低温合成超导体Ba1-xKxBiO3

2014-02-18李国宝王稼国廖复辉林建华

刘 孟 李国宝 王稼国,* 廖复辉 林建华

(1温州大学化学与材料工程学院,浙江温州325035;2北京大学化学与分子工程学院,北京分子科学国家实验室,稀土材料化学及应用国家重点实验室,北京100871)

1 Introduction

Ba1-xKxBiO3(BKBO)is a very interesting superconductor with transition temperature(Tc)about 30 K because it has threedimensional(3D)perovskite structure and no transition metal elements,1which has been known for more than thirty years with continuous studies up to now.2-16Comparing to other superconductors such as cuprate superconductors,17,18MgB2,19,20and Fe-base superconductors,21,22the studies on BKBO seem less.One possible reason may be that the pure superconducting BKBO is not easy to be obtained.Several methods have been reported to synthesize the bulk BKBO superconductors,such as the traditional solid state,3,4the high temperature and high pressure,5,6electrochemical,7hydrothermal,8and molten salt method.9,10,11Impurities are usually found in the final products to obtain BKBO superconductor by traditional solid state reaction.The BKBO superconductor with less impurity can be obtained by the high pressure method.However,this method is not easily available and the amount of products is too less.Small single crystals of BKBO superconductor can be obtained by electrochemical reaction,hydrothermal synthesis,or molten salt method.But it is difficult to get a large quantity of samples using these methods.Therefore,it is still worthy to find a new way to synthesize Ba1-xKxBiO3superconductor and to check if it is useful.In this paper,a topotactic reaction route(topotactic reaction is the chemical reaction,where the topology of the structures of the product and the one raw material are the same23)is introduced to obtain the Ba1-xKxBiO3superconductor with acceptable quality and quantity.

2 Experimental

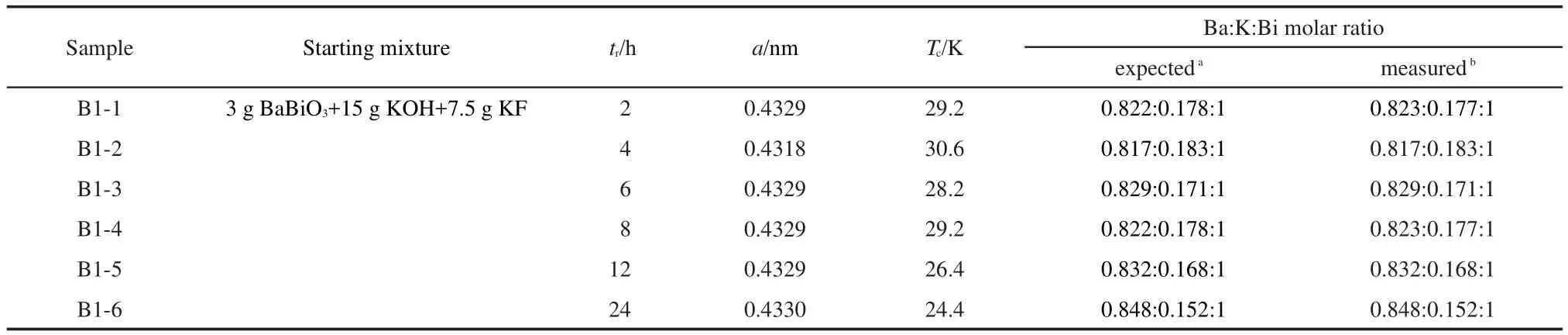

As the precursor,BaBiO3was firstly synthesized from stoichiometric amounts of BaCO3(AR)and Bi2O3(AR)with the process reported previously.24Then 3 g of BaBiO3was mixed with KOH(AR)and KF(AR)and put into a 20 mL alumina crucible.The mixture was treated at 450°C for several hours and then cooled to room temperature at a cooling rate of 60 °C∙h-1under the flow of oxygen.The cooled mixture is washed with water and dried at 80°C.Usually about 2.5 g of products can be obtained.To obtain samples with variousTcvalues,the reaction time(tr)was varied from 2 to 24 h(Series-1),the molten salt ratio was varied from 1:1 to 1:10(Series-2).The detailed synthesis parameters are listed in Tables 1-2.

Powder X-ray diffraction(XRD)data of all the samples were collected on a Rigaku D/Max-2000 diffract meter using a rotating anode(CuKαradiation,40 kV and 100 mA),a graphite monochromator and a scintillation detector(Japan).The mole ratios of Ba:K:Bi in the obtained samples were analyzed by inductively couple plasma(ICP)carried out on a PROFILE SPEC ICP instrument(America).Magnetic susceptibility was measured in the temperature range between 5 and 50 K by SQUID magnetometer(Quantum Design MPMS)in an applied magnetic field of 10 Oe(Britain).

3 Results and discussion

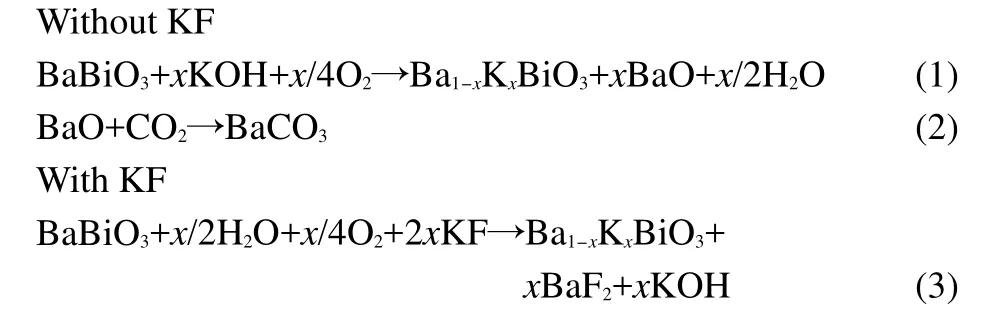

BaCO3will appear in the final samples if only KOH is mixed with BaBiO3(see the equations(1)and(2)),which could not be washed away by water(see Fig.S1 in Supporting Information).After the addition of KF,no peaks corresponding to BaCO3are observed in the powder X-ray diffraction patterns of the obtained samples(shown in Fig.1(a)).This may be due to the change of BaCO3to BaF2by adding KF,which can be washed away by water.The reaction equations are as follows(CO2or H2O comes from air):

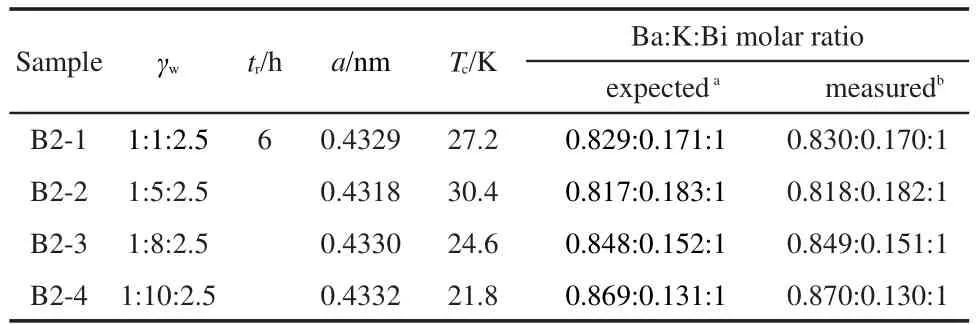

Table 2 Lattice parameters and Tcof the sample treated in KOHKF flux with different molten salt mass ratio(γw)values

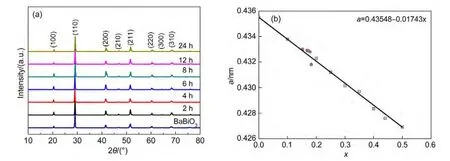

The synthesis information,sample composition,andTcof the BKBO Series-1 are listed in Table 1.The XRD patterns of the samples treated with different times are very similar and can be indexed using a pseudo-cubic cell(the true structure for them is under studying,the results will be presented as soon as possible).The pseudo-cubic lattice parameters15are shown in Fig.1(b)and are listed in Table 1.The lattice parameteradecreases with the K content increases in the sample,which agrees well with the data previously reported by Peiet al.,25where the relationship ofa=0.43548-0.01743xwas reported(herexis the value of the mole ratio of K/(Ba+K)in the sample,ais the lattice parameter of this sample).

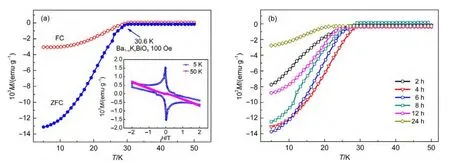

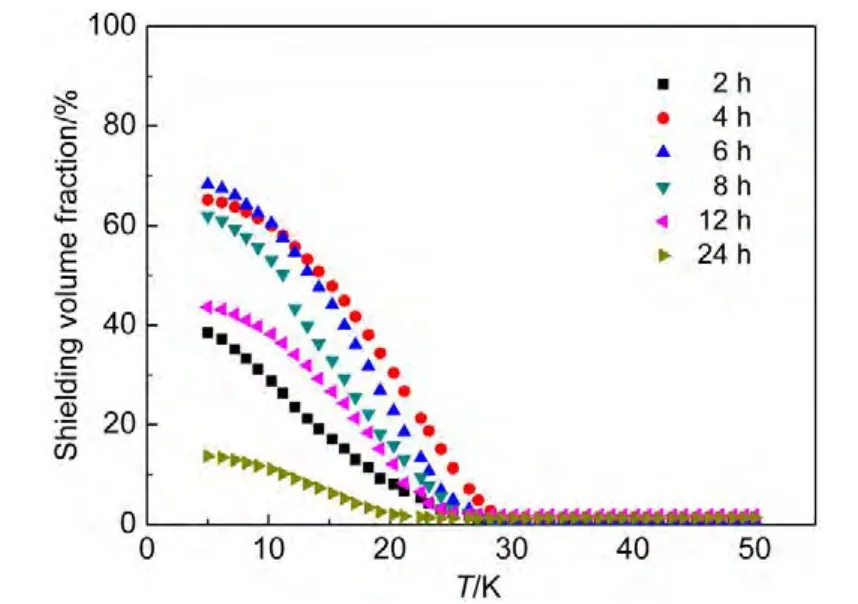

The temperature dependent magnetization of the sample B1-2 is shown in Fig.2(a).Adrop around 30.6 K is found in both zerofield-cooling(ZFC)and field-cooling(FC)curves,which indicates that a possible superconductivity transition begins at about 30.6 K.The magnetizationversusmagnetic field(M-H)curves blow and above 30.6 K(5 and 50 K)were also obtained andshown in Fig.2(a).TheM-Hcurve at 5 K exhibits a clear butterfly type of magnetic hysteresis,which is the typical feature of type-II superconductor.TheM-Hcurve at 50 K shows a linear character across the second and forth quadrants,which is the typical feature of diamagnetism.Therefore the transition occurred at 30.6 K should be a superconductivity transition.The superconductive shielding fraction is estimated to be about 70%at 5 K(shown in Fig.3).

Table 1 Lattice parameters and Tcof the sample treated in KOH flux with different time

Fig.1 XRD patterns of the samples B1-1 to B1-6(a),and doping level x dependence of Pseudo-cubic lattice parameters obtained from XRD of samples(b)

Fig.2 Temperature dependence of the magnetization for B1-2(a)and magnetic susceptibility for BaBiO3 treated in KOH flux with different reaction time(b)

Fig.3 Curves of shielding volume fraction at different time

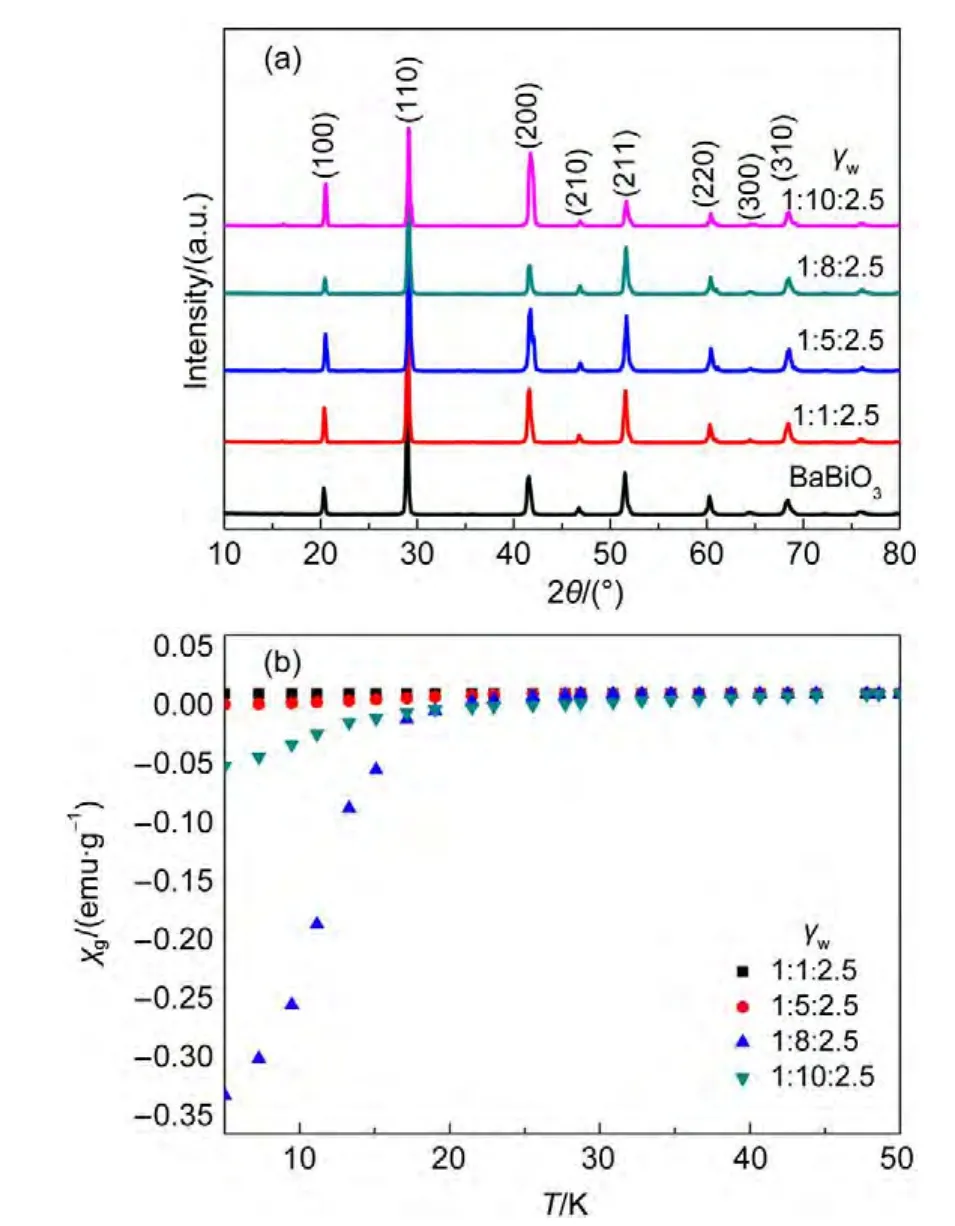

Temperature dependence of magnetic susceptibility for B1-1,B1-3,B1-4,B1-5,and B1-6 is similar to that for B1-2,and is shown in Fig.2(b),from which the superconductivity transition temperature(Tc)could be obtained.The transition temperature tends to increase initially as the treating time increases and then decreases after it reaches a maximum at abouttr=4 h.The highest transition temperature is 30.6 K.A similar process had been reported by Chenet al.,11which may be related to the volatilization of KOH when the treated time is too long.It is believed that the volatilization of KOH induces the molten salt to be lost,which may cause the decomposition of Ba1-xKxBiO3.The synthesis information,sample composition andTcof the BKBO Series-2 are listed in Table 2.As shown in Fig.4(a),by adjusting can be indexed using a pseudo-cubic cell(molten salt ratioγw=mBaBiO3:mKOH:mKF)in the starting compositions,we can synthesize similar XRD patterns samples and can be indexed using a pseudo-cubic cell.Fig.4(b)shows the temperature dependencies of dc susceptibility for Series-2.From the picture we can see that the transition temperature tends to increase initially as the molten salt ratio increases and then decreases after it reaches a maximum at aboutγw=1:5:2.5.The reasons may be that when have little molten salt the reaction is not sufficient,however,when the molten salt too much will isolated the samples from the air,results in the decrease of oxygen content in samples.We get the ICP data consistent with this conjecture.

Fig.4 X-ray diffraction patterns of the samples B2-1 to B2-4(a)and temperature dependence of magnetic susceptibility for B2-1 to B2-4(b)

4 Conclusions

In summary,we have presented a new method to synthesize the superconductor Ba1-xKxBiO3.By treating the precursor BaBiO3in KOH flux at about 450°C for a couple of hours,pure superconductor Ba1-xKxBiO3can be easily obtained.A large amount of superconductor Ba1-xKxBiO3can be also easily obtained by this method(about 10 g of superconductor Ba1-xKxBiO3has been obtained when a large crucible is used to contain about 12 g of BaBiO3,48 g of KOH,and 24 g of KF).This new method can also be easily applied to prepare other related compounds.Our preliminary work suggests that superconducting(Ba,K)(Bi,Sb)O3,(Ba,K)(Bi,Yb)O3and(Ba,K)(Bi,Ta)O3can also be obtained by this way.The corresponding results will be reported soon.

Supporting Information:available free of chargeviathe internet at http://www.whxb.pku.edu.cn.

(1) Cava,R.J.;Batlogg,B.;Krajewski,J.J.;Farrow,R.;Rupp,L.W.,Jr.;White,A.E.;Short,K.;Peck,W.F.;Kometani,T.Nature1988,332,814.doi:10.1038/332814a0

(2) Park,C.;Snyder,R.L.J.Am.Ceram.Soc.1995,78,3171.doi:10.1111/jace.1995.78.issue-12

(3) Shaikh,F.I.;Kalubarme,R.S.;Pawar,S.H.Applied Surface Science2008,254,5772.doi:10.1016/j.apsusc.2008.03.143

(4) Hinks,D.G.;Dabrowski,B.;Jorgensen,J.D.;Mitchell,A.W.;Richards,D.R.;Pei,S.;Shi,D.Nature1988,333,836.doi:10.1038/333836a0

(5) Kim,D.C.;Baranov,A.N.;Kim,J.S.;Kang,H.R.;Kim,B.J.;Kim,Y.C.;Pshirkov,J.S.;Antipov,E.V.;Park,Y.W.Journal of Superconductivity2002,15,331.doi:10.1023/A:1021009927768

(6)Kim,D.C.;Baranov,A.N.;Kim,J.S.;Kang,H.R.;Kim,B.J.;Kim,Y.C.;Pshirkov,J.S.;Antipov,E.V.;Park,Y.W.Physica C2003,383,343.doi:10.1016/S0921-4534(02)01332-1

(7) Shiryaey,S.V.;Barilo,S.N.;Ustinovich,S.N.;Fedotova,V.V.;Gatalskaya,V.I.;Szymczak,H.;Szymczak,R.;Baran,M.J.Cryst.Growth2000,211,471.doi:10.1016/S0022-0248(99)00766-6

(8) Zhang,G.H.;Li,G.B.;Huang,F.Q.;Liao,F.H.;Li,K.;Wang,Y.X.;Lin,J.H.J.Alloy.Compd.2011,509,9804.doi:10.1016/j.jallcom.2011.08.031

(9) Cui,Y.J.;Chen,Y.L.;Wang,F.S.;Li,J.;Zhang,Y.;Zhao,Y.Rare Metal Materials and Engineering2009,38,583.doi:10.1016/S1875-5372(10)60030-6

(10) Liu,S.F.;Fu,W.T.Mater.Res.Bull.2001,36,1505.doi:10.1016/S0025-5408(01)00609-2

(11)Chen,Y.L.;Cui,Y.J.;Yang,Y.;Zhang,Y.;Zhao,Y.Physica C2011,471,704.doi:10.1016/j.physc.2011.05.032

(12) Kohler,J.Angew.Chem.Int.Edit.2001,40,2435.

(13) Nagata,Y.;Mishiro,A.;Uchida,T.;Ohtsuka,M.;Samata,H.J.Phys.Chem.Solids1999,60,1933.doi:10.1016/S0022-3697(99)00217-6

(14) Sleight,A.W.;Gillson,J.L.;Bierstedt,P.E.Solid State Commun.1975,17,27.doi:10.1016/0038-1098(75)90327-0

(15) Wignacourt,J.P.;Swinnea,J.S.;Steinfink,H.;Goodenough,J.B.Appl.Phys.Lett.1988,53,1753.doi:10.1063/1.100430

(16) Cui,Y.J.Molten Salt Technique Preparation of Bismuthate Superconductors and Researches on the Doping Effect.Ph.D.Dissertation,Southwest Jiaotong University,Sichuan,2009.[崔雅静.铋酸盐超导体的熔盐制备技术以及掺杂效应的研究[D].成都:西南交通大学,2009.]

(17) Guner,S.B.;Gorur,O.;Celik,S.;Dogruer,M.;Yildirim,G.;Varilci,A.;Terzioglu,C.J.Alloy.Compd.2012,540,260.doi:10.1016/j.jallcom.2012.06.082

(18) Sagsoz,M.E.;Ertugrul,M.;Cevik,U.Mater.Lett.2006,60,1778.doi:10.1016/j.matlet.2005.12.020

(19) Liu,X.Y.;Huang,Y.;Zeng,Z.M.Materials Science and Engineering Journal2003,21,104.[刘心宇,黄 蛹,曾中明.材料科学与工程学报,2003,21,104.]

(20) Cui,Y.J.;Chen,Y.L.;Zhang,Y.;Zhao,Y.Journal of Low Temperature Physics2008,30,129.[崔雅静,陈永亮,张 勇,赵 勇.低温物理学报,2008,30,129.]

(21) Hiramatsu,H.;Katase,T.;Kamiya,T.;Hirano,M.;Hosono,H.Appl.Phys.Lett.2008,93,162504.doi:10.1063/1.2996591

(22)Yang,C.X.;Ju,J.;Zhao,S.D.;Xu,H.Y.;Liu,M.;Liao,F.H.;Li,G.B.;Lin,J.H.Acta Phys.-Chim.Sin.2013,29,2661.[杨承旭,鞠 晶,赵世迪,徐航宇,刘 孟,廖复辉,李国宝,林建华.物理化学学报,2013,29,2661.]doi:10.3866/PKU.WHXB201310151

(23) Zhang,K.L.;Sun,J.T.;Yuan,L.J.Inorganic Synthesis Chemistry;Wuhan University Press:Wuhan,2004;pp 134-139.[张克立,孙聚堂,袁良杰.无机合成化学.武汉:武汉大学出版社,2004:134-139.]

(24) Wang,H.;Wang,C.H.;Li,G.B.;Jin,T.N.;Liao,F.H.;Lin,J.H.Inorg.Chem.2010,49,5262.doi:10.1021/ic100361y

(25) Pei,S.;Jorgensen,J.D.;Dabrowki,B.;Hinks,D.G.;Richards,D.R.;Mitchel,A.W.;Newsam,J.M.;Sinha,S.K.;Vaknin,D.;Jacobson,A.J.Phys.Rev.B1990,41,4126.doi:10.1103/PhysRevB.41.4126