Mechanism Study on Tip Leakage Vortex in Ducted Propeller and a Method to Delay TLV Cavitation

2015-05-02ZHOUJunweiNIHaoliang

ZHOU Jun-wei,NI Hao-liang

(School of Naval Architecture and Ocean Engineering,Harbin Institute of Technology in Weihai,Weihai 264209,China)

Mechanism Study on Tip Leakage Vortex in Ducted Propeller and a Method to Delay TLV Cavitation

ZHOU Jun-wei,NI Hao-liang

(School of Naval Architecture and Ocean Engineering,Harbin Institute of Technology in Weihai,Weihai 264209,China)

This paper studies the mechanism of Tip Leakage Vortex(TLV)in ducted propeller through numerical simulation and presents a method to delay TLV cavitation.From the analysis of the TLV cavitation number in different clearances,it is discovered that with increasing tip clearance,the position of the minimum cavitation number moves downstream and closer to the suction side of the blade,and the value of the minimum cavitation number decreases.The mechanism how tip clearance affects the TLV cavitation number is very complicated and can be interpreted in terms of three aspects:(1)The change of tip clearance alters the velocity of the tip leakage flow,hence its hydrodynamic parameters;(2)It affects the pressure distribution near blade tip,along with the pressure in TLV;(3)It influences generation and development of the vorticity in tip clearance as well as in TLV. Since TLV core is the primary cavitation inception position in a ducted propeller,in order to delay cavitation inception,the blade tip injection(BTI)is numerically investigated to reduce pressure drop in TLV core.Influence of BTI parameters of injection velocity,injector gap height and injection angle on TLV cavitation number is studied.Simulation results reveal that the BTI can decrease the tip foil loading,therefore improve the TLV core pressure and delay TLV cavitation.The higher injection velocity can more effectively raise TLV core pressure comparing different injection velocities,and the injection of sufficient velocity even blows off TLV.The analysis of injectors of different gap heights indicates that higher gap is better at raising core pressure,but also decreases propeller thrust,as the higher gap reduces blade tip loading at larger region.The investigation of injection angle states that the injection with a slight positive pre-whirl flow is beneficial to TLV cavitation delay.

ducted propeller;TLV;tip clearance;cavitation number;cavitation delay,BTI

0 Introduction

The ducted propeller has been proved to provide extra thrust force at heavy loading condition,and is widely used on commercial ships,tugboats,bulk carriers,submarines,trawlers, etc.However,the tip vortex cavitation occurs when the ducted propeller works at the heavy loading condition.According to previous studies,the cavitation mostly incepts at the core of tipvortexes[1],which is in the vicinity of the duct.As a result,it erodes the inner wall of the duct and results in decreased propeller performance and high noise.This problem has not been well resolved yet.

The tip vortex cavitation in ducted propeller was investigated by Rains[2],Oweis[3]and Hah[4]et al.Rains’s[2]experiment showed that the tip vortex cavitation incepted in the tip leakage vortex(TLV)and the inception position was in the vicinity of 50%chord length.Oweis[3]and Hah[4]discovered that the tip vortex cavitation could also occur in the trailing edge vortex besides TLV.The experiment of Wu[5]indicated that the tip vortex cavitation occurred first in the TLV,and then spread to the tip separation vortex as blade loading increased.From these researches,it can be concluded that the tip vortex cavitation in ducted propeller mostly incepts in the TLV.

Definite characteristics of TLV flow are required on TLV mechanism study.Some researches of TLV trace[6],speed[7]and core pressure[8]in compressors and pumps have been carried out,which shed light on the understanding of TLV flow.Chen[6]aimed to build a flow prediction model of the TLV,but it did not regard the tip clearance influence on TLV and the TLV core pressure expression.From the reviews of the researches,it can be said that the study of TLV flow and its mechanism is still necessary at present.

Also,the method to weaken TLV in ducted propeller has not been developed in the recent decades.But evidence reveals that it can be achieved by controlling blade tip flow,which has been widely used in the axial compressor which shares similar geometric structure with ducted propeller.The TLV in compressor can be weakened and the core pressure can be raised by blade tip injection(BTI)through the researches of Khaleghi[9-10].So BTI may be a way to delay cavitation in ducted propeller.

In this paper,the cavitation number in the TLV core in ducted propeller 19A/Ka 4-55 will be predicted at different tip clearances,as well as the factors affecting TLV.The effects of BTI on TLV core pressure will be studied too,the parameters of which include injection velocity,angle and gap height.CFD method will be utilized considering that the pressure at TLV core is difficult to measure.The propeller model and numerical method used in this study will be introduced in the following.

1 Ducted propeller

The study will be performed on ducted propeller 19A/Ka4-55 with 4 blades,the blade area ratio of which is 0.55.The 250 mm-diameter propeller model with uniform pitch rotates at 2.5rev/s.The pitch ratio at the blade tip is 0.963.

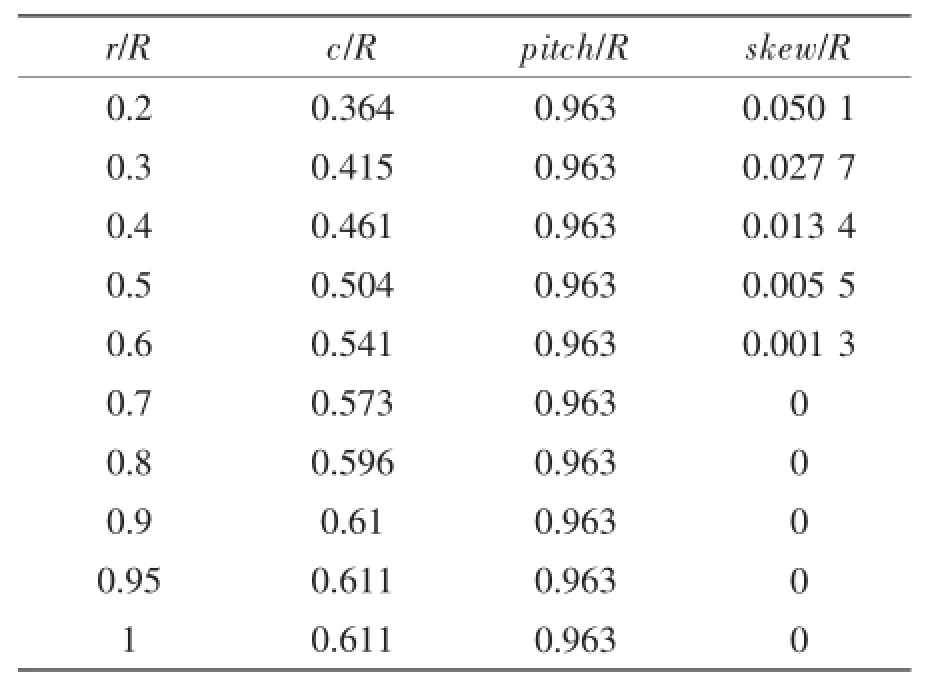

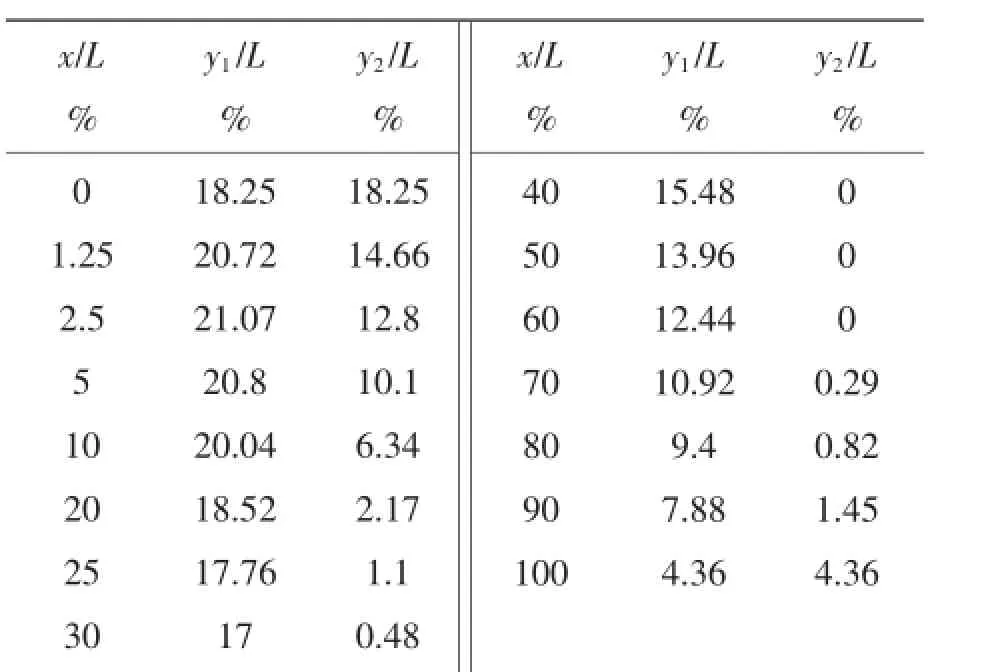

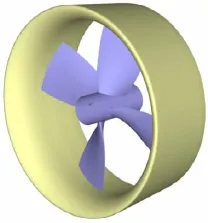

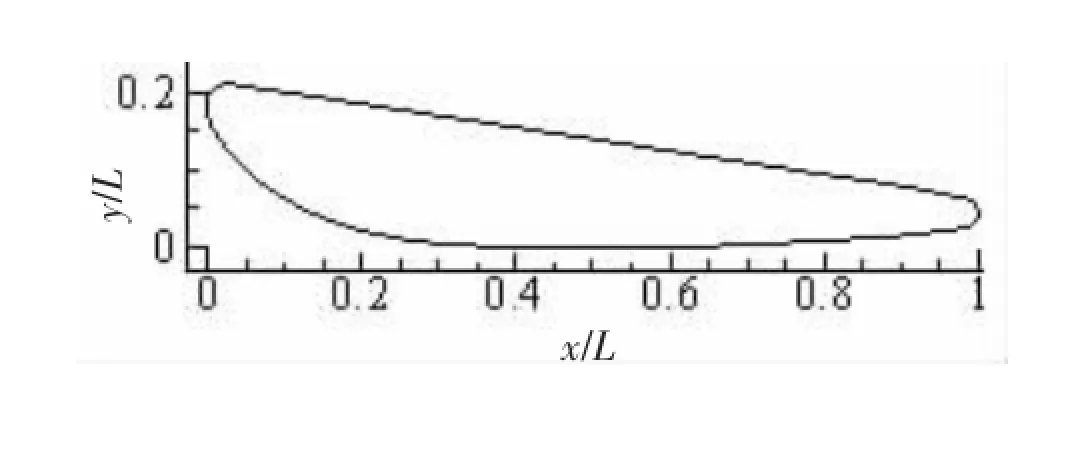

The chord length and the skew angle of the blade are shown in Tab.1,in which the R is the propeller radius,r the radius position,c the chord length and the skew negative to the rotating direction.The coordinates of duct 19A are listed in Tab.2,where L is duct length and y1and y2are Y coordinates of duct foil.The tip clearance τ is 2 mm and the ratio of duct lengthto propeller diameter(L/D)is 0.5.The appearance of the ducted propeller 19A/Ka4-55 is displayed in Fig.1 and the foil of duct 19A in Fig.2.

The performance of the propeller was measured by Kuiper[11]at MARIN laboratory in the Netherlands and the performance curves are shown in numerical method validation below.

Tab.1 Design parameters of propeller Ka 4-55

Tab.2 Foil data of 19A duct

Fig.1 Appearance of 19A/Ka4-55

Fig.2 View of duct 19A

2 Numerical method and validation

2.1 Numerical method

The ducted propeller in this work is fully immersed in deep water.Consequently,the flow will not be affected by free surface and the gravity acceleration can be ignored.As a result,the relative pressure prelwill take the place of the absolute pressure p in the momentum equation, thus

where p∞is the faraway pressure of the same immersion.The relative cavitation number of the TLV is defined as

The reference velocity is blade tip tangential velocity U.Since the relative cavitation number is independent of immersion of the propeller,it will be used to evaluate pressure drop in TLV.

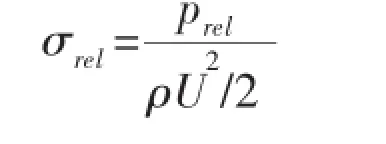

The position of the propeller is fixed,and the advanced velocity is controlled by uniform inflow velocity,which is parallel to axis of the propeller.In order to save calculating time,only 1/4 flow field is simulated due to rotating periodical.The field is divided into rotating and stationary regions(Fig.3)where the fluid equations are solved respectively,and the interfaces of which are treated by the Frozen Rotor method.

Fig.3 Region divisions and boundary conditions

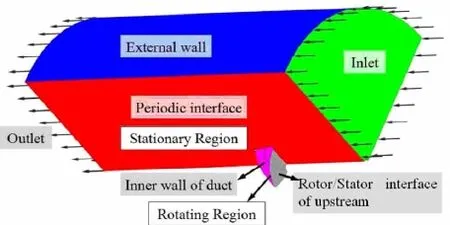

Fig.4 Mesh of ducted propeller flow field

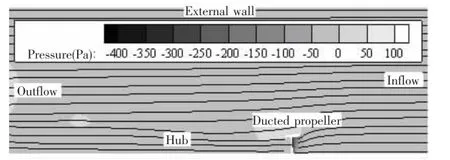

Fig.5 Streamline and pressure contour on the vertical surface(J=0.24)

The flow field is discretized with hexahedron grid as shown in Fig.4.The surfaces of duct and blades are covered with denser grid(y+<1.0)to simulate boundary layer.The outlet is 20 times propeller radii downstream the rotor in order to make the flow fully developed there. The inlet boundary is 10 times radii in front of the rotor for flow uniformity.In the radius di-rection,the region extends to 10 times radii to avoid the wall effect.The streamlines and pressure contours of a heavy loading condition in the periodic interface are shown in Fig.5,from which it seems that the flow at the boundaries of the inlet,outlet and external wall is approximately uniform and flow across the Rotor/Stator Interfaces is continuous.

2.2 Validation

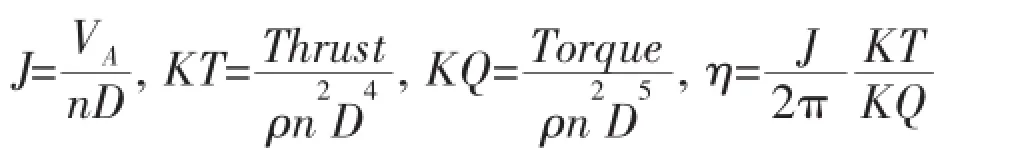

Since the velocity in TLV is difficult to measure and measuring instruments are expensive,only the performance of the ducted propeller namely thrust and torque coefficients and propulsion efficiency is used to validate.As shown in Fig.6,performances of the ducted propeller with two different mesh nodes are computed,which coincide very well.The error of thrust coefficient KT and torque coefficient KQ can be ignored,and propulsion efficiency η has error of about 3%at design condition(J=0.55).The J,KT,KQ and η are defined as

in which the VAis inflow velocity.

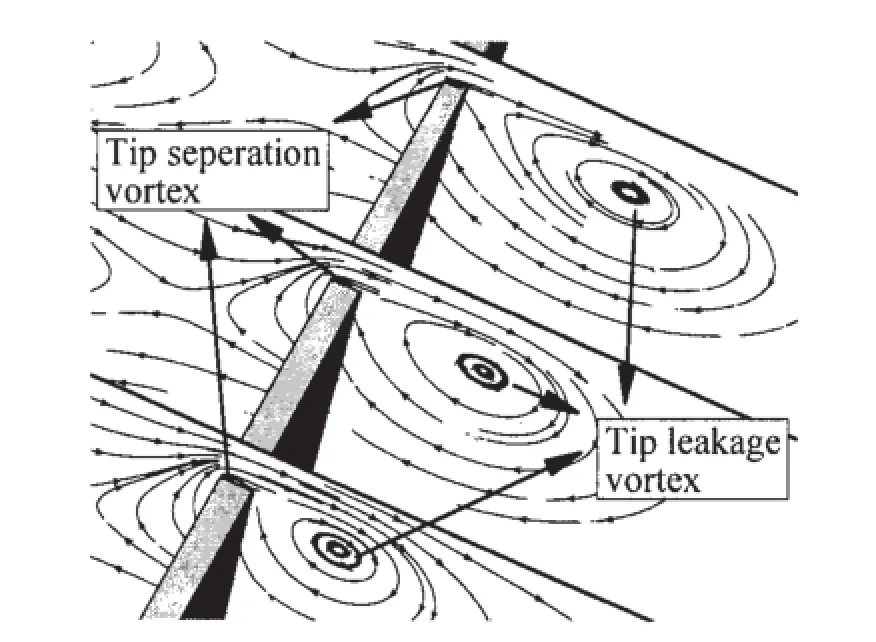

Fig.7 shows numerical simulation of TLV and tip separation vortex at a heavy loading condition near blade tip.

Fig.6 Propeller performance curves by experiment and CFD of different mesh density

Fig.7 Vortexes distribution at a heavy loading condition near blade tip(J=0.08)

3 TLV mechanism study

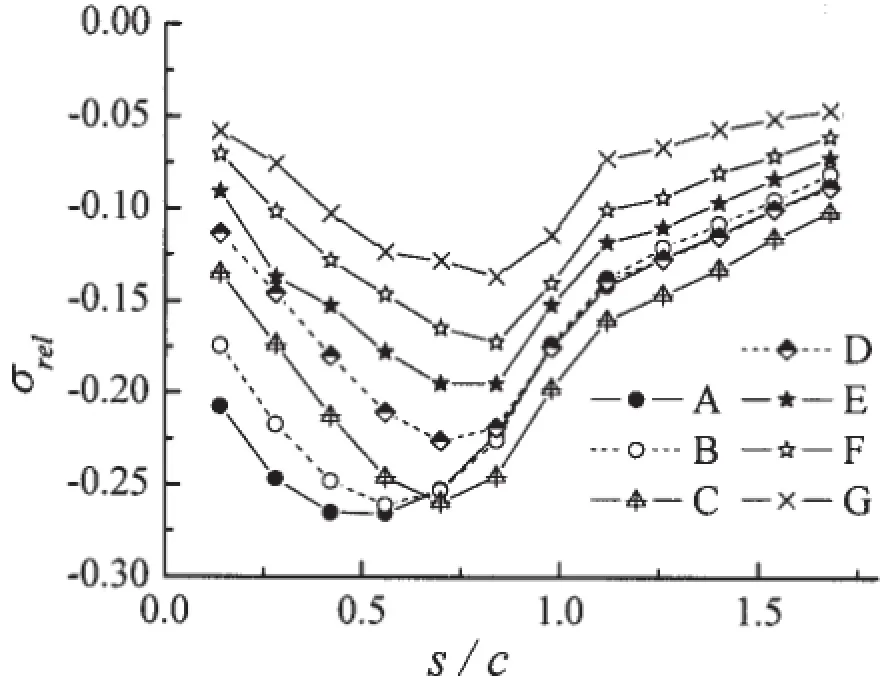

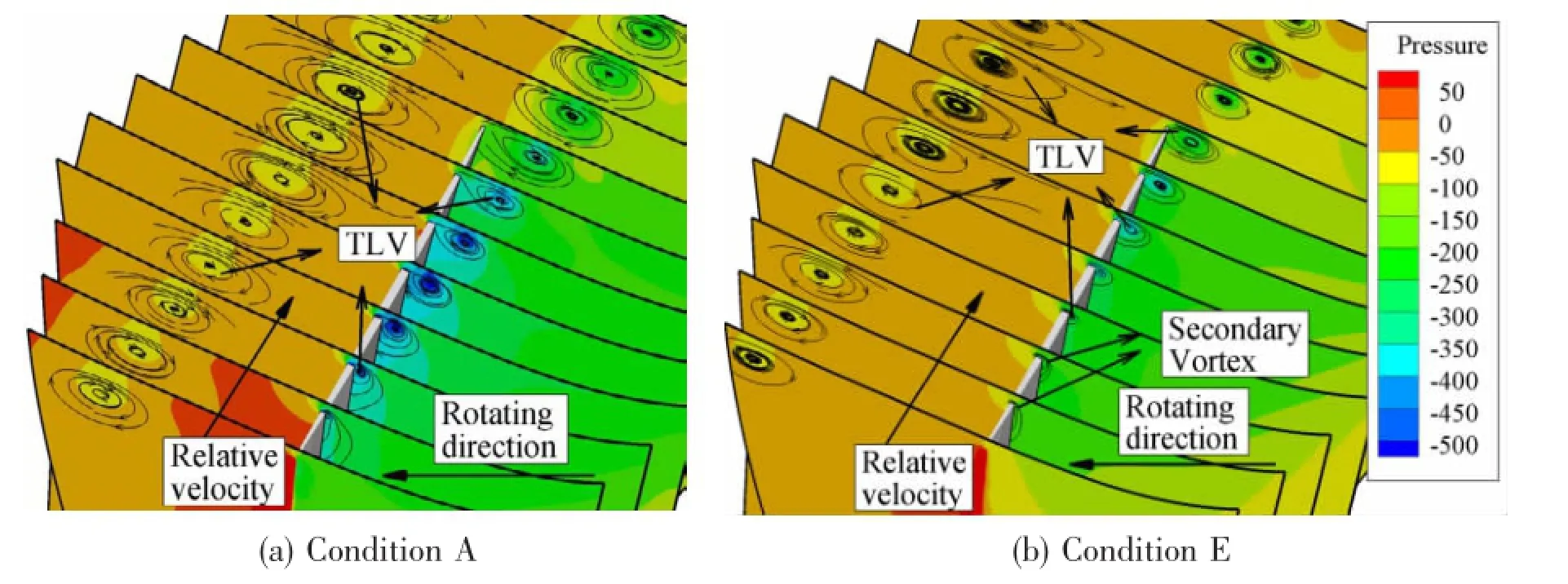

The cavitation number in TLV core along blade tip foil of the ducted propeller with designed tip clearance at different advanced coefficient is shown in Fig.8,where s means distance from tip foil leading edge to the measured slice perpendicular to the foil and the TLV core is the valley pressure position,as shown in Fig.9.The symbols from A to G indicate different advanced coefficients listed in Tab.3.The condition A has advanced coefficientof 0.08 approximating zero,and is set to be starting condition in this paper and E is designed working condition of the ducted propeller.Not only the TLV but also the secondary vortex can be observed on the slices.At condition A(Fig.9(a)),the TLV rolls up near the leading edge, while at condition E(Fig.9(b)),it is not visible till middle of the tip foil.

Fig.8 Curves of cavitation number in the TLV core at different advanced coefficients

Fig.9 The tip flow pressure contour and streamline of TLV at conditions A and E

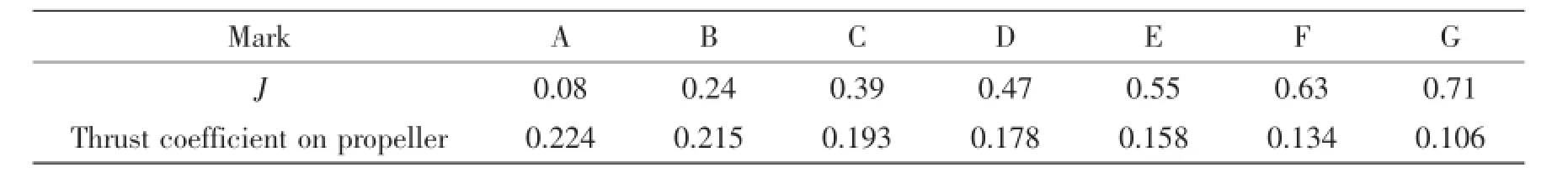

Tab.3 Advanced coefficient and trust coefficient of the seven working conditions

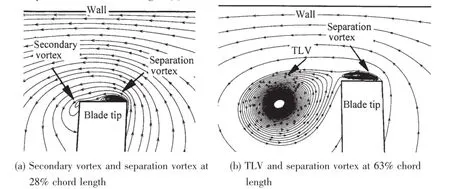

It is known that the TLV is formed by crossing flow of the tip leakage flow(TLF)and the relative inflow.Before the TLV takes shape,the secondary vortex forms first at the corner of suction side of the blade tip(Fig.10(a)).At this condition,the vortex core is defined at the minimum pressure location of the secondary vortex.The structure comparison of the TLV and secondary vortex is shown in Fig.10(b)in detail.

Fig.10 The streamline of tip flow on slice perpendicular to tip foil at different positions

From Fig.8,a valley point exsits on each cavitation number curve,the position of which ranges probably from 50%to 80%along the chord.It can be concluded that the TLV cavitation inception always occurs in middle region of the tip foil.As the advanced coefficient decreases, the cavitation inception position moves upstream.At the starting condition,the valley point isapproximately at 50%chordwise position.

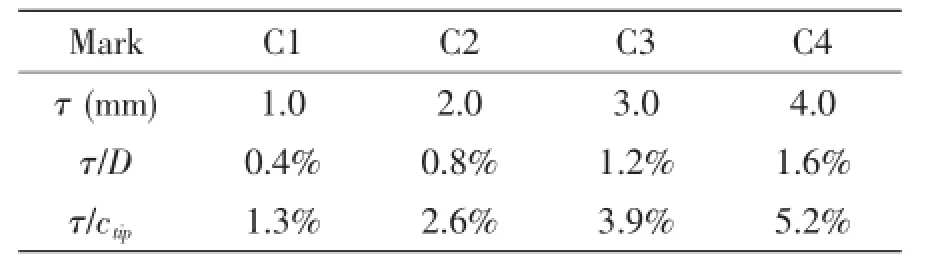

The cavitation number in TLV core in different tip clearances will be analyzed at the starting condition when minimum cavitation number comes about.Propellers of 4 tip clearances shown in Tab.4 are studied,where 2mm is the designed clearance size.The ratios of tip clearance size to propeller diameter and tip foil chord length are also listed for the comparison.

3.1 Effect of tip clearance on TLV cavitation number

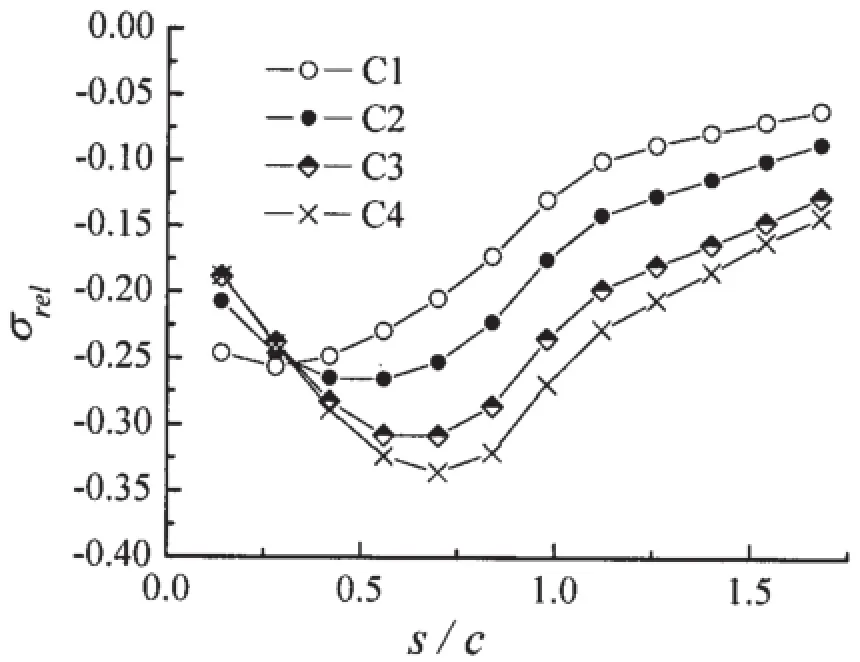

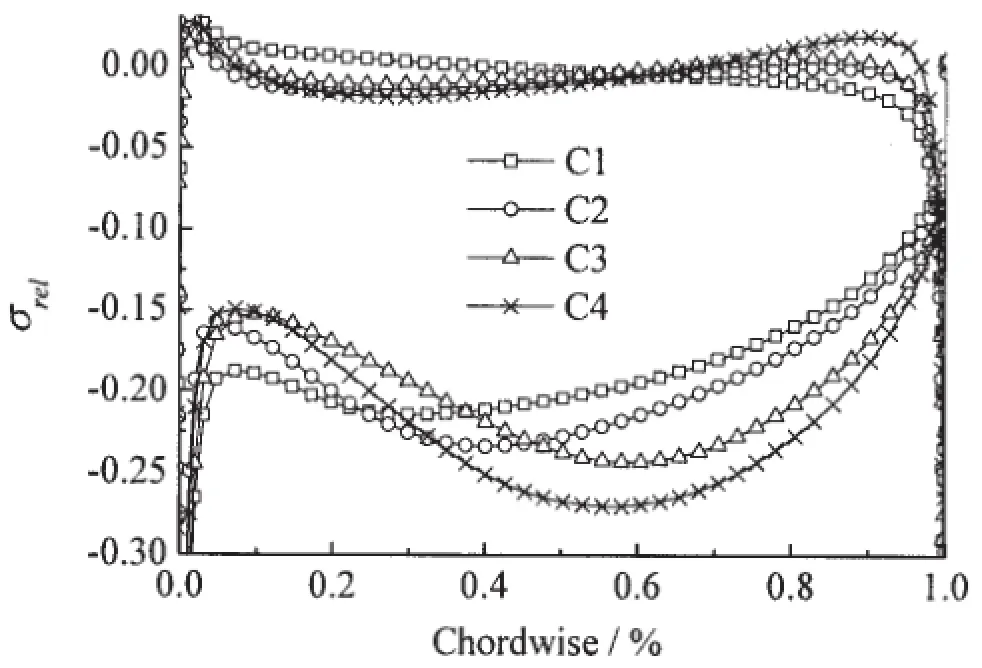

The TLV core cavitation number curves of ducted propellers of four different tip clearances working at starting condition(J=0.08)are shown in Fig.11.It can be seen that as the tip clearance size increases,the valley point of the curve moves downstream and the minimum cavitation number decreases.The minimum cavitation number of C4 is lower than that of C1 by 30%.From C1 to C2,the minimum cavitation number value changes little and the potion moves downstream,while from C3 to C4,the value decreases distinctly but the position is nearly unchanged.

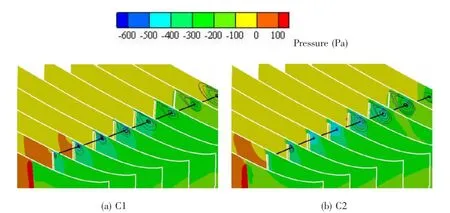

The pressure contours and streamlines of TLV at different tip clearances are shown in Fig.12.It can be seen that the TLV moves slightly towards blade suction side as tip clearance increases.In order to study the tip clearance effect on pressure and velocity distribution in TLV,the TLF and blade tip loading will be analyzed in the following since they play an important role on the formation of TLV.

Tab.4 Values of the 4 tip clearances

Fig.11 TLV core cavitation number along the tip foil in different tip clearances

Fig.12 The pressure contour and streamline of TLV in different tip clearances

3.2 Effect of tip clearance on TLF and tip loading

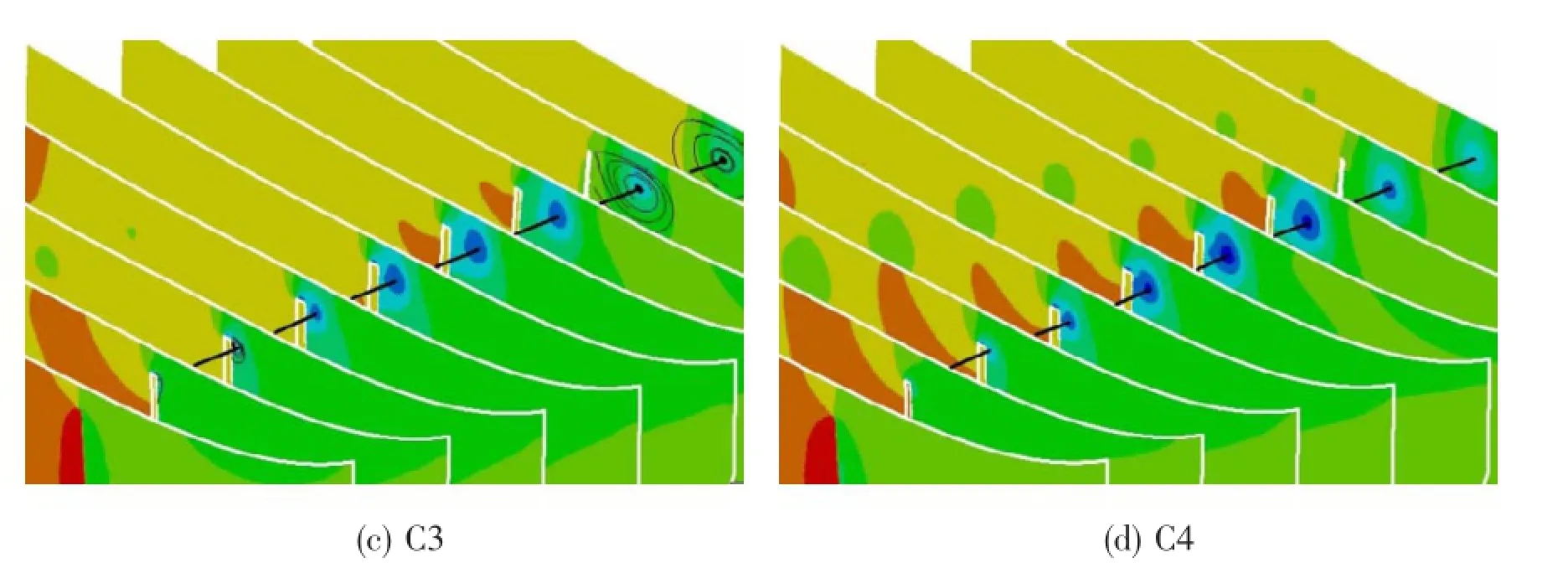

The velocity contours and streamlines on the cylindrical surface in the middle of the tip clearances are exhibited in Fig.13.The tip foil is also drawn on each surface.The Vnis the component of TLF that is vertical to the tip foil chordwise.

From Fig.13 it can be seen that increasing tip clearance results in larger Vnand the position of the maximum Vnmoving downstream.The maximum Vnof C1 appears at 20%chordwise.C2 at nearly 50%,and C3 and C4 at 75%approximately.

Fig.13 TLF velocity component perpendicular to tip foil in different tip clearances

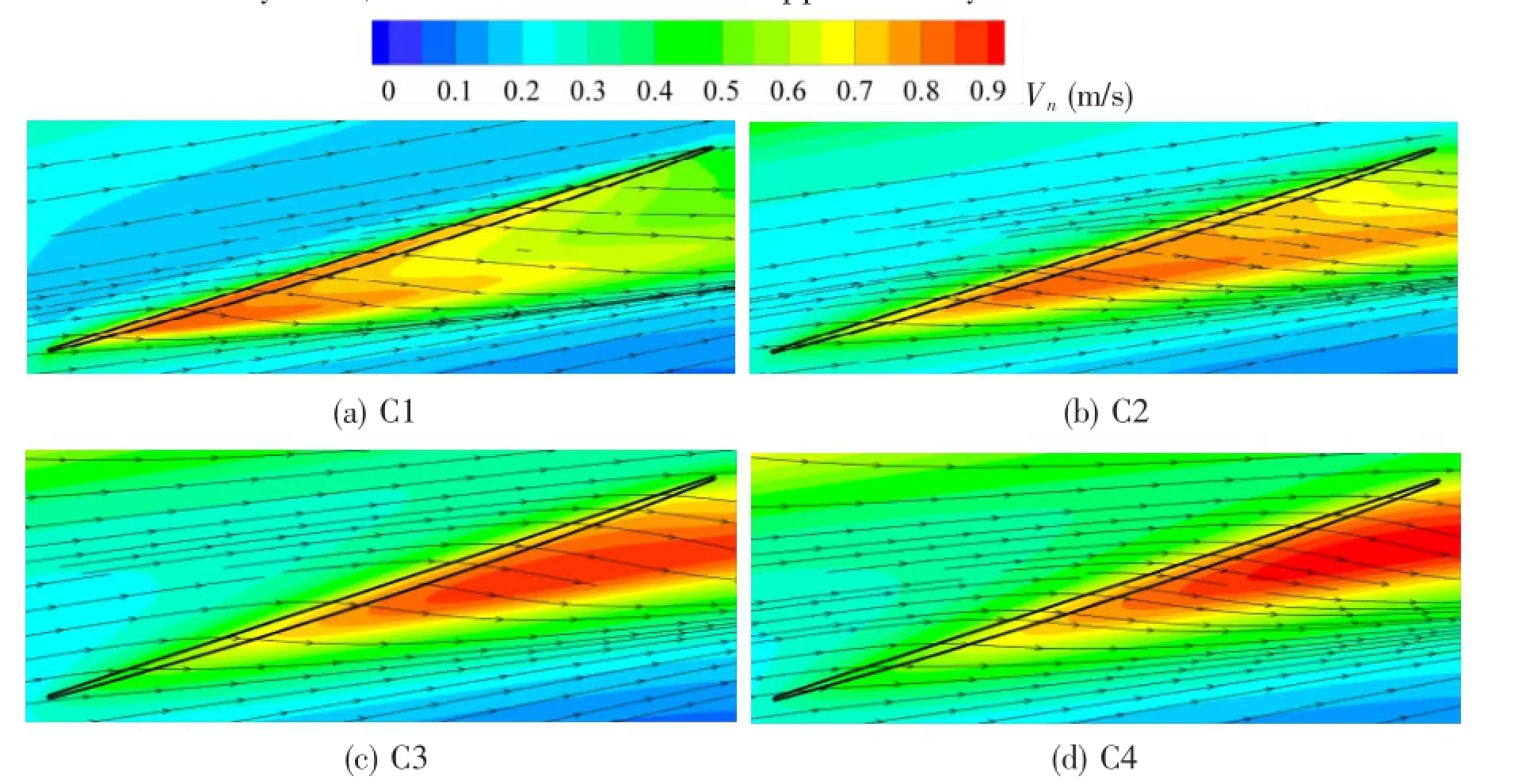

The surface pressure distribution of the tip foil is displayed in Fig.14.The foils share the same radius position with the TLV core in different tip clearances.The pressures distribution on the pressure side changes little with the different clearances,but obviously on the suction side.The pressure difference of the two sides equals foil loading,which shifts from the leading to trailing edge with increasing clearance.

Comparing the tip foil loading in Fig.14 and the TLF in Fig.13,it can be discovered that the chordwise positions of the maximum TLF velocity and the maximum tip foil loading agreeapproximately with each other,suggesting that the two factors are closely associated.

From previous studies on the propellers,the vorticity distribution in the tip clearance is related to the velocity and pressure distribution near the tip.Since it is also influenced by the duct inner wall, which affects the tip clearance size,the vorticity distribution will be analyzed later.

3.3 Effect of tip clearance on vorticity distribution

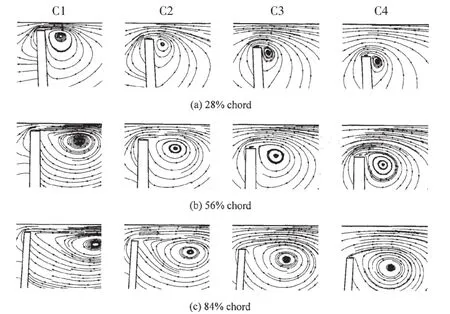

Firstly,the streamlines of the tip vortexes in four tip clearances at different chordwise positions are shown in Fig.15.It can be concluded that the larger the tip clearance is or the closer it is to the leading edge,the rounder the shape of TLV will be,such as C2(a),C3(a),C4(a),C3(b),C4(b)and C4(c).The phenomenon reveals that the flow parameters of TLV vary along the tip foil.

Fig.14 The blade surface pressure distribution of foil at the same radius with TLV core trajectory

Fig.15 TLV of different tip clearances at different chordwise positions

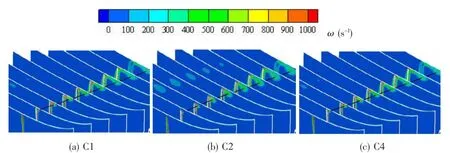

The vorticity distribution at tip region of three tip clearances C1,C2 and C4 are shown in Fig.16.When the tip clearance is large enough like C4,the vorticity is barely influenced by inner wall of the duct,while at conditions of C1 and C2,the vorticity is distinctly affected,so is its distribution.The variation of vorticity distribution in ducted propeller of different tip clearances may be the cause of the change of the velocity and the pressure field in TLV.

Fig.16 Vorticity distribution at tip region at 3 tip clearance conditions

4 BTI method

4.1 Design of injection

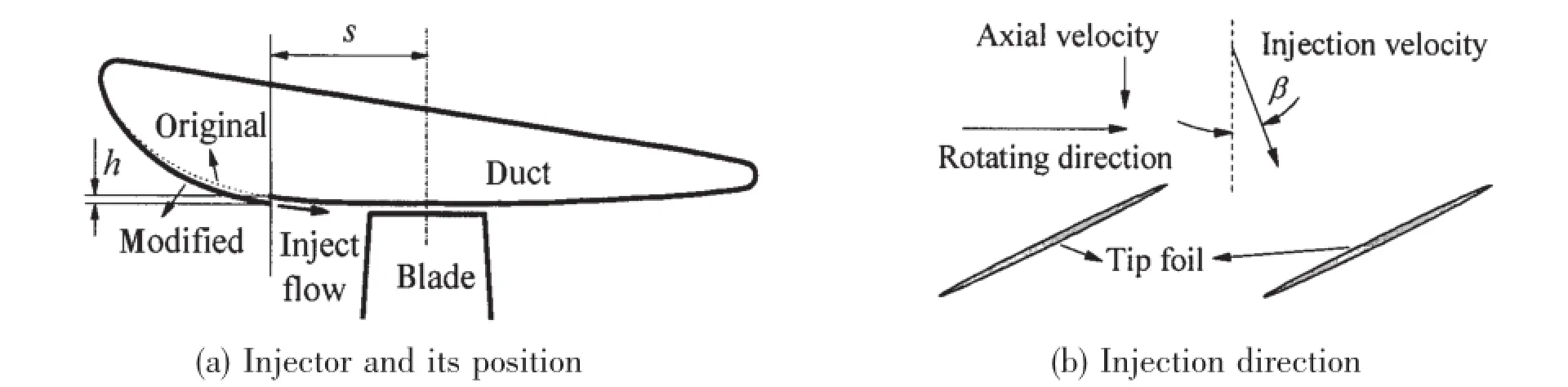

Most injectors used in compressor are discrete around duct inner wall.Some are sheet injectors like band gap,such as that used in Weigl’s[12],Suder’s[13]and Day’s[14]work.Weigl also studied the hole injector,which has a simple structure.The discrete injector impacts blade frequently as the propeller rotates.A previous research of Zhou[15]in compressor revealed that the impacting frequency affects pressure inside the TLV.In order to avoid injection frequency effect on TLV,an annular gap like injector will be designed in this paper,similar to that used in Khaleghi’s[9]research.

The BTI designed for the ducted propeller is shown in Fig.17 and the design parameters are listed in Tab.5.

Fig.17 Scheme of injection parameters

Tab.5 Design parameters of BTI

4.2 Delay of TLV cavitation

When the pressure in TLV falls below vapor pressure,the cavitation will occur.It can be delayed or avoided if the core pressure improves.However,the complex TLV flow causes great difficulty in judgment of TLV cavitation.The criterion in this paper will be introduced below.

About inception position

As mentioned before,the cavitation in ducted propeller incepts at the core of TLV in most cases.The delay of TLV cavitation probably alters cavitation inception position.For example,the cavitation may incept on suction side surface of the blade when the TLV is weakened.Since the purpose of this study is to explore effect of BTI on TLV cavitation,only the pressure in TLV will be discussed.

About TLV unsteadiness

The TLV oscillates all the time as propeller works.This phenomenon was observed by Oweis[3]in a ducted propeller experiment using PIV.Hah’s[16]measurement in ducted propeller and Zhou’s[15]unsteady simulation in a compressor have confirmed it as well.Moreover, in the research of Zhou[15],the BTI alters amplitude of pressure fluctuation in TLV.Fortunately,the pressure oscillation is quasi-periodic,so the minimum transient pressure is easy to snap and when it falls below vapor pressure,the cavitation will incept.The unsteadiness of TLV will be studied in the future separately due to its complexity.Only the time-averaged pressure in TLV is discussed in this paper.

5 Results and discussion about BTI method

In this paper,the effect of BTI on TLV core pressure is studied mainly on the injection velocity and injection angle,in light of Khaleghi’s[9]and Suder’s[13]researches in compressor that these two were the most important parameters.In addition,the effect of injector gap height will also be discussed,as it alters injection flow rate when injection velocity is fixed,and the injection flow rate probably affects of the propeller thrust.

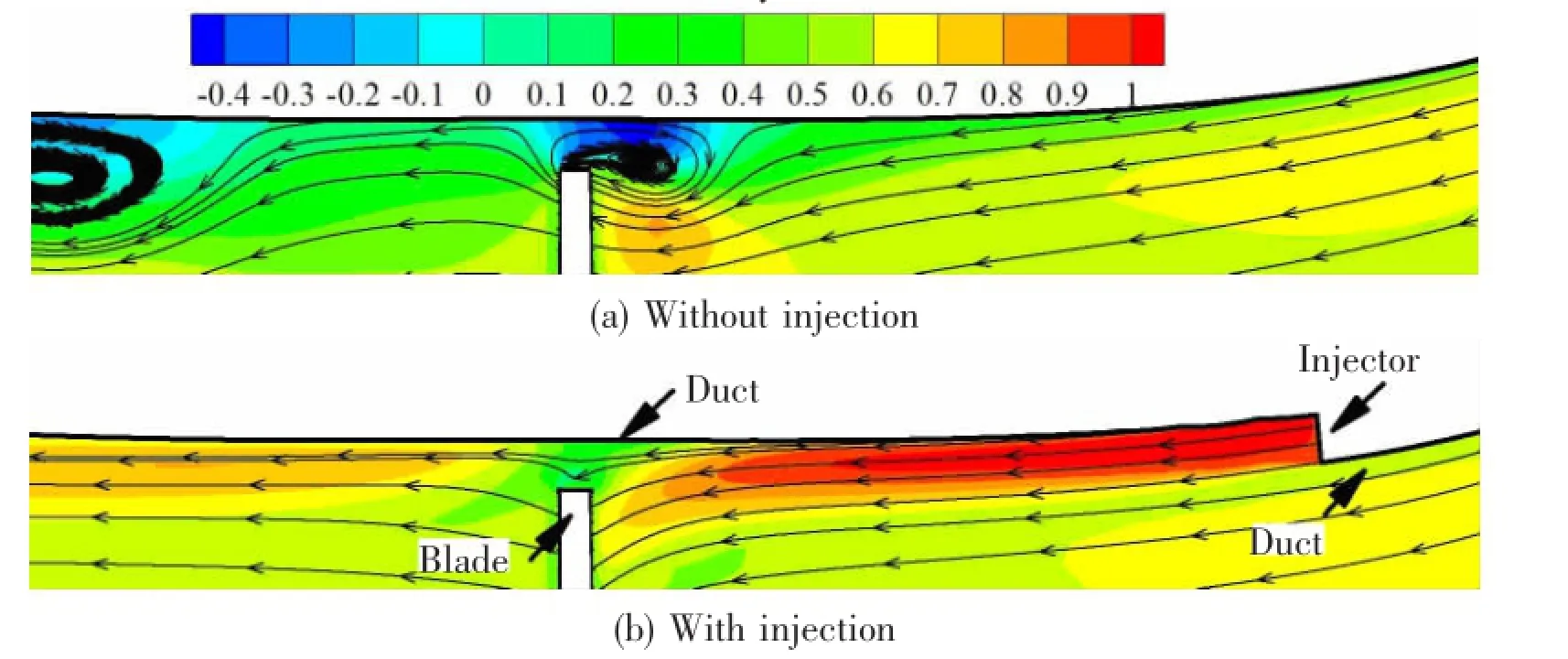

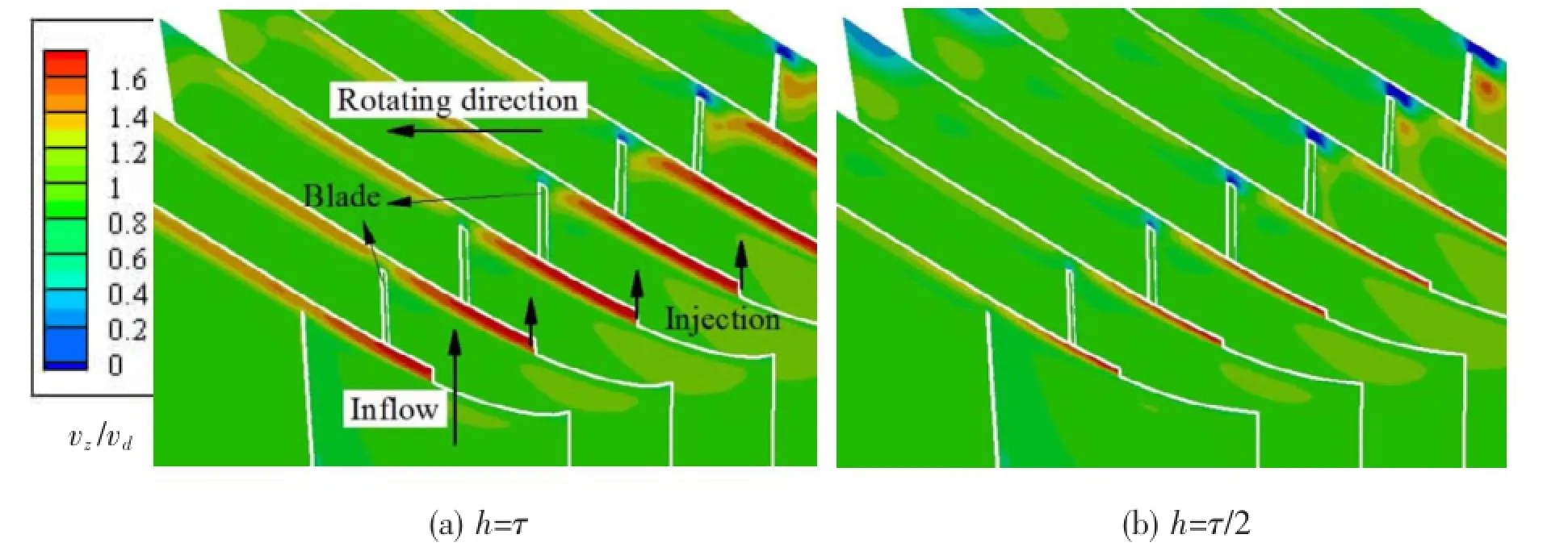

The injection velocity is along duct wall and can increase flow kinetic energy near blade tip.As shown in Fig.18,the ducted propeller works at starting condition,and the axial velocity contour near blade tip is plotted,where the injection velocity is 1.0 m/s,about 1.66 times of averaged axial velocity in duct.It is clear that the injection can propagate to the blade tip, remove backflow and also increase axial velocity in downstream of blade.

Fig.18 Comparison of tip flow axial velocity with and without injection at starting condition

In order to compare injection velocity with axial velocity in duct,the injection velocity is non-dimensionalized by vd,which is defined as

In this ducted propeller,the vdis about 0.602 m/s.In the following discussion,all mentioned injection velocities are dimensionless.The injection velocity value larger than 1.0 means that the actual injection velocity is higher than flow velocity nearby.

5.1 Effect of injection velocity on TLV

In this study,the injection velocities from 0.66 to 1.99 will be investigated.The injection velocity of zero represents without injection condition.

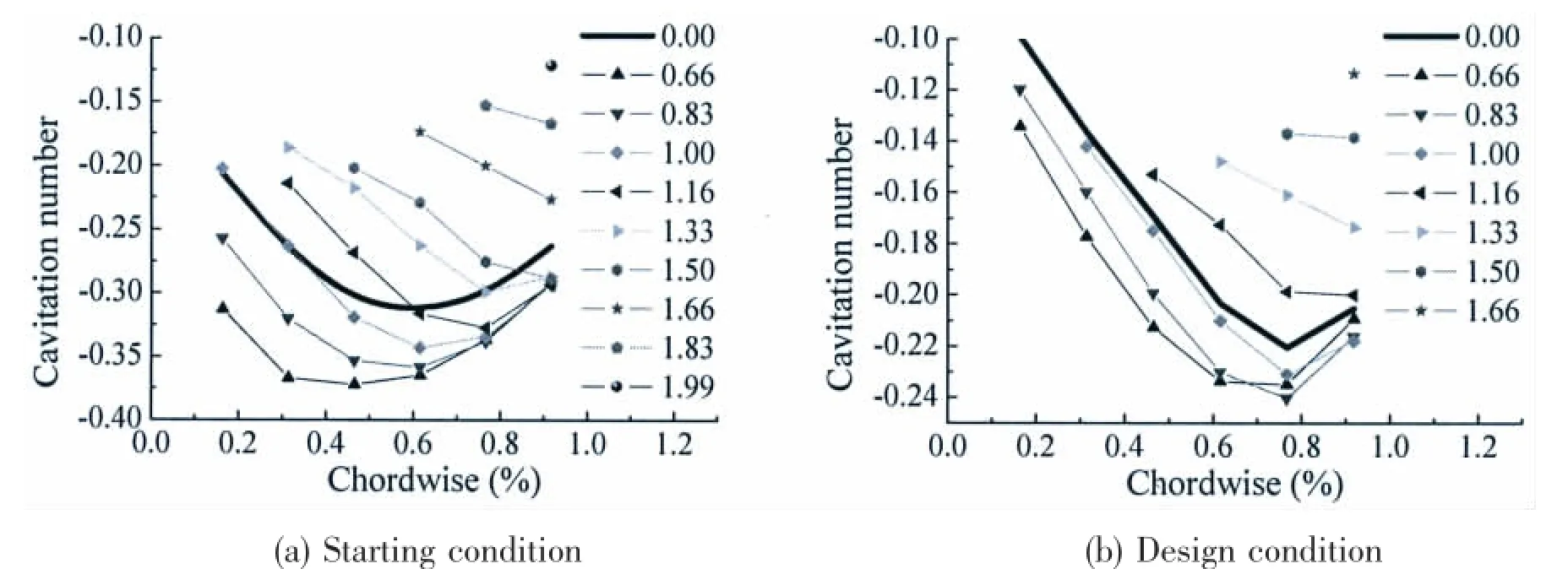

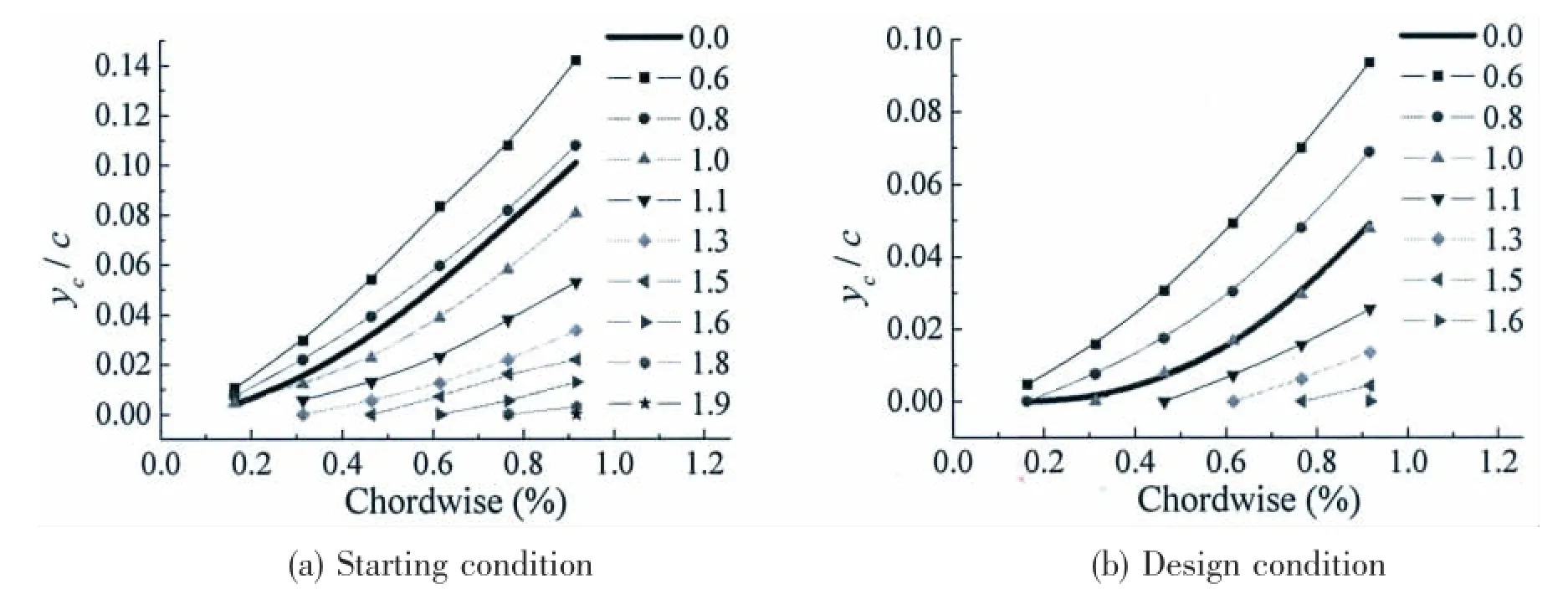

Fig.19 shows cavitation number of the TLV with different injection velocities at both starting and design working conditions.It is obvious that as injection velocity increases,the minimum cavitation number along chord rises and moves downstream at both conditions.At starting condition,when injection velocity is larger than 1.33,the minimum cavitation number in TLV begins to surpass that of without injection,when larger than 1.50,the minimum cavitation number appears at trailing edge of the blade,when reaches 1.99,the TLV disappears. At design condition,the effective injection velocity is probably between 1.0 and 1.33 when minimum cavitation number starts to increase.As velocity exceeds 1.16,the minimum cavitation number appears at trailing edge.The ultimate injection velocity that eliminates TLV is 1.66.

Fig.19 Cavitation number of TLV along chord length with different injection velocities

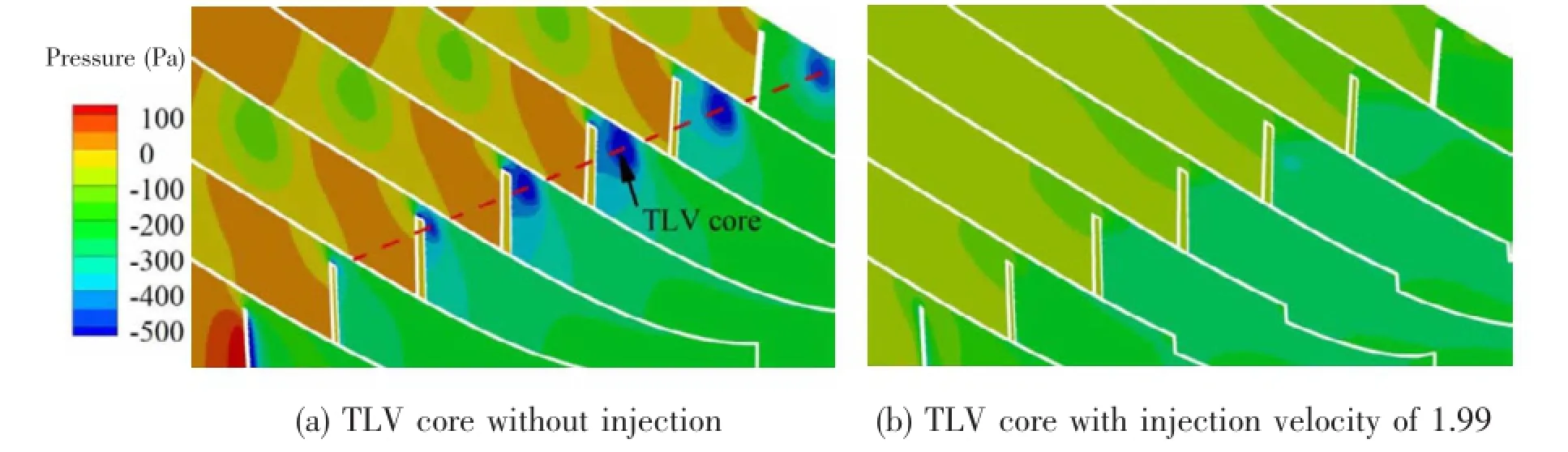

Fig.20 Tip flow pressure contours with and without injection at starting condition

Fig.20 demonstrates TLV pressure contours with and without injection at starting condi-tion.The injection velocity is set to be 1.99.The TLV can be identified by low pressure vortex core and it disappears with the BTI in Fig.20(b).

The BTI also decreases blade tip loading,according to pressure difference between two sides of the blade.Pressure upstream changes very little with BTI,while the pressure downstream drops distinctly.The effect of BTI on propeller performance will be discussed in the following.

The trace of the TLV is also analyzed for better understanding of the flow mechanism of TLV.The trajectories of TLV with BTI of different velocities are shown in Fig.21 including the starting and design conditions.The ycrepresents the vertical distance from the vortex core to blade.Although the BTI moves minimum cavitation number position downstream,as shown in Fig.19,the trace curves of TLV change nearly proportionally with different injection velocities, which means that the shapes of TLV with different injection velocities are similar.At starting condition,as the injection velocity reaches 0.83,the TLV trajectory curve probably coincides to that of without injection.While at design condition,the coincided injection velocity is nearly 1.0.

Fig.21 Trajectories of TLV with different injection velocities at the two conditions

5.2 Effect of injector gap height on TLV and propeller performance

Tip flow of two injectors of different gap heights will be analysed next.The heights of the two injectors are 1 mm and 2 mm,which are 0.5 and 1.0 time of blade tip clearance τ respectively. Without injection situation will also be included in the discussion,for the comparison of propeller performance.The duct walls of the two injectors and without injection are shown in Fig.22,where the original wall indicates without injection.

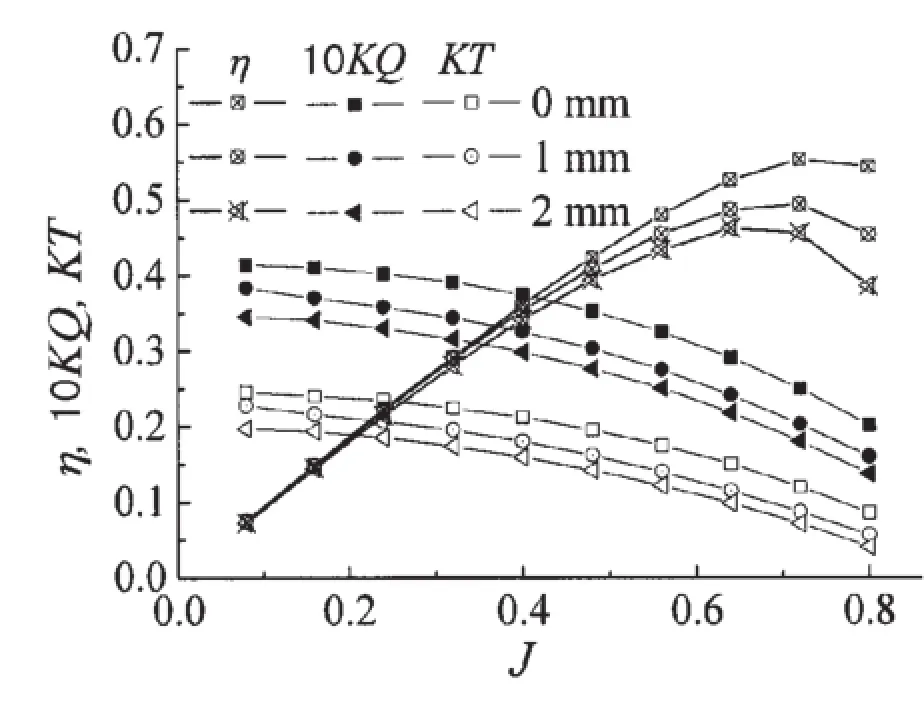

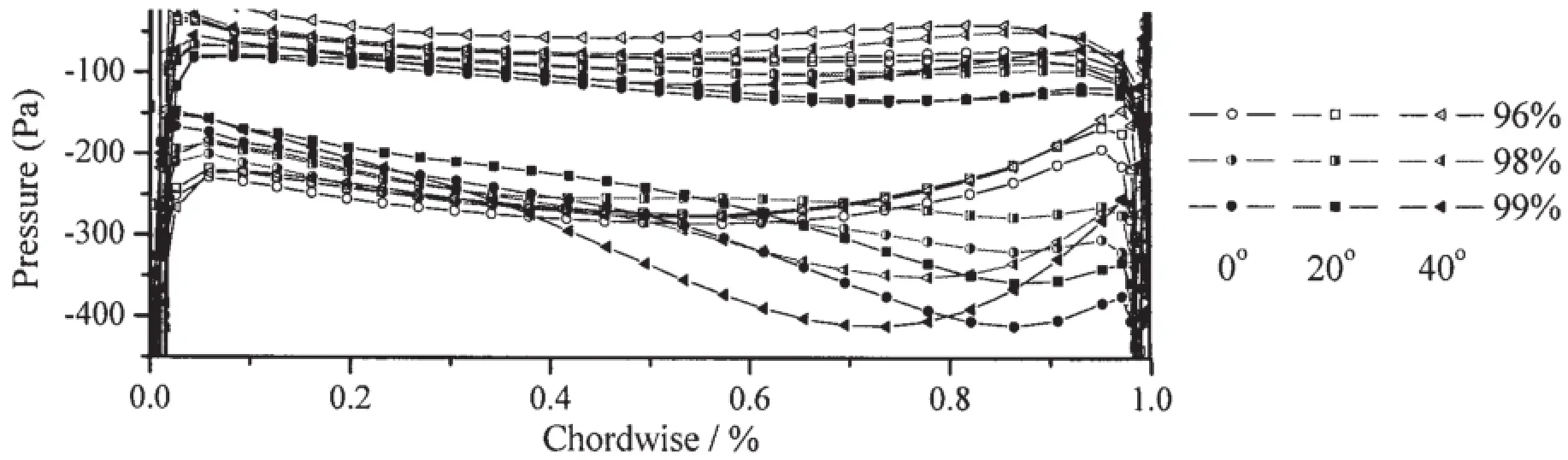

Firstly,the performance parameters are showed in Fig.23.The injection velocity is set to be 1.66 for all conditions in this section,and will not be repeated in the subsequent discussion. It is obvious that the injection reduces thrust and torque of the ducted propeller,as well as propulsive efficiency.The efficiency drop mainly takes place at higher advanced coefficient,while little changes at starting condition.

Fig.22 Modified duct wall with injectors

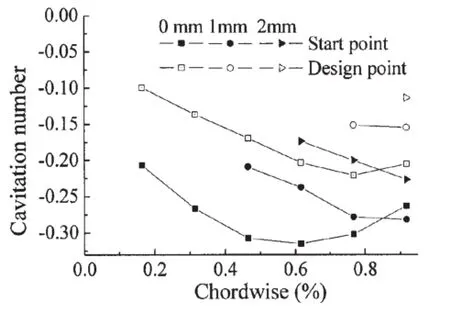

The TLV core cavitation number along chordwise at starting and design condition with the two injectors and without injection is shown in Fig.24.It is discovered that the higher injector is more effective to raise TLV cavitation number at both conditions.Comparing the cases of the two injectors and without injector,it can be easily obtained that the 2 mm injector increases minimum cavitation number by 28%,while the 1mm 10.5%.

Fig.23 KT&10KQ of the propeller with injectors of 0 mm,1 mm and 2 mm height gap

Fig.24 Cavitation number of TLV in the propeller with injectors of 0 mm,1 mm and 2 mm height gap

See the tip flow of the two injectors in Fig.25.Both injecting flow can propagate to the blade tip and larger gap injector can lead to higher speed at the blade downstream and tip clearance.

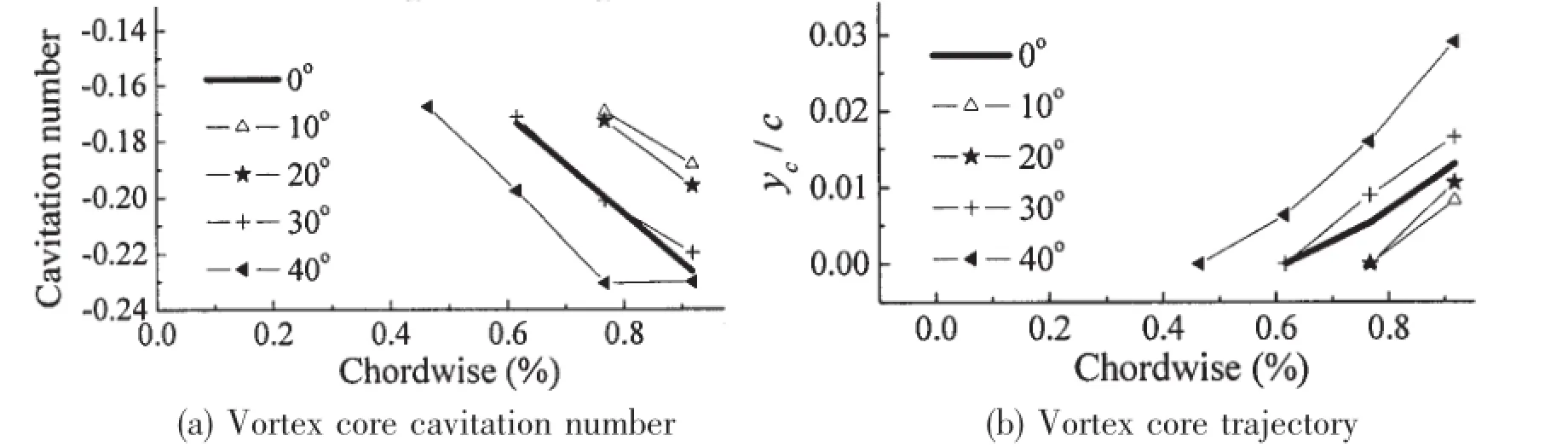

In order to clarify the effect of injector gap height on propulsive efficiency and TLV cavitation number,comparison of blade tip foil pressure distribution of the three cases is made in Fig.26.It can be included that

(1)The existence of injector results in pressure decrease at pressure side and increase at the suction side,hence the dropping loading at blade tip.

(2)At of 96%radius,two cases with injectors have similar pressure distribution and de-creasing tip loading.

(3)At 98%R and 99%R,the 2 mm injector generates lower tip loading than 1 mm injector which indicates that the difference between the two injectors primarily occurs at this region.

Fig.26 Tip pressure distribution at different radius with different injector gap heights

5.3 Effect of injection angle on TLV

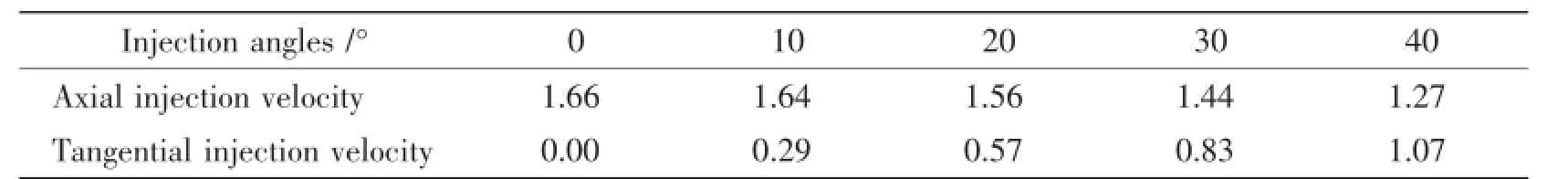

Injection angles of 0°,10°,20°,30°and 40°will be discussed in the following.The injection is towards rotating direction as shown in Fig.17.An injection backwards rotating direction will increase the angle of attack(AOA)of tip foil,which means heavier loading and lower TLV core pressure and will not be discussed here.The magnitudes of injection velocity with five different angles are the same,so larger injection angle means smaller axial injection velocity.The injection velocity applied in this section is 1.66,and the ducted propeller works at starting condition.Axial and tangential components of injection velocity of the five cases are listed in Tab.6.

Tab.6 Axial and tangential components of injection velocity of the five injection angles

Fig.27 demonstrates cavitation number and trace of TLV with different injection angles. The cavitation number curve rises and then drops with increasing injection angle.The optimal injection angles are 10°and 20°,which produce similar minimum cavitation number.The minimum cavitation number of 10°injection is larger than that of 0°injection by 0.038,about 17%increase.From Fig.27(b),10°injection indeed eliminates much a large amount of TLV. The result reveals the existence of optimal injection angle in BTI design.

Comparing the 40°injection of 1.66 with 0°injection of 1.33,both of which have similar axial velocity component(1.27 and 1.33),40°case indeed has larger cavitation number than the latter.The comparison indictaes that the tangential velocity plays an important role in cavitation delay.

Tip streamlines of the three injection angles of 0°,20°,40°and velocity magnitude 1.66 are shown in Fig.28.Tip flow is affected by BTI at the pressure side,while different injectionangles produce similar streamline at the suction side.Larger injection angle does not alter AOA more.The flow of 40°case at pressure side rolls up to TLV before the other two.

In order to study the impact of injection angles on TLV,the tip foil surface pressure distribution with injection angles of 0°,20°and 40°is plotted in Fig.29.It can be seen that,at pressure side,the 40°case has the highest pressure among the three;while at suction side,the pressure distributions of the three cases are very close to one another at 96%radius,but different from each other at 98%and 99%radius chordwise ranging from about 40%chord to trailing edge.The 40°case has the lowest pressure at the suction side,while 20°has the highest, therefore,the former has higher loading.

Fig.27 TLV characteristics of different injection angles

Fig.28 Blade tip streamline of different injection angles

Fig.29 Tip pressure distribution at different radius with different injection angles

6 Conclusions

The effects of tip clearance on TLV are studied on ducted propeller 19A/Ka4-55.The flow field is numerically solved with CFX and the performance curves are validated by the experi-mental results.It can be concluded that:

(1)Each curve of cavitation number in vortex core along tip foil has a valley point at different advanced coefficients.

(2)As the tip clearance increases,the cavitation number decreases and the valley point moves downstream.When the tip clearance is relatively small,as it increases,the minimum cavitation number position moves downstream and the value decreases little;when clearance becomes large,as it continues to increase,the minimum cavitation position barely moves and the value decreases clearly.

(3)The change of clearance size alters the distribution of tip leakage flow,thus pressure distribution on blade surface near the tip.The loading shifts from the leading to trailing edge with increasing clearance,and the chordwise position of the maximum velocity in TLF moves towards trailing edge correspondingly.

(4)The tip clearance affects the shape of TLV,as well as the generation and development of the vorticity in the clearance.

Next,a method called Blade Tip Injection(BTI)to alter the tip flow and delay cavitation in TLV of ducted propeller is also studied in this paper.Three critical parameters of the BTI namely injection velocity,injector gap height and injection angle are studied respectively.Conclusions can be drawn that:

(1)Increasing injection velocity has more effect on delaying TLV cavitation.Moreover, the TLV will be eliminated at starting when the injection velocity reaches 1.99,design conditions 1.66.

(2)BTI increases the axial velocity near blade tip,thus decreases the angle of attack,and results in reduction of tip loading and the thrust.The higher injector gap causes more thrust drop,because of the larger light loading region near blade tip.Consequently,the injection of higher gap is more effective to delay TLV cavitation.

(3)The injection angle provides flow pre-whirl and reduces AOA of tip foil.When the injection angle reaches 10°,the TLV gets the highest cavitation number curve on the ducted propeller used in this research.Additionally,with the similar axial injection velocity,the injection with pre-whirl is more effective.

[1]Li Jianbo.CFD analysis of tip clearance effects on duct propeller’s performance[J].Ship&Ocean Engineering,2010,39 (3):36-39.(in Chinese)

[2]Rains D A.Tip clearance flow in axial compressors and pumps[R].California Institute of Technology,Hydrodynamics and Mechanical Engineering Laboratories Report No.5,1954.

[3]Oweis G F,Ceccio S L.Instantaneous and time-averaged flow fields of multiple vortices in the tip region of a ducted propulsor[J].Experiments in Fluids,2005,38:615-636.

[4]Hah C,Lee Y.Unsteady pressure field due to interactions among tip leakage vortex,trailing edge vortex,and vortex shedding in a ducted propeller[C]//ASME,2007.

[5]Wu Huixuan,Tan D,Rinaldo L,et al.Three-dimensional flow structures and associated turbulence in the tip region of a waterjet pump rotor blade[J].Exp Fluids,2011,51:1721-1737.

[6]Chen G T,Greitzer E M,Tan C S,et al.Similarity analysis of compressor tip clearance flow structure[J].Journal of Turbomachinery,1991,113:260-269.

[7]Zhou Sheng,Zheng Xinqian,Hou Anping,Lu Yajun.Interaction of unsteady separated flow over multi-bodies moving relatively in the same flow field[J].Journal of Sound and Vibration,2005,288:981-1009.

[8]Brewer W H,Marcum D L,Jessup S D,et al.An unstructured rans study of tip-leakage vortex cavitation inception[C]. ASME Fluids Engineering Division Summer Meeting,2003-45311.

[9]Khaleghi H,Teixeira J A,Tousi A M,et al.Parametric study of injection angle effects on stability of transonic axial compressors[J].J Propul Power,2008,24:1100-1107.

[10]Khaleghi H,Boroomand M,Teixeira J A,Tousi A M.A numerical study of the effects of injection velocity on stability improvement in high-speed compressors[J].Proceedings of the Institution of Mechanical Engineers.Part A,Journal of Power and Energy,2008,222(2):189-198.

[11]Kuiper G.The Wageningen propeller series[M].Netherland:MARIN Publication 92-001,1992.

[12]Weigl H J,Paduano J D,Frechette L G,et al.Active stabilization of rotating stall and surge in a transonic single stage axial compressor[J].J Turbomach,1998,120:625-636.

[13]Suder K L,Hathaway M D,Thorp S A,et al.Compressor stability enhancement using discrete tip injection[J].Journal of Turbomachinary,2001,123:14-23.

[14]Day I J.Active suppression of rotating stall and surge in axial compressors[J].J Turbomach,1993,11:40-47.

[15]Zhou Junwei,Hou Anping,Zhou Sheng.Effects of injection frequency on the rotor stall margin[J].Science China Technological Sciences,2010,53(1):213-219.

[16]Hah C,Lee Yu-Tai.Unsteady pressure field due to interactions among tip leakage vortex,trailing edge vortex,and vortex shedding in a ducted propeller[C]//ASME Turbo Expo 2007:Power for Land,Sea and Air.Montreal:Canada,GT2007-27407.

导管螺旋桨叶梢泄漏涡机理研究及一种推迟梢涡空化的方法

周军伟,倪豪良

(哈尔滨工业大学(威海)船舶与海洋工程学院,山东威海264209)

文章运用数值模拟研究了导管螺旋桨叶梢泄漏涡机理,并提供了一种推迟泄漏涡空化的方法。通过分析不同间隙时的泄漏涡的空泡数发现,随着间隙增大,最小空泡数发生了位置向下游移动,靠近桨叶吸力面,其数值减小。间隙尺寸影响梢涡空泡数的机理很复杂,可以从三个方面来解释:第一、间隙大小改变了泄漏流动速度,从而影响了泄漏涡水动力参数;第二、间隙大小影响叶梢区域压强分布,泄漏涡压强随之改变;第三、间隙大小改变了间隙内黏流的产生和发展,影响泄漏涡黏性分布。而且叶梢泄漏涡核是导管螺旋桨空泡初生位置。文中研究一种叶梢喷射流方法降低叶梢涡核压降,推迟空化初生,探究了不同喷射速度和喷射间隙高度、喷射角度对泄漏涡空泡数的影响。从模拟结果看,叶梢喷射可以降低叶梢翼型载荷,改善泄漏涡核压强分布,推迟泄漏涡空化。比较不同喷射速度,发现速度越高,越能有效提高泄漏涡核压强,速度足够高时甚至可以“吹掉”涡核;研究不同喷射间隙高度发现,间隙越高,越能有效提高泄漏涡核压强,但由于会降低了叶梢更大区域的载荷,降低了桨叶推力;喷射角度的研究表明,轻微的正向预旋对推迟叶梢空化有利。

导管螺旋桨;叶梢泄漏涡;叶梢间隙;推迟空化;叶梢喷射

U664.33

:A

周军伟(1981-),男,哈尔滨工业大学船舶与海洋工程学院(威海)副教授;

1007-7294(2015)12-1445-18

U664.33

:A

10.3969/j.issn.1007-7294.2015.12.002

倪豪良(1990-),男,哈尔滨工业大学船舶与海洋工程学院(威海)博士研究生。

Received date:2015-04-05

Foundation item:Supported by the National Natural Science Foundation of China(Grant No.51309070); and the Natural Science Foundation of Shandong Province(ZR2012EEQ004)

Biography:ZHOU Jun-wei(1981-),male,Ph.D.,associate professor,E-mail:zhou_junwei@foxmail.com;

NI Hao-liang(1990-),male,Ph.D.student,E-mail:nihaoliang82206732@foxmail.com.

猜你喜欢

杂志排行

船舶力学的其它文章

- Flows Around a Circular Cylinder Controlled by Electromagnetic Force at Subcritical Reynolds Numbers

- Ship Manoeuvring Performance and Construction of its Metamodels

- Hydrodynamic Force and Motion Response Analysis for Diver’s Ladder under the Disturbance of Mother Ship

- Study on the Dynamic Response and Tension Characteristics of a TLP with One Tendon Broken

- A New Concept of ETLP and Its Hydrodynamic Performance

- Theoretical and Numerical Research on CTOD for Ship Plate under Cyclic Loading Considering Accumulative Plastic Strain