5 kW/m2<q<20 kW/m2;0.1<x<0.9;0.8<Pr<10;500<Rem<2×105;0.2 MPa<P<1.2 MPa.Here,L is the heating length;Ptis the pitch;P is the system pressure.

In order to quantitatively determ ine the predictive accuracy of the new correlation,their mean relative error(MRE)and rootmean square error(RMSE)are calculated,respectively.

The results demonstrate that good predictive accuracy is achieved by the developed correlation,w ith the MRE and RMSE being 8.23%and 0.532,respectively.

3 Conclusion

Based on large amounts of experimental data available in the literature,a new heat transfer coefficient correlation is developed for flow boiling in horizontal helically coiled tubes by superposing the nucleate boiling contribution and the convective heat transfer one.The Dnfactor is introduced to take into account the effect of geometrical parameters on flow boiling heat transfer in helically coiled tubes,and the regressionmethod is used to obtain the index of the Dn.The experimental data verifies that the developed correlation has good prediction accuracy.

[1]Zhao L,Guo L J,Bai B F,et al.Convective boiling heat transfer and two-phase flow characteristics inside a small horizontal helically coiled tubing once-through steam generator[J].International Journal of Heat and Mass Transfer,2003,46(25):4779- 4788.

[2]Shao L,Xu Z C,Han JT,et al.Experimental investigations on two-phase flow boiling heat transfer of R134a inhelically coiled tube[J].Proceedings of the CSEE,2011,31(8):62- 66.(in Chinese)

[3]Gungor K E,W interton R H S.A general correlation for flow boiling in tubes and annuli[J].International Journal of Heat and Mass Transfer,1986,29(3):351-358.

[4]Tran T N,WambsganssM W,France D M.Small circular-and rectangular-channel boiling w ith two refrigerants[J].International Journal of Multiphase Flow,1996,22(3):485- 498.

[5]Chen JC.A correlation for boiling heat transfer to saturated fluids in convective flow[J].Industrial&Engineering Chemistry Process Design&Development,1966,5(3):322- 329.

[6]Liu Z,W interton R H S.A general correlation for saturated and subcooled flow boiling in tubes and annuli,based on a nucleate pool boiling equation[J].International Journal of Heat and Mass Transfer,1991,34(11):2759- 2766.

[7]Steiner D,Taborek J.Flow boiling heat transfer in vertical tubes correlated by an asymptotic model[J].Heat Transfer Engineering,1992,13(2):43- 69.

[8]Bertsch S S,Groll E A,Garimella S V.A composite heat transfer correlation for saturated flow boiling in small channels[J].International Journal of Heat and Mass Transfer,2009,52(7/8):2110- 2118.

[9]Chen C N,Han JT,Jen T C.Thermo-chemical characteristics of R134a flow boiling in helically coiled tubes at low mass flux and low pressure[J].Thermochimica Acta,2011,512(1/2):163- 169.

[10]Elsayed A M,A l-Dadah R K,Mahmoud S,etal.Investigation of flow boiling heat transfer inside small diameter helically coiled tubes[J].International Journal of Refrigeration,2012,35(8):2179- 2187.

[11]Wongw ises S,Polsongkram M.Evaporation heat transfer and pressure drop of HFC-134a in a helically coiled concentric tube-in-tube heat exchangers[J].International Journal of Heatand Mass Transfer,2006,49(3/4):658 -670.

[12]Ghorbani N,Taherian H,Gorji M,et al.Experimental study ofm ixed convection heat transfer in vertical helically coiled tube heat exchangers[J].Experimental Thermal and Fluid Science,2010,34(7):900- 905.

[13]Haruki N,Horibe A.Flow and heat transfer characteristics of ice slurries in a helically-coiled pipe[J].International Journal of Refrigeration,2013,62(36):1285-1293.

[14]Wang W H,Chen Y P,Cao R B,etal.Analysis of secondary flow in shell-side channel of trisection helix heat exchangers[J].Journal of Southeast University:English Edition,2010,26(3):426- 430.

[15]Chen C N,Han JT,Jen T C,etal.Dry-out CHF correlation for R134a flow boiling in a horizontal helicallycoiled tube[J].International Journal of Heat and Mass Transfer,2011,154(3):739- 745.

[16]Shao L,Han JT,Wang M X,etal.Experimental investigation on flow patterns and pressure drop of R134a flow boiling in a horizontal helically coiled pipe[J].Journal of Enhanced Heat Transfer,2013,20(3):225- 233.

[17]Cooper M G.Heat flow rates in saturated nucleate pool boiling—a w ide-ranging exam ination using reduced properties[J].Advances in Heat Transfer,1984,97:157- 239.

[18]CuiW Z,Li L J,Xin M D,etal.A heat transfer correlation of flow boiling inm icro-finned helically coiled tube[J].International Journal of Heat and Mass Transfer,2006,49(17/18):2851- 2858.

一种新的螺旋管内流动沸腾传热关联式

冀翠莲1,2韩吉田1刘晓鹏2邵 莉1陈常念1

(1山东大学能源与动力工程学院,济南250061)

(2山东城市建设职业学院市政与环境工程系,济南250103)

为了改善螺旋管内流动沸腾换热特性的预测方法,利用核态沸腾项和对流换热项的叠加原理建立了新的预测关联式.基于收集的大量实验数据和流动沸腾换热机理,分析螺旋管几何参数和实验参数对流动沸腾传热的影响,将已经建立的关联式分为2类,并用大量实验数据对其进行计算.为了考虑复杂管道对传热特性的影响,在新建立的螺旋管内流动沸腾传热预测关联式中引入了Dn因子.采用以R134a为介质的螺旋管内流动沸腾传热实验数据进行了验证,并计算新关联式的平均相对误差和均方根误差.结果表明,新的预测关联式与实验值吻合较好,可以用于螺旋管流动沸腾传热特性的预测分析.

螺旋管;流动沸腾;传热系数关联式;传热

TK121

10.3969/j.issn.1003-7985.2015.03.014

2014-12-29.

Biography:Ji Cuilian(1975—),female,master,associate professor,jicuilian75@163.com.

The National Natural Science Foundation of China(No.50776055,51076084).

:Ji Cuilian,Han Jitian,Liu Xiaopeng,et al.A new heat transfer correlation for flow boiling in helically coiled tubes[J].Journal of Southeast University(English Edition),2015,31(3):380- 383.

10.3969/j.issn.1003-7985.2015.03.014

猜你喜欢

杂志排行

Journal of Southeast University(English Edition)的其它文章

- CoMP-transm ission-based energy-efficient scheme selection algorithm for LTE-A system s

- Detection optim ization for resonance region radar w ith densemulti-carrier waveform

- Dimensional emotion recognition in whispered speech signal based on cognitive performance evaluation

- Cascaded projection of Gaussian m ixturemodel for emotion recognition in speech and ECG signals

- Action recognition using a hierarchy of feature groups

- Ergodic capacity analysis for device-to-device communication underlaying cellular networks