ZF8HP新一代自动变速器

2014-06-27AntonLocher,RolfGall,RudolphBaumann等

试验 检测

ZF8HP新一代自动变速器

本文介绍了ZF公司新一代8速自动变速器技术的发展过程,该型变速器在紧凑化、低转速化、启停系统和滑行模式等方面具有突出的优势。

[Abstraet]This paper introduces a new generation eight-speed ZF automatic transmission technology development process,this type of transmission has outstanding advantages in the downsizing,downspeeding,start-stop system and coasting function,etc.

自动变速器 紧凑化 低转速化 启停系统 滑行模式

1 简介

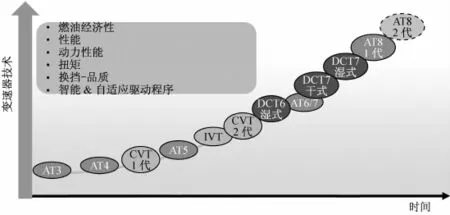

过去的几十年中,自动变速器技术一直在稳步发展,燃料消耗及二氧化碳排放量在下降(图1)。

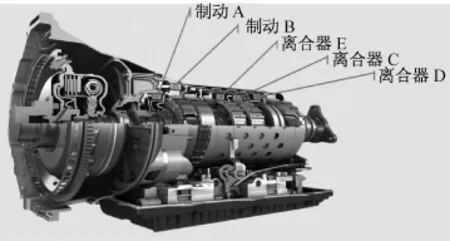

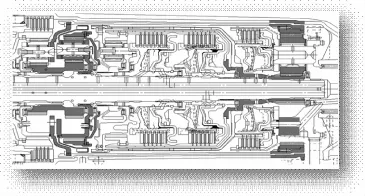

新一代8HP自动变速器在改善乘坐舒适性和动力性方面的同时,具有更高的节能和二氧化碳减排的潜力:成功的8HP 8速自动变速箱在2009年开始生产以来就已定制具备这些优点。当前在第二代中所有这些优点更为显著并且自2014年7月在宝马一些系列(5系;X5,X6)上首次实现量产。新8 HP(图2)提供了包括更低拖曳扭矩、更宽速比范

1 Introduetion

During the past decades,the technology of automatic transmissions has been steadily increased and fuel consumption and CO2 emissions have been decreased(Fig.1).

图1 自动变速器的技术发展Fig.1 Technological Trend of Automatic Transmissions

Higher savings potential in terms of consumption and CO2combined with increased ride comfort and dynamics:The successful 8HP 8-speed automatic transmission has been characterized by these advantages since the start of production in 2009.All of the advantages are now even more pronounced in the second generation that initially is in volume production since July 2014 in several BMW-applications(5er;X5,X6).The new 8HP(Fig.2)offers comprehensive further developments that range from lower drag torques and higher spread through to an improved torsional vibration absorption.Through many further developments,the 8HP is significantly more efficient compared to the predecessor transmission-up to three percent in total.

The new 8HP entered volume production at the start of July as the 8HP50 version that is designed for torques of up to 500 Nm.In the future,the 8HP75 will be part of the ZF portfolio for drives with even higher torque of up to 750 Nm.=>8HP75 launched already in August 2014!围以及更优扭振吸收新能的全面技术改进。经过多阶段的提升发展,8HP相比之前的变速器效率更为显著-总共高达3%。

图2 新8HP剖面图Fig.2 Cross Section of the new 8HP transmission

7月初新8HP以8HP50版本进入批量生产,其设计扭矩高达500牛米。未来具有更高扭矩性能的750牛米8HP75将被列入ZF驱动系产品目录。=>8HP75已在2014年八月量产!

2 紧凑化及低转速优化

全新的8速自动变速器结合了许多技术改进:首先,ZF进一步优化了新变速器的运算以适应现代发动机技术的要求。其发端为内燃发动机界由于需要在不损失扭矩和性能前提下满足即将实施的二氧化碳排放法规而形成的两个中心趋势:紧凑化,即具有更少气缸数及更小排量的涡轮增压发动机,以及低转速化,即在低转速区尽早达到最大扭矩。

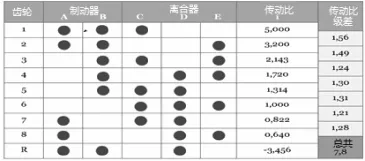

图3 8 HP换挡组合及传动比级差→更高的传动比范围7.8Fig.3 8HP Shift Pattern and ratio Steps→Increased Ratio Coverage 7.8

2 Optimized for downsizing and downspeeding

The new 8-speed automatic transmission combines many technological advances:Above all,ZF has further optimized the new transmission generation for the requirements of modern engine technology.This is due to the fact that,in order to meet the forthcoming CO2emission specifications without losses in terms of torque and performance,there are two central trends when it comes to combustion units:Downsizing,which means turbocharged engines with fewer cylinders and less engine displacement and downspeeding,which is the reduction of the engine speeds combined with a maximum torque that is applied at a very early stage.

It is the reduction of the speeds in particular that demands transmissions with a higher spread which is the reason why ZF has increased it from 7.1 to 7.8 on the new 8HP by means of optimized gearsets.

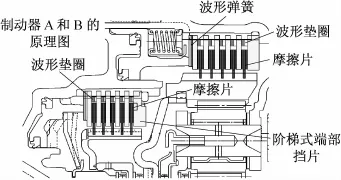

This measure alone reduces the speed across all gears by 50 revolutions per minute on average and reduces fuel consumption by almost one percent.Furthermore,the ZF developers have succeeded in once again reducing the internal transmissionlosses.This is primarily ensured by the new multidisk separation(Fig.4):Additional springs integrated into the multidisk packages of the shift elements ensure that the friction shift elements are almost fully opened and,consequently,cause less drag torque.Compared to the first 8HP model range,the power losses have been reduced by more than two-thirds with the new generation.

发动机转速的降低尤其要求变速器具有更宽的速比范围,这就是ZF在新8HP通过优化齿轮机构的设置、把速比范围从7.0增加到7.8原因。

这项措施降低了所有档位上平均50转每分钟的转速和近1%的油耗。此外,ZF开发人员成功地再次降低了内部传输损耗。这主要归功于新的多重摩擦片分离(图4)技术:集成到换挡元件多片组合包的附加弹簧确保了在换挡摩擦元件的几乎完全分离,并因此降低了开放离合器的拖拽损失。相比第一代8HP系列,新一代功率损耗减少了超过三分之二。

图4 多重摩擦片分离A,BFig.4 Multidisk Separation A,B

同时,进一步的创新功能最大限度地减少了蠕行扭矩:减速时和当车辆静止时,其中一个离合器现已完全开放。其结果是,不再需要通过“制动”来阻止前行。另一个正面的结果是ZF自动变速器的油泵工作的系统压力从5巴减小为至3.5巴,因此总体上需要的能量更少。

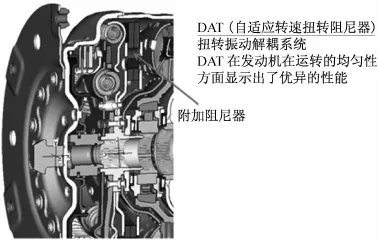

图5 DAT-液力变矩器Fig.5 DAT-Torque Converter

此外,我们的目标是要考虑到经济性更好而尺寸更紧凑的新型发动机不同的振动特性。因此,所有的8HP自动变速器设有特别先进的扭振阻尼器:这些阻尼器以特别有效的表现消除了发生至发动机中的振动,使它们不会进一步向驱动系后端及车

Meanwhile,a further innovative function minimizes the creeping torques:A clutch is now fully opened during deceleration and when the vehicle is stationary.Consequently,it is no longer necessary to'brake'against the drive.Another positive effect is that the oil pump belonging to the ZF automatic transmission works with a system pressure that has been reduced from 5 to 3.5 bar and,as a result,requires less energy overall.

Furthermore,the objective was to take the changing vibration behavior of the increasingly economical yet,at the same time,more powerful downsizing units into account.Therefore,all 8HP automatic transmissions feature particularly advanced torsional vibration dampers:These dampers eliminate the vibrations that occur on the engine side in a particularly effective manner so that they are unable to move further along and into the driveline and the body.The newly developed torque converter contributes to downspeeding because the hydrodynamic transmission of power can be bridged even more quickly-this enables traveling with a closed lock-up clutch at an early stage and at an extremely low engine speed.

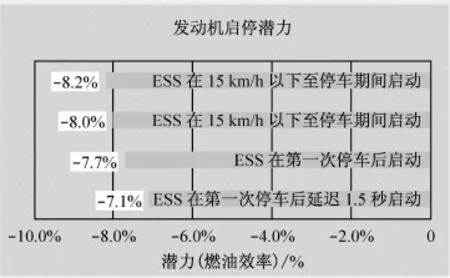

3 Optimized start/stop and eoasting funetion

The tailored,fuel-efficient uncoupling of the transmission in connection with a temporary engine stop,the so-called coasting function,is now possible at speeds up to 160 km/h.At the other end of the speed scale,ZF has further optimized the optional start/stop function of the 8HP:After the vehicle has come to a stop,it stops the engine without any discernible delay-instead of after 1.5 seconds as was previously the case.身传递。新开发的液力变矩器对低速化有显著贡献,因为它能使动力传递路径更快地实现硬连接---这使得车辆能行驶在更早结合的锁止离合器及极低的发动机转速条件下。

3 优化的发动机自动启停系统和滑行节能模式

在发动机临时停机时启动的定制发动机解耦节油功能,即所谓的滑行节能模式,现在可在高达160 km/h车速下实现。在速度范围的另一端,ZF对8HP的发动机自动启停系统做了进一步的优化:在车辆停止时,系统在停止发动机时并无明显的延迟---而不像之前的情况,会产生1.5秒的延迟。

尽管如此,在带来巨大节油潜力的同时,动力性能没有受到忽视:除其他方面外,新的变速器控制单元能够嵌套多级降档,其使得8HP在有必要时可作出更自发和动态的响应。

4 总结与结论

变速器技术曾经并正在随燃油效率的改善而不断发展。

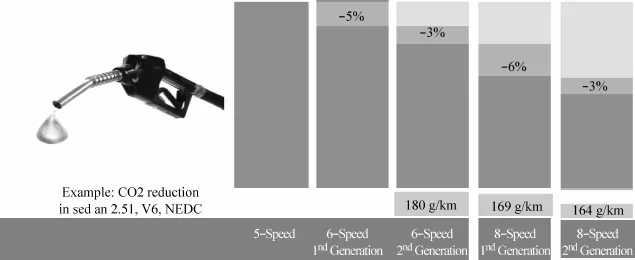

ZF 8HP自动变速器在高效的基础上又做了进一步优化,以提高燃油效率。为实现这一目标采取一些不同的措施。这些包括:

·多重摩擦片分离A/B

·降低蠕行扭矩

·转速降低50转每分钟

·更高的传动比范围/

·阻尼系统

·发动机启停系统

实现的燃料效率见图7。

图6 发动机自动启停系统带来的燃油效率优化Fig.6 Fuel Efficiency Benefit by Engine Start Stop(ESS)

However,dynamics is not neglected despite the great fuel-saving potential:Amongst other things,the new transmission control unit enables nested multiple downshifts which permits the 8HP to respond in an even more spontaneous and dynamic manner where necessary.

Summary&Conelusions

Transmission technology evolution was and is driven by fuel efficiency improvement.

New Generation of ZF’s 8HP Automatie Transmission

Anton Locher,Dr.Rolf Gall,Rudolph Baumann,陈烨,叶惟人

ZF Friedrichshafen AG,Germany

Anton Locher,Dr.Rolf Gall,Rudolph Baumann,Chen Ye,Ye Weiren ZF Friedrichshafen AG,Germany

Automatic Transmission Compact Design Start-Stop System Coasting Function

图7 变速器技术的改进-在NEDC条件下燃油效率的改进Fig.7 Transmission Technology Improvements-Fuel Efficiency Improvements in NEDC

U463.212

B

1006-8244(2014)03-03-04