Research on temperature control module of injection molding machine based on C8051F020

2014-09-07XINGuozhiLVChangzhi

XIN Guo-zhi,LV Chang-zhi

(College of Electrical Engineering and Automation,Shandong University of Science and Technology,Qingdao 266590, China)

The injection molding machine is one of the mechanical types,which has the fastest developing speed and level. And most of them are the ordinary injection molding machines. In many aspects such as the super-huge type,special,specified and precise injection molding machines,lots of products are blank spaces in China,and the point is the main gap with the developed countries[1]. In this day and age,plastics is more widely used to manufacture the parts and components in manufacturing industries,the electronic components in electrical industries and the anti-corrosion materials in chemical industries,and it is also indispensible material in defense industry. While the injection molding machine is developing vigorously,the control technique of the injection molding machine is also improving constantly,as well as micro-processor control,contactor control,PLC control and special micro-processor control. Design of control system is one of the key technologies of design in the injection molding machine and determines technical level and economic benefit of the injection molding machine to a large extent. In recent years,control technique of the injection molding machine has achieved tremendous development and laid the solid foundation for advanced production of the plastic products[2].

1 Structure of measurement and control system of injection molding machine

Overall hardware block diagram of the measurement and control system of the injection molding machine is shown in Fig.1.

Fig.1 Overall hardware block diagram of measurement and control system of injection molding machine

Wherein the whole system is formed by an upper computer control plate and a lower computer main control plate. The upper computer control plate is responsible to complete input and output (I/O) of the switching value,collecting data,controlling algorithm,pre-treating data,controlling technological process and the like. The lower main control plate is directly connected with sensors and a controlling element. Measurement and control system of the injection molding machine is comprised of a CPU and real-time clocks,and has functions such as man-machine interaction,storage,input and output,and communication.

2 Design of circuit module in core processor of lower computer

The C8051F020[3]is adopted in this system as micro-processor of the lower computer,wherein the C8051F020 is compatible with 8 051 cores,and provides ADC,DAC,inner temperature sensor,PWM resource and the like. Additionally,the simulation debugging of online system can be achieved through C8051F020 to observate and modificate memories and registers,breakpoints,observation points,single-step,start-up and showdown orders all supported. When the JTAG debugging is used,all analogs and digital peripheral devices can operate with their full functions.

In this design,input and output of the switching values and the analog values,the detection of the temperatures of eight-channel charging barrels,the output of proportional pressure and flow valves and the output of the temperature control relay can be achieved by the lower computer.

3 Design of temperature control module

The producing quality of products and working efficiency of the injection molding are directly influenced by the temperature control,so it is very important to choose an appropriate system of the temperature control module. According to engineering practices and tests of the labs,an integral separated PID control strategy is adopted in this design.

When the practical temperature acquired by coupling sampling deviates from the anticipated designated,the PID control is adopted. According to error temperature value between the practical temperature and the anticipated temperature,operations of proportional (P),integral (I) and differential (D) are carried out. Therefore,one control system drives the actuating mechanism to adjust heating system,and the designated value can be tracked rapidly by the measured value,and the effect of constant-temperature control is achieved.

3.1 PID control algorithm of charging barrel temperature

The controlled object of the temperature is charging barrel of the injection molding machine. Temperature of the charging barrel is assumed to be the controlled parameter,wherein ideal mathematical module of the controlled object can be expressed by Eq.(1)[4]

(1)

According to Eq.(1),the controlled object is a first-order,inertance and pure lag system,and the temperature of the system can be controlled by the digital PID control algorithm.

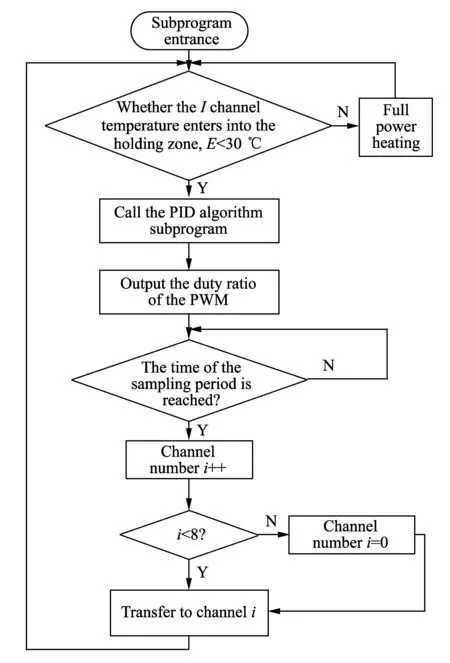

Combined with temperature feature and digital PID algorithm of charging barrel of the injection molding machine,Clanguage is adopted to achieve PID algorithm. Overall flow chart of the temperature control is shown in Fig.2.

Fig.2 Overall flow chart of temperature control

When the subprogram is called by the main program,the first defaulted channel temperature heating coil is controlled,and the subprogram judges whether the errorEof this channel is larger than 30 ℃. If it is larger than 30 ℃,this heating coil is heated by total power. Otherwise,the digital PID control algorithm program is called,and the controlled value can be calculated on-line and transferred to the duty ratio of PWM pulse in controlling the heating coil. Heating power of the heating coil in this channel is adjusted and transferred to control the second channel charging barrel's heating coil when the sampling time 4.8 s is reached,and then that cycle repeats. The constant temperature control of eight-channel charging barrels can be achieved.

During production of the injection molding,if the ordinary PID control is adopted,a serious integral saturation phenomenons often occur due to facts that large deviation is generated in a short time and lags exist in the system. Therefore,very large overshoot or long-time oscillation is prone to be caused. When this method is adopted,advantages of the integral control on offset eliminating and precision improvement can be fully played,and the problems that stability of the system is changed and the deviation caused by improvement of the integral control is incresed can be avoided.

The flow chart of the digital PID control algorithm is shown in Fig.3.

Fig.3 The flowchart of digital PID control algorithm

According to the situation of temperature control system,an error threshold valueAof the integral separation is set (the value ofAin this system is equal to 30 ℃). When the error is larger than the regulated threshold valueA,the PID control is adopted and the integral effect is forbidden,while the integral item in the incremental equation does not work any more. Therefore,the accumulated sum of the errors can not be too large,and the overshoot is decreased significantly. When the error is relatively small and within range of the threshold value,the integral effect is introduced and the PID control is adopted to eliminate the offset to improve the control precision of the system. Therefore,temperature of the charging barrel is not prone to enter into the saturation region. If temperature of the charging barrel enters into the saturation region,it quickly quits so that output characteristics of the temperature control system is improved.

After the integral separation control is introduced,the incremental PID equation can be improved to be[5]

ΔUn=Kp[(e(n)-e(n-1))]+KiKfe(n)+

Kd[e(n)-2e(n-1)+e(n-2)].

(2)

Wherein the logic coefficient is

(3)

This algorithm can be called the integral separation PID equation,whereinAis a predetermined threshold value. When |e(n)|>A,the integral item does not work. Only when |e(n)|≤A,the integral effect can be introduced and the adjusting performance can be improved.

3.2 Adjustment of PID parameter

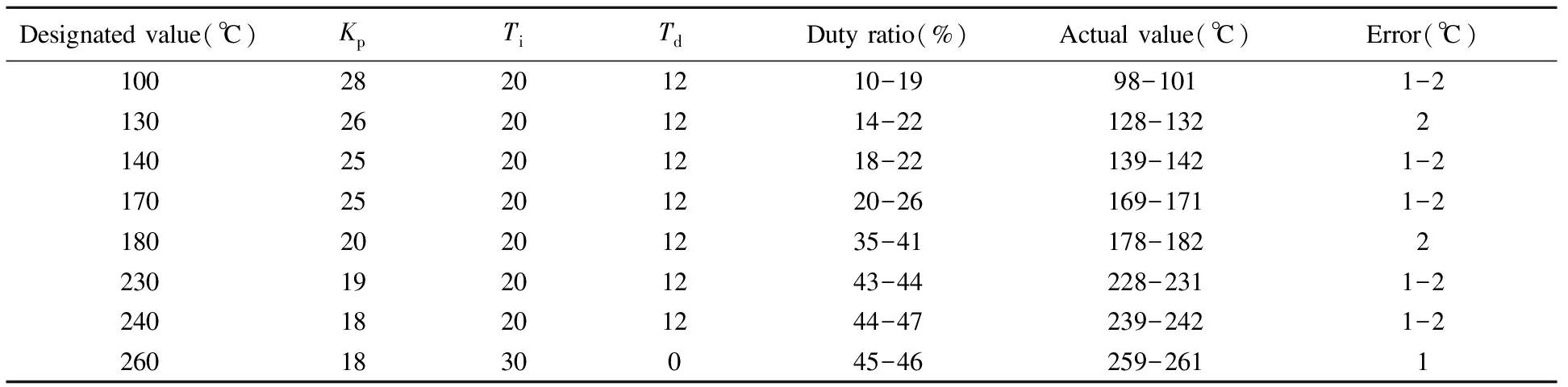

When the PID controller parameters are adjusted,parameters of the controller can be regulated by the method of trial and error according to parameters relationship between the dynamic performance and the steady-state performance of the system[6].

The proportional parameter is firstly adjusted. The proportional coefficientKpchanges from the smaller value to the larger value,and the corresponding temperature response curve can be observed. When a temperature response curve with a fast response and a small overshoot is acquired,the adjustment of the proportional parameterTiis basically over. At this time,the response curve should be observed. If the system offset can not meet the design requirement,the integral element should be consided to be introduced. At the beginning of the adjustment,the integral time parameterTiis set to be an infinite value,and then the proportional coefficientKpis slightly diminished according to a regulated percentage of the proportional coefficient. And the integral time coefficientTiis not being stopped diminishing gradually until a group of parameters is acquired and the system is maintained under the situation of rapid dynamic response. Therefore,the offset of system is eliminated. If the design requirement still can not be met when the integral element is introduced,the another differential element should be considered to be introduced,and the satisfied temperature response curve may be obtained. At the beginning of the adjustment,the differential time coefficientTdis set to be 0 and is increased gradually. Meanwhile,the proportional coefficientKpand the integral time coefficientTiare slightly adjusted,and the trial and error are conducted repeatedly to obtain the satisfied control effect[7,8].

4 Test and analysis of charging barrel temperature control

In order to monitor temperature of the charging barrel in the injection molding machine and obtain the satisfied corresponding temperature response curve,it is more convenient and rapid to adjust the PID parameters during experiments of the temperature control in the charging barrel of the injection molding machine. When design of this system is conducted,a serial control part is adopted to make a temperature real-time collection and a monitoring interface[9].

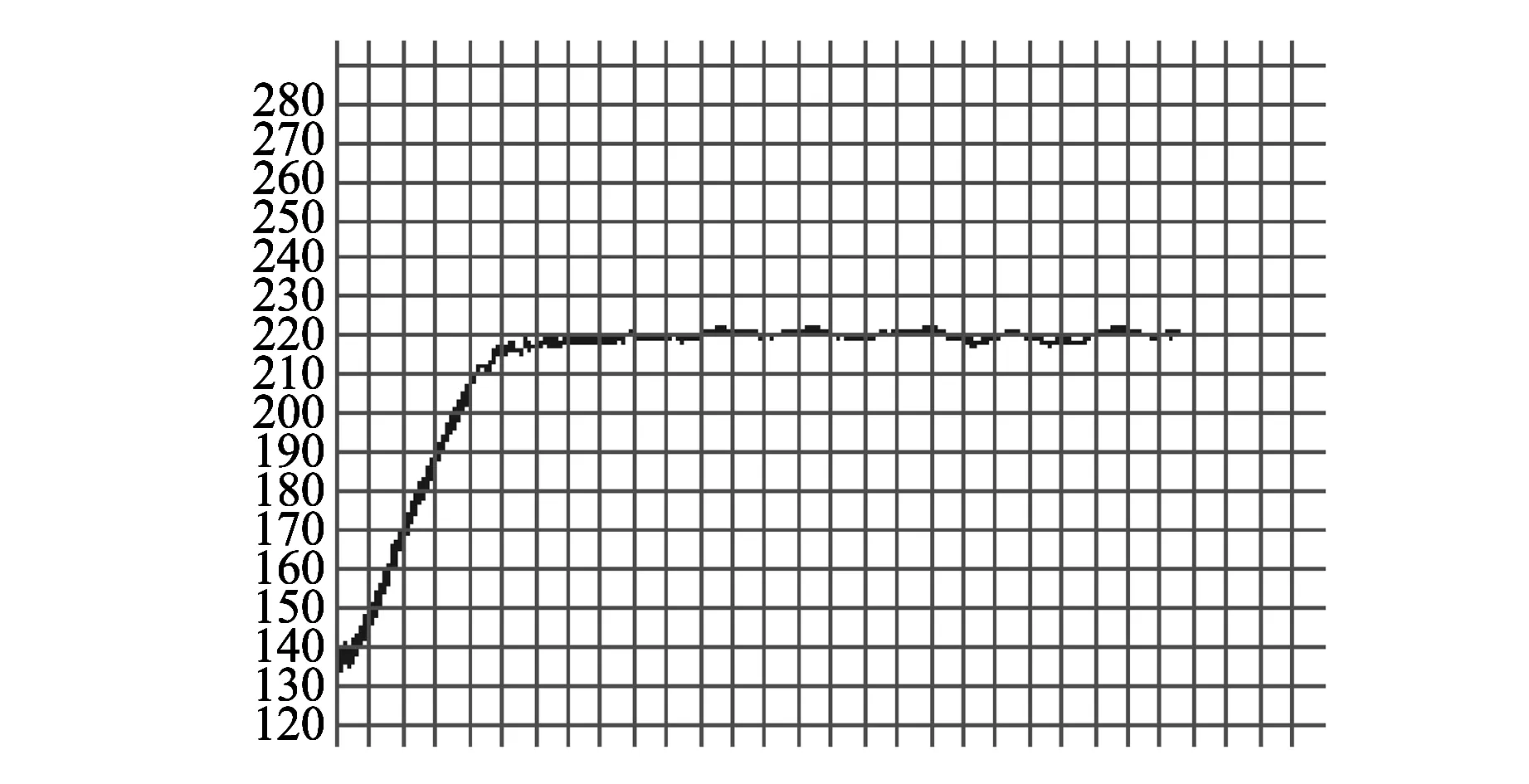

When experiments of the temperature control in the charging barrel of the injection molding machine are carried out,the temperature response curve can be obtained in the way that the monitoring interface describes the real-time temperature value collected by SCM in the coordinate planes of temperature and time. The temperature response curve with a designated value of 170 ℃ is shown in Fig.4 and the temperature response curve with a designated value of 220 ℃ is shown in Fig.5.

As shown in Fig.2 and Fig.5,overshoot of the temperature curve is small; the response speed is fast; and steady-state portion error of the curve is relatively small and it is basically a line. According to the values,different PID parameters are shown in Table 1.

Fig.4 Temperature response curve when the designated temperature is 170 ℃

Fig.5 Temperature response curve when the designated temperature is 220 ℃

Table 1 Records of the corresponding PID parameters with different designated temperature during the experiments

Temperature control precision of the charging barrel is within 3 ℃,and the designated temperature can be rapidly tracked by the practical temperature. Therefore,requirement of the injection molding manufacturing technique can be met,and the designated control object can be achieved.

5 Conclusion

In view of requirement for the control precision among the molding process parameters,a control scheme of the measurement and control system of the injection molding machine based on the C8051F020 is presented,and system hardware is also carried out and prepared. Control of the temperature in the charging barrel of the injection molding machine is illustrated. A modified integral separation PID algorithm is adopted in this system,and many production requirement of the injection molding products can be satisfied[10]. From now on,study of the self-adaption PID control algorithm should be enhanced. Meanwhile,charging barrel of the injection molding machine is a multi-channel control object,and the system is of multiple outputs and multiple inputs,wherein the channels interference with each other in coupling mode. Therefore a fuzzy weighting decoupling control should be introduced.

[1] ZHANG Xin-zhi,LI Min,MENG Chen. Multi-circuit anisothermal temperature controller design of injection molding machine. Microcomputer information,2001,(6): 21-24.

[2] ZENG Lu. Research and design of injection molding machine control system based on ARM. Nanchang: Jiangxi University of Science and Technology,2008.

[3] C8051F020. Datasheet.pdf,www.xhl.com.cn/upfile/Flash/2011/4/20110426170720.pdf.

[4] YANG Su-ying,ZHANG Zhong-xian,LI Chui-jun. The research and simulation of the PID controller in resistance furnace temperature control. Control Engineering,2007,14(7): 57-60.

[5] Su Y X,DONG Sun,Duan B Y. Design of an enhanced nonlinear PID controller. Mechatronics,2005,15(8): 1005-1024.

[6] UC3842.pdf. http://www.ic-cn.com.cn/static/pdf/UC3844BN STMICROELECTRONICS 140348.pdf.

[7] Zhong L,Rahman M F,Hu W Y,et al. Analysis of direct torque control in permanent synchronous motor drives. IEEE Transactions On Power Electronics,1997,12(3): 528-535.

[8] LEE Shi-young. Application of the PID control to the programmable logic controller course. American Society for Engineering Education,P.O. Box 10819-A,Chantilly,VA 20153,United States,2009.

[9] Yoshifumi Y,Hidenori K,Azuma O,et al. Simulation and implement of memory-based PID control for indoor blimp robot. Proceedings of the 13th International Symposium on Artificial Life and Robotics,2008,(13): 151-154.

[10] SONG Xiao-yan,YANG Qing-jie,ZHANG Xue-ming,et al. Application of compound PID control in the DC servo motor. The 7th International Conference on E-Engineering and Digital Enterprise Technology,2009,(7): 89-95.

杂志排行

Journal of Measurement Science and Instrumentation的其它文章

- Application of Kalman filter on mobile robot self-localization

- Design of a titl angle measurement system based on ADXL345 sensor

- Status and development trend of asphalt foaming process

- Research and simulation of two-level grid-connected photovoltaic inverter system

- Design and application of integrated automation system platform of mine based on PON

- A method of elimination of undesired resonant points of microstrip antenna by cutting U-shaped slot on the ground