Impact analysis of supplier relationship on supply chain resilience using biological cellular resilience theory

2015-05-08WangXinpingZhaoLindu

Wang Xinping Zhao Lindu

(School of Economics and Management, Southeast University, Nanjing 211189, China)

Impact analysis of supplier relationship on supply chain resilience using biological cellular resilience theory

Wang Xinping Zhao Lindu

(School of Economics and Management, Southeast University, Nanjing 211189, China)

A supply chain resilience model is established based on the biological cellular resilience theory to analyze the impact of the supplier relationship on supply chain resilience. A scenario where the market demand is changed suddenly by some undesired events is considered. The results reveal that enhancing collaboration with a more resilient supplier can significantly improve supply chain resilience and reduce supply chain losses. It is also found that enhancing the supplier relationship can significantly benefit supply chain resilience if the collaborative intensity is relatively low, and it has less effect if supply chain members have already collaborated closely. Thus, enhancing the supplier relationship to a limited intensity is a relatively effective and economic method to strengthen supply chain resilience.

supply chain risk; supply chain resilience; biological cellular resilience; demand shocks; supplier relationship

Supply chain management aims at optimizing the operation mechanism to realize high supply chain benefits, and efficiency, and consequently sustaining competitiveness in the industry. To this end, many advanced supply chain management principles have been proposed, such as just-in-time (JIT), the original equipment manufacturer (OEM), centralized production and distribution, etc. However, these principles make supply chains much more vulnerable to unpredictable shocks in today’s uncertain and turbulent market[1]. Many examples of significant supply chain disruptive events have been witnessed[1-2]. One of the most famous cases is the March 2000 fire at the Philips microchip plant in Albuquerque, which sent his major buyers, Nokia and Ericsson, into chaos. Nokia learned of the impending chip shortage in just three days and took advantage of its rapid coordination and multiple sourcing strategy to obtain chips from other sources. Ericsson, however, could not avoid a production shutdown and exited from the mobile business market[2].

Facing such disruptive events, some supply chains survived and expanded, but others perished. How does this happen? The critical factor is supply chain resilience. In materials science, resilience represents the ability of a material to recover its original shape following a deformation. It was then introduced into social ecology, engineering and organizational behavior areas[3-5]. Since 2001, research on supply chain resilience has gradually attracted people’s attention. Christopher and Peck[6]defined supply chain resilience as the ability to recover to its initial state or moving to a new and more satisfied state after disruption. Sheffi[7]proposed that resilience refers to the ability of a company to bounce back from a large disruption. Zhao[8]pointed out that supply chain resilience was the self-adaptive and self-repairing ability of a supply chain when facing unexpected shocks, like biological cellular resilience. Despite different definitions, the essence of supply chain resilience is the ability to adapt to a changed environment efficiently and recover its original or even a better state post the disruptive event[9].

Supply chain collaboration has been proposed to be an effective way to create supply chain resilience[6,10-11]. Christopher and Peck[6]identified supply chain collaboration to be one of the principles of creating supply chain resilience. Muckstadt et al.[10]proposed that constructing a collaborative relationship between supply chain partners will reduce uncertainties in supply chain operations. Lee[11]pointed out that aligning the interests of all the firms in the supply network will optimize the chain’s performance when companies maximize their interests. Although these works all emphasize the importance of supply chain collaboration, there is less work about how to manage a supplier relationship against supply disruption risks. To address the gap in the current literature, we investigate the impact of supplier relationships on supply chain resilience to give convincing arguments on supplier relationship management.

Considering a two-stage supply chain consisting of two suppliers and one manufacturer, we establish a supply chain resilience model and discuss how supplier relationship influences supply chain resilience under a demand shock. The results shed light on how to develop correct alignment with suppliers to co-create a secure and resilient supply chain.

1 Supply Chain Resilience Model

1.1 Biological cellular resilience

The biological cell is the basic structural, functional, and biological unit of living organisms. Biological cells in human body are constantly subjected to mechanical stimulations from both the external environment and internal physiological conditions, causing deviation from their normal structural and physical properties. However, cells are able to withstand and respond to these stimuli with their complex skeleton and membrane systems, demonstrating great resilience[12].

Some mechanical models have been developed to characterize biological cellular resilience, using either the micro/nanostructural approach or the continuum approach. The continuum approach is simple and more straightforward to compute the mechanical properties of cells, although it provides less insight into the detailed molecular mechanical events. Generally, the continuum approach treats cells as comprising viscous materials, elastic materials, or viscoelastic materials, depending on the properties of cells. Accordingly, models viewing cells as a viscous component[13-14], an elastic component[15], or a connection of both viscous and elastic components[16-17]are established to study biological cellular resilience.

1.2 Supply chain resilience model formulation

Supply chain is a complex adaptive system open to the outside world. It has several similarities to biological cells. First, modern supply chains are dynamic networks of interconnected firms and industries, which is similar to the cytoskeleton system constituting the primary structure of biological cells. Secondly, supply chains exchange material, capital, and information with the outside world and biological cells exchange material, energy, and information with the external environment. Thirdly, once a sudden event occurs and breaks the balance of exchange between supply chains and the environment, supply chains will form an adaptive and self-repairing reaction to resist and reduce the negative effects. This is similar to the passive and active response of biological cells to mechanical stimuli from both the external environment and internal physiological conditions. Considering the similarities between supply chains and biological cells, Zhao[8]first proposed a basic framework for the supply chain resilience model following the continuum approach of biological cellular resilience. Li and Zhao[18]further took the supply chain as a cell and studied how the strain of the “cell” changes after a shock occurs and is eliminated. The strain of the “cell” shows the change of supply chain performance under unexpected shocks.

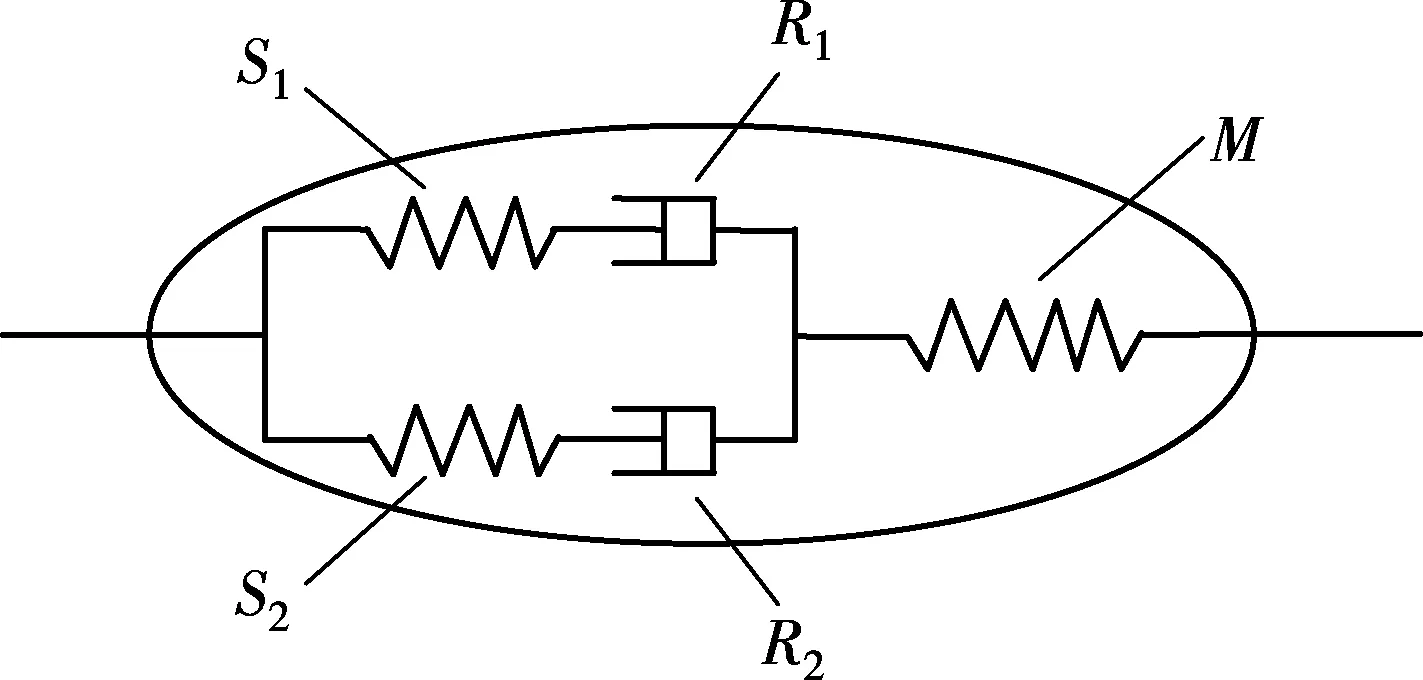

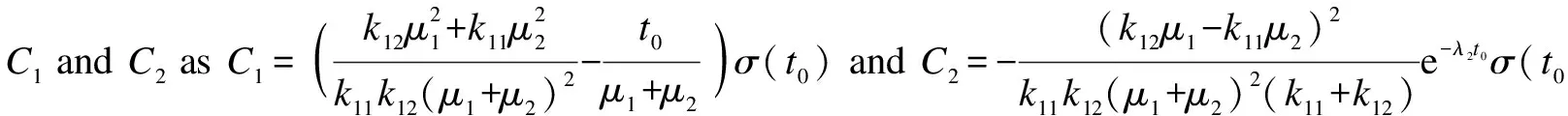

Based on the above analysis, we view a two-stage supply chain as a biological cell in this paper and regard the members in the supply chain and the collaborative relationships between the members to be some elastic and viscous components of the biological cell respectively, as shown in Fig.1. Specifically, the three members of the supply chain, manufacturerM, supplierS1, and supplierS2, are regarded as elastic components because they are all resilient to external shocks[12], similar to elastomers. The collaborative relationships between the manufacturer and the two suppliers are supposed to be two viscous componentsR1andR2, because they take effect on resisting the impact of sudden shocks, similar to viscoid.

Fig.1 Supply chain resilience model

Suppose thatεis the strain of the supply chain system under the stressσ;k11is the elastic coefficient ofS1;μ1is the viscous coefficient ofR1.S1suffers stressσ111and strainε111.R1suffers stressσ112and strainε112.The Maxwell component consists ofS1andR1in a series connection suffers stressσ11and strainε11.k12is the elastic coefficient ofS2, andμ2is the viscous coefficient ofR2.S2suffers stressσ121and strainε121.R2suffers stressσ122and strainε122.The Maxwell component consists ofS2andR2in series connection suffers stressσ12and strainε12. The parallel connection of the two Maxwell components suffers stressσ1and strainε1.k2is the elastic coefficient ofM, and it suffers stressσ2and strainε2. According to the connection way of elastic and viscous components in Fig.1, we obtain the following relationships between stresses and strains when the supply chain is attacked by a shock.

σ=σ1=σ2

(1)

σ1=σ11+σ12

(2)

σ11=σ111=σ112

(3)

σ12=σ121=σ122

(4)

ε=ε1+ε2

(5)

ε1=ε11=ε12

(6)

ε11=ε111+ε112

(7)

ε12=ε121+ε122

(8)

The mechanical properties of the elastic and viscous components give the constitutive equations of the elastic componentS1and the viscous componentR1[19].

(9)

Similarly, we can also obtain the constitutive equations of the elastic componentS2and the viscous componentR2.

(10)

CombiningEqs.(3), (6), (7), (9)andEqs.(4), (6), (8), (10),respectively,weobtain

(11)

(12)

Combining Eqs.(1), (2), (5), (11), (12) and with some algebraic manipulations, we obtain the relationship between the supply chain strain and the stress as

(13)

1.3 Supply chain resilience model analysis

Generally, there are three types of risks inherent to all supply chains, namely, supply, process, and demand risks. In this paper, we focus on demand risks. Unexpected changes of the market demand are very common in practice. For example, the outbreak of SARS caused a sudden demand shock for respirators and disinfectors. The epidemic of mad cow disease affected a large degree of the demand for beef consumption. There are also frequent reports about events of a defective part of a car, which will sharply decline the demand of the car in a short period of time.

(14)

(15)

ThecharacteristicequationofEq.(15)is

(16)

(17)

Attimet0,whenthedemandshockoccurs,theviscouscomponentsR1andR2keeptheirshapeswhilethetwoelasticcomponentsS1andS2deform.Accordingtothemechanicalpropertiesoftheelasticcomponents,weobtain

(18)

(19)

On the other hand, we have the following equations from the general solution (17),

(20)

(21)

SubstitutingEq.(18)intoEq.(20)andsubstitutingEq.(19)intoEq.(21),weobtain

(22)

(23)

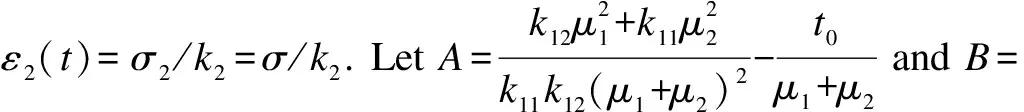

(24)

(25)

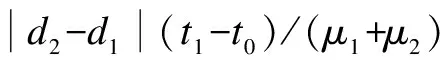

2 Analysis of Supplier Relationship Impacts on Supply Chain Resilience

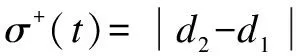

Aclosercollaborativerelationshipbetweensupplychainmemberscanleadtoamuchfasterandmoreefficientcoordination.Also,asupplychainmemberwhoismoreresilientreactsmuchmorerapidlytoshocks.Therefore,thetimeperiodΔtrequiredtocoordinatebetweenthesupplychainmembersandadjustproductioncapacityisinverselyproportionaltothecollaborativeintensitybetweensupplychainmembersandtheresiliencelevelofeachmember.Consideringthestructureofthesupplychainwithtwosuppliersandonemanufacturerdiscussedinthispaper,wemakeahypothesisthatΔt=min[G/(μ1k11k2),G/(μ2k12k2)],whereG>0istheproportionalcoefficient.

(a)

(b)

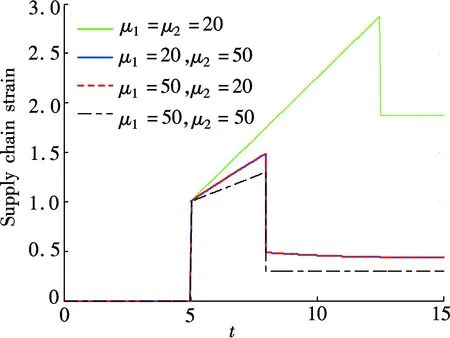

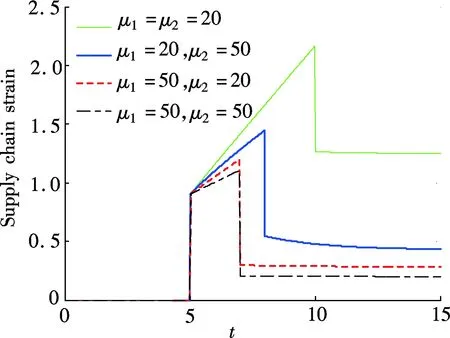

From Fig.2, we find that there are three key performance indicators of supply chain resilience during the reaction process: 1) Coordination time Δt. 2) The supply chain strain at timet1, which is the maximal strain during the whole period. Ifε(t1) is smaller than the maximum strain the supply chain can afford, the supply chain will gradually recover or move to a new equilibrium state; otherwise the supply chain will perish and can never recover. 3) The new equilibrium state whent→∞ indicates the long-term impact of the shock on the supply chain.

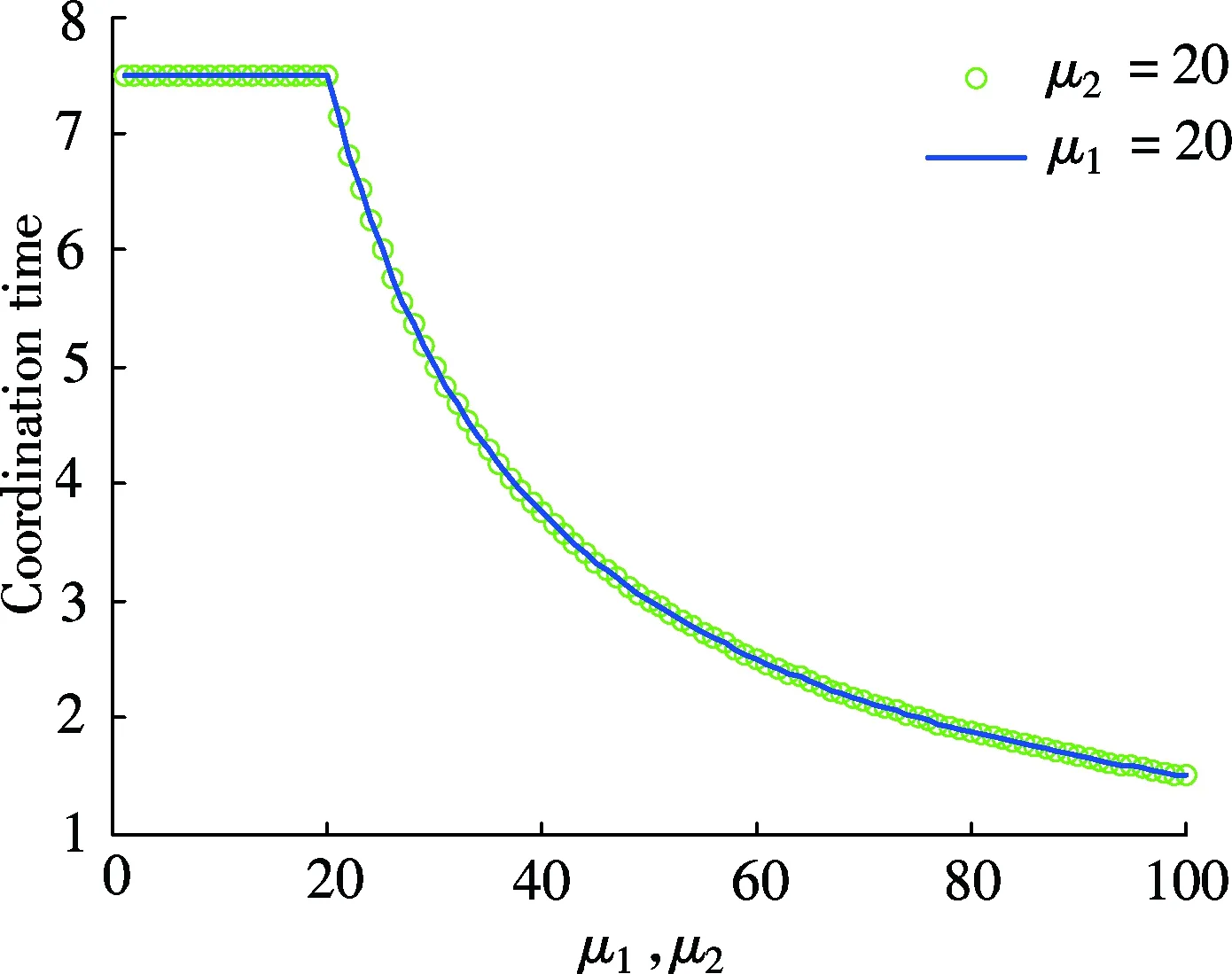

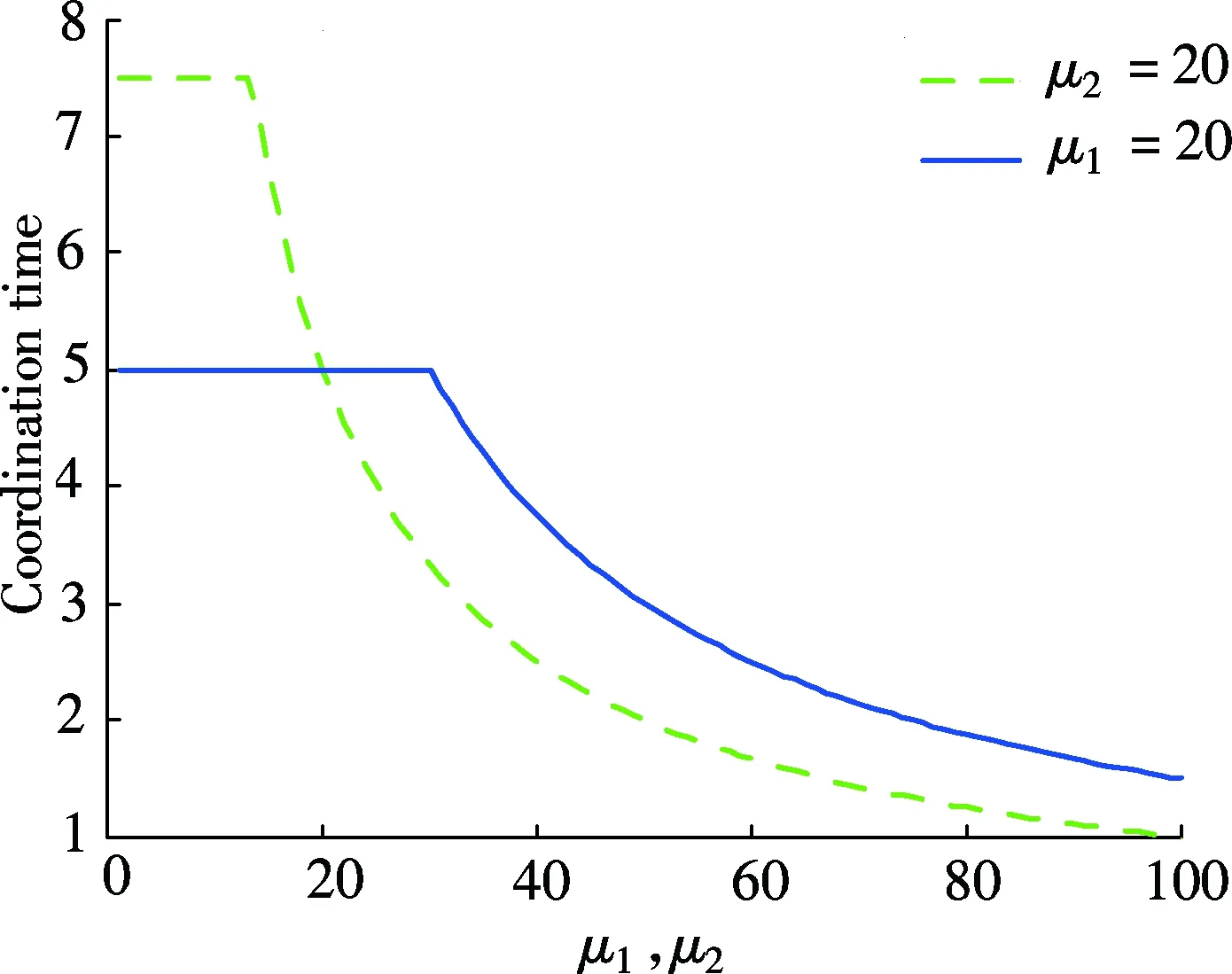

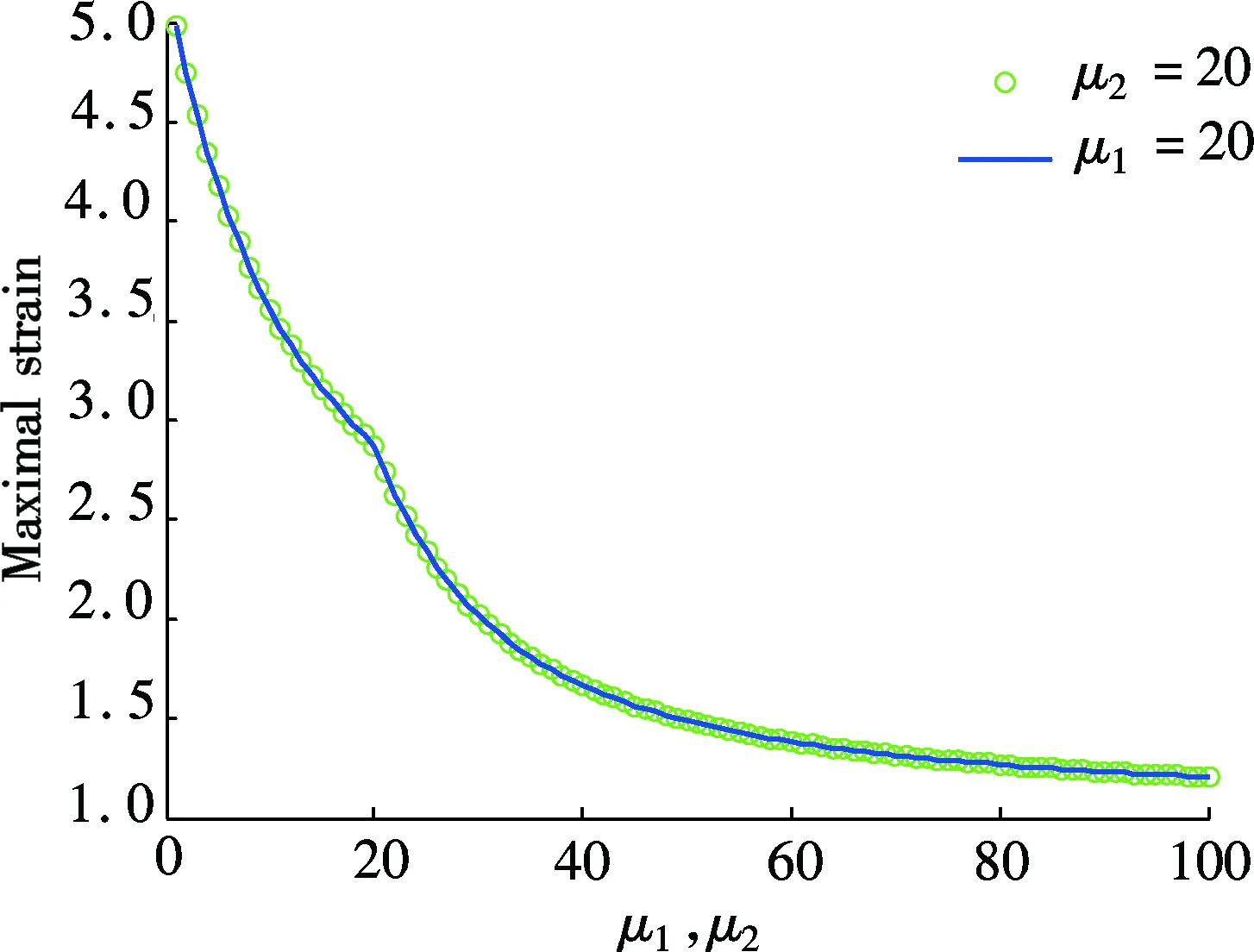

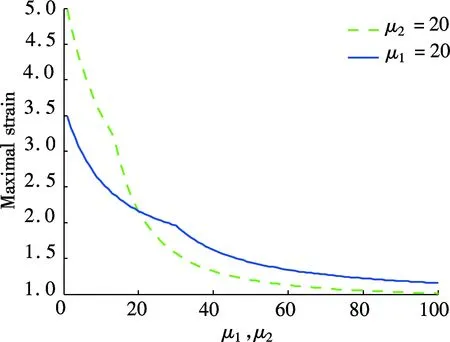

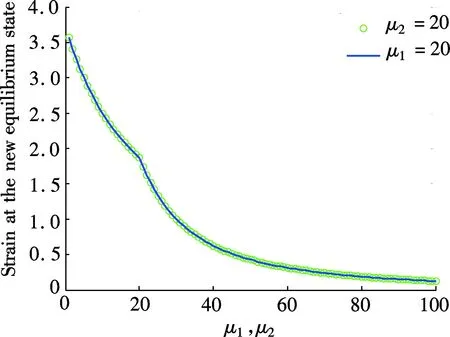

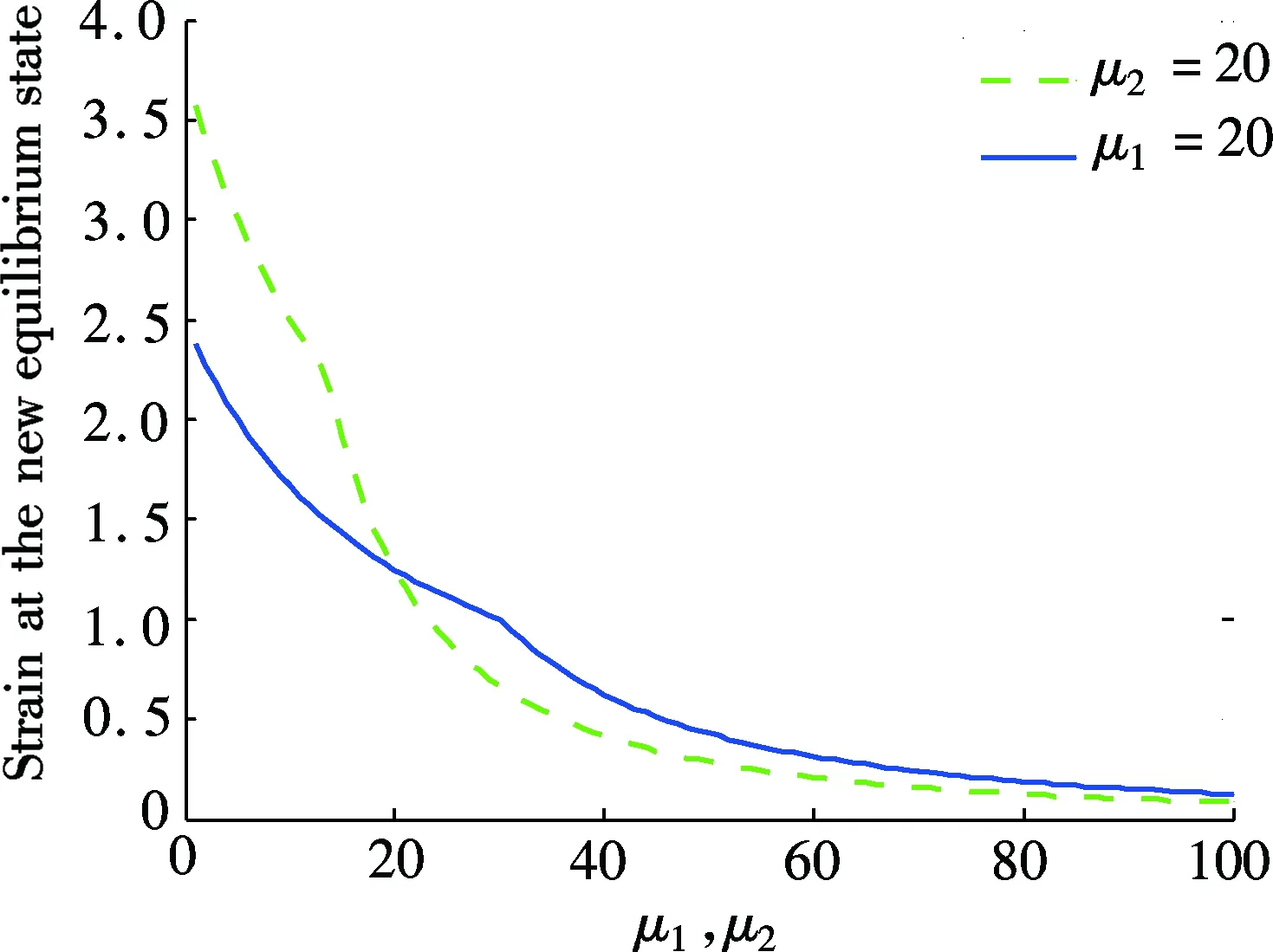

Figs.3, 4 and 5 describe, respectively, how the three indicators change with the collaborative intensity with one of the suppliers, when the two suppliers are at the same of different levels of resilience. From the figures of the three groups, the following results are obtained:

(a)

(b)

(a)

(b)

(a)

(b)

1) If two suppliers have the same resilience, the two curves are always coincident, including the coordination time, the maximal strain during the period, and the strain at the new equilibrium state.

2) If one supplier is more resilient than the other, its supply chain resilience is more sensitive to the supplier relationship with the more resilient supplier.

3) Whenμ1andμ2are small, e.g. in [1, 30], increasingμ1andμ2can increase supply chain resilience more efficiently. In contrast, whenμ1andμ2are larger, e.g. in [30, 100], increasingμ1andμ2has less effect on enhancing supply chain resilience.

From the above comparison results, we obtain the following insights.

Insight 1 The relationships between different suppliers and manufacturer have the same effect on supply chain resilience if the suppliers have the same level of resilience.

Insight 2 Enhancing collaboration relationship with the more resilient supplier contributes much more to improving supply chain resilience if the suppliers have different levels of resilience.

Insight 3 Since developing collaboration relationships between supply chain members is costly, manufacturers can improve the supplier relationship within a relatively small scope, which will not only improve supply chain resilience, but also save costs.

3 Conclusion

In this paper, a supply chain resilience model of two suppliers and one manufacturer is built, and the influence of the supplier relationship on supply chain resilience is investigated by using the biological cellular resilience theory. Some conclusions are reached. First, supply chain resilience is influenced by the supplier relationship, which has been testified by the quantitative model proposed in this paper. Secondly, the collaborative relationship with a more resilient supplier has much more effect on enhancing supply chain resilience. When attacked by a disruptive event, the manufacturer should first consider enhancing the collaborative relationship with more resilient suppliers. Thirdly, enhancing supplier relationship significantly benefits supply chain resilience if the collaborative intensity is relatively low, and it has less effect if supply chain members have already collaborated closely. Manufacturers should enhance supplier relationship to a limited intensity from the perspective of saving costs. In future research, we will take the cost of building supply chain resilience into consideration and try to achieve the balance between supply chain resilience and supply chain cost/profit.

[1]Stecke K E, Kumar S. Sources of supply chain disruptions, factors that breed vulnerability, and mitigating strategies [J].JournalofMarketingChannels, 2009, 16(3): 193-226.

[2]Latour A. Trial by fire: a blaze in albuquerque sets off major crisis for cell-phone giants [N].TheWallStreetJournal, 2001-01-29.

[3]Holling C S. Resilience and stability of ecological systems [J].AnnualReviewofEcologyandSystematics, 1973, 4(1): 1-23.

[4]Pimm S L. The complexity and stability of ecosystems [J].Nature, 1984, 307(5949): 321-326.

[5]Mallak L. Putting organizational resilience to work [J].IndustrialManagement, 1998, 40(6): 8-13.

[6]Christopher M, Peck H. Building the resilient supply chain [J].InternationalJournalofLogisticsManagement, 2004, 15(2): 1-29.

[7]Sheffi Y. Building a resilient supply chain [J].HarvardBusinessReview, 2005, 1(8): 1-4.

[8]Zhao L D. Analysis on supply chain resilience based on cell resilience model [J].LogisticsTechnology, 2009, 28(1): 101-104. (in Chinese)

[9]Ponomarov S Y, Holcomb M C. Understanding the concept of supply chain resilience [J].TheInternationalJournalofLogisticsManagement, 2009, 20(1): 124-143.

[10]Muckstadt J A, Murray D H. Guidelines for collaborative supply chain system design and operation [J].InformationSystemsFrontiers:SpecialIssueonSupplyChainManagement, 2001, 3(4):427-453.

[11]Lee H L. The triple—a supply chain [J].HarvardBusinessReview, 2004, 82(10): 102-112.

[12]Lim C T, Zhou E H, Quek S T. Mechanical models for living cells-a review [J].JournalofBiomechanics, 2006, 39(2): 195-216.

[13]Yeung A, Evans E. Cortical shell-liquid core model for passive flow of liquid-like spherical cells into micropipets [J].BiophysicalJournal, 1989, 56(1): 139-149.

[14]Tsai M A, Frand R S, Waugh R E. Passive mechanical behavior of human neutrophils: power-law fluid [J].BiophysicalJournal, 1993, 65(5): 2078-2088.

[15]Fung Y C.Foundationofsolidmechanics[M]. Englewood Cliffs, New Jersey: Prentice-Hall Inc., 1965.

[16]Dong C, Skalak R, Sung K L, et al. Passive deformation analysis of human leukocytes [J].JournalofBiomechanicalEngineering, 1988, 110(1): 27-36.

[17]Schmid-Schonbein G W, Sung K L, Tozeren H, et al. Passive mechanical properties of human leukocytes [J].BiophysicalJournal, 1981, 36(1): 243-256.

[18]Li Y H, Zhao L D. Analyzing supply chain risk response based on resilience model [J].JournalofSystems&Management, 2010, 19(5): 563-570. (in Chinese)

[19]Gong X N, Ye Q Y, Xu R Q.Constitutiveequationsofengineeringmaterials[M]. Beijing: China Architecture and Building Press, 1995. (in Chinese)

基于生物细胞弹性理论分析供应商关系对供应链弹性的影响

王新平 赵林度

(东南大学经济管理学院,南京211189)

基于生物细胞弹性理论建立了供应链弹性模型,研究了制造商与不同供应商之间的合作关系在需求中断事件的冲击下如何影响供应链的弹性.研究结果表明:加强与自身弹性更强的供应商的合作更能够提高供应链弹性,降低供应链的损失;当供应链上下游企业之间的合作程度较低时,加强两者之间的合作能够迅速提高供应链弹性,而当上下游之间的合作程度较高时,继续加强合作对供应链弹性的影响较小,因此在一定范围内增强上下游之间的合作关系是提高供应链弹性相对经济有效的方法.

供应链风险;供应链弹性;生物细胞弹性;需求突变;供应商关系

N945.12

Foundation items:The National Natural Science Foundation of China (No.71171050, 71390333), the National Key Technology R& D Program of China during the 12th Five-Year Plan Period (No.2013BAD19B05), the Scientific Innovation Research of College Graduates in Jiangsu Province (No.CXZZ12_0107), the Scientific Research Foundation of Graduate School of Southeast University (No.YBJJ1237).

:Wang Xinping, Zhao Lindu. Impact analysis of supplier relationship on supply chain resilience using biological cellular resilience theory[J].Journal of Southeast University (English Edition),2015,31(2):282-287.

10.3969/j.issn.1003-7985.2015.02.022

10.3969/j.issn.1003-7985.2015.02.022

Received 2014-12-07.

Biographies:Wang Xinping (1985—), female, graduate; Zhao Lindu (corresponding author), male, doctor, professor, ldzhao@seu.edu.cn.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Adaptive modulation in MIMO optical wireless communication systems

- An improving energy efficiency cooperation algorithm based on Nash bargaining solution in selfish user cooperative networks

- Performance analysis of an O2/CO2 power plantbased on chemical looping air separation

- Model of limestone calcination/sulfation under oxy-fuel fluidized bed combustion

- A novel carbon trap sampling systemfor coal-fired flue gas mercury measurement

- Applicability of Markov chain-based stochastic modelfor bubbling fluidized beds