Softkill: 3D打印预制住宅

2015-03-02NicholetteChang,GillesRetsin,AaronSilver等

Softkill: 3D打印预制住宅

学生组:Softkill (Nicholette Chang, Gilles Retsin, Aaron Silver, Sophia Tang)

导师: Robert Stuart-Smith

工作室技术顾问:Knut Brunier

本项目探讨了利用3D打印技术建造由预制建筑件构成的住宅的可能性。作为一种增材制造工艺,3D打印技术可使各种不同设计由出自同一台机器的材料拼装而成,虽然工艺复杂,但不增加额外的制造成本。此外,增材制造几乎可以实现零浪费。本项目对这种潜在复杂性增加对于优化结构性能的可能性进行了研究探讨,以减少建筑的总材料用量。这种设计采用了一种定制的拓扑结构优化方法,以确保在设计中没有任何地方的材料是不承受结构荷载的。此外还采用了仿真模拟的设计算法,以通过建筑物内部的应力和应力方向确定材料的颗粒方向和孔隙率。这就形成了一种极具装饰性的多孔设计,这种设计在局部上存在差异,并且只用了等比例建筑物所通常需要使用的材料量的一小部分。这样产生了一种体积大而多孔的建筑类型。该项目通过数字脚本开发,并通过一个由大量不超过1mm厚的构件组成的1:33大比例模型原型进行测试。该模型本身由15个部分组装而成。

-- PREFABRICATION --SOFTKILL: A 3D PRINTED PRE-FABRICATED HOUSE

STUDENTS: SOFTKILL: NICHOLETTE CHANG, GILLES RETSIN, AARON SILVER, SOPHIA TANG

SUPERVISOR: ROBERT STUART-SMITH

STUDIO TECHNICAL CONSULTANT: KNUT BRUNIER

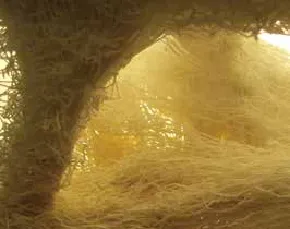

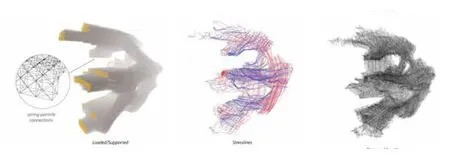

This project explores the potentials of 3D Printing to construct a house composed of prefabricated building components. As an additive manufacturing process, 3D Printing enables a wide variety of different designs to be fabricated from the same machine, with complexity not adding additional costs to the fabrication. Additionally, additive manufacturing operates with almost zero percent waste. This increase in potential complexity was investigated for its opportunity in optimising structural performance in order to reduce overall material quantities of the construction. The design utilised a custombuilt topological structural optimisation method to ensure no material was placed within the design that was not undergoing any structural loading. Agent-based design algorithms were also implemented to locally determine material grain direction and porosity in relation to stress and stress orientation within the building. This results in a highly ornamental porous design that is locally differentiated and utilises a fraction of material normally utilised within similar scale buildings. This results in a building typology that is volumeous yet porous. The project was developed through digital scripts and tested on a large 1:33 scale model prototype comprised of a multitude of elements no more than 1mm thick. The model itself is assembled from 15 parts that contribute to the overall assemblage.

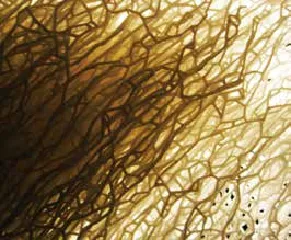

在自定制的运算化方法下完成结构优化与材料最少化计算 custom computer design methodology optimises structure and minimises material

纤维材料的颗粒和孔隙率根据当地的结构要求而不同fibrous material grain and porosity varies according to local structural requirements