Modeling and Simulation about Sinusoidal Non-circular Gear Pitch Curve of the High Order and Denatured Feature

2013-12-07XUGaohuanCHENJianneng

XU Gaohuan, CHEN Jianneng

1.Zhejiang Water Conservancy and Hydropower College, Hangzhou 310018, China;2.Zhejiang Sci-Tech University, Hangzhou 310018, China

ModelingandSimulationaboutSinusoidalNon-circularGearPitchCurveoftheHighOrderandDenaturedFeature

XU Gaohuan1*, CHEN Jianneng2

1.ZhejiangWaterConservancyandHydropowerCollege,Hangzhou310018,China;2.ZhejiangSci-TechUniversity,Hangzhou310018,China

Theellipticalgearpairtransmissionhassoundcharacteristics,withwhichthenon-circularplanetarygearmechanismhasplayedauniqueroleinthenewhydraulicmotor.Sinusoidalnon-circulargearalsohasthecharacteristicsoftheclosureandsmoothoftheellipticalgear.Inordertogetthebestperformance,amathematicalmodelforthesinusoidalnon-circulargearpitchcurvewiththehighorderandthedeformedfeature,aswellasthesimulateexamples,isestablished.

highorderdeformed,sinusoidal,non-circulargear

Non-circular gear hydraulic motors will gradually replace the drive piston hydraulic motor because of its characteristics of simple structure, strong anti-pollution, non-hydraulic pulse, no trapped oil, the stability of the output torque and the long lifecycle[1]. The core institution of the non-circular gear hydraulic motor is composed of non-circular gear planetary gear mechanism. The main components are the non-circular sun gear, the cylindrical planetary gear and the non-circular gear (motor housing). The design of non-circular pitch curve is one of the key technologies. The general line is the high-order elliptical pitch curve or the multi-arc curve. You can also use other curves which have the engagement requirements[1].

ZHANG et al[2] described a sinusoidal non-circular gear pair, which also has the excellent characteristics of high order elliptic curve, and its basic forms. But the paper was lack of the discussion of the combination of design, and it did not create the mathematical model. On this basis, we propose that the sinusoidal non-circular gear pitch curve with the high order and deformed feature is characterized by continuity and smoothness. More adjustable parameters are easier to optimize the hydraulic performance of the motor. This paper mainly studies on the design and mathematical model of the sinusoidal non-circular gear pitch curve with the high order and the deformed feature, and also performs the simulation with a true example. These works provide a theoretical basis for the design of new low speed high torque hydraulic motor.

1.The basic principles of sinusoidal gear pair

The main feature of the sinusoidal gear is that the angle of driving wheel and the driven have the relationship of the sinusoidal function[2]. On the planexO1y, the relationship just follows this equation:

y=Asin(bx)

(1)

On the planeφ1O2φ2, the angle of driving wheel and the driven have the relationship withx,y, and they are just satisfied with these equations:

φ1=xcosθ-ysinθ

(2)

φ2=xsinθ+ycosθ

(3)

here,θrepresents the angle betweenO2φ1andO1x, in the equation (1),Ais the amplitude ofyin thexO1yplane, andb=cos(θ).

In order to comply with the gear meshing law: ① non-circular gear pitch curve is closed, ② The circumference meets the relationship ofl=πmz(mis the modulus andzis the number of teeth).

2.The mathematical model of the sinusoidal non-circular gear pitch curve with the high order and deformed feature

The high-level order of non-circular gear is said that the pitch curve in a rotation cycle finished the order cycle of sinusoidal transformation, and the deformed pitch curve, said non-circular gear pitch curve with a number of different sections of the order form[3-4]. The high order and deformed sinusoidal non-circular gear pitch curve constituten1 andn2 pitch curve, which meets the engagement requirements of that the pitch curve is continuous, and the circumference is integer multiple of the modulus and the number of teeth[3]. In order to achieve these goals, this research studies on the curve equation, the circumference and the transmission ratio function, and gives the angular velocity and angular acceleration equations.

1) Rotation relationship, the angle and the transmission ratio function

In the high order and deformed sinusoidal non-circular gear pair, angleφ1,φ2andx,yfollow the piecewise function expression:

(4)

The relation between the driving wheel angle and the driven wheel angle:

(5)

here,θis the angle betweenO2φ1andO1x

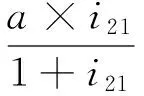

The transmission ratio function:

(6)

2) Pitch curve equation

(7)

r2=a-r1

(8)

hereais the wheelbase

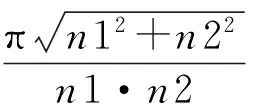

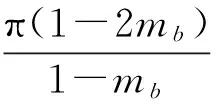

3) Pitch curve perimeter

(9)

(10)

4) Driven wheel angular velocity and angular acceleration driven wheel angular velocity:

ω2=sin(θ)+Abcos(bx)cos(θ)

(11)

angular acceleration

(12)

hereAandbare taken in different ranges ofA1,b1andA2,b2.

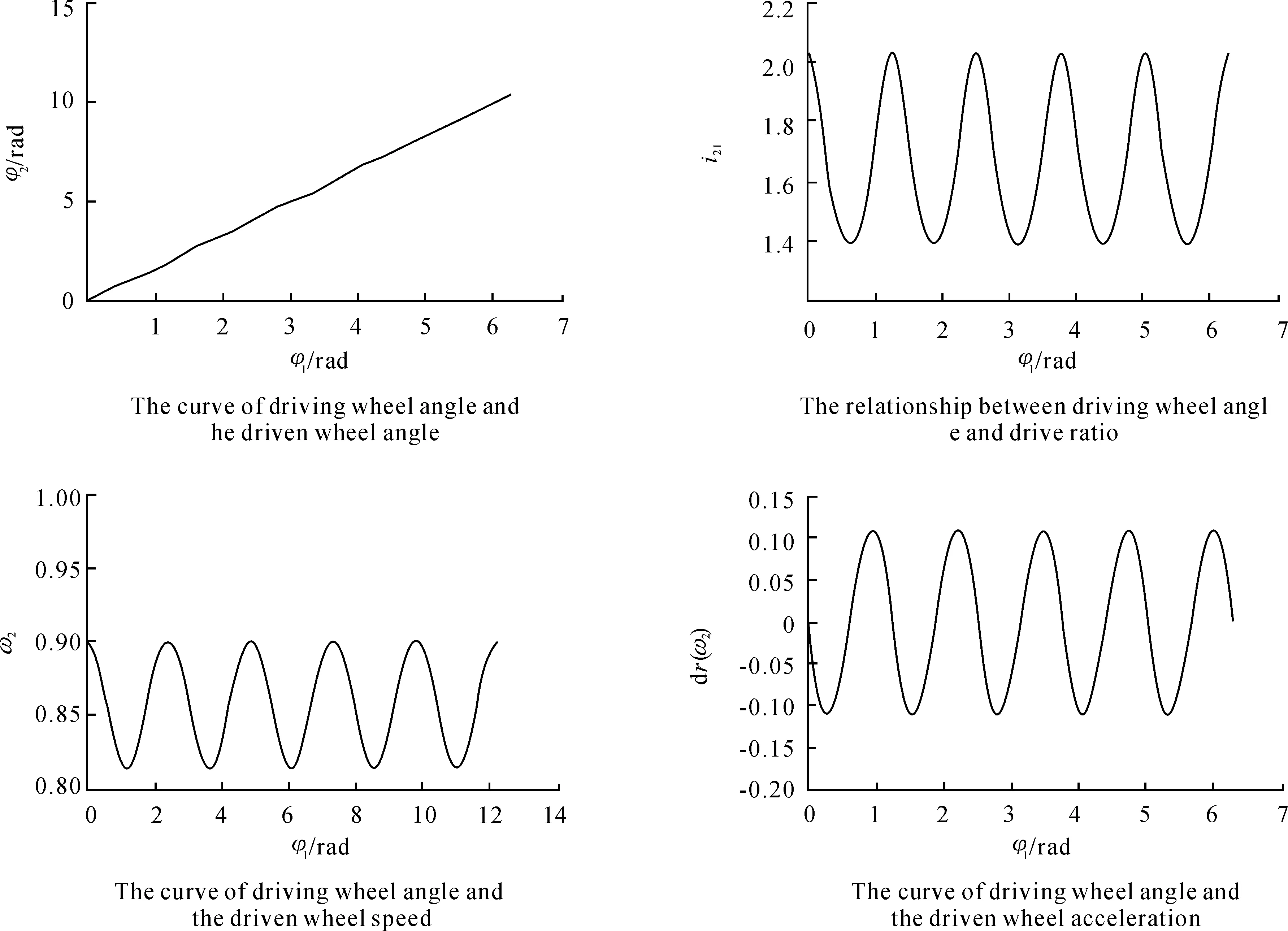

3.Examples and simulation

To study the high order and deformed sinusoidal non-circular gear pair characteristics more easily, Matlab2011b was selected for the simulation platform, and the program was written to simulate the gear pair as follows.

1)xis taken as the independent variable. Depending onn1 andn2, discreted to 360 equal parts in area 0~2T×n1 or 0~2T×n2.

2) Calculate the parameters ofy,φ1,φ2,i12, and store them in the array.

3) According to the gear teeth and the mode automatically, adjust the wheelbase.

4) Calculate the high order and deformed sinusoidal non-circular gear pair pitch curve coordinates into the appropriate array.

5) Establish a GUI interface, call the high order and deformed sinusoidal non-circular gear pair pitch curve function, plot output corresponding curve through matlab library function.

Example: for the high order and deformed sinusoidal non-circular gear pair, the input parameter isz=m=3,a=120 mm,mb=0.5,n1=5,n2=3,γ=pi/38.

Fig.1 is the high order and deformed sinusoidal non-circular gear pair pitch curve simulation graphics. Fig.2 isφ1,φ2,i12The relationship between the characteristic values of simulation graphics

Fig.1 The high order and deformed sinusoidal non-circular gear pair pitch curve simulation graphics

4.Conclusions

1) The mathematical model of the high order and deformed sinusoidal non-circular gear pair in line with the gear combination principle, and the Matlab graphical simulation confirm the correctness of the design method.

2) Based on the adjustment of the high order and deformed sinusoidal non-circular gear pair by parametersz,m,a,mb,n1,n2 andγ, a variety of sinusoidal noncircular gear pitch curve can be designed, which extends the range of options.

3) Adjusting the parameters can change the high order and deformed sinusoidal non-circular gear pair bump in considering the processing problems, you can control its concave.

4) The design methods and the properties of the high order and deformed sinusoidal non-circular gear can be used in the follow-up of new hydraulic motors and vane pump drive mechanism, and provide a theoretical basis.

Fig.2 φ 1,φ 2,i 12 The relationship between the characteristic values of simulation graphics

[1] LI Lei,DU Changlong,YANG Shanguo.The Development of Hydraulic Motor with Non-circular Planetary Gear and Its Application in Coal-mining Machinery[J].CHINESE HYDRAULICS & PNEUMATICS,2007,9:16-18.

[2] ZHANG Rui,ZAO Fengxia,WU Xutang.Study on the Design Method of a New-style Sinusoidal Noncircular Gear[J].MACHINE DESIGN&RESEARCH,2010,26(4):71-74.

[3] WU Xutang,WANG Haigui. Non-circular Gear and Non-uniform Drive [M].Beijing:Mechanical Industry Press,1996:105-106.

[4] GAO Hong,LU Xingsheng. Design and Graphic Simulation about Pitch-line of Denatured Ellipse Gear[J].CHINA MECHANICAL ENGINEERING,2003,10(14):1645-1648.

HarbinGeneralHydraulicMachineryWorksCo.,Ltd.

Harbin General Hydraulic Machinery Works Co., Ltd. of Yilin Hydraulic Group is the most professional production base of large-scale metallurgy oil cylinder and oil machinery cylinder in the Northeast of China. The main products include metallurgy cylinder, swell-shrink cylinder, rotating injection device, lifting cylinder, main lifting jack, front lifting jack, engineering oil cylinder, vehicle oil cylinder, substitute imported oil cylinder, etc. Our company can design and manufacture non-standard oil cylinder according to clients’ demand, and design and manufacture whole-set of hydraulic system and pump station. Our company possesses modernized workshops for machinery production, assembling and experiments, and has established complete quality control system. Our company passed through the authentication of ISO9001—2000 quality system in 2005. “Quality+Service” is the tenet of Yilin people.

The sales centers of Yilin Group, namely Harbin Yilin Hydraulic and Pneumatic Equipment Co. Ltd. and Harbin Liming Hydraulic Equipment Sales Company, locate in the busy streets of Harbin with convenient transportation. They are the general agents of Beijing Huade and Wenzhou Liming in Heilongjiang and run the business of all kinds of hydraulic and pneumatic equipment both at home and abroad.

With “Focusing on Quality and Maintaining Reputation” as its tenet, Yilin Group insists on the principle of broadening market with the quality of products, improving quality with scientific management, and winning customers with best service. The choice of Yilin means ease and success.

General Manager: TIAN Jianpin

Mobile: 13904516319

Office: 0451-86781022 86781200

Fax: 0451-86781033

E-mail: yl@ylin.cn Http://www.ylin.cn

高阶变性正弦类非圆齿轮节曲线建模及仿真

徐高欢1*,陈建能2

1.浙江水利水电专科学校,杭州 310018;2.浙江理工大学,杭州 310018

椭圆齿轮副传动特性优良,由它组成的非圆行星齿轮机构在新型液压马达中起到了独特的作用。正弦非圆齿轮也具有椭圆齿轮的封闭、光滑的特性。为获得最佳性能,建立了新型的高阶变性正弦类非圆齿轮节曲线数学模型,并通过算例进行动态仿真。

高阶变性;正弦类;非圆齿轮

TH13

2012-11-28

*XU Gaohuan.E-mail: 6787135@qq.com

10.3969/j.issn.1001-3881.2013.06.023

猜你喜欢

杂志排行

机床与液压的其它文章

- Research and Realization of the Control System for Cement Screw Packing Machine Based on MCGS and S7-200PLC

- The Study of Stability Control Based on the Yawing Moment of Electric Vehicle

- Structure Optimization Design of Time-Grating with Variable Coupling Coefficient Based on ANSOFT Electromagnetic Analysis

- Prediction Chatter Stability and Bifurcation in Milling Machine

- Design of Structure Optimization for Engine Exhaust Manifold

- Design and Research on the Length of Piston’s Buffer Oil Mat Area of a New Type of Hydraulic Rock Drill