Effects of carbonaceous conductive fillers on electrical and thermal properties of asphalt-matrix conductive composites

2013-01-08ZhouXiaofengZhangXiaosongZhouJiancheng

Zhou Xiaofeng Zhang Xiaosong Zhou Jiancheng

(1School of Energy and Environment, Southeast University, Nanjing 210096, China)(2Department of Fundamental Sciences, Yancheng Institute of Technology, Yancheng 224003, China)(3School of Chemistry and Chemical Engineering, Southeast University, Nanjing 210096, China)

Asphalt, a class of complex mixtures, has been a valuable material because it is readily adhesive, waterproof and durable. Asphalt-matrix materials are composites, in which thermal or mechanical functional materials are dispersed in asphalt (or aggregates)[1-6]. Taking account of the advantages from asphalt and functional materials, asphalt-based materials have been widely applied on highway pavements, bridge decks, airport roads and so on[7-8].

Mixing carbonaceous conductive fillers (such as carbon fiber, graphite and carbon black) in asphalt has attracted great interest recently because of their enhanced thermal, electrical and mechanical properties. For thermal properties, graphite powder (9.0% in volume fraction) dispersed in matrix asphalt to enhance the thermal conductivity of asphalt-based materials were reported to increase the softening temperature from 45 to 82 ℃[9]. For electrical properties enhancement, it is theoretically feasible to melt and remove snow or ice on asphalt pavement. Especially, the modification of carbonaceous conductive fillers on asphalt pavement is expected to become the most efficient, convenient, and environmentally protective method to remove snow and ice[10]. Recent experimental studies have also shown that the thermal/electrical conductivity of the asphalt concrete is proportional to the volume fraction of carbonaceous conductive fillers[11-12]. However, the increase in the additive contents without limit will decrease the volumetric properties and mechanical properties of the asphalt pavement. The relationship between the thermal/electrical conductivity enhancement and the properties of filling conductive particles requires quantitative study of heat/electricity transfer processes in asphalt-matrix mixtures.

1 Experiment

In this paper, we study the effects of graphite and carbon fiber powder additives on the thermal conductivity modification in asphalt-matrix mixtures. By taking into account the shape and volume fraction of filling materials, we would like to generalize the Bruggeman effective medium theory[13-14]to investigate the effective thermal conductivity and electrical conductivity in asphalt-matrix conductive composites. Our theoretical predication on the effective thermal and electrical conductivity of asphalt-matrix conductive composites is in good agreement with the experimental results. Furthermore, our model can also elucidate the non-zero percolation threshold for the electrical transport process.

Asphalt (AH-70) was obtained from Wuxi Road Department, Jiangsu, China. In order to investigate the effects of particle shape on the electrical and thermal properties of asphalt-matrix conductive composites, we chose graphite (spherical-like) and carbon fiber (large aspect ratio) as conductive fillers. The graphite was obtained from Xingtai Graphite Ore Factory in Hebei province, China. Its particle size is less than 150 μm, and the mass fractions of carbon, ash and icon are 98.9%, 0.2% and 0.03%, respectively. The carbon fiber was supplied by An Shan Eastern Asia Carbon Fiber Co. Ltd., in China. The diameter and average length are 10 and 5 mm, respectively. The electrical resistivity is 10-3Ω·cm.

Asphalt was heated to (150±5) °C in an oil-bath heating container until it flowed fully. In order to investigate the effective thermal properties of the asphalt-based mixture, the carbon fiber particles and graphite powders of 1%, 3%, 5%, 7%, 9%, 11%, 13%, 15%, 17%, 20% in volume fraction were chosen. Then the carbon fiber particles and graphite powders were filled into the heated asphalt and operated under a high rotation speed for about 20 min to ensure the well dispersion of the additive filling particles in the asphalt-matrix. The thermal conductivity of the asphalt-based mixture was measured by the use of a thermal testing device (ZKY-BRDR).

2 Results and Discussion

In the course of understanding the electrical (thermal) transport behavior of the asphalt-matrix mixture, we would like to generalize the Bruggeman effective medium theory[13-14]to investigate the effective thermal conductivity and electrical conductivity in asphalt-matrix conductive composites. We consider that the carbonaceous conductive fillers composites in which the carbon fiber or the graphite particles with the volume fractionfand the asphalt-matrix with conductivityKmare randomly mixed. For simplicity, we assume that the asphalt-matrix particles and the graphite particles are spherical, while the carbon fiber conductive particles are spheroidal in shape with radiia,b,c, andb=c. For the good dispersion of additive filling particles in the asphalt-matrix, we operate the composites under a high rotation speed for about 20 min. So, the effective conductivity of the asphalt-matrix containing carbonaceous conductive fillers is isotropic[15-16]. For such an asphalt-matrix composite, the effective medium theory (EMT) gives[14]

(1)

whereKc,jis the equivalent thermal (or electric) conductivity along thej-axis, and the depolarization factorLjdepends on the carbonaceous conductive fillers aspect ratiop=a/c, which is expressed as

(2)

Hence, one hasKc,j=Kp/(1+QRBdLjKp) withQ=(2a+c)/(ac). As a result, Eq.(1) is simplified as

(3)

For the electrical transport of asphalt-matrix composites, the interfacial resistance is so small that it can be ignored[17], i.e.RBd=0. Therefore, we shall substituteKc,j=Kpinto Eq.(3) in the electrical transportation of asphalt-matrix composites. Note that Eq.(3) can predict the very low percolation thresholds in self-monitoring asphalt-matrix composites.

Fig.1 shows the effective thermal conductivity of asphalt matrix composites with filling carbon fiber particles and graphite powders of 1%, 3%, 5%, 7%, 9%, 11%, 13%, 15%, 17%, 20% in volume fraction, respectively. We find that the effective thermal conductivity enhancement of carbon fiber/asphalt composites is greater than that of the graphite/asphalt composites at the same additive volume fraction. This may be due to the difference of particle shape and the thermal properties of the filling particles. To further verify the validity of our theory, we make a comparison between Eq.(3) and our measured experimental data in Fig.1. For numerical calculations, the thermal conductivity of carbon fiber, grap-hite particles, asphalt matrix are taken as 120, 50 and 0.8 W/mK, respectively. The aspect ratio of carbon fiber, graphite particles, asphalt matrix are taken as 500, 3 and 1, respectively[18-19]. The contact thermal resistance is taken asRBd=1.5×10-9m2·K/W. This estimatedRBdused in our calculation is of the same magnitude as that in the asphalt-matrix composites[19-20]. Our theoretical results are found to be in reasonably good agreement with the experimental data.

Fig.1 Effective thermal conductivity of asphalt-matrix composites compared with our numerical results

The addition of carbonaceous conductive fillers to the conventional asphalt mixture can produce asphalt concrete with excellent electrical performance, which is expected to be used due to its electro-thermal behavior as an efficient method to melt and remove snow or ice on pavements, bridge decks and airport runways. A sudden change of electrical conductivity occurs in asphalt-matrix composites at a very low critical additive volume fraction. The low critical additive volume fraction is called the percolation threshold[10]. Fig.2 shows the calculation for carbon fiber/asphalt, graphite/asphalt composites[10]. In the calculation, the electric conductivities of asphalt, graphite and carbon fiber are taken as 1×10-12, 1×104and 1×103S/m, respectively[10]. The aspect ratios of graphite and carbon fiber are taken as 3 and 500. We can see that the theoretical results are in good agreement with the experimental data[10]. For carbon fiber/asphalt and graphite/asphalt composites, the percolation thresholdfcis estimated as 5% and 12%, respectively. Such percolation threshold values are of the same order as those reported in experimental study[10].

Fig.2 Enhancement of effective electrical conductivity compared with numerical results

Now we are looking at the dependence ofKeon the shape of filling conductive particles. Fig.3 shows the results (f=0.05,Kp/Km=1 000). We can conclude that for both oblate (P<1) and prolate (P>1) particles,Ke/Kmincreases significantly with an increase in the geometric anisotropy. It can be well understood that when filling conductive inclusions with a large aspect ratio (prolate) or a small aspect ratio (oblate), it is helpful to form a path for heat flow through the composites. For instance, carbon fiber (prolate) produces a long uninterrupted conductive path and tends to easily contact with each other to form a conductive network. As a result, the conductivity enhancement of filling particles with a disk-like shape (P→0) may be greater than those with a needle-like shape (P→∞). It indicates that the use of disk-shaped conductive inclusion may be helpful to realize the effective conductivity enhancement. Previous researches have shown that additive contents that increase without limit will decrease the volumetric properties and mechanical properties of the asphalt pavement[10-12, 19]. We suggest that choosing suitable shapes of filling conductive particles such as disk-like high conductivity particles can limit the additive contents.

Fig.3 Ke/Km as a function of aspect ratio

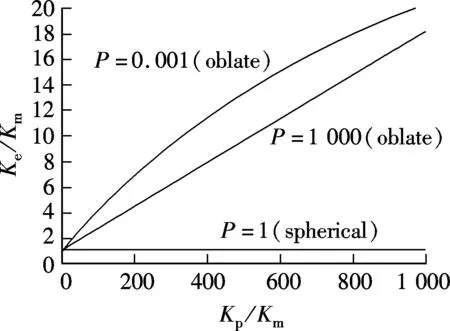

We further study the dependence of effective thermal conductivity on the conductivity ratioKp/Kmin Fig.4. Obviously, filling oblate-shaped conductive particles can achieve higher thermal conductivity enhancement than filling prolate or spherical inclusions. The enhancement of effective thermal conductivityKe/Kmincreases with the increase in the ratio ofKp/Km. As a result, the thermal conductivity and the shape of the constituents play key roles in the enhancement of the effective thermal conductivity.

Fig.4 Ke/Km vs. Kp/Km

3 Conclusion

In this paper, we investigate the thermal conductivity modification of the carbon fiber/asphalt and graphite/asphalt composites. We find that the effective thermal conductivity enhancement of the carbon fiber/asphalt composites is greater than the graphite/asphalt composites with the same additive volume fraction. Based on the generalized EMT, we theoretically elucidate the effective thermal and electrical conductivity of carbon fiber/asphalt and graphite/asphalt composites. Our theoretical results are found to be in reasonably good agreement with the experimental data. A particular point is that our model can describe the value of the percolation threshold for the electrical transport process in conductive asphalt composites. Moreover, we predict that the disc-shaped conductive particles can give a great thermal conductivity enhancement.

[1]Alvarez A E, Ovalles E, Caro S. Assessment of the effect of mineral filler on asphalt-aggregate interfaces based on thermodynamic properties [J].ConstructionBuildingMaterials, 2012,28(1): 599-606.

[2]Liu X, Wu S. Study on the graphite and carbon fiber modified asphalt concrete [J].ConstructionBuildingMaterials, 2011,25(4): 1807-1811.

[3]Alvarez A E,Fernandez E M,Martin A E, et al. Comparison of permeable friction course mixtures fabricated using asphalt rubber and performance-grade asphalt binders [J].ConstructionBuildingMaterials, 2012,28(1): 427-436.

[4]Al Hadidy A I, Tan Y Q. The effect of SBS on asphalt and SMA mixture properties [J].JournalofMaterialsinCivilEngineering, 2011,23(2):504.

[5]You Z, Mills B J, Foley J M, et al. Nanoclay-modified asphalt materials: preparation and characterization [J].ConstructionBuildingMaterials, 2011,25(2):1072-1078.

[6]Jahromi S G, Khodaii A. Effects of nanoclay on rheological properties of bitumen binder [J].ConstructionBuildingMaterials, 2009,23(8):2894-2904.

[7]Arabani M, Hamedi G H. Using the surface free energy method to evaluate the effects of polymeric aggregate treatment on moisture damage in hot-mix asphalt [J].JournalofMaterialsinCivilEngineering, 2011,23(6):802-812.

[8]Demirdag S, Gunduz L. Strength properties of volcanic slag aggregate lightweight concrete for high performance masonry units [J].ConstructionBuildingMaterials, 2008,22(3):135-142.

[9]Liu X M, Wu S P, Ye Q S, et al. Properties evaluation of asphalt-based composites with graphite and mine powders [J].ConstructionBuildingMaterials, 2008,22(3):121-126.

[10]Wu S P, Mo L T, Shui Z H, et al. Investigation of the conductivity of asphalt concrete containing conductive fillers [J].Carbon, 2005,43(7):1358-1363.

[11]Wu S P, Mo L T, Shui Z H. An improvement in electrical properties of asphalt concrete [J].JournalofWuhanUniversityTechnology:MaterialsScienceEdition, 2002,17(4): 69-72.

[12]Wu S P, Mo L T, Shui Z H. Preparation of electrically conductive asphalt concrete [J].JournalofWuhanUniversityTechnology:TransportationandEngineeringEdition, 2002,26(5): 566-569.

[13]Bruggeman D A G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen [J].AnnalsofPhysics, 1935,24(4):636-679.

[14]Choy T C.Effectivemediumtheory:principlesandapplications[M]. New York: Oxford University Press, 1999.

[15]Nan C W, Liu G, Lin Y H, et al. Interface effect on thermal conductivity of carbon nanotube composites [J].AppliedPhysicsLetter, 2004,85(3):3549-3551.

[16]Yu W, Choi S U S, The role of interfacial layers in the enhance thermal conductivity of nanofluids: a renovated Maxell model [J].JournalofNanoparticleResearch, 2004,6(1):355-361.

[17]Shenogina N, Shenogin S, Xue L, et al. On the lack of thermal percolation in carbon nanotube composites [J].AppliedPhysicsLetter, 2005,87(3):133106-133108.

[18]Li Y K, Wang Y, Electromagnetic interfering shielding of aluminum alloy [J].JournaloftheChineseCeramicsSociety, 2002,30(1): 664-667.

[19]Wen S H, Chung D D L. Effects of carbon black on the thermal mechanical and electrical properties of pitch-matrix composites [J].Carbon, 2004,42(6): 2393-2397.

[20]Lin C G, Chung D D L. Graphite nanoplatelet pastes vs. carbon black pastes as thermal interface materials [J].Carbon, 2009,47(6): 295-305.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Uplink capacity analysis of single-user SA-MIMO system

- A broad-band sub-harmonic mixer for W-band applications

- Feature combination via importance-inhibition analysis

- Transmission cable fault detector based on waveform reconstruction

- Force measurement between mica surfaces in electrolyte solutions

- Flexural behaviors of double-reinforced ECC beams