Packaging Bags of Peanuts with Function of Prevention of Aflatoxin B1

2013-12-20WUHaibo吴海波JINXiangyu靳向煜WANGHong

WU Hai-bo(吴海波),JIN Xiang-yu(靳向煜),WANG Hong(王 洪)

Key Laboratory of Textile Science and Technology,Ministry of Education,Donghua University,Shanghai 201620,China

Introduction

Peanuts are a dietary mainstay in Asia and Africa.They are susceptible to molds and fungal invasions.Aflatoxin,a poison produced by a fungus,called Aspergillus flavus[1],is more concerned by researchers.Previous researches have demonstrated that packaging methods and storage have big influences on the quality of peanuts by controlling temperature,relative humidity (RH),and oxygen content inside the package[2-6].Polymer film bags are widely used as packaging materials due to their excellent gas barrier property,mechanical strength,low cost,et al.Especially the composite films,such as PP/EVOH/PE,are also called barrier films[7].In addition,desiccant is often used in package of foodstuffs and medicaments to prolong preserving time by absorbing moisture inside the packaging.

As traditional packaging materials,natural fibers,such as jute fibers,have been widely used as packaging bags for grains with excellent hygroscopicity and moisture retention properties[8-10].Jute is primarily composed of cellulose and lignin.It has excellent biodegradability,high tensile strength,and moisture management properties.Jute fiber fabrics will absorb and/or desorb moisture in the open air due to the changes of environmental RH and temperature[11].When a jute sack is used as packaging material, its moisture absorption and desorption properties will influence the stability of foods by influencing the micro-environmental conditions inside the package.

As a fibrous superabsorbent,super-absorbent fiber (SAF)is composited with acrylic acid polymers which can provide extremely high rates of water uptake[12-13].It is widely used as agro textiles,medical textiles,packaging textiles,et al.

In this paper,packaging bags composited with barrier film and moisture absorbent nonwoven fabrics were designed in order to find out how to prevent the contamination of aflatoxin B1of peanuts.SAF and jute fibers are used as moisture absorbents,which are processed into absorbent nonwoven fabrics.Their influences on the internal moisture humidity inside packaging bags are analyzed.

1 Materials and Methods

1.1 Materials

Peanuts with moisture content of 6.9% were bought from the supermarket.Impurities and broken peanuts were sorted out and then the peanuts were moistened to the targeted moisture content for storage experiment.

The barrier film is used in this paper with O2transmission rate and water vapor transmission rate of 0.3 cm3·(m2·24 h·atm)-1and 20 g ·(m2·24 h)-1,respectively.The thickness of the film is 0.675 mm.

Three kinds of packaging bags,e.g.,jute nonwoven fabric bag,jute nonwoven/barrier film composite bag,and SAF nonwoven bag sheathed with barrier film bag were made as follows.

Jute fibers blended with low-melt core/sheath PE/PP fibers with the mass ratio of 60/40 were carded and needle-punched into a loft fiber web.The web was thermally bonded into jute nonwoven fabric with the basis weight of 220 g/m2.Then the fabrics were made into bags with the size of 32 cm ×33 cm.

The jute nonwoven fabric above was further thermally laminated with the barrier film,as shown in Fig.1.Then the fabrics were made into bags with the size of 32 cm ×33 cm.

SAF fibers blended with low-melt core/sheath PE/PP fibers and viscose fiber with the mass ratio of 50/20/30 was carded and needle-punched into a kind of nonwoven fabric with basis weight of 1 050 g/m2.SAF nonwoven fabric was made into bags with the same size of 32 cm ×33 cm,as shown in Fig.2.The bags were sheathed with the barrier film bag for storage experiment.

1.2 Methods

1.2.1 Measurement of the content of aflatoxin B1of peanuts

Fig.2 SAF nonwoven bag sheathed with barrier film bag

The content of aflatoxin B1of peanuts was measured by Shanghai Municipal Center for Disease Control & Prevention according to GB/T 18979-2003-Determination aflatoxins content in food-Cleanup by immunoaffinity chromatography and determination by high-performance liquid chromatography and fluorometer.

1.2.2 Measurement of the RH inside the packaging bags during the storage of peanuts

A sample of 2 500 g peanuts with moisture content of 13.0% were sealed in the jute nonwoven/barrier film composite bag and SAF nonwoven bag sheathed with barrier film bag,respectively.Then they were put in an LHH-250SDP model Environmental Chamber (Shanghai Yiheng Instruments Co.,China)for 15 d which was controlled under 30℃and RH 95%.A ZDR-20 model Relative Humidity Recorder (Hangzhou Zeda Equipment Co.,China)was sealed in the bag with peanuts and the RH inside the bag was recorded every 10 min.

1.2.3 Long term moisture absorption properties of jute fiber,SAF,and peanuts

Jute fiber,SAF,and peanuts were dried in an oven under 105℃for 2 h until their weight difference within 30 min was not higher than 0.01%.Then they were put in the environmental chamber under 20℃ and RH 90%,and weighed every day.The moisture content of the samples in each day can be calculated according to Eq.(1).

where R1is the equilibrium moisture content of the sample,%;G0is the initial weight of the sample,g;G is the balanced weight of the sample,g.

1.2.4 Isothermal moisture absorption characteristics of jute fiber,SAF,and peanuts

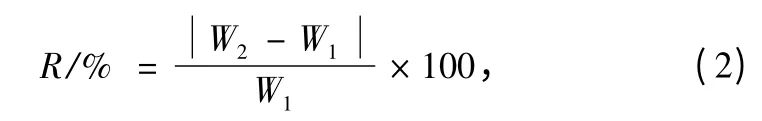

Jute fiber,SAF,and peanuts were dried in an oven under 105℃until their weight changed less than 0.01% within 2 h.A small piece of aluminum foil was put into the Conway unit center and 1 g sample was put on the foil.Saturated salt solutions listed in Table 1 were placed around the center of the Conway unit.Then the Conway units were covered by a glass plate and put in the environmental chamber under 25℃and RH 65%.The foil together with the sample was weighed every 2 h until their weight changed less than 0.01%.The equilibrium moisture content of samples are calculated according to Eq.(2).

where R is the equilibrium moisture content of samples under different saturated salt solutions,%;W1is the initial weight of the foil and the sample,g;W2is the final weight of the foil and the sample,g.

Table 1 The water activity of saturated salt solutions under 25℃

2 Results and Discussion

2.1 Aflatoxin B1 content of peanuts after storage

Aspergillus flavus is slow-growing.It may take weeks to store peanuts to ensure that they have been infected with Aspergillus flavus.In this paper,peanuts with moisture content of 13.0% were sealed in the jute nonwoven fabric bag and jute nonwoven/barrier film composite bag, and stored in the environmental chamber under 30℃and RH 95% for 80 d.Then they were taken out and their contents of aflatoxin B1were measured as shown in Table 2.The samples were named as sample 1 and sample 2,which corresponded to peanuts stored in the jute nonwoven fabric bag and jute nonwoven/barrier film composite bag,respectively.

It could be found from Table 2 that there was no detectable aflatoxin B1in the peanuts stored in the jute nonwoven/barrier film composite bag,while the content of aflatoxin B1of peanuts stored in the jute nonwoven fabric bag was 2.6 μg/kg.Hence jute nonwoven/barrier film composite bag shows excellent effect to prevent the contamination of aflatoxin B1of peanuts under the environment studied in paper.

Table 2 Aflatoxin B1 content of peanuts after storage

It is believed that peanuts undergo aerobic respiration during storage.The barrier film used in this paper has low O2transmission rate and water vapor transmission rate.Hence a hermetic system was formed inside the packaging bags within which O2could be consumed by the aerobic respiration of peanuts.Hence the growth of aflatoxin B1was prevented in the jute nonwoven/barrier film composite bag.

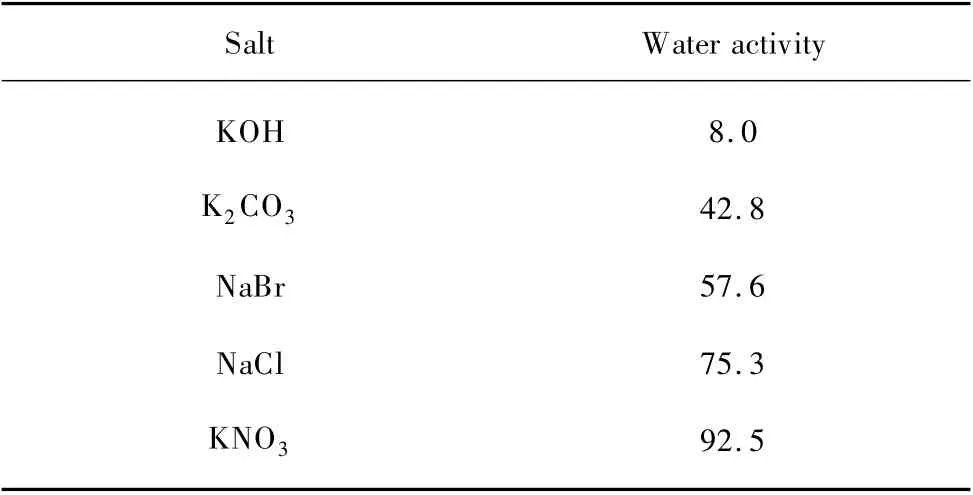

2.2 Change of RH inside jute nonwoven/barrier film composite bag

Grains can be stored for longer period of time in a dry environment[14].Therefore it is necessary to know the RH inside the jute nonwoven/barrier film composite bag filled with peanuts.In this paper,a humidity recorder was sealed inside the jute nonwoven/barrier film composite bag stored with peanuts and the RH inside the bags was recorded,as shown in Fig.3.It could be seen from Fig.3 that the RH inside the bag decreased sharply and a peak appeared on the curve in the first day of the storage.Then the RH started to increase and nearly balanced at a higher level in the sixth day of the storage.This meant that the jute nonwoven/barrier film composite bag only absorbed moisture inside the bag at the early stage.After it reached the equilibrium moisture content,the RH inside the bag started to increase.At the end of storage,the RH inside the bag was close to the RH of the environmental chamber,which was too high to retain the quality of peanuts for longer period.Therefore,the moisture absorption capacity of the bag should be improved to keep the peanuts in a lower humidity environment.

Fig.3 RH inside the jute nonwoven/barrier film composite bag

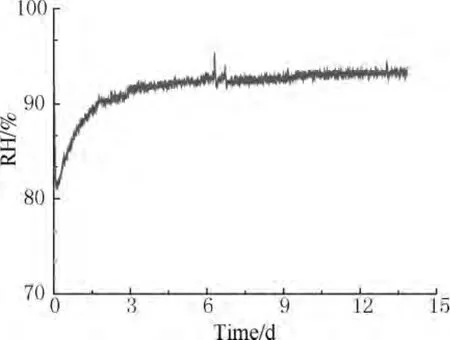

2.3 Change of RH inside the SAF packaging bag of peanuts

In order to decrease the RH inside the packaging bag,SAF was used as the desiccant of the packaging bag.the SAF nonwoven bag sheathed with barrier film bag was filled with peanuts with moisture content of 13.0% and stored in the environmental chamber under 30℃and RH 95% for 11 d.It is believed that 11-day is long enough for the RH inside the bag to be balanced.The RH inside the bags was monitored and the results were shown in Fig.4.

Fig.4 RH inside SAF nonwoven bag sheathed with barrier film

It was interesting to find from Fig.4 that the RH inside the SAF nonwoven bag sheathed with barrier film bag decreased slowly and balanced at about 80%,which was much lower than that of the jute nonwoven/barrier film composite bag.This means that SAF is better than jute fiber to decrease the RH inside the bag.

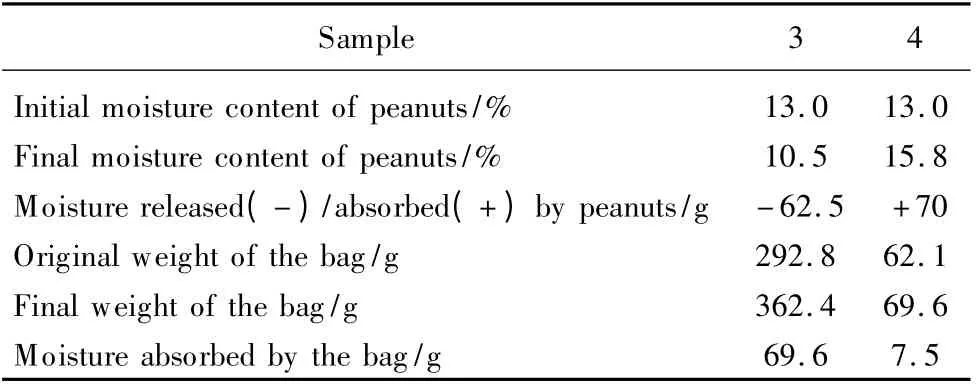

In order to investigate the moisture exchange inside the packaging bags,the changes of moisture content of peanuts and bags were measured and the results were shown in Table 3.The samples are named as sample 3 and sample 4,which correspond to peanuts stored in the SAF nonwoven bag sheathed with barrier film and jute nonwoven/barrier film composite bag,respectively.

Table 3 Changes of moisture content of peanuts and bags

It could be found from Table 3 that the moisture content of peanuts stored in the SAF nonwoven bag sheathed with barrier film decreased from 13.0% to 10.5%.It meant that SAF had excellent effect to decrease the moisture content of peanuts than jute fiber.It could also be found from Table 3 that SAF bag weighed about 70 g heavier after the storage experiment.It was believed that SAF nonwoven fabric sheathed with barrier film exhibited the unidirectional water-penetration property.More moisture penetrated into SAF nonwoven bag sheathed with barrier film bag because of its better moisture absorption property in comparison with jute fiber.

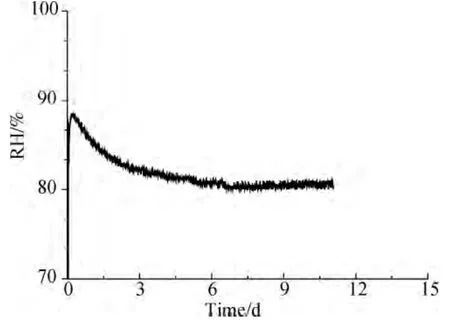

2.4 Isothermal moisture absorption properties of jute fiber,SAF,and peanuts

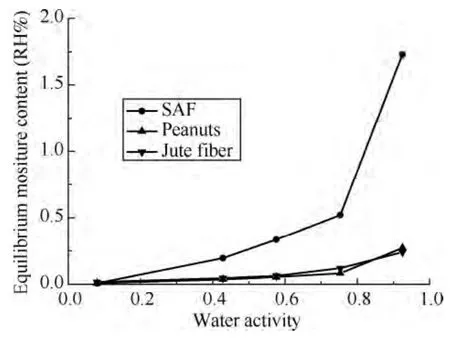

In order to uncover the reason why SAF had better effect of decreasing the moisture content inside the packaging bag stored with peanuts,the isothermal moisture absorption properties of jute fiber,SAF,and peanuts were measured and the results were shown in Fig.5.

Fig.5 Isothermal moisture absorption curves of jute,SAF,and peanuts

It could be found from Fig.5 that the equilibrium moisture content of jute fiber and peanuts increased slightly with the increase of the water activity in a similar trend,which meant that jute fiber and peanuts had similar cohesion to water molecular in the wide range of water activity.When the jute fiber is used as the desiccant of the packaging bag of peanuts with high moisture content,the peanuts can only lose moisture water to certain extent and the RH inside the bag will be balanced at a relative high level.However,the equilibrium moisture content of SAF increased sharply with the increase of the water activity in Fig.5.Hence SAF has higher cohesion to water molecular than peanuts,especially in the higher water activity.When peanuts with moisture content of 13.0% were stored in the SAF nonwoven bag sheathed with barrier film bag,the moisture water would be released by peanuts and absorbed by SAF.Hence a lower RH was achieved finally in the packaging bag.

3 Conclusions

In this paper,functional packaging bags composited with barrier film and nonwoven fabrics with good moisture absorption property were designed with the aim of preventing the contamination of aflatoxin B1of peanuts during storage.The internal moisture humidity was monitored and the influences of jute fiber and SAF were compared.The following conclusions can be achieved.

Jute nonwoven/barrier film composite bag shows excellent effect to prevent the contamination of aflatoxin B1of peanuts under the environment studied in this paper.A high RH environment is formed when jute fiber nonwoven fabric is used as the absorbent component of the composite bag.A lower RH micro-environment can be achieved by using SAF as the moisture absorbent,suggesting it has better effect to prevent the contamination of aflatoxin B1of peanuts for longer period.

SAF shows higher equilibrium moisture content than peanuts in the whole range of water activity,especially in the higher water activity,which means that SAF has higher cohesion to water molecular than peanuts.Hence a microenvironment with lower RH can be achieved by using SAF as the moisture absorbent.

It is promising to design a packaging bag which can create a micro-environment with low RH and high CO2content by selecting proper moisture absorbent and barrier film of the composite bag, which can prevent the contamination of aflatoxin B1of peanuts.

[1]Wagacha J M,Muthomi J W.Mycotoxin Problem in Africa:Current Status,Implications to Food Safety and Health and Possible Management Strategies [J].International Journal of Food Microbiology,2008,124(1):1-12.

[2]Li X Q,Zhang W,Zhang A J,et al.Prevention and Control of Aflatoxin in Peanuts and Removal Methods [J].Food Engineering,2010(2):25-27.(in Chinese)

[3]Yang S X,Han H M.Inhibiting of Aflatoxin Contamination of Peanuts[J].Henan Agriculture,2009(9):16-17.(in Chinese)

[4]Chulze S N.Strategies to Reduce Mycotoxin Levels in Maize during Storage: a Review [J].Food Additives and Contaminants,2010,27(5):651-657.

[5]Magan N,Lacey J.Effects of Gas Composition and Water Activity on Growth of Field and Storage Fungi and Their Interactions[J].Transactions of the British Mycological Society,1984,82(2):305-314.

[6]Cardoso L,Bartosik R,Rodriguez J,et al.Factors Affecting Carbon Dioxide Concentration in Interstitial Air of Soybean Stored in Hermetic Plastic Bags (Silo-bag)[C].The 8th International Conference on Controlled Atmosphere and Fumigation in Stored Products,Chengdu,China,2008:68-74.

[7]Zhou B.The Properties and Application of EVOH Resin with Good Barrier Property [J].Plastics Packaging,2012,22(3):10-13.(in Chinese)

[8]Dong Z E,Chen H L,Yu C W.Status and Research Fronts in Modification of Jute Fibers[J].Journal of Donghua University:Natural Science,2011,37(2):146-152.(in Chinese)

[9]Watt I C,Kabir M.Sorption of Water Vapor in Jute Fibers[J].Textile Research Journal,1975,45(1):42-48.

[10]Das S,Saha A K,Choudhery P K,et al.Effect of Steam Pretreatment of Jute Fiber on Dimensional Stability of Jute Composite[J].Journal of Applied Polymer Science,2000,76(11):1652-1661.

[11]Wang H,Jin X Y,Wu H B,et al.Research on Moisture Absorption and Desorption Properties of Thermo-Bonded Jute Nonwovens[J].Shanghai Textile Science &Technology,2013,41(3):50-54.(in Chinese)

[12]Mölnlycke A B,Chihani T,Canböck G,et al.A Superabsorbent Fiber or Nonwoven Material,a Method for Its Manufacture,and an Absorbent Article Comprising the Superabsorbent Fiber or Nonwoven Material:US,WO 1995/008353 [P].(1995-03-30).

[13]Zhong L,Wang H,Jin X Y,et al.The Feasibility of the Replacement of SAP by SAF in Hygiene Material[J].Shanghai Textile Science & Technology,2010,38 (1):10-12.(in Chinese)

[14]Huang S X,Tian H J,Cai J P.Study on Moisture Absorption Characteristics of Grain and Moisture Diffusion Characteristics in Grain Bulk [J].Journal of Henan University of Technology:Natural Science,2010,31(2):15-18.(in Chinese)

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Electrospun Small Diameter Tubes to Mimic Mechanical Properties of Native Blood Vessels Using Poly(L-lactide-co-ε-caprolactone)and Silk Fibroin:a Preliminary Study

- Properties of Scaffold Reinforcement for Tendon Tissue Engineering in vitro Degradation

- Mineralized Composite Nanofibrous Mats for Bone Tissue Engineering

- Promoted Cytocompatibility of Silk Fibroin Fiber Vascular Graft through Chemical Grafting with Bioactive Molecules

- Fatigue Performance of Fabrics of Stent-Grafts Supported with Z-Stents vs.Ringed Stents

- Effect of Media on the in vitro Degradation of Biodegradable Ureteral Stent