碲化铋热电薄膜的电沉积制备与形貌分析

2014-08-15刘磊苏杰马昊张汉高玉微

刘磊,苏杰 ,马昊 ,张汉,高玉微

(1.河北大学 电子信息工程学院,河北 保定 071002;2.中国科学院 半导体研究所,北京 100083)

热电材料所独有的Seebeck效应和Peltier效应使其在温差发电与温差制冷方面有着广泛的应用,如空间飞行器的电源、测温热偶,以及CCD相机与激光器的制冷器等方面[1].同时,电子技术与微纳技术的不断发展对热电材料的要求越来越高,而相对于传统的块体材料,热电薄膜材料具备更优异的物理性能与工艺适配性[2].Bi2Te3以及其衍生化合物被认为是近室温范围内热电优值最好的热电材料,近年来Bi2Te3薄膜与其低维纳米材料的制备与研究工作备受国内外研究者关注[3-9].

Bi2Te3薄膜的制备主要利用快速蒸发[10]、有机物气相淀积(MOVCD)[11]和分子束外延(MBE)技术[12],但这些制备工艺往往需要复杂的设备,工艺成本较高.而电沉积技术具有薄膜制备温度低、沉积薄膜面积大、成本低等优点,非常适用于Bi2Te3薄膜的制备.目前国外利用电沉积技术制备Bi2Te3薄膜已经见诸报道[13-15],国内杨君友等[16]利用电化学原子层外延技术成功制备了Bi2Te3薄膜,王为等[17]也利用电沉积技术制备了Bi2Te3纳米线,但总体上看国内对于Bi2Te3材料的电沉积制备研究还较少,有待进一步深入.本文首先利用电化学沉积技术通过循环伏安法确定Bi2Te3薄膜共沉积电位,然后利用X线衍射分析(XRD)、扫描电镜(SEM)和原子力显微镜(AFM)对沉积薄膜成分和形貌进行了表征.

1 实验

1.1 沉积溶液配比

1.2 循环伏安法测试与薄膜的表征

2 结果与讨论

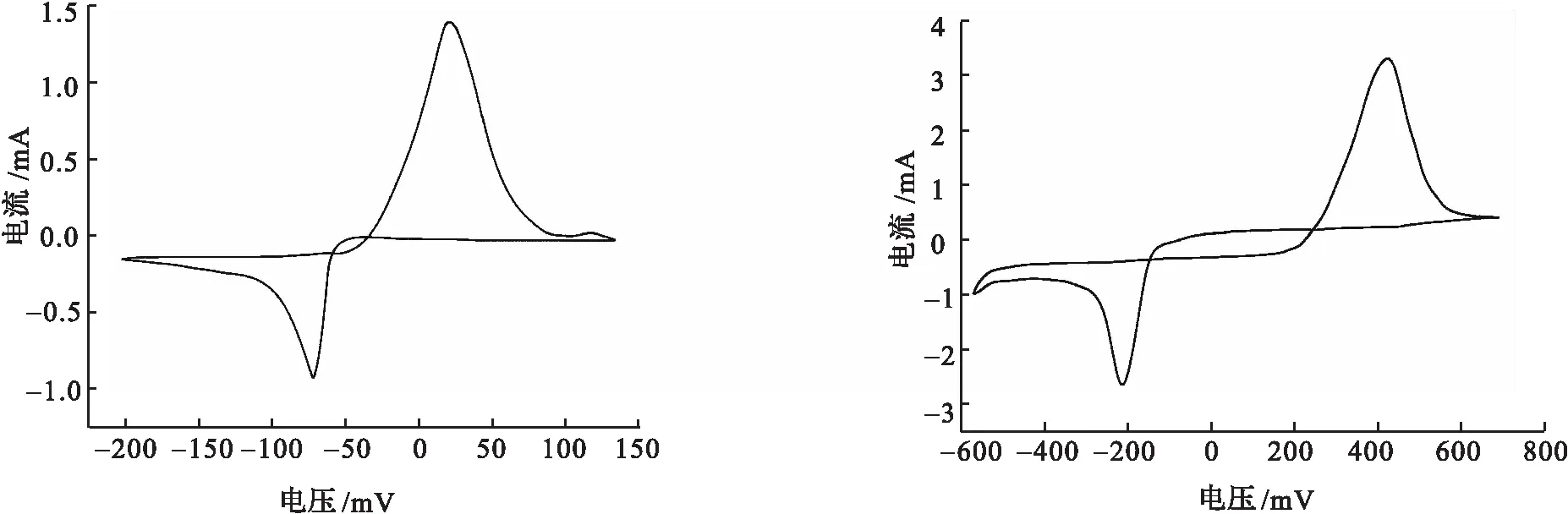

2.1 循环伏安测试结果

(1)

(2)

-560 mV处的还原峰可能是高价氧化态Te还原为低价氧化态的结果.

a ba.15 mmol/L Bi3+;b.10 mmol/L HTe.图1 Bi3+和分别在1 mol HNO3酸溶液中的循环伏安测试曲线Fig.1 Cyclic voltammogram of Bi3+ and HTe in 1 mol HNO3

(3)

图2 15 mmol/L Bi3+和10 mmol/共存1 mol HNO3酸溶液中的循环伏安测试曲线Fig.2 Cyclic voltammogram of 15mmol/L Bi3+and 10mmol/L HTe coexist in 1mol HNO3

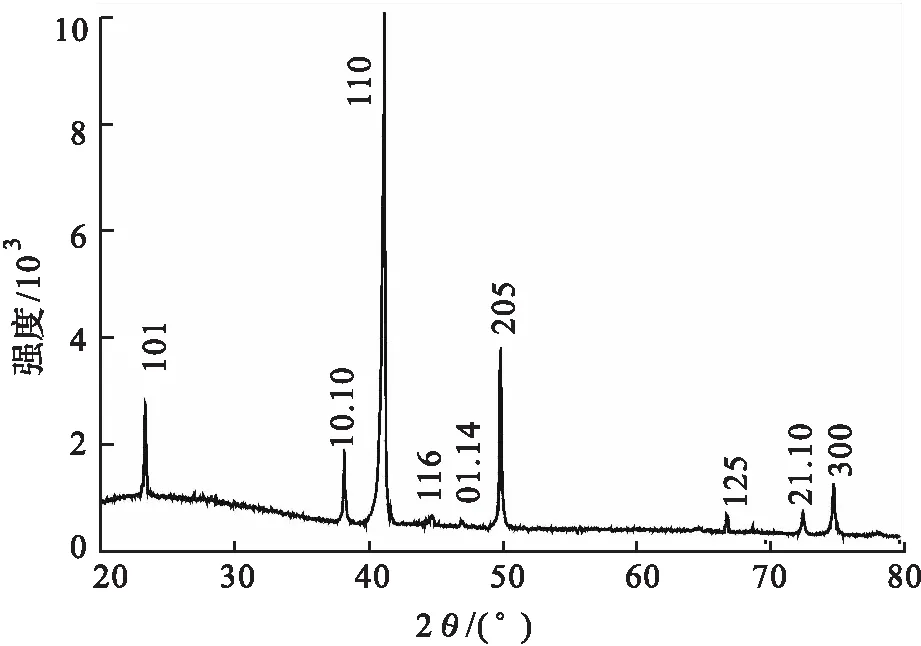

2.2 X线衍射分析

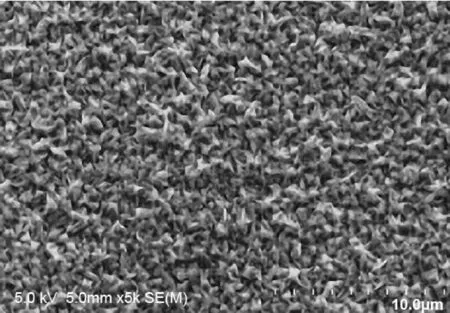

2.3 扫描电镜分析

利用扫描电镜(SEM)观察了退火后的-50 mV,20 mA·cm-2条件下电沉积得到的Bi2Te3薄膜,结果如图4所示.由图4可知,电沉积得到的Bi2Te3薄膜为典型的多晶薄膜,且多晶颗粒致密均匀,晶粒大小约在1×0.3 μm左右.利用X线能谱分析(EDAX)确定了Bi原子为39.7%,Te原子为60.3%,符合Bi2Te3的化学计量比.

图3 电沉积Bi2Te3薄膜的X线衍射 Fig.3 X-ray diffraction pattern of electrodeposited Bi2Te3 film

图4 Bi2Te3薄膜的扫描电镜分析Fig.4 SEM image of electrodeposited Bi2Te3 film

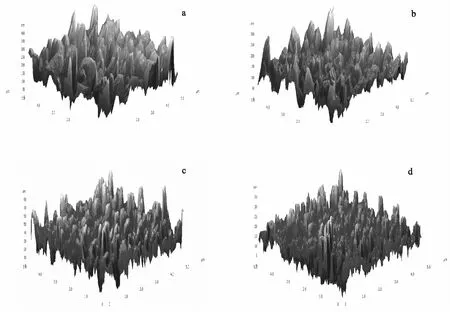

2.4 原子力显微镜分析

为进一步了解电沉积条件对电沉积薄膜质量的影响,先后在20,50,80,110 mA·cm-24种沉积电流密度下制备Bi2Te3薄膜,以上4种电流密度对应的沉积电位均为-50 mV.对不同条件下制备的Bi2Te3薄膜在高真空200 ℃下退火20 min,然后利用AFM观察了其表面形貌,结果如图5所示.由图5可知,沉积电流密度为20 mA·cm-2条件下得到的Bi2Te3薄膜的晶粒尺寸与SEM观察的结果基本吻合,晶粒大小约在1×0.3 μm左右.随沉积电流的增大,晶粒尺寸明显减小,110 mA·cm-2沉积电流密度下得到的晶粒大小约为0.3×0.3 μm左右,而且表面粗糙度随沉积电流增大而减小,这是由于沉积电流密度增大一方面使薄膜生长速率增大,另一方面也使得衬底表面成核密度增大,因此使晶粒的平均尺寸减小.

a.20 mA·cm-2;b.50 mA·cm-2;c.80 mA·cm-2;d.110 mA·cm-2.图5 不同沉积电流密度下的Bi2Te3薄膜原子力显微镜图像Fig.5 AFM images of Bi2Te3 films electrodeposited under different current densities

3 结论

参 考 文 献:

[1] ROWE D M. CRC Handbook of Thermoelectrics[M]. New York:CRC Press, 1995.

[2] ROWE D M. Thermoelectrics Handbook Nano to Macro[M]. Taylor & Francis:CRC Press, 2006.

[3] ZHANG Y, WANG X L, YEOH W K, et al. Electrical and thermoelectric properties of single-wall carbon nanotube doped Bi2Te3[J]. Applied Physics Letters, 2012, 101:031909.

[4] ZHANG Y L, MEHTA R J, BELLEY M, et al. Lattice thermal conductivity diminution and high thermoelectric power factor retention in nanoporous macroassemblies of sulfur-doped bismuth telluride nanocrystals[J]. Applied Physics Letters, 2012, 100:193113

[5] TAKASHIRI M, TAKIISHI M, TANAKA S, et al. Thermoelectric properties of n-type nanocrystalline bismuth-telluride-based thin films deposited by flash evaporation[J]. Journal of Applied Physics, 2007, 101(7):074301.

[6] DESALEGNE T, VIVEK G, RAHMAN M, et al. Atomically-thin crystalline films and ribbons of bismuth telluride[J]. Applied Physics Letters, 2010, 96: 053107.

[7] ZHU W, YANG J Y, GAO X H, et al. Effect of potential on bismuth telluride thin film growth by electrochemical atomic layer epitaxy[J]. Electrochimica Acta, 2005, 50(20): 4041-4047.

[8] WANG W, HUANG Q H, JIA F L, et al. Electrochemically assembled p-type Bi2Te3nanowire arrays[J]. Journal of Applied Physics, 2004, 96(1): 615-618.

[9] MICHEL S, DILIBERTO S, BOULANGER C, et al. Galvanostatic and potentiostatic deposition of bismuth telluride films from nitric acid solution: effect of chemical and electrochemical parameters[J]. Journal of Crystal Growth, 2005, 277(1-4): 274-283.

[10] TAKASHIRI M, MIYAZAKI K, TANAKA S, et al. Effect of grain size on thermoelectric properties of n-type nanocrystalline bismuth-telluride based thin films[J]. Journal of Applied Physics, 2008, 104:084302.

[11] KIM J H, JEONG D Y, KIM J S. Metal organic vapor phase epitaxy of BiSbTe3 films on 001 GaAs vicinal substrates[J]. Journal of Applied Physics, 2006, 100:123501.

[12] PERANIO N, EIBL O. Structural and thermoelectric properties of epitaxially grown Bi2Te3thin films and superlattices[J]. Journal of Applied Physics, 2006, 100:114306.

[13] MARTIN-GONZALEZ M, PRIETO A L, GRONSKY R, et al. Insights into the electrodeposition of Bi2Te3[J]. Journal of the Electrochemical Society, 2002, 149(11): C546-C554.

[14] FRARI D D, DILIBERTO S, STEIN N, et al. Pulsed electrodeposition of (Bi1-xSbx)2Te3thermoelectric thin films[J].Journal of Applied Electrochemistry, 2006, 36(4): 449-454.

[15] YOO B, XIAO F, BOZHILOV K N, et al. Electrodeposition of thermoelectric superlattice nanowires[J].Advanced Material, 2007, 19:296-299.

[16] 侯杰, 杨君友, 朱文, 等. Bi2Te3热电薄膜的电化学原子层外延制备[J]. 功能材料, 2006, 37(7):1054-1056

HOU Jie, YANG Junyou, ZHU Wen, et al. The Bi2Te3thin film deposition on Au substrate using electrochemical atomic layer epitaxy[J]. Journal of Functional Materials, 2006, 37(7):1054-1056.

[17] 贾法龙, 王为, 黄庆华, 等. 电化学法制备Bi2Te3纳米线用于微型温差发电器[J]. 纳米技术与精密工程, 2006, 4(1):20-24.

JIA Falong, WANG Wei, HUANG Qinghua, et al. Electrochemical fabrication of Bi2Te3nanowire arrrays for thermoelectric microgenerator[J]. Nanotechnology and Precision Engineering, 2006, 4(1):20-24.