Self-diagnosis method for faulty modules on wireless sensor node

2013-11-05ZHAOJun赵军CHENXiangguang陈祥光LIZhimin李智敏WULei吴磊

ZHAO Jun(赵军), CHEN Xiang-guang(陈祥光), LI Zhi-min(李智敏), WU Lei(吴磊)

(School of Chemical Engineering and Environment,Beijing Institute of Technology,Beijing 100081,China)

With the advantage of the embedded systems technology,the usage of wireless sensor network has extended to various applications and the wireless sensor networks have emerged as the solution for remote sensing applications,such as military monitoring and environment detecting.

In this paper,we study the wireless sensor network used in the airfield fuel oil supply system.Fig.1 shows the architecture of the wireless sensor network.The network includes several mobile sensor nodes and one sink node.The sensor node is installed on the oil trucks,which are movable and could not be connected by the wired fieldbus.The sink node is connected to the monitor computer via USB or serial port.Every sensor node gets the measuring values and sends them to the sink node,while the sink node collects and submits the measurements to the monitor computer.

As the sensor nodes work outdoor,the electrical connections may be damaged due to malicious impacts or corrosion of metal.The modules of the sensor nodes may fail owing to the physical damage orthe fabrication process problems.These failed nodes will decrease the quality of service and make the entire wireless sensor network function improperly.

Fig.1 Wireless sensor network architecture

If we replace the whole node when only one module fails,that will cause the device wastes and increase costs.It will be more economic and proper if we can find the failed module and replace it.So we design every module as a separate circuit,and add a state detection module to detect the status of all modules in the node.Another reason of our design is that the wireless sensor network is applied at the airfield oil fuel supply system and the nodes of WSN may be installed on the devices which may be vary from each other in function and dimensions.

Fig.2 shows the architecture of the sensor node we install on oil trucks.We design a fundamental circuit as a common part which contains the power supply module,processor module and state detection module.The other modules are designed as separate circuits.At last we connect these different function circuits together with electrical connections according to the function of different sensor node.

Fig.2 Architecture of the sensor node

In later chapters,we will discuss the self-diagnosis algorithm on the state detection module to detect the status of each module of sensor node and find the failure module timely in order to ensure the system more reliability.

1 Related works

Self-diagnosis is important especially in assuring the dependability of mission-critical information systems.Built-in self-test(BIST)is widely used in voting based systems or off-line testing.There are many methods[1-2]applied the self-diagnosis to hardware and design in some unconventional circuits,but they used the hardware resources extremely.Ref.[3] proposed an evolutionary method in designing the self-diagnostics circuits in nature exhibit self-diagnostic system.

Ref.[4]evolved the digital circuits with online built-in self-test design.It describes the generational genetic algorithm(GA)as the theoretic of self-diagnosis method and designs the self-diagnosis analog circuits.But with the increasing number of sensors on each sensor node,the genetic algorithm will become complicated and the design of the self-diagnosis analog circuits will be more and more difficult.Ref.[5] described a method of introducing a level of fault tolerance into wireless sensor networks by monitoring the status of each wireless sensor node.It focuses on the detection of physical malfunctions caused by impacts or incorrect orientation,and designs a flexible circuit using accelerometers that acts as a sensing layer around a node,which will be capable of sensing the physical condition of a node.The software analyses the raw data from the accelerometers to determine the orientation of the node and access the damage probability.At last the whole sensor network should be made aware of the faulty nodes to ensure that faulty nodes are routed around.

Ref.[6] proposed a built-in and self-organized diagnosis mechanism to monitor each node in real time and identify faulty nodes.This diagnosis is operated within a cluster of nodes.It can reduce power consumption and communication traffic.Ref.[7] presents a methodology for fault characterization.This self-learning approach is developed in initial and learning phases.The process units are simulated without and with different faults that will let the system(in an automated way)detect the key variables to characterize the faults.This method can be used on line,and key variables will be monitored in order to diagnose possible faults.

Ref.[8] proposed an energy efficient faulttolerant detection scheme that explicitly introduces the sensor fault probability into the optimal event detection process.As the relationship between measurement noise and sensor faults is likely to be stochastical and unrelated,while the event measurements are likely to be spatially correlated,the authors attempted to disambiguate e-vents from both noise related measurement error and sensor fault simultaneously in fault-tolerant detection and limit the effects of faulty sensor on the event detection accuracy.Since the optimal detection error was shown to decrease exponentially with the increase of the neighborhood size,the Bayesian detection scheme is used to achieve the balance on the event detection accuracy and the energy consumption by choosing a proper neighborhood size for a sensor node in fault correction,as such the energy could be conserved.

Although the self-diagnosing hardware can monitor the conditions of the node,this self-diagnosis suffers from two main disadvantages.The first is that they require the circuit’s operation to go off-line periodically to feed in the test patterns.The second is that we will never know what is derived from the node if the testing logic fails and the rest of the circuit is functioning properly.We propose a new distributed fault detection method in this paper to remedy the shortcomings above;there is a circuit as the self-diagnosing hardware around a sensor node to monitor the status of the sensor node and the software to analyze the measurements and check out the failed modules.

2 Self-diagnosis algorithm

As mentioned,we could not replace the entire sensor node because of the failure of one module,so we need an accurate diagnosis of each failure module, forexample, when the screen is not shown,we need to diagnose whether it is the failure of the screen or the processor module.In this paper,sensor nodes are distributed sparsely together with the oil tank trucks.Because the measurement of each sensor node may vary from each other and the operation of every sensor node may be different for each time,and the method of collecting and comparing its own measurement is not appropriate in this paper.

The self-diagnosis algorithm on state detection module is working by observing the voltage changes of each module.This fault detection system can be expressed by the fault identification principle S=(U,A,R,P),where U is the diagnostic object,A={a[i],i=1,2,…,k}is condition attributes,R={r}is the results of condition attributes,P={s[i],i=1,2,…,k}is the working status of each module.We define a[i]=0 and s[i]=0 means the condition attribute is normal and the module is working well,and a[i]=1 and s[i]=1 means the condition attribute is abnormal and the module fails.We will discuss the parameters of each module separately below.

2.1 Choice of condition attributes

2.1.1 Power supply module

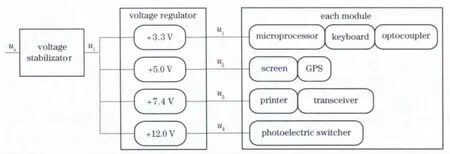

The power supply module is the basis of the system to normal operation.The power supply module is running by the storage battery on the truck,and the source voltage may fluctuate according to the working state of the truck.Therefore,we add a voltage stabilization module before the regulation of voltage and the power supply module can be divided into two parts,voltage stabilization and voltage regulation.Most modules are ready-made.Fig.3 shows the architecture of the power supply module and the power supply for each module.

In our sensor node,the voltage stabilization module is DLM20-24D12,the input range of which is 18-36 V and the output range is 12±1%V.The voltage regulation module is LM2596 step-down voltage regulator and the accuracy of each output voltage is 5%.The state detection module detects the input and output voltage of the voltage stabilization module and the four outputs voltage from the voltage regulation module supplied for each modules to diagnose whether there are some failures.Sometimes,when the battery power drops,the internal resistance will increase.If the printer energy consumption increases suddenly,the output voltage may be dropped,resulting in shortterm failure.

Fig.3 Power supply for each module

We define the condition attribute that the four outputs of the regulator and one output of the stabilizator are all in their normal range as a[1],and the working status of the power supply module as s[1].

2.1.2 Wireless communication module

The communication module we selected is coRE1 OEM long distance Ad-hoc wireless module.Tab.1 shows the mainly technical parameters of the module.

Tab.1 Technology parameters of the wireless module

We can distinguish the transmission working mode from the other working modes through the input current.Another method to distinguish the working mode transmission is the electrical level changes of the interface between the processor module and the wireless communication module.The electrical level change of interface TX means the wireless communication module need to switch the working mode to transmission and send data,resulting the increase of input current.If there is no change in consumption,we can diagnosis the transceiver fails.

Also we define that results of two distinguish methods are the same as a condition attribute a[2]and the diagnosis result of working status as s[2].

2.1.3 Sensor module

The sensor module has two components,flow sensor and GPS.The most important components of flow sensor are photoelectric switch and photocoupler.When the photoelectric switch turns off the leakage current is 10 mA,and the breakover current is 40 mA when the photoelectric switch turns on.We can distinguish whether there is liquid flow by these current and diagnosis whether the current in the normal range as well as the photoelectric switch working normal.For the photocoupler,we can diagnose whether there is failure based on front-end and back-end voltage level changes.The GPS returns a set of data per second,based on which we can accomplish the diagnosis.

We define a condition attribute a[3]to describe whether the relationship between the current and the output of photoelectric switch is normal.Also we define s[3]to describe whether the photoelectric switch is working normal.

We define another condition attributes a[4]to describe whether the front-end and back-end voltage level changes of the photocoupler are correct,and another working state result s[4]to describe whether the photocoupler is working normal.

Also,we define a condition attributes a[5]to describe whether the data format of the GPS are correct,and the working state result s[5]to describe whether GPS is working normal.

2.1.4 Man-machine interface module

The three components in the main-machine interface module are keyboard,screen and miniprinter.Because the keyboard is the initiation of some operations,we can diagnosis the working status of other modules according to the operation of the keyboard.Therefore,the fault diagnosis of keyboard is more important than the other components.The fault of keyboard usually comes from poor contact and interference,which will lead to instability of the keyboard and spikes in keyboard scanning.

We define a condition attribute a[6]for the keyboard todescribe whether there are many spikes in keyboard scanning,and the key board working status s[6]to describe whether the keyboard is working normal.

Thescreen and mini-printerare working when the“Print” and“Display” keys are pressed,and the“Busy”state on the interface can be taken as the reaction of the pressed keyboard.We can use the relationship between the keyboard and two modules’“Busy”state to detect whether they are working normal.Another condition is that the consumption of min-printer will increase rapidly when it is working,so we can distinguish its working state by its input current.

We define a condition attribute a[7] for screen to describe whether the relationship between the pressed“Display”key and the“Busy”state on the interface is normal.Also we define s[7] to describe whether the screen is working normal.

We define a condition attribute a[8]for minprinter to describe whether the relationship between the pressed“Print”key and the“Busy”state on the interface is normal.We define s[8]to describe whether the min-printer is working normal.We define another condition attribute a[9]for min-printer to describe whether the relationship between the pressed“Print”key and the input current is normal.

2.1.5 Processor module

Processor module is the most important part ofsensornode and the micro-processorwe choose is MSP430FG4618.Because of its low power consumption and its small input current,we could not diagnose working status by the input current changes.Like other nodes,we use the response of the processor to diagnose working status.Because wireless sensor node sends information after receiving the DSR(data sending request)from the sink node,the DSR can be taken as the incentive of the working of micro-processor,the electrical level of interface RX changes can be taken as a symbol of the incentive and the electrical level of interface TX changes can be taken as a symbol of the response.If all is normal,we set condition attribute a[10]=0 and the working status result s[9]=0.

The condition attributes a[7]and a[8]are all take the micro-processor’s response into account in the diagnosis of the man-machine interface module,and these two condition attributes can also be used in the diagnosis of the processor module.

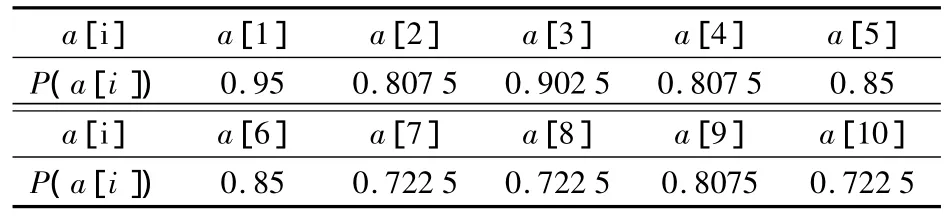

2.2 Fault identification system

According to the fault of each module and the changes of condition attributes,we can diagnose the module fault by the fault identification system.At first we collect statistics data about the condition attributes,and Tab.2 shows the condition attributesand theirdescriptions. Tab.3 shows the statistics of the module faults.

3 Performance evaluation

Asmentioned before,we determine the working state of each module according to the interface voltage changes and the input current changes.We achieve the interface voltage changes and the input current changes through the current transformer and the voltage transformer.

Tab.2 Statistics of the condition attributes

Tab.3 Statistics of the module faults

Because digital signals with low energy capacity,the detection accuracy of digital signal in current changes or voltage changes is lower than that of the detection of power supply lines.

We set the detection accuracy of digital signal as 0.85,while the detection accuracy of power supply lines as 0.95.Now we can discuss the accuracy of the fault detection method we mentioned previously.

Tab.4 Correct detection probabilities of each condition attribute

Because a[8]and a[9]are involved in the same module fault diagnosis,and P(a[8])is smaller than P(a[9]),so condition attribute a[8]can be removed.Tab.5 shows the changes of the module faults with improved condition attributes.

Tab.5 Improved module faults

These module faults can be expressed by:

We set{P(s[i]),i=1,2,…,n}as the correct diagnosis probability of each module fault.According to the correct detection probability of each condition attribute,we can get the correct diagnosis probability of each module fault.Because the condition attribute a[7],a[9] and a[10]are involved in the fault detection of module faults s[7],s[8]and s[9],these three condition attributes are correlated in diagnosis of module fault and the fault detection of these are all based on the reaction of the sensor node,so the correct diagnosis probabilities of these three faults will be lower than the others as shown in Tab.6.On the other hand,these also improve the diagnostic accuracy of fault mode s[9].Tab.6 shows the correct diagnosis probabilities of each module fault.

Tab.6 Correct diagnosis probabilities of each module fault

When i=1 to 6,the condition attribute a[i]and module fault s[i]are one-to-one corresponding,there is no misdiagnosis between each module fault.And the missed-diagnosis probability of each module fault is the difference between 1and its correct diagnosis probability.

When i=7,9 and 10,these three condition attributes a[7],a[9]and a[10]are involved in the fault detection of module faults s[7],s[8]and s[9].The fault diagnosis of the module fault s[9] may be a misdiagnosis to the other two faults s[7]and s[8].Tab.7 shows the misdiagnosis probabilities between s[9] and the other two faults when the fault s[9]happens.

Tab.7 Misdiagnosis probability

Another problem is that the miss-diagnosis probability of s[9]=0.477 7,which is too large to diagnose the module fault.The method reduces the time interval for each diagnosis to resolve this problem.If we operate the diagnosis algorithm everyoneminute,themiss-diagnosis probability will drop to less than 0.001 after ten minutes.

4 Conclusion

In this paper we propose a method to diagnose different faults for each module on sensor node by itself.It is based on the hardware of state detection module and the software of self-diagnosis algorithm.We will discuss the diagnosis method using intelligent algorithm based on the performance ofthe microprocessoron sensor node in next paper.The diagnosis accuracy of faulty modules for WSN nodes we proposed can meet the needs for real-field requirement and it will be improved with the development of processor performance.The experiment and simulation results show that the accuracy of this self-diagnosis method can be accepted in engineering application.

[1] Koza J R.Genetic programming:on the programming of computers by means of natural selection[M].Cambridge,MA:MIT Press,1992.

[2] Miller J F,Job D,Vassilev V K.Principles in the evolutionary design of digital circuits-part 1[J].Genetic Programming and Evolvable Machines,2000,1:7-35.

[3] Avizienis A.Design diversity and the immune system paradigm:cornerstones for information system survivability[C]∥Information Survivability Workshop.Carnegie Mellon,USA:[s.n.],2000:27 -36.

[4] Garvie M,Thompson A.Evolution of combinatonial and sequential on-line self-diagnosing hardware[C]∥Proceedings of the 2003 NASA/Dod Conference on Evolvable Hardware.Washington,D.C.,USA:NASA,2003:177-183.

[5] Harte S,Rahman A,Razeeb K M.Fault tolerance in sensor networks using self-diagnosing sensor nodes[C]∥The IEEE International Workshop on Intelligent Environments.Colchester,UK:[s.n.],2005:7-12.

[6] You Zhiyang,Zhao Xibin,Wan Hai.A novel fault diagnosis mechanism for wireless sensor networks[J].Mathematical and Computer Modelling,2011,54(1-2):330-343.

[7] José Luis de la Mataa,Manuel Rodrígueza.Selflearning of fault diagnosis identification[J].Computer Aided Chemical Engineering,2011(29):885-889.

[8] Luo X,Dong M,Huang Y.On distributed fault-tolerant detection in wireless sensor networks[J].IEEE Trans Comput,2006(55):58 -70.

猜你喜欢

杂志排行

Journal of Beijing Institute of Technology的其它文章

- Optical micro-scanning location calibration of thermal microscope imaging system

- Multiple-impairment monitoring for optical duobinary system based on delay-tap asynchronous sampling

- Experimental study on durability fracture behavior and vibration modal sweep for vehicle rear axle

- Control strategy for hybrid tracked vehicles using fuzzy logic

- Strategy to control crawling vehicles with automated mechanical transmission

- Roundness error evaluation by minimum zone circle via microscope inspection