Effects of Applying Bio-bacterial Fertilizer on Aroma Components of Flue-cured Tobacco

2015-02-05YanqiuJINGYuzhenGAOWeifengWANGJinfengZHUXiuxiuYUANBaolinZHANGYuyuanCHENGHuaiqiLIYuehuaZHANGPingLU

Yanqiu JING,Yuzhen GAO,Weifeng WANG,Jinfeng ZHU,Xiuxiu YUAN,Baolin ZHANG, Yuyuan CHENG,Huaiqi LI,Yuehua ZHANG,Ping LU*

1.Henan Agricultural University/Key Laboratory for Tobacco Cultivation of Tobacco Industry,Zhengzhou 450002,China;

2.Technology Research and Development Center,Gansu Tobacco Industry Co.,Ltd.,Lanzhou 730050,China;

3.Guangxi Zhuang Autonomous Region Provincial Branch of CNTC,Nanning 530022,China;

4.Luohe Branch of Henan Tobacco Company,Luohe 462000,China;

5.Nanyang Branch of Henan Tobacco Company,Nanyang 47300,China;

6.Chinese Tobacco Industrial Company in Henan,Zhengzhou 450000,China

Effects of Applying Bio-bacterial Fertilizer on Aroma Components of Flue-cured Tobacco

Yanqiu JING1,Yuzhen GAO2,Weifeng WANG3,Jinfeng ZHU4,Xiuxiu YUAN1,Baolin ZHANG1, Yuyuan CHENG5,Huaiqi LI6,Yuehua ZHANG6,Ping LU6*

1.Henan Agricultural University/Key Laboratory for Tobacco Cultivation of Tobacco Industry,Zhengzhou 450002,China;

2.Technology Research and Development Center,Gansu Tobacco Industry Co.,Ltd.,Lanzhou 730050,China;

3.Guangxi Zhuang Autonomous Region Provincial Branch of CNTC,Nanning 530022,China;

4.Luohe Branch of Henan Tobacco Company,Luohe 462000,China;

5.Nanyang Branch of Henan Tobacco Company,Nanyang 47300,China;

6.Chinese Tobacco Industrial Company in Henan,Zhengzhou 450000,China

[Objective]This research aimed to investigate the effects of bio-bacterial fertilizer on quality of flue-curved tobacco.[Method]The various concentrations of bio-bacterial fertilizer were applied to flue-cured tobacco as leaf fertilizer and base fertilizer respectively.[Result]The effect of bio-bacterial fertilizer on flue-cured tobacco differed among different treatments.Compared with the control,the bio-bacterial fertilizer significantly affected the quality of flue-cured tobacco.Among all the treatments,Treatment 3(leaf fertilizer)showed the best treatment effect,and it significantly improved the quality of flue-cured tobacco.[Conclusion]The bio-bacterial fertilizer showed significant improving effect on quality of flue-cured tobacco if spayed as leaf fertilizer.

Bio-bacterial fertilizer;Plasmid pigment;Neutral aroma components; Flue-cured tobacco

B io-bacterial fertilizer contains a large amount of biological bacteria.The activities of biological bacterial can not only improve soil physical and chemical properties and increase soil organic matter content,but also dissolve potassium,release phosphorus and fix nitrogen.After the bio-bacterial fertilizer is applied to soil,the biological bacteria will multiply rapidly,forming into dominant community.They can decompose the fixed nitrogen in soil that cannot be directly absorbed and utilized,providing available nitrogen to plants[1-4].In the previous studies on application of biobacterial fertilize in tobacco,the biobacterial fertilizer is mostly used as base fertilizer.There are rare reports on the application of bio-bacterial fertilizer,as leaf fertilizer in tobacco,especially on the effect of bio-bacterial fertilizer on quality of flue-cured tobacco.In this study,based on conventional fertilization,the bio-bacterial fertilizer was applied to flue-cured tobacco as base fertilizer and leaf fertilizer respectively so as to investigate the effect of bio-bacterial fertilizer on quality of flue-cured tobacco.

Material and Methods

Material

The test was carried out in the test field located in Baohe Village, Wuyang County,Luohe City,Henan Province in 2013.The test soil had moderate fertility,with pH value of 7.16,organic matter content of 12.04 g/kg,available nitrogen content of 12.08 mg/kg,available phosphorus content of 50.21 mg/kg and available potassium content of 142.78 mg/kg. The tested tobacco cultivar was Zhongyan 100 with row and plant spacing of 120 cm×55 cm.The to-

Test design

The randomized block design was adopted.A total of four treatments were arranged,including T1(water, CK),T2(base fertilizer),T3(leaf fertilizer)and T4(base fertilizer+leaf fertilizer).There were three replicates for each treatment.The bio-bacterial fertilizer was buried in soil as base fertilizer(diluted in water with a dilution of 200)or sprayed on tobacco leaves as leaf fertilizer(diluted in water with a dilution of 500).The treatment was carried out on the 45thand 70thd since the transplanting.When the bio-bacterial fertilizer was applied as base fertilizer, the application amount was 500 ml per plant;when the bio-bacterial fertilizer was applied as leaf fertilizer,both the front and back of tobacco leaves were spayed.For the field cultivation,the row and plant spacing was 120 cm× 50 cm,and the conventional fertilization was carried out.There were 100 tobacco plants per plot.

Determination of indicators and methods

Conventional ingredients in tobacco leavesThe water-soluble sugar, reducing sugar,total nitrogen,proteins,nicotine,potassium and chlorine contents in the flue-cured tobacco leaves were determined in accordance with YC/T 59-2002,YC/T 160-2002, YC/T 161-2002,YC/T 162-2002,YC/T 166-2002 and YC/T 173-2003,respectively.

Plasmid pigment contentThe plasmid pigment content in flue-cured tobacco leaves was determined using high-performance liquid chromatography(YC/T 382-2010).The pretreatment of tobacco leaves samples were performed as follows:A certain amount(2 g)of tobacco leaves was weighed and placed into a flask;in the flask,a certain volume of 90%acetone was added;after sealed,the flask was placed in ultrasonic for 20 min;the solution was filtered,and the obtained supernatant was added in the chromatogram vial.

Main neutral aroma components

The aroma components in the tobacco leaf samples were extracted with simultaneous distillation extraction method.The extract was first extracted with dichloromethane,and then concentrated to 1 ml in a rotary evaporator.The aroma components in the finally obtained extract were determined qualitatively using gas chromatography-mass spectrometry (HP6890-5975 GC-MS,US).

Results and Analysis

Effects of different treatments on aroma components in tobacco leaves

There were many aroma components in tobacco leaves.Some aroma components had relatively low contents,and some had extremely low contents.The aroma components are commonly classified according to the differences in chemical functional groups,aroma precursors and both chemical functional groups and aroma precursors.To facilitate the analysis, the characteristics of main aroma components were determined combining with different genotypes.If classified according to the differences in aroma precursors,the aroma components were divided into five categories, including carotenoids degradation products,neophytadiene,aromatic amino acids degradation products, Maillard reaction degradation products and cembratriendid alkyl degradation products.

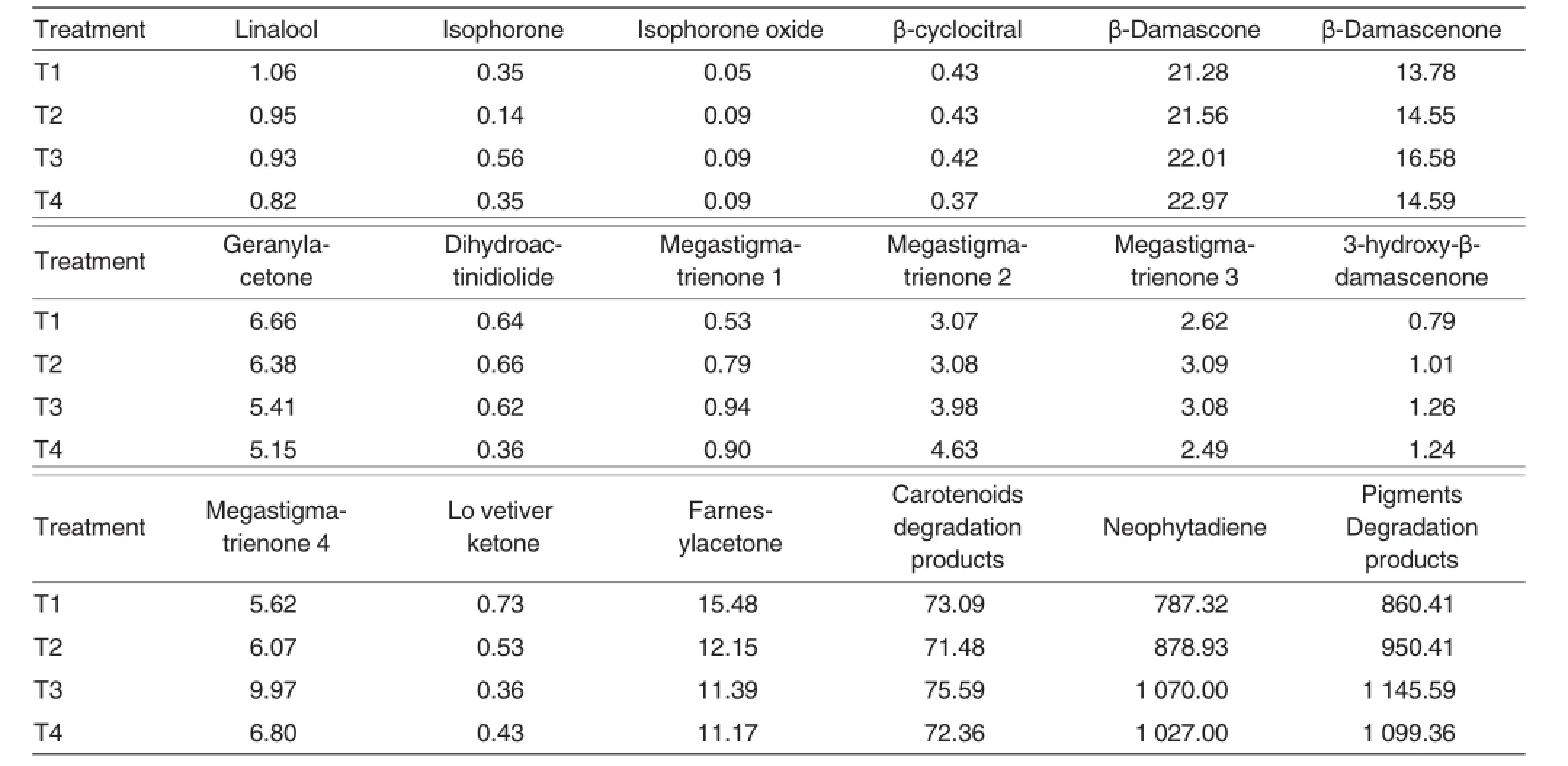

Effects of different treatments on degradation products of plasmid pigment

The plasmid pigment degradation products mainly divided into carotenoids degradation products and chlorophyll degradation products.The carotenoids degradation products contain many types,but the chlorophyll degradation products are primarily neophytadiene.As shown in Table 1,among all the four treatments,T3 showed the highest total content of carotenoids degradation products, which was 3.42%higher than that of T1;T1 showed the lowest total content.There were no significant differences in total content of chlorophyll degradation products among all the treatments.The carotenoids degradation products covered many types, among which,the β-Damascenone, farnesyl acetone and β-Damascone showed the highest contents.In all the four treatments,the total contents of β-Damascenone,farnesyl acetone and β-Damascone all accounted for more than 66%of the total carotenoids contents.The content of neophytadiene,a chlorophyll degradation product,ranked as T3>T4>T2>T1,and it differed significantly among all the treatments except between T3 and T4. The neophytadiene content accounted for more than 90%of the total degradation products amount of plasmid pigment.So the variation of total degradation products contents of plasmid pigment was in line with the variation of neophytadiene content among different treatments.

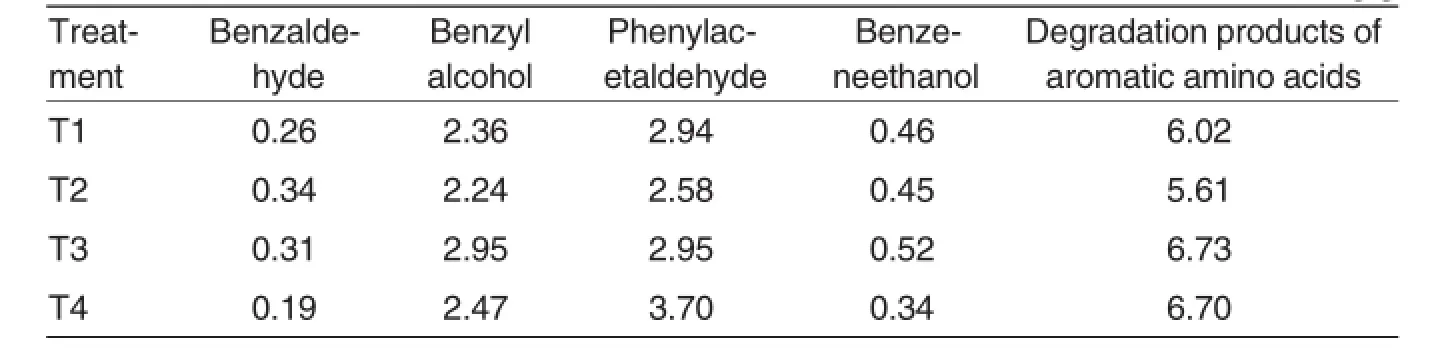

Effects of different treatments on degradation products of aromatic amino acids

In the degradation products of aromatic amino acids in flue-cured tobacco leaves,the neutral aroma components mainly included benzaldehyde(almond aroma,cherry aroma),phenylacetaldehyde(sweet flower fragrancy similar to hyacinth flavor; bitter under high concentration,but sweet fruit flavors after diluted),benzyl alcohol(soft sweet jasmine-like scent) and phenethyl alcohol(sweet and gentle aroma of roses and honey), which all had high contents in fluecured tobacco leaves.Table 2 showed that there were no significant differences in degradation products contents of aromatic amino acids in tobacco leaves among different treatments. T3 had the highest total amount of degradation products of aromatic amino acids,followed by T4,and T2 had the lowest total amount.

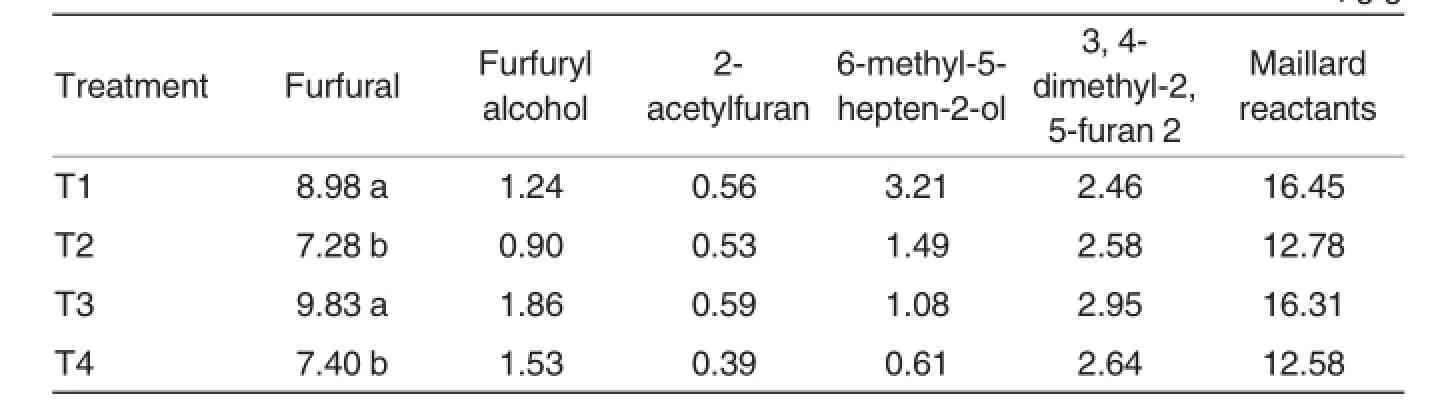

Effects of different treatments on Maillard reactants contents

Maillard reaction products and their degradation products are important constitutes of aroma of tobacco. The furfural is a major reaction product,and its aroma is characterized by bread flavor and butter flavor,endowing the tobacco flavor with a sweet taste.The furfuryl alcohol has the fla-vors of cereals and oil,and it can increase the concentration of tobacco aroma.The 2-acetyl-pyrrolo can enhance the sweetness of tobacco flavor,making the tobacco flavor soft.As shown in Table 3,T1 showed the highest total Maillard reactants amount (16.45 μg/g),followed by T3(16.31 μg/g),and T4 showed the lowest Maillard reactant amount(12.58 μg/g). Among all the Maillard reaction products,furfuryl showed the highest content,and it accounted for more than 55%of the total Maillard reactants amount.In terms of furfuryl content, there were significant differences among all the treatments except between T1 and T3 and T2 and T4.

Table 1Effects of different treatments on carotenoids degradation productsμg/g

Table 2Effects of different treatments on degradation products of aromatic amino acids μg/g

Table 3Effects of different treatments on Maillard reactantsμg/g

Conclusions and Discussion

Chlorophyll is one the substances of which the contents vary most greatly during the maturity and processing of tobacco leaves.Neophytadiene is the main degradation product of chlorophyll,and it is an important terpene compound in tobacco leaves. The neophytadiene itself has a certain aroma,and it can also be transformed into low molecular aromatic compounds[5].Zhou et al.[6]considered that the ratio between neophytadiene content and the other aroma components content may be one of the main factors in the formation of aroma in tobacco leaves.In the tobacco leaves sprayed with bio-bacterial fertilizer,the neophytadiene content was relatively high, but the neophytadiene content in T3 was higher than that in T4.As precursors for many aroma components, carotenoids play an important role in the formation of aroma in tobacco leaves.The aromatic degradation products of carotenoids have weak stimulating smell but high quality.They make great contributions for the aroma in tobacco leaves,and are also important components affecting the quality and quantity of aroma in tobacco leaves[6].The variation of neophytadiene among all the four treatments in this study was also consistent with the study results of Zhou et al[6].In the tobacco leaves sprayed with bio-bacterial leaf fertilizer,the neophytadiene content was relatively high,and it was highest in T3.In the degradation products of non-plasmid pigment,the main volatile aroma components include the metabolites of aromatic amino acids, Maillard reaction products and cembratriendid alkyl degradation products, of which the amounts were all increased compared with those of the control in this study.T3 showed the highest total degradation products amount of aromatic amino acids.Considering the Maillard reactants,the four treatments ranked as T1>T3>T2>T4,but none significant differ-ences were found among them.Combining with the coordination among aroma components contents,based on the conventional fertilization,applying a certain amount of bio-bacterial fertilizer as leaf fertilizer can effectively improve the intrinsic quality of tobacco leaves.

[1]WANG WL(王维亮).Preparation and utilization of microbial fermentation fertilizer(微生物发酵肥的制作与使用)[J]. New Rural Technology(农村新技术), 2008,16:79-80.

[2]LI XM(李先明),CHEN QQ(陈青奇),LEI N(雷娜).Application effect of Luzhou Jiaosu fermented manure in cultivation of Chinese cabbage(绿洲酵素发酵肥在大白菜栽培上的应用效果试验)[J]. Non-State Running Science&Technology Enterprises(民营科技),2009, 10:119.

[3]PIAO LJ(朴林姬),JIANG XZ(姜学哲). Effects of applying organic fermented manure on changes in soil nutrients and yield of rice(施用有机发酵肥对土壤养分变化及水稻增产作用)[J].Yanbian Agricultural Science and Technology(延边农业科技),2001,55:37-41.

[4]PIAO SJ(朴顺姬),ZHU HL(朱虎烈).Application effect of fermentation fertilizer of crop straws(作物秸秆发酵肥使用效果的研究)[J].Journal of Jilin Agricultural Sciences(吉林农业科学),2001,26(1): 42-45.

[5]SHI HZ(史宏志),HAN JF(韩锦峰), GUAN CY(官春云).Changes in aroma precursors during maturity and processing of tobacco leaves(烟叶香气前提物在成熟和调制过程中的变化)[J]. Crop Research(作物研究),1996,10(2): 44-49.

[6]ZHOU JH(周冀衡),YANG HQ(杨虹琦), LIN GH(林桂华),et al.Studies on the main volatile aroma components in tobacco from different flue-cured tobacco production regions(不同烤烟产区烟叶中主要挥发性香气物质的研究)[J].Journal of Hunan Agricultural University(湖南农业大学学报),2004,30(1):20-23.

Responsible editor:Xiaoxue WANG

Responsible proofreader:Xiaoyan WU

施用生物菌肥对烤烟香味物质成分的影响

景延秋1,高玉珍2,王卫峰3,朱金峰4,袁秀秀1,张豹林1,程玉渊5,李怀奇6,张月华6,鲁平6*

(1.河南农业大学烟草学院/烟草行业烟草栽培重点实验室,河南郑州450002;2.甘肃烟草工业有限责任公司技术研发中心,甘肃兰州730050;3.中国烟草总公司广西壮族自治区公司,广西南宁530022;4.河南省烟草公司漯河市公司,河南漯河462000;5.河南省烟草公司南阳市公司,河南南阳47300;6.河南中烟工业公司,河南郑州450000)

[目的]为了研究生物菌肥对烤后烟叶的提质增效的效果。[方法]用不同浓度的生物菌肥进行叶面喷肥和土壤施肥。[结果]不同处理对烟叶内在化学成分的影响不同。与对照相比,微生物菌肥对烤烟的品质都有显著的改变,其中表现最好的为处理③叶面施肥,它对烟叶品质有所提高。[结论]叶面喷施微生物菌肥在烤烟品质上表现出较好的效果。

生物菌肥;质体色素;中性致香物质;烤烟bacco plants were transplanted on May 25thand topped on August 2nd.A total of 18-22 leaves were retained per plant.In the field,the tobacco plants were all cultivated and managed in accordance with the high-quality tobacco leaves cultivation and production measures.The middle-layer roasted tobacco leaves were sampled for index determination.

河南省烟草公司资助项目(HYKJM201203,HYKJ201305)。

景延秋(1972-),女,河南南阳人,副教授,博士,研究方向:农业(烟草)化学,E-mail:jingyanqiu72t@163.com。*通讯作者,工程师,E-mail:xyluping@126.com。

2015-01-27

修回日期 2015-05-28

Supported by Funding Projects of Henan Provincial Tobacco Company(HYKJM201203, HYKJ201305).

*Corresponding author.E-mail:xyluping@126.com

Received:January 27,2015 Accepted:May 28,2015

猜你喜欢

杂志排行

Agricultural Science & Technology的其它文章

- Analysis and Discussion on Some Problems of the Edible Fungi Production in Asmara Area

- The Control Research Progress ofLiberobacter asiaticumin Taizhou City

- Application of Genetically Modified Technology in Maize Breeding

- Breeding of Indica Rice CMS Line Renong 1A with Virescent-yellow Leaf

- Breeding and Application of Indica PTGMS Line Yan 161S and Its Hybrid Yanliangyou 1618 in Rice

- Thoughts on the Sustainable Development of the Fava Bean Industry in Chongqing