Symbiosis Analysis on Industrial Ecological System*

2014-07-18WANGGang汪刚FENGXiao冯宵andKhimHoongChuDepartmentofChemicalEngineeringXianJiaotongUniversityXian70049ChinaStateKeyLaboratoryofHeavyOilProcessingChinaUniversityofPetroleumBeijing049China

WANG Gang (汪刚), FENG Xiao (冯宵),,** and Khim Hoong ChuDepartment of Chemical Engineering, Xi’an Jiaotong University, Xi’an 70049, ChinaState Key Laboratory of Heavy Oil Processing, China University of Petroleum, Beijing 049, China

Symbiosis Analysis on Industrial Ecological System*

WANG Gang (汪刚)1, FENG Xiao (冯宵)1,2,** and Khim Hoong Chu11Department of Chemical Engineering, Xi’an Jiaotong University, Xi’an 710049, China2State Key Laboratory of Heavy Oil Processing, China University of Petroleum, Beijing 102249, China

Industrial ecological system is a sustainable mode of modern industry development. Industrial symbiosis, a sub-field of industrial ecology, engages traditionally separate industries in a collective approach, involving exchange of materials, energy, water, and/or by-products, to enhance competitive ability and environmental performance. To construct a symbiosis analysis method, this article employs a number of parameters embodying information about materials, energy and economics as the main essential parameters in system analysis and introduces symbiosis profit and symbiotic consumption elements as the economic indicators. A modeling and simulation program is designed using the agent-based modeling approach to simulate the evolvement of a hypothetical coal-based industrial system and the change of symbiosis conditions in the process of construction is examined. The simulation program built using the Swarm library, which is a freely available multi-agent simulation package, provides a useful demonstration for the symbiosis analysis method.

symbiosis analysis, symbiosis degree, agent-based modeling, multi-agent simulation, coal-based industrial system

1 INTRODUCTION

Industrial ecology is an interdisciplinary framework for designing and operating industrial systems as living systems interdependent with natural systems [1]. It seeks to balance environmental and economic performance within emerging understanding of local and global ecological constraints [2, 3]. Industrial symbiosis is part of industrial ecology [4].

The concept of symbiosis was first proposed by Heinrich Anton de Bary, a German mycologist, in 1879 [5]. The theory of symbiosis has seen a number of applications in various fields, including anthropology, ecology, sociology, economics and even politics [6].

In the industrial ecology field, the term industrial symbiosis was first used to describe the high level of resource cycling among separate firms in Kalundborg, Denmark. Industrial symbiosis refers to the cooperation among geographically proximate individual firms to physically exchange by-products, share in the management of utilities and share ancillary services [7, 8].

The literature has documented various examples of industrial symbiosis in different regions around the world, including the best-known city of Kalundborg in Denmark [9], the Kwinana Industrial Area in Western Australia [10], Landskrona in Sweden [11] and many other industrial sites in the UK [12, 13] as well as China [14]. Industrial symbiosis in these industrial areas has resulted in significant economic and environmental benefits.

In the last a few years, researchers have built a theoretical framework of social science to understand how industrial symbiosis develops [15] and drawn organizational theories such as the open-systems view of the firm to describe how industrial symbiosis is influenced by external forces [16]. Economic geographers have introduced social network analysis methods to explore the connectivity among firms and managers in industrial symbiosis [17].

In recent years more and more researchers have recognized the importance of quantitative analysis in industrial symbiosis and research from different viewpoints. For example, the technique of water distribution modeling has been applied to water management in an industrial park, the Bayport chemical manufacturing complex in Houston, Texas in the United States [18]. The work of Chertow and Lombardi quantified economic and environmental costs and benefits for the symbiosis participants in Guayama, Puerto Rico [19]. Van Berkel et al. studied several industrial symbiosis cases in Kawasaki, Japan, which primarily involved“byproduct exchanges”, using similar proxy quantifications based on comparison of principal material flows in scenarios with and without symbiosis [20]. Although the analysis methods for symbiosis are well established in the fields of biology and economics, they are not directly relevant to chemical process industry owing to the need to use different main essential parameters in system analysis and different indexes to quantify the economic dimensions of industrial symbiosis.

In this article, the analysis method for industrial symbiosis system is proposed on the basis of symbiosis theory and a calculation procedure for determination of symbiosis degree is introduced. The symbiosis analysis method is constructed by adopting a number of parameters that incorporate information about materials, energy and economics as the main essential parameters, and introducing the indexes of symbiosis profit and symbiotic consumption as quantitative indicators of economic impacts. Since industrial symbiosissystem is a complex system, they can be understood through modeling. A modeling exercise is conducted to simulate the economic impacts of industrial symbiosis exchanges in a hypothetical coal-based industrial system using the agent-based modeling approach, which can test how changes in individual behavior will affect the overall behavior of the system and simulate the system by capturing the behavior of individual entities (the agents) and their interconnections [21]. The simulations are carried out using the Swarm library [22], a freely available multi-agent simulation package, implemented in the Java programming language.

2 SYMBIOSIS ANALYSIS ON INDUSTRIAL ECOLOGICAL SYSTEM

The symbiosis unit, symbiosis relation and symbiosis environment are the three essential elements of industrial symbiosis [23]. A symbiosis unit constitutes the basic unit of energy production and exchange in a symbiosis relationship. The industrial ecological system is a set of symbiosis relations, which consists of the relations between units according to certain relations in a certain environment [24, 25]. The symbiosis relations include positive symbiosis, reverse symbiosis, neutralism, commensalism and so forth [24]. The symbiosis environment includes technology environment, marketing environment, resource environment and so on.

A parameter, symbiosis degree, is often used to describe the correlation degree of two symbiosis units, expressed in the change of the main essential parameters. The essential parameters that play key roles in the system are utilized to determine the internal characters [24]. The flows of materials and energy represent the essential attribute of an industrial process and the economic benefit is the basic target of an industrial enterprise. Energy and profit are the most important factors that can describe the status of an energy transfer system, so they are selected as the essential parameters. The energy, in this article, is defined as the sum of the energy value included in the product. In other words, it is the heat value of the product plus the energy consumption in the production process. The energy reflects the flow and transfer of the energy in the system. In this article, the energy of unit product and the profit from unit product are used to express the main essential parameter, defined as

2.1 Unit symbiosis degree

The unit symbiosis degreeijδ is described by the main essential parameters of symbiosis units i and j,

whereijδ is the unit symbiosis degree,iZ andjZ are the main essential parameters of symbiosis units i and j, respectively.

The unit symbiosis degree expresses the change rate of the main essential parameter of symbiosis unit i corresponding to the change rate of the main essential parameter of unit j. It not only reflects the relation between units as shown in Table 1, but also indicates which unit has more influence on the other. For example, if δij>δji, unit i has more influence on unit j than the other way round [25, 26]. Positive symbiosis is a symbiotic relationship between two symbiosis units where both mutually benefit from the relationship and their association is necessary for their survival. Reverse symbiosis refers to a negative interaction involving struggle for common requirements between any two symbiosis units to obtain economic profit. Commensalism is a kind of symbiotic relationship between two symbiosis units where one benefits and the other is not significantly harmed or helped. Parasitism is a type of symbiotic relationship between two symbiosis units where one unit benefits from the other, while the other is harmed. The neutralism relation dictates that neither symbiosis units benefit nor are harmed, so both symbiosis units are unaffected.

Table 1 δijand symbiosis relations

2.2 Symbiosis degree of individual element

The symbiosis degree of individual elementsiδ expresses the change rate of the main essential parameter of unit i corresponding to the change rate of the main essential parameter of the symbiosis system,

where δsiis the symbiosis degree of individual element in the system and Zsis the main essential parameter of symbiosis system.

Comparing the symbiosis degree of individual element and the unit symbiosis degree provides a simple way to analyze the stability of a symbiosis system. For all i, if δsi>δijthe symbiosis system is stable and for any i, if δsi<δijthe system is not stable. The stability of a symbiosis system is defined by its ability to resist external disturbance and its capacity to repair the damage caused by the external force [25, 26]. A stable symbiosis system means that the energy flow and the profit distribution of the system are reasonable and the system can operate continuously.

2.3 Symbiosis degree of total element and symbiosis profit

The main essential parameter of a symbiosis systemcomprising m units, Zs, is a function of each individual units, that is, Zs=f(Z1, Z2, …, Zm). The symbiosis degree of total element indicates the correlation degree of the symbiosis units and the system. The definition of the symbiosis degree of total elementsδ is

where λ is the character coefficient of the symbiosis interface.

The so-called symbiosis interface is the medium that is applied to exchange information, materials and energy between symbiosis units and to implement the interaction between units. A lower value of λ means that the interactions and exchanges are more convenient and vice versa.

Whileijδ represents the symbiosis degree between units i and j,siδ denotes the symbiosis degree between the system and unit i. The symbiosis degree of total elementsδ reflects the symbiotic extent of the system. The greater the value ofsδ, the better the symbiosis.sδ is a criterion to judge whether the symbiosis profit can be yielded. Only ifs0δ>, will the symbiosis profit be yielded. The net profit from the symbiosis process of the system is defined as the symbiosis profitsE.

where E is the total profit of the industrial ecological system and Ei(i=1, …, m) is the profit of each unit when the system has no symbiosis relations [25].

In the symbiosis theory of biology, the term that corresponds to the concept of symbiosis profit is symbiosis energy. The concept of symbiosis profit is more appropriate in the current context because energy cannot be created in the chemical process industry. It is also more fitting to describe the elements of economic efficiency, environmental benefits and survivability resulted from the symbiosis process in the system.

2.4 Symbiotic consumption

Because there are various symbiosis interfaces in the symbiosis system, the symbiosis process has some loss, defined as symbiotic consumption Ecin this article. The symbiotic consumption Ecis the cost to perform the symbiosis and gain symbiosis profits. In a stable symbiosis system, both the symbiosis profit Esand the symbiotic consumption Ecwill increase with symbiosis dimension ηs, which is the number of symbiosis units [24, 26]. When ΔEs/δηs=0, ΔEs=Es−Echas the maximum valuesmE, as depicted in Fig. 1. It should be noted that the symbiosis dimension of an industrial system cannot be over expanded under certain limiting conditions of technology, resource and market if the system wants to gain more profits.

Figure 1 The relation between ΔEsand ηs

2.5 Method for analysis of symbiosis degree

The symbiosis degrees are the most essential characteristic parameters of a symbiosis system and reflect directly the essence and development law of the system. The symbiosis degree analysis is the most basic method for the symbiosis analysis and has three steps, as described below.

First, the unit symbiosis degreeijδ is used to measure the interaction between units and to confirm their relations. Second,ijδ and the symbiosis degree of individual elementsjδ are used to analyze the stability of the symbiosis system. Third, the symbiosis degree of total element is used to measure the extent of symbiosis and to confirm whether the symbiosis profit Esis yielded. This step can be done on the basis of the concept of multi-agent simulation, by constructing a program to simulate the change conditions ofsδ,sE andcE with the evolution of the symbiosis system.

3 ILLUSTRATIVE EXAMPLE

The production and operation mode of a coal production enterprise consists of mining activities and selling the raw coal but the extensive processing of coal is not commonly carried out at the mining site. In practice, less than 34% of coal is washed and prepared before use in China, while that proportion in developed countries is 95%. At the same time, the coal mining generates coal bed gas, waste rock, waste water and so on, which will cause severe environmental pollution. High cost is incurred in the treatment of wastes caused by coal mining. However, conventional end-of-pipe waste treatment alone cannot eliminate the pollution problem that exists in the traditional production and operation mode of the coal industry [27, 28].

In this study, a virtual industrial system based on coal resource is used as an example of industrial symbiosis. The annual output of the coal mine is assumed to be six million tons. The system will add new production plants annually and all of the plants form symbiosis relations with each other. The product and the waste from one plant will be the raw material of the other plants, so that the plants in the system will form an industrial symbiosis system. Coal and byproducts of coal mining will be transformed intovaluable products with higher added value, and the pollution impacts of the system will be reduced. The general outline of the coal-based industrial system is shown in Fig. 2.

The symbiosis system plans to construct seven plants according to the characteristics of coal industry and current technical level, as shown in Table 2. The investments, construction scale, power consumption of unit product, water consumption of unit product, number of employees, starting time, and construction period of each plant are listed. The starting time is the year that the plant is constructed.

Figure 2 Coal-based industrial system

Table 2 Data of individual plants in a coal-based industrial system

3.1 Modeling approach

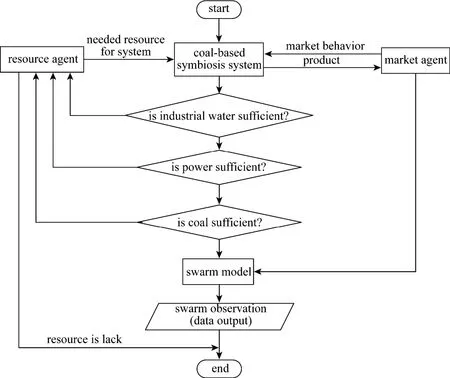

A simulation program is used to simulate the symbiosis of the coal-based industrial ecological system using the Java programming language on the Swarm platform. Swarm is a platform for agent-based models, based on the concept of multi-agent modeling [21, 29]. The program adopts some classes to construct the agent, and the behavior and the interaction between agents are implemented based on their attributes. There are three classes in the program: resource agent, market agent and enterprise agent, as described below.

3.1.1 Resource agent

Target: provide resource to enterprise agent.

Attribute: resource consumption, resources for enterprise agents.

Behavior: according to the request of enterprises, the resource agent provides corresponding resources. 3.1.2 Market agent

Because the real market is very complex, it is simplified for the symbiosis analysis in this work. The market behavior is assumed to vary with the prices of materials and production gross outputs.

Target: implement the trade for products among enterprises.

Attribute: determine product price and product volume.

Behavior: adopt the optimum price model to determine the price for products. The optimum price model used in this article is

where P is the price of a product, c is the cost of theproduct, a is the absolute demand and b expresses the increase or decrease of the sales with the decrease or increase of the price, which is a sensitivity coefficient of the price [30].

3.1.3 Enterprise agent

Target: maximize economic profit, minimizes pollution.

Attribute: cost, yield, profit, material quantity and so on.

Behavior: based on the yield of the enterprise, send request for material to resource agent and send request for sales to market agent.

Figure 3 Agents of the coal-based industrial system

Figure 4 Details of the simulation steps

3.1.4 Simulation details

As shown in Fig. 3, eight agents are utilized to simulate the behavior of symbiosis units in the coal-based industrial system and their relations. The simulation steps are shown in Fig. 4. In each simulation, the program determines whether resources are sufficient to meet the production requirement of the system. If any resource is insufficient, the resource agent will provide corresponding resource to the system. If a resource is insufficient and the resource agent isunable to provide required resource, the simulation is terminated. The market agent determines the price for products and simulates the product trade behavior between the industrial system and the market and the internal trade between the production plants in the system. It should be noted that the simulation is implemented under the condition that sufficient resources are available to the system.

3.2 Symbiosis degree analysis

3.2.1 Unit symbiosis degree

According to Eq. (2), the unit symbiosis degree can be calculated using the design data given in Tables 2 and 3. The unit symbiosis degrees among plants are taken as an example to illustrate the calculation steps for two continuous production cycles.

For all units, it is assumed that the electricity price is 0.5 CNY·(kW·h)−1, water cost is 3.5 CNY·t−1, average staff cost is 4000 CNY per month, other expenditure is taken as 10% of the total cost, annual operation time is 333 days, and the plant depreciation is 15 years.

(1) Calculate the cost of unit product

cost of unit product=raw material cost+cost of fuel and power+water cost+staff cost+depreciation of fixed assets+other expenditure

(2) Forecast the unit product price

The product price is estimated according to Eq. (6).

(3) Calculate the product profit

product profit=product price−product cost

(4) Calculate the energy of unit product

energy of unit product=heat value+energy consumption in production process

(5) Calculate the main essential parameters

The main essential parameters of units is calculated according to Eq. (1).

The above calculation results are shown in Table 4.

(6) Calculate the unit symbiosis degree

The unit symbiosis degree is calculated according to Eq. (2). The results are shown in Table 5.

The results show that the relations of symbiosis units include positive symbiosis (e.g., coal mining and thermoelectric plant), commensalism (e.g., coal mining and coal preparation) and neutralism (e.g., brick plant and ammonia synthesis plant or methanol synthesis plant). The coal-based industrial system can work continually and stably once the relations among the symbiosis units are properly maintained. Such symbiosis relations are need when a symbiosis system is planned and constructed.

Table 3 Data used in the simulation

Table 4 Computed parameter values for two continuous production cycles

Table 5 Computed values of the unit symbiosis degree

Table 6 Computed values of the symbiosis degree of individual element

3.2.2 Symbiosis degree of individual element

As shown in Table 6, any one of the symbiosis degree of individual element (δsi) is more than the corresponding unit symbiosis degree (δij) shown in Table 5. According to the symbiosis theory, the hypothetical coal-based industrial system is stable under the design conditions. In an actual symbiosis system, δsimust always be greater than δijin order to maintain the stability of the system.

3.2.3 Simulation analysis

The program simulates the evolution of the coal-based industrial system as functions of symbiosis degree, symbiosis profit, symbiotic consumption and trade volume within the system. The results of the simulation are shown in Figs. 5-7.

Figure 5 Simulation result showing the symbiosis degree of total element versus time

Figure 5 shows that the symbiosis degree of total elementsδ increases with the implementation of the system layout, indicating that both the symbiosis degree and symbiosis profit increase with time. It should be noted that the trade volume within the system has been adopted as the coupling index of symbiosis in the work of Zhou [31]. Comparing Figs. 5 and 6, it can be seen that bothsδ and the trade volume in the system exhibit the same increasing trend with the gradual development of the system.

Figure 6 Simulation result showing the trade volume within the system versus time

Figure 7 Simulation result showing Esand Ecversus time

Furthermore,sδ can reflect well the development state of the system structure. As indicated by section B in Fig. 6, the trade volume within the system does not show a clear increase while section A in Fig. 5 demonstrates two clear increasing processes. During this period, the brick plant and the water treatment plant are constructed. The raw materials of them are considered the waste of the system, so the amounts arecomparatively less and the prices are fairly low. Therefore, the two plants exert little influence on the trade volume within the system but they contribute to the waste utilization and reduction process, enhancing the effect of symbiosis. It may be concluded that, compared with the trade volume within a system,sδ can better reflect the relation and interaction between symbiosis units and the system. For a symbiosis system,sδ should be maximized as much as possible. However, the trade volume should not be increased relentlessly. Compared with the trade volume,sδ would be a better indicator in the expansion and planning of a symbiosis system.

The economic viability of the symbiosis is shown in Fig. 7, in which the upper curve shows the symbiosis profit Esand the lower one the symbiotic consumption Ec. Section C shows the economic benefit of the system when the brick plant and the water treatment plant are implemented. The increase rate of Esis lower than that of Ec. The difference between Esand Ecincreases gradually as the system layout expands, indicating that the system is still in the development phase. When the system is fully developed, the participants derive considerable economic benefits from the symbiosis.

To test the ability of the program to simulate the effect of adverse external market conditions, we conduct another simulation by assuming that ammonia and methanol are sold in relatively low prices to the external market with the prices of other raw materials and products unchanged. Specifically, it is assumed that the price of ammonia drops by 43% from 3500 CNY·t−1to 2000 CNY·t−1while that of methanol reduces from 4500 CNY·t−1to 2500 CNY·t−1, representing a reduction of 45%. Fig. 8 depicts the evolution of Esand Ecas a function of time. It is clear that under this scenario the difference between Esand Ecis rather small, indicating that the economic viability of the coal-based industrial system is significantly less attractive compared to the previous case described in Fig. 7. Given that prices of commodity chemicals are subject to strong market fluctuations and therefore difficult to forecast with accuracy, selecting a proper mix of business units within the coal-based industrial system requires careful analysis in order to mitigate investment risk.

Figure 8 Simulation result showing Esand Ecversus time with the prices of ammonia and methanol lower than those used in Fig. 7

In summary, the larger the difference between Esand Ec, the higher the symbiosis profit, which serves as a powerful incentive for the symbiosis units to maintain the stability of the coal-based industrial system. In addition, the difference between Esand Eccan also serve as a guide in selecting new business units to expand the symbiosis system or replacing existing business units with new ones.

4 CONCLUSIONS

In this paper, a symbiosis analysis method is proposed for industrial ecological systems, by using a number of parameters embodying information about materials, energy and economics as the main essential parameters and introducing the symbiosis profit and symbiotic consumption elements. A modeling and simulation program is developed based on the agent-based modeling approach.

The symbiosis analysis method is applied to a hypothetical coal-based industrial system by making use of easily available data sources such as the material flow data, investment data and market prices of products.

With sufficient resources the method is able to describe the essential attributes of material and energy exchanges in the coal-based industrial system and the basic target of industrial enterprise for economic benefits. The study shows that symbiosis degree of total elementsδ can illustrate the symbiosis relation and symbiosis extent while symbiosis profit Esand symbiosis consumption Eccan reveal the economics and development extent of the system. In particular, the economic viability of the coal-based industrial system is shown to be inherently sensitive to fluctuations in prices of commodity chemicals.

The proposed method can be applied to evaluate and analyze an existing industrial symbiosis system and provide guides for managers, and can be applied to the planning of an industrial symbiosis system and provide guiding opinions on the scale and product structure of the industrial system.

NOMENCLATURE

REFERENCES

1 Côté, R.P., “A primer on industrial ecosystems: A strategy for sustainable industrial development”, Dalhousie University, Halifax, Nova Scotia (2003).

2 Korhonen, J., Snäkin, J.P., “Analyzing the evolution of industrial ecosystems: Concepts and application”, Ecological Economics, 52 (2), 169-186 (2005).

3 Jin, Y., Li, Y., Feng, J., Ecological Industry: Theory and Application, Tsinghua University Press, Beijing (2003). (in Chinese)

4 Chertow, M.R., “Industrial symbiosis: Literature and taxonomy”, Annual Review of Energy and the Environment, 25, 313-337 (2000).

5 Paracer, S., Ahmadjian, V., “Symbiosis: An introduction to biological associations”, 2nd edition, Oxford University Press, Oxford (2000).

6 Sapp, J., Evolution by Association: A History of Symbiosis, Oxford University Press, Oxford (1994).

7 Ehrenfeld, J., Gertler, N., “Industrial ecology in practice: The evolution of interdependence at Kalundborg”, Journal of Industrial Ecology, 1 (1), 67-79 (1997).

8 Chertow, M.R., “Uncovering industrial symbiosis”, Journal of Industrial Ecology, 11 (1), 11-30 (2007).

9 Jacobsen, N.B., “Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects”, Journal of Industrial Ecology, 10, 239-255 (2006).

10 Bossilkov, A., van Beers, D., van Berkel, R., “Industrial symbiosis as an integrative business practice in the Kwinana industrial area: Lessons learnt and ways forward”, In: Proceedings of the 11th Annual International Sustainable Development Research Conference, 6-8 June, Helsinki (2005).

11 Mirata, M., “Experiences from early stages of a national industrial symbiosis program in the UK: Determinants and coordination challenges”, Journal of Cleaner Production, 12, 967-983 (2004).

12 Mirata, M., Emtairah, T., “Industrial symbiosis networks and the contribution to environmental innovation: The case of the Landskrona industrial symbiosis program”, Journal of Cleaner Production, 13, 993-1002 (2005).

13 Green, K., Randles, S., Industrial Ecology and Spaces of Innovation, Edward Elgar Publishing, Cheltenham, UK (2006).

14 Zhu, Q., Lowe, E.A., Wei, Y., Barnes, D., “Industrial symbiosis in China: A case study of the Guitang Group”, Journal of Industrial Ecology, 11 (1), 31-42 (2007).

15 Baas, L.W., Boons, F.A., “An industrial ecology project in practice: Exploring the boundaries of decision-making levels in regional industrial systems”, Journal of Cleaner Production, 12, 1073-1085 (2004).

16 Hoffman, A., “Linking social systems analysis to the industrial ecology framework”, Organization & Environment, 16 (1), 66-86 (2003).

17 Ashton, W., “Understanding the organization of industrial ecosystems: A social network approach”, Journal of Industrial Ecology, 12 (1), 34-51 (2008).

18 Keckler, S.E., Allen, D.T., “Material reuse modeling: A case study of water reuse in an industrial park”, Journal of Industrial Ecology, 2 (4), 79-92 (1999).

19 Chertow, M.R., Lombardi, D.R., “Quantifying economic and environmental benefits of co-located firms”, Environ. Sci. Technol., 39 (17), 6535-6541 (2005).

20 Van Berkel, R., Fujita, T., Hashimoto, S., Fujii, M., “Quantitative assessment of urban and industrial symbiosis in Kawasaki, Japan”, Environ. Sci. Technol., 43 (5), 1271-1281 (2009).

21 Kraines, S., Wallace, D., “Applying agent-based simulation in industrial ecology”, Journal of Industrial Ecology, 10, 15-18 (2006).

22 Luna, F., Perrone, A., Agent-Based Methods in Economics and Finance: Simulations in Swarm, Vol. 17, Springer (2002).

23 Chen, L., Meng, B., “Research on the symbiotic relationship between small & medium-sized enterprises and banks in Jilin province”, International Business and Management, 2 (1), 107-112 (2011).

24 Douglas, A.E., Symbiotic Interactions, Oxford University Press, Oxford (1994)

25 Liu, R., He, H., “Extended enterprise information sharing in a supply chain environment based on symbiosis theory”, In: International Federation for Information Processing, Research and Practical Issues of Enterprise Information Systems, Vol. 205, Tjoa, A.M., Xu, L., Chaudhry, S., eds., Springer, Boston (2006).

26 Yuan, C., Symbiosis Theory: Concurrent Discussion for Small-scale Enterprise, Economic Science Press, Beijing (1998). (in Chinese)

27 Ni, W., Li, Z., “Multi-generation energy system from coal gasification process”, Coal Chemical Industry, 104 (2), 3-10 (2003). (in Chinese) 28 Gray, D., Tomlinson, D., “Coproduction: A green coal technology”, MP2001-28, U.S. Department of Energy (2001).

29 Minar, N., Burkhart, R., Langton, C., Askenazi, M., “The Swarm simulation system: A toolkit for building multi-agent simulations”, Working Paper 96-06-042, Santa Fe Institute, Santa Fe (1996).

30 Zhang, Y., “The establishment and solution of optimum price model”, Modern Information, 4, 207-208 (2004).

31 Zhou, Z., “The study of complex adaptive system of industrial ecology”, Ph.D. Thesis, Tsinghua University, Beijing (2005). (in Chinese)

2013-08-21, accepted 2013-10-08.

* Supported by the National Basic Research Program of China (2012CB720500) and the National Natural Science Foundation of China (20936004).

** To whom correspondence should be addressed. E-mail: xfeng@cup.edu.cn

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- Unified Model of Purification Units in Hydrogen Networks*

- Photochemical Process Modeling and Analysis of Ozone Generation

- Removal of Thiophenic Sulfur Compounds from Oil Using Chlorinated Polymers and Lewis Acid Mixture via Adsorption and Friedel-Crafts Alkylation Reaction*

- Roles of Biomolecules in the Biosynthesis of Silver Nanoparticles: Case of Gardenia jasminoides Extract*

- Phase Behavior of Sodium Dodecyl Sulfate-n-Butanol-Kerosene-Water Microemulsion System*

- Modeling and Optimization for Short-term Scheduling of Multipurpose Batch Plants*