Shodhana (purifi catory procedures) of Bhallataka (Semecarpus anacardium Linn.) fruit by traditional frying method

2014-05-15IlnhezhinRngsmyRinrynAhryRoshyChowllurVinyShuklAyurphrm216IrulpppurmNgeroil629002Indi

Ilnhezhin Rngsmy, Rinryn Ahry, Roshy J Chowllur, Viny J ShuklAyurphrm, 216 Irulpppurm, Ngeroil 629002, Indi;

bInstitute for Post Graduate Teaching & Research in Ayurveda, Gujarat Ayurved University, Jamnagar 361008, India;

cGovernment Ayurveda Medical College & Hospital, Nagercoil 629002, India

Regular articles

Shodhana (purifi catory procedures) of Bhallataka (Semecarpus anacardium Linn.) fruit by traditional frying method

Ilanchezhian Rangasamya*, Rabinarayan Acharyab, Roshy J Chowallurc, Vinay J ShuklabaAyurpharm, 216 Irulappapuram, Nagercoil 629002, India;

bInstitute for Post Graduate Teaching & Research in Ayurveda, Gujarat Ayurved University, Jamnagar 361008, India;

cGovernment Ayurveda Medical College & Hospital, Nagercoil 629002, India

Bhallataka (Semecarpus anacardium Linn.) is one among the wonderful drugs used to cure many diseases like infl ammation, piles, cancer etc in Indian system of medicine. Shodhana (purifi catory procedures) is must before administering the drug to the patients. The oily fraction in the pericarp of the fruit is responsible for the toxic nature of the drug. In southern parts of India, to purify Bhallataka fruit, frying method is followed traditionally. Here an attempt has been made to fi nd out the impact of traditional folk-lore Shodhana (purifi catory procedure) method by the physico-chemical parameters including HPTLC analysis. In 254 nm, raw bhallataka showed fi ve spots but the shodhita Bhallataka showed only four spots, this difference may be due to the shodhana procedures.

Ayurveda; Shodhana; Bhallataka; physicochemical; HPTLC

1 Introduction

Bhallataka fruit (Semecarpus anacardium Linn.; Anacardiaceae) is used to treat various diseases in Ayurvedic system of medicine [1]. Earliest references of this drug are available since vedic period [2]. The word Bhallataka is mentioned as early as 4thcen. BC [3]. Many formulations of Ayurveda contain Bhallataka as an ingredient [4]. Acharya Charaka mentioned ten formulations especially for rejuvenation [5]. Though the Bhallataka fruit is having many therapeutic values, pharmacies are scared to use this drug because of its irritant vesicating nature. However, the vesicant nature of the tarry bhilwa juice and the manufacturing diffi culties of Bhallataka prevent its usage [6]. If this vesicant nature is abolished, the drug could be a good source for pharmaceutical industry.

It is stated that, Bhallataka must be purified (shodhana) before administering to the patients [7]. Bhallataka (Semecarpus anacardium Linn.) is mentioned under the List of Poisonous Substances under the Ayurvedic including Siddha and Unani Systems of Medicine [8].

Shodhana is the purification/processing method adopted in Ayurveda to purify the poisonous medicinal plants, metals and minerals etc. Shodhana is a process by which unwanted impuritiesare separated from the substance by various pharmaceutical methods like boiling, frying, washing etc. with specific media, thereby minimization the toxicity of the substance [1]. Recent researches have proved the impact of shodhana (purification/ processing) of various poisonous herbal drugs like Vatsnabha (Aconitum ferox Wall.), kupilu (Strychnos nux-vomica Linn.), dhattura (Datura metel Linn.), Bhallataka etc [9].

Another study reported that the traditional way of administration bhallataka oil with peanut oil was found to be safe and upto 25 mg/kg/day × 9 days, increase of weight, RBCs & haemoglobin % was observed without mortality. Same dose with Tween-80 saline was found to have adverse effects regarding all the parameters with 16.5% mortality. This study supports Ayurvedic method of administration for effi cacy without toxicity [10].

Toxicological study was carried out in rats with chloroform-soluble fraction of Semecarpus anacardium nuts to study its safe non-toxic dose. The fraction produced toxicity at all levels tested (50-400 mg/kg) but the extent of toxicity was found dose-dependent. At lower doses this fraction induced partial growth inhibition over 36 days and higher doses proved fatal within 6 days. It was observed that 230 mg/kg caused 50% mortality in rats and this value is 1380 mg/m2when expressed for body surface area. This may have some use in the cancer chemotherapy study of the fraction [11].

Oral administration of Semecarpus anacardium nut oil extract at selected range (83.33 mg to 750.00 mg/kg b w/day) induced severe anaemia at acute as well as sub chronic levels [12].

Detoxifi ed Bhallaataka nuts (SA) are used for treating toxic conditions, obstinate skin diseases, tumors, malignant growths, fevers, haemoptysis, excessive menstruation, vaginal discharge, defi cient lactation, constipation, intestinal parasites [13].

Different shodhana methods are mentioned in Ayurvedic classics for the drug Bhallataka [7], but it is diffi cult to follow these methods in large scale purification. Traditional purificatory method i.e. frying the Bhallataka fruit is followed traditionally in southern parts of India. It is cost effective and time saving. But there is no scientific research regarding this shodhana method. Here an attempt has been made to analyse the impact of shodhana pharmaceutically and analytically including HPTLC.

2 Materials and methods

2.1 Collection of drug

Matured fruits of Semecarpus anacardium Linn., were collected from the trees growing wildly in Jalna (19°50′N 75°53′ E19.83° N 75.88°E), Maharashtra, India. The fruits were authenticated and voucher specimen was preserved in the department (Vide no. 6010/2009). The fruits were dried under sunlight for 10 days, followed by removing the false fruit and stored in an air tight container. Bhallataka fruits, which sunk in water, were used for therapeutic purposes [14]. So fruits which sunk in water were used for further studies.

2.2 Sample selection

The dried fruits were mixed thoroughly and sample was selected randomly.

2.3 Collection of charcoal

Charcoal was collected from the local market from Jamnagar, Gujarat, India.

2.4 Equipments for shodhana

Iron frying pan (82 cm circumference) with 62 cm long handle and a depth of 6 cm, stainless steel spatula (65 cm long) were used for processing of the nuts.

2.5 Chemical used for analysis

Precoated silica gel 60 F254TLC aluminium plates (10×10 cm, 0.2 mm thick), AR grade benzene, ethyl acetate, methanol and were obtained from M/s Merck Ltd. Mumbai, India.

2.6 Pharmaceutical study

The randomly selected fruits (200 g) were taken in an iron pan and heat was given from below by charcoal. Smoke started coming from the nuts after 5 minutes of heating. Then burning charcoal was put on the pan containing Bhallataka nuts. Immediately the hot nuts caught fi re. After 2 minutes the fire was extinguished by removing the burning nuts from the pan to the floor and spreading it immediately with a long ladle to extinguish the fi re. (Fig. 1) Then the nuts were allowed to cool and stored in air tight glass container for further studies. The same procedure was repeated thrice.

Fig. 1. Shodhana procedures of Bhallataka (Semecarpus anacardium) fruit.

2.7 Physico-chemical evaluation

In physico-chemical evaluation, moisture content, ash values viz., total ash, acid insoluble ash, and extractive values viz., alcohol soluble extractive value, water soluble extractive values were determined. The ash value represents the inorganic salts present in the drug. Extracts obtained by exhausting crude drugs are indicative of approximate measures of certain chemical compounds they contain, the diversity in chemical nature and properties of the drug. The determinations were performed in triplicate and results are expressed as mean. The percentage w/w values were calculated with reference to the air-dried drug [15, 16].

2.8 Preliminary phytochemical screening

The coarse powder of the fruit was subjected for extraction in methanol and water for 18 hrs in room temperature and the extracts were evaporated to dryness. The dried extracts were weighed, and percentage yield were calculated. The extracts were used for preliminary phyto-chemical screening with a set of various chemical tests viz., Dragendorff’s Mayer’s, Hager’s and Wagner’s tests for alkaloids; ferric chloride, lead acetate, potassium dichromate and dilute iodine tests for tannins and phenolics; foam test for saponin glycosides. These parameters were carried out by following the standard procedures [16].

2.9 Equipments used for HPTLC

Pre coated silica gel GF 60254 aluminiumplates as 5 mm bands, 5 mm apart and 1 cm from the edge of the plates, by means of a Camag Linomate V sample applicator fitted with a 100 μl Hamilton syringe. The mobile phase used was Benzene : Ethyl acetate (6 : 1). The plates were developed in Camag twin trough chamber (20×10 cm2) and spots were detected in short U.V. (254 nm), Long U.V (366 nm). Camag Scanner II (Ver. 3.14) and Cats soft ware (Ver. 3.17) were used for documentation.

2.10 Preparation of raw and shodhita sample solutions for the HPTLC study

Methanol extractives were prepared by standard method [15]. The concentrated methanol extracts were used as test solutions. 10 mg of extract was accurately weighed and dissolved in methanol in standard flask and final volumes were adjusted to 10 ml with methanol (1 μg/μl). 5 μl of each test solutions were spotted. The plates were developed in mobile phase of Benzene : Ethyl acetate (6 : 1 v/v) and scanned at 254 nm and 366 nm.

2.11 Application of sample

The sample solutions 5 μg was applied on TLC plates (10 cm×10 cm), precoated with silica gel as 5 mm, 5 mm apart and 1 cm from the edge of the plates by using CAMAG Linomat V sample applicator. The mobile phase used was Benzene : Ethyl acetate (6 : 1). The plates were developed in Camag twin trough chamber (20 ×10 cm2) up to a distance of 77 mm at a temperature of 30 ± 2°C. and spots were detected in short U.V. (254 nm), Long U.V (366 nm). Camag Scanner II (Ver. 3.14) and Cats soft ware (Ver. 3.17) were used for documentation.

3 Results

3.1 Pharmaceutical study

200 g of samples were taken for shodhana. Shodhana was repeated for three times as three batches. The average loss of the sample after shodhana was 22.08%. (Table 1, Fig. 1)

Table 1. Weight of the Bhallataka fruit before and after process.

3.2 Analytical study

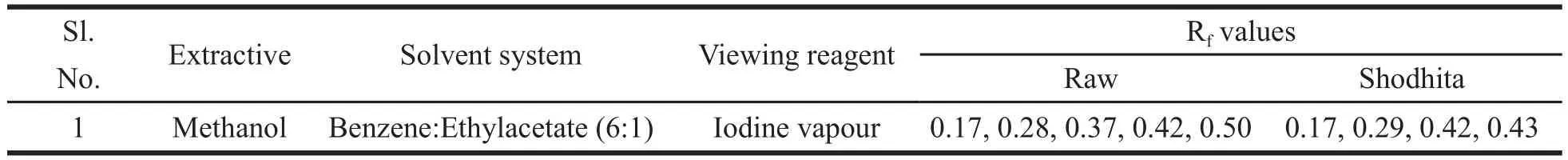

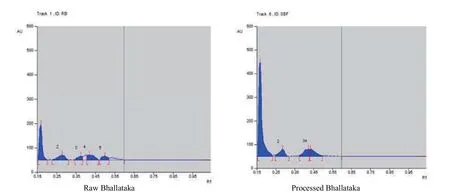

In analytical study the parameters like physico-chemical analysis, qualitative tests of raw and shodhita Bhallataka was carried out and systematically presented in Table 2, Table 3. Chromatography studies was carried out and the Rfvalues observed under 254 nm and 366 nm was presented in Table 4 and Table 5 respectively. (Fig. 2)

Table 2. Physico-chemical analysis of raw and shodhita (processed) Bhallataka.

Table 3. Qualitative analysis of raw and shodhita (processed) Bhallataka

Table 4. Rfvalues of raw and shodhita (processed) Bhallataka at 254 nm

Table 5. Rfvalues of raw and shodhita (processed) Bhallataka at 366 nm

Fig. 2. Densitogram of raw and shodhita Bhallataka (Semecarpus anacardium) fruit

4 Discussion

Many shodhana methods are mentioned in classics which seem to be complicated, time consuming and costly. Traditional vaidyas (practitioners) in Southern parts of India are using this drug widely for their clinical practice. They are following simple and cost effective shodhana methods i.e. frying the Bhallataka nuts. The tarry oil present in the pericarp of the fruit is responsible for the irritation [17]. The tarry oil of pericarp constitutes 90% of an oxyacid named Anacardic acid and 10% of a higher non-volatile alcohol called Cardol. The major constituent is bhilawanol, a mixture of 3-n-pentadec(en)ylcatechols [18]. Also it was reported to be two incompletely identified phenols, one was named semecarpol, and appears to be an undecenylphenol [19] and the other named anacardol, appears to be a dodecenylphenol [20]. The corrosive juice from the pericarp of the fruit found to contain catechol, fixed oil and anacardol (C18H13O3·COOH) to which the corrosive properties of the juice are due to two phenolic acids C16H15O3·COOH and C14H13O3·COOH [18]. In Bhallataka Bhilawanol, Anacardic acids are the main chemical constituents responsible for the blisters. Bhilawanol are known as Urushiol and the anacardic acid are closely related to Urushiol. When the Urushiol on the tarry oil comes in contact with skin, produces dermatitis [21]. Medically it is named asurushiol induced contact dermatitis. The American Academy of Dermatology estimates that there are up to 50 million cases of urushiol-induced dermatitis annually in the United States alone, accounting for 10% of all lost-time injuries in the United States Forest Service [22].

The decorboxylation process is helpful to convert the toxic anacardic acid into anacardol [23]. Decorboxylation process starts right while cutting the fruit itself and will catalyze by giving heat/fi re.

Reduction of the oil in the fruit is one of the main aims of the shodhana in Bhallataka. Three batches of the samples were processed by the frying shodhana method. Weight loss was observed in all the three samples. After shodhana average loss of the sample is 22.08% (Table 1). This loss is mainly due to reduction of the oil content in the fruits and some portions of mesocarp were also burnt in this process. The methanol soluble extractive was 35.40% w/w in raw Bhallataka and 16.47% w/w in shodhita Bhallataka. The difference between raw and shodhita was 18.93% w/w. It reveals that after shodhana the methanol soluble extractives are reducing. The ash value of processed nut was more when compared to raw. Ash value of raw bhallataka and shodhita was 2.68% w/w and 4.34% w/w respectively. The increase in ash value may be due to the burning process. Qualitative test showed no variation in raw and shodhita (processed) sample. In HPTLC study the Rfvalues were observed under 254 and 366 nm. In 254 nm, raw Bhallataka showed five spots at the Rf0.17, 0.28, 0.37, 0.42, 0.50 but the shodhita showed only four spots at the Rf0.17, 0.29, 0.42, 0.43. Rfvalues 0.37 and 0.50 was absent in shodhita samples, this may be due to the shodhana procedures. It proves the chemical changes during the frying purifi catory measures.

5 Conclusion

Difference in the Rfvalues of raw sample and the processed sample reveals that the chemical changes are taking place during the shodhana process. The data reveals that traditional method of shodhana of Bhallataka fruits definitely reduces the irritation. Further studies should be carried out to quantify the individual components which are reduced by the shodhana methods.

Acknowledgement

The authors are thankful to the Director, I.P.G.T. & R.A., Gujarat Ayurved University, Jamnagar, India for providing the facilities to carry out the work.

[1] Anonymous. Ayurvedic Pharmacopoeia of India, Part-1, Vol-2. New Delhi: Govt. of India, Ministry of Health of Family Welfare, 2004, 20.

[2] Sastry JLN. Dravyaguna vijnana, Vol-2. 3rded. Varanasi: Chaukhamba Orientalia, 2008, 135.

[3] Ilanchezhian R, Roshy Joseph C, Acharya RN, et al. Pharmacognostical and Physicochemical Analysis of Bhallataka (Semecarpus anacardium Linn.) – Fruit. Pharmacog J, 2011, 3: 9-16.

[4] Govind Das. Bhaishajyaratnavali. Ambikadatta sastry, editor. Varanasi: Chaukhambha Sanskruta Samsthan, 2001, 610: 685-686.

[5] Samhita C, Trikamji J, editor. 4thed. Varanasi: Chaukhamba Sanskrit Sansthan, 1994, 377-383.

[6] Ramasastri BV, Shenolikar IS. Nutritive value of two unusual foods: Adda (Bauhinia vahilii) and marking nut (Semecarpus anacardium) kernels. Ind J Med Res, 1974, 62: 1673-1677.

[7] Sharma S. Rasatarangini. Kasinath sastri, editor. 11thed. New Delhi: Motilal Banarasidas, 2004, 478-479.

[8] Lohar DR. Legal status of Ayurvedic, Siddha & Unani medicines. Ghaziabad: Department of AYUSH Ministry of Health & Family Welfare. p.72.

[9] Ilanchezhian R, Roshy JC, Acharya R. Importance of media in shodhana (purification/Processing) of poisonous herbal drugs. Anc Sci Life, 2010, 30: 27-30.

[10] Patwardhan B, Saraf MN, David SB. Toxicity of Semecarpus anacardium extract. Ancient Sci Life, 1988, 8: 106-109.

[11] Kesava Rao KV, Gothoskar SV, Chitnis MP, et al.Toxicological study of Semecarpus anacardium nut extract. Indian J Physiol Pharmacol, 1979, 23: 115-120.

[12] Choudhari CV, Deshmukh PB. Acute and subchronic toxicity study of Semecarpus anacardium on haemoblobin percent and RBC count of male albino rat. J Herb Med Toxicol, 2007, 1: 43-45.

[13] Chopra RN. Indigenous drugs of India. 2nded. Calcutta: Dhar VN & Sons, 1982, 407-409.

[14] Chunekar KC, Pandey GS. Bhavaprakasha Nighantu. 10thed. Varanasi: Chaukhamba Bharati Academy, 1999, 139-141.

[15] Anonymous. Ayurvedic Pharmacopoeia of India, Part-2, Vol-2. Appendices. 1sted. New Delhi: Govt. of India, Ministry of Health of Family Welfare, 2008, 15-17.

[16] Harborne JB. Phytochemical methods - A Guide to Modern Techniques of Plant analysis. Berlin: Springer Verlag, 2005.

[17] Agnives CR, Unnikrishnan P, George MJ, editors. Toxicology – Ayurvedic perspective. 1sted. Kottakkal: Department of Agadatantra, Vaidyarathnam PS Varier Ayurveda College, 2002, 201-202.

[18] Naidu DS. Constituents of the marking-nut: Semecarpus anacardium Linn. Journal of Indian Institute of Science, 1925, 8: 129-142.

[19] Khare CP, editor. Indian Medicinal Plants-An illustrated Dictionary. 1sted. New Delhi: Springer (India) Private Limited, 2007, 597.

[20] Nagabhushanaa KS, Umamaheshwari S, Tocolic FE, et al. Inhibition of soybean and potato Lipoxygenases by Bhilawanols from Bhilawan (Semecarpus anacardium) nut shell liquid and some synthetic Salicylic acid analogues. J Enzyme Inhib Med Chem, 2002, 17: 255-259.

[21] Urushiol induced contact dermatitis. http://en.wikipedia. org/wiki/Urushiol-induced_contact_dermatitis [15/6/2011].

[22] Armstrong WP, Epstein WL. Poison Oak: More than Just Scratching the Surface. Herbalgram (American Botanical Council) [Online], 1995, 34: 36-42, http:// waynesword.palomar.edu/ww0802.htm [8/6/2011].

[23]Anacardol. http://www.cardochem.com/cardanol.html [8/6/2011].

* Author to whom correspondence should be addressed. Address: Ayurpharm, 216 Irulappapuram, Nagercoil 629002, India; Tel.: +91-9487024577; Email: ayurilan@yahoo.com

Received: 2012-09-08 Accepted: 2013-12-04