Stress Relaxation Behavior of GH4169 Superalloy

2015-01-12CHANGPengpeng常鹏鹏KONGYonghua孔永华CHENGuosheng陈国胜XIELixiong谢黎雄ZHUShigen朱世根

CHANG Peng-peng(常鹏鹏), KONG Yong-hua(孔永华)*, CHEN Guo-sheng(陈国胜), XIE Li-xiong(谢黎雄), ZHU Shi-gen(朱世根)

1 College of Mechanical Engineering, Donghua University, Shanghai 201620, China2 Baosteel Group, Special Steel Branch, Shanghai 200940, China3 Guizhou Liyang Aero Engine Corporation, Pingba 561102, China

Stress Relaxation Behavior of GH4169 Superalloy

CHANG Peng-peng(常鹏鹏)1, KONG Yong-hua(孔永华)1*, CHEN Guo-sheng(陈国胜)2, XIE Li-xiong(谢黎雄)3, ZHU Shi-gen(朱世根)1

1CollegeofMechanicalEngineering,DonghuaUniversity,Shanghai201620,China2BaosteelGroup,SpecialSteelBranch,Shanghai200940,China3GuizhouLiyangAeroEngineCorporation,Pingba561102,China

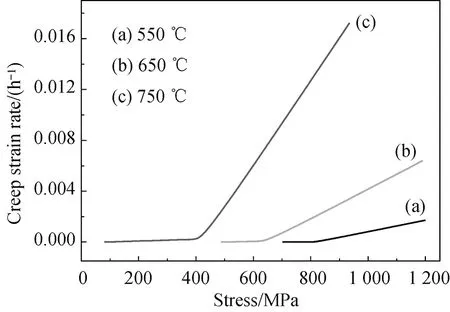

GH4169 superalloy stress relaxation test was investigated to study its characteristics of stress relaxation curves at various temperatures (550, 650, and 750℃). These curves presented jointly two distinct stages, the stage of inner stress relaxing quickly, and the stage of inner stress relaxing slowly and closing to the stress relaxation limit. And these curves obtained could be fitted by second order exponential decay function well. Based on the experimental stress relaxation curves, the relationship between stress relaxation rate and time were derived, which showed that the higher relaxation temperature and the greater initial rate of stress relaxation. The whole process presented two different stages, the stage of stress relaxation rate falling rapidly and the stage of stress relaxation rate slowing down and tending to be constant. The relation curve between creep strain rate and stress of GH4169 superalloy can be divided into three stages, low stress stage, transition stage, and high stress stage. Both the high stage and the low stage present linear correlation.

GH4169superalloy;stressrelaxationexperiment;secondorderexponentialdecayfunction

Introduction

GH4169 is a Ni-Cr-Fe wrought superalloy with high strength, good welding performance, and resistance to radiation, oxidation, and thermal[1-3]. It is widely used in the field of aviation, nuclear power, and petroleum due to its high strength, plasticity, good fatigue characteristic, and corrosion resistance below 650℃[4-6]. The number of GH4169 parts in gas turbine engines has increased from several to over two hundred. For instance, the 60% of core engine weight and 30% of total weight of a new type of aircraft engine are occupied by GH4169 parts[7]. Most of the turbine disk and blade are made of GH4169, which is the important component. Blades are installed on the turbine disk tightly, and only a little microns relative movement is allowed between them.

Previous study on this material was mainly focused on the creep behavior[8-9]. However, there was little research related to the stress relaxation behavior and the relationship between stress relaxation and creep. Creep behavior is that the inelastic deformation gradually increase under high temperature and the condition of constant stress. However, the stress loading on the turbine disk and blade can not keep constant for a long time, on the contrary, it changes frequently. The stress relaxation is the gradual decrease of stress while the material is held at constant strain. At high temperature environment, relaxation of such stress can result in losses of tension in fitting and cause undesirable vibration[10]. Hence, the main objective of this study is to explore the stress relaxation behavior of GH4169 superalloy at high temperature environment and the relationship between stress relaxation and creep.

1 Experimental Materials and Procedures

GH4169 superalloy used in the experimental was supplied by special steel branch of Baosteel Group. Figure 1 shows the original optical microstructure of GH4169 superalloy with 10-20 microns grain size and smooth boundaries. In the as-received condition, it has been coldly rolled to a diameter ofφ30 mm, subjected to the high temperature diffusion composed of 1160℃/24 h and 1190℃/72 h and then cooled at a rate equivalent to air cooling or faster. The chemical composition of the as-received experimental material is shown in Table 1.

Fig.1 Original optical microstructure of GH4169 superalloy

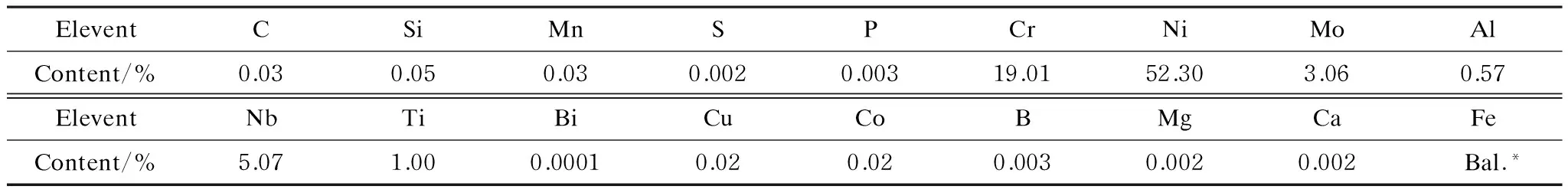

Table 1 Chemical composition of experimental GH4169 alloys (ω/%)

Note:*means the left content within the whole material

The specimens for stress relaxation tests were machined according to the ASTM E8M-08. The stress relaxation testing was conducted at strain level 1% and the testing temperatures included 550, 650, and 750℃. The specimens reach desired temperatures and leave for thermal equilibrium for 25 min. Then strain at 1% was applied to a specimen. All the mentioned tests were carried out using a computer-controlled stress relaxation testing machine RGM-X300C(REGER Co., China).

2 Results and Discussion

2.1 The stress relaxation behavior of GH4169 superalloy

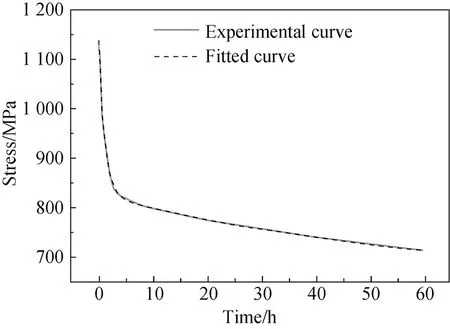

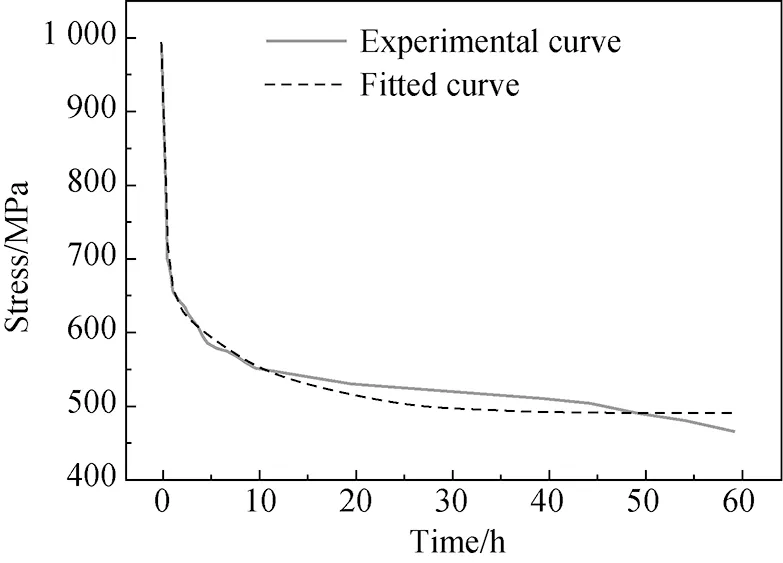

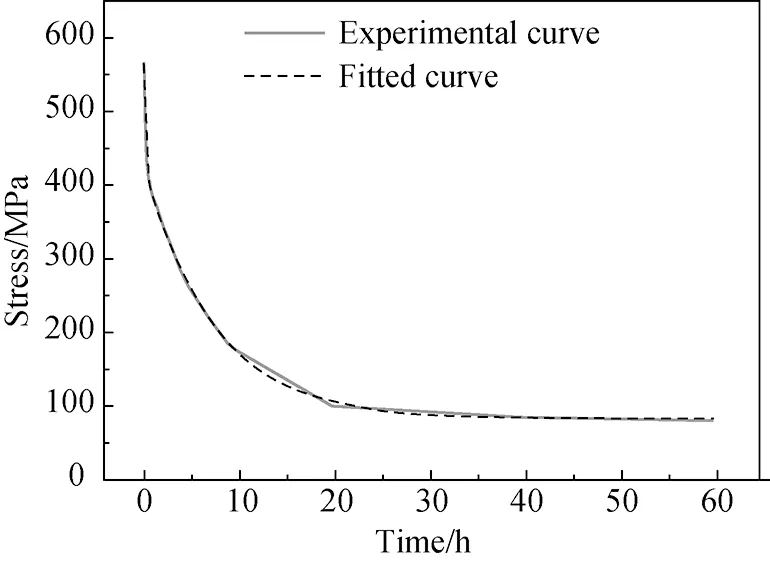

Figure 2 shows the stress relaxation behavior of GH4169 superalloy. The solid lines in them are experimental stress relaxation curves, from which the similar characteristics of stress relaxation behavior of GH4169 superalloy at temperature 550, 650, and 750℃ are found. The whole process of stress relaxation could be divided into two stages. In the first stage, the inner stress of specimens relaxed quickly and then slowed down gradually as the extension of time. In the next stage, the stress relaxation rate further reduced but steadily and constantly, and was infinitely closed to the stress relaxation limit. The same results pattern was discussed by Pan and Xiong[10]by using different material.

(a)

(b)

(c)

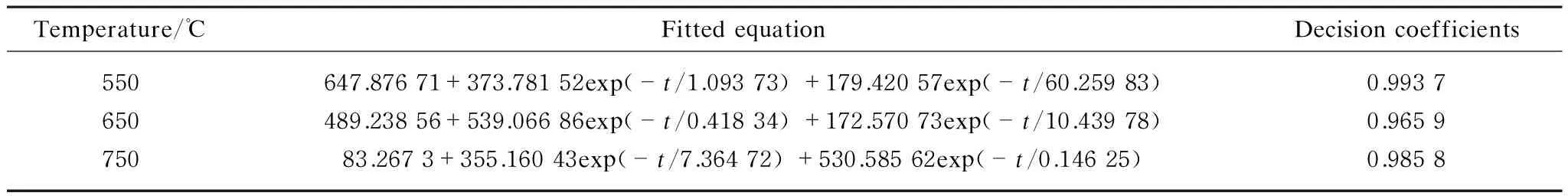

The form of index or logarithmic equation is generally adopted to fit the stress relaxation curves of metal material. Lietal.[11]discussed the fitting of 65Mn spring steel stress relaxation curves by adopting the second order exponential decay function and finally got a good result. Same results were discussed by Zhuetal.[12-14]for Hastelloy C-276 superalloy. Therefore, Eq.(1) was employed to fit the stress relaxation curves of GH4169 superalloy.

y=y0+A1exp(-t/t1)+A2exp(-t/t2),

(1)

whereyis the instantaneous stress;tis the relaxation time; y0, A1, A2, t1, and t2are constants which are related to the material properties and test conditions and directly determine the shape of fitted curves. Origin 8.0 software was adopted to build the fitted equations and decision coefficients were obtained. The results are presented in Table 2, and the fitted curves are displayed as imaginary lines in Fig.2.

Based on the high decision coefficients in Table 2. and the degree of coincidence between fitted curves and experimental curves from Fig.2, it is reasonable to conclude that the relationship between stress and time in the stress relaxation process can be depicted well by the second order exponential decay function.

Table 2 Fitted curves of stress relaxation data

Temperature/℃FittedequationDecisioncoefficients550647.87671+373.78152exp(-t/1.09373)+179.42057exp(-t/60.25983)0.9937650489.23856+539.06686exp(-t/0.41834)+172.57073exp(-t/10.43978)0.965975083.2673+355.16043exp(-t/7.36472)+530.58562exp(-t/0.14625)0.9858

2.2 The effect of temperature on the stress relaxation

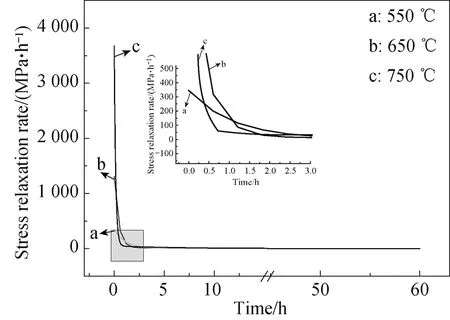

The stress relaxation rate-time curves of GH4169 superalloy under different relaxation temperatures are shown in Fig.3. It can be seen that the higher the relaxation temperature is, the greater the initial rate of stress relaxation is. At the same relaxation temperature, the stress relaxation rate decreased as the extension of test time. These curves could be divided into two stages. In the first stage, the stress relaxation rate decreased rapidly. In the next stage, stress relaxation rate decreased slowly and gradually tended to be constant. At the junction of two stages, the stress relaxation rate at high temperature was lower than that at low temperature.

Fig.3 Relationship of GH4169 superalloy between stress relaxation rate and the temperature

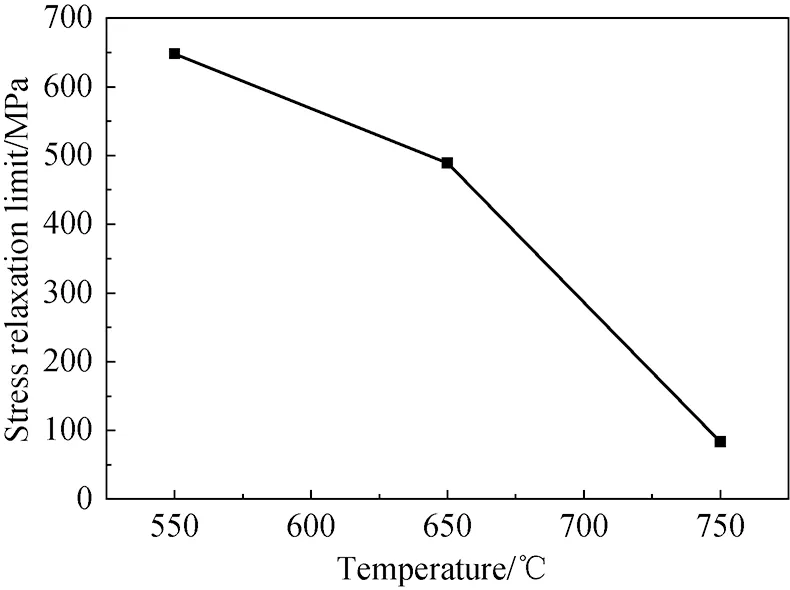

The stress relaxation limits of GH4169 superalloy at different temperatures can be calculated through the fitted equations listed in Table 2. Figure 4 shows the effect of temperature on the stress relaxation limit. It is reasonable to conclude that the stress relaxation limit decreased with increasing the temperature and the higher the temperature was, the faster the limit value decreased.

Fig.4 The stress relaxation limit at different temperatures: 550, 650, and 750℃

2.3 Creep strain rate-stress curves

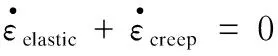

Creep strain rate is the key physical quantities for the process of stress relaxation. In addition, the relationship between creep strain rate and stress also is the basic equation for stress relaxation[15-17]. Based on the experimental relaxation curves at temperature 550, 650, and 750℃, the creep strain rate-stress curves can be derived. For the whole process of stress relaxation test, total strain was set as 1% constant, then Eq.(2) can be obtained:

εtotal=εelastic+εcreep,

(2)

where εtotalis the total strain, εelasticis the elastic strain, and εcreepis the creep strain. In the process of stress relaxation, the total strain always remains constant, while elastic strain gradually changes into creep strain. So there is:

(3)

then based on the Hooke law, there is:

(4)

(5)

According to Eqs.(1)-(4), the creep strain rate-stress curves can not be depicted directly through Eq.(5). However, the fitted stress relaxation curve can be divided into 60000 equal parts according to the time, then the corresponding stress dates per 0.001 h can be obtained. As a consequence, the stress-time curve with 60000 date combinations is obtained. Then the derivative of stress-stress curve is obtained. Meanwhile creep rate-stress curves at different temperatures can be derived easily. Figure 5 shows these curves. It can be concluded that the creep rate-stress curves can be divided into three stages: low stress stage, transition stage, and high stress stage. In the low and high stress stages, the relationship between creep rate and stress presents a linear correlation while it is relatively complicated for the transition stage.

Fig.5 Creep strain rate-stress curves of GH4169 superalloy at different temperatures: (a) 550℃; (b) 650℃; (c) 750℃

3 Conclusions

(1) The whole process of stress relaxation of GH4169 superalloy could be divided into two stages. In the first stage, the inner stress of specimens relaxed quickly and then slowed down gradually as the extension of time. In the next stage, the stress relaxation rate further reduced but steadily and constantly, and was infinitely closed to the stress relaxation limit.

(2) The relationship between stress and time in the stress relaxation process could be depicted well by the second order exponential decay function.

(3) The higher the relaxation temperature was, the greater the initial rate of stress relaxation was. The stress relaxation rate-time curves could be divided into two stages. In the first stage, the stress relaxation rate decreased rapidly. In the next stage, stress relaxation rate decreased slowly and gradually tended to be constant. At the junction of two stages, the stress relaxation rate at high temperature was lower than that at low temperature.

(4) The stress relaxation limit decreased with increasing the temperature and the higher the temperature was, the faster the limit value decreased.

(5) Creep strain rate-stress curves could be divided into three stages: low stress stage, transition stage, and high stress stage. In the low and high stress stages, the relationship between creep rate and stress presented a linear correlation.

[1] Lu X D, Du J H, Deng Q. High Temperature Structure Stability of GH4169 Superalloy [J].MaterialsScienceandEngineering:A, 2013, 559(1): 623-628.

[2] Tian S G, Wang X, Liu C,etal. Influence of Phosphorus and Boron on Creep Behavior and Fracture Mechanism of GH4169 Superalloy [J].HighPerformanceStructureMaterials, 2013, 747/748(2): 672-677.

[3] Zhou J, Han R D. Experimental Study of Green High-Speed Turning Nickel-Based Superalloy GH4169 [J].AdvancedMechanicalEngineering, 2010, 26/27/28(2): 1132-1136.

[4] Ye J. American Ni-Base Superalloy[M]. Beijing: Science Press, 1979: 62-65. (in Chinese)

[5] Huang Q Y, Li H K. Superalloy[M]. Beijing: Chinese Metallurgy Industry Press, 2000: 1-8. (in Chinese)

[6] Kuo C M, Yang Y T, Bor H Y,etal. Aging Effects on the Microstructure and Creep Behavior of Inconel718 Superalloy [J].MaterialsScienceandEngineeringA, 2009, 510/511(6): 289-294.

[7] Zhuang J Y. Deformation Superalloy GH4169[M]. Beijing: Chinese Metallurgy Industry Press, 2006: 2-3. (in Chinese)

[8] Li Z R, Tian S G, Zhao Z G,etal. Creep Behavior and Fracture Mechanism of HCP GH4169 Superalloy [J].JournalofAeronauticalMaterials, 2011, 31(3): 71-76.

[9] Li H Y, Kong Y H, Chen G S,etal. Effect of Different Processing Technologies and Heat Treatments on the Microstructure and Creep Behavior of GH4169 Superalloy [J].MaterialScienceandEngineering:A, 2013, 582: 368-373.

[10] Pan Y S, Xiong D S. Stress Relaxation Behavior of Nano-hydroxyapatite Reinforced Poly (vinyl alcohol) Gel Composites as Biomaterial [J].JournalofMaterialScience, 2010, 45(20): 5495-5501.

[11] Li J M, Zhao N Q, Li Q Y,etal. Bending Stress Relaxation Behavior of 65Mn Spring Steel [J].HeatTreatmentofMetals, 2007, 32(5): 90-94. (in Chinese)

[12] Zhu Z, Zhang L W, Gu S D. Stress Relaxation Test of Hastelloy C-276 Alloy and Its Creep Constitutive Equation [J].ChineseJournalofNonferrousMetals, 2012, 22(4): 1063-1067. (in Chinese)

[13] Zhu Z, Zhang L W, Song G Y,etal. Study on Creep Deformation of Reactor Coolant Pump Rotor-Can during Vacuum Hot Bulge Forming Process [J].AdvancedMaterialsResearch, 2011, 189/190/191/192/193(2): 2415-2420.

[14] Zhu Z, Zhang L W, Song G Y,etal. Study on Stress Relaxation Behavior of Hastelloy C-276 Alloy [J].RareMetalMaterialandEngineering, 2012, 41(4): 697-700. (in Chinese)

[15] Guo J Q, Xuan F Z, Wang Z D,etal. Creep Performance Prediction Method through Short-Term Stress Relaxation Tests [J].ProceedingsoftheCSEE, 2009, 29(11): 92-95. (in Chinese)

[16] Beddoes J, Mohammadi T. Comparison of Stress Relaxation and Creep Strain Rates for the Superalloy IN738LC [J].JournalofStrainAnalysisforEngineeringDesign, 2010, 45(8): 587-592.

[17] Jung Y, Seol Y, Choi B K,etal. Behavior of Stress-Relaxation and the Estimation of Creep in Zr-1.1Nb-0.05Cu Alloy [J].MaterialsandDesign, 2012, 42(12): 118-123.

TG146.1+5 Document code: A

1672-5220(2015)01-0058-04

Received date: 2014-01-06

* Correspondence should be addressed to KONG Yong-hua, E-mail: yhkong@dhu.edu.cn

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Joint Optimization Strategy for Video Transmission over Distributed Cognitive Radio Networks

- Asymptotic Behavior of the Drift Coefficient Estimator of Stochastic Differential Equations Driven by Small Noises

- Adaptive Modulation and Coding Based on Fuzzy Logic Cognitive Engine

- Modeling and Simulation of P-Aloha, CSMA/CA and MACAW Protocols for Underwater Acoustic Channel

- Design and Analysis of Axial Thrust Roller-Exciting Vibrating Table and Its Motor-Control System Based on Co-simulation

- Effects of Compression Garments on Lower Limb Muscle Activation via Electromyography Analysis during Running