Properties of tungsten coating deposited onto copper under atmospheric plasma spraying†

2011-11-26LIUYingWANGFanHUANGJianjunJIANGShishouWANGXishengQIBingandGAOLiang

LIU Ying,WANG Fan,HUANG Jian-jun,JIANG Shi-shou,WANG Xi-sheng,QI Bing,and GAO Liang

1)College of Physics Science and Technology Shenzhen University Shenzhen 518060 P.R.China

2)Applied Low Temperature Plasma Laboratory,Shenzhen 518060 P.R.China

Tungsten(W)is an excellent candidate armour material for plasma facing components(PFCs)of nuclear fusion reactors because of its high physical sputtering threshold energy,high melting point(3 420 ℃),low vapor pressure(1.3×10-7Pa at Tmelt)and good thermalconductivity (180 W/mK)[1-3].However,the high elastic modulus,high brittleness and thermal expansion mismatch with other metals,in particular copper(Cu)alloys(aCu≈4aW),make the joining of W to heat sink metals extremely challenging[4-5].Among all the methods able to realize W armours,atmospheric plasma spray(APS)looks particularly attractive owing to its simplicity and low cost[6].However,APS coatings have also some drawbacks such as higher impurity content,intrinsic porosity and lower physical and mechanical properties[7-8].In order to avoid the adverse effects of APS,some researchers have carried out studies in vacuum or low pressure called vacuum plasma spray(VPS)and controlled atmosphere plasma spray(CAPS).Despite the relatively desirable results obtained,the complexity and cost of operations increased dramatically[9-10].

In this paper,tungsten coatings were fabricated on copper by means of APS and high-speed atmospheric plasma spray(HAPS)techniques.The test results of porosity,oxygen content,and bonding strength of tungsten coating show that the performance of HAPS-W coating is better than that of the APS-W coating and is close to that of VPS-W[10-14].Nevertheless,its low cost and operation convenience are very considerable,and it is a very practical and feasible method to get high-quality tungsten coating.

1 Experimental procedures

Commercially available tungsten powder with a median size of 6 μm(Fig 1)was plasma-sprayed onto a copper substrate(Φ 50 mm ×5 mm)by APS and HAPS technique respectively.The HAPS technique uses an SG-100 spray gun(Praxiar,USA)with MachⅡ hardware.This MachⅡ plasma spray gun adopts a de Laval nozzle design,which can accelerate a hot,pressurized gas passing through it to a supersonic speed(twice the speed of sound).This process can accelerate the tungsten powders to a higher velocity,reduces the flight time of the tungsten powder in the air,and greatly reduces the possibility of the oxidation of tungsten.In addition,the particles have a greater kinetic energy impinged on the substrate,making it more likely to obtain a dense coating.

A six-axis industrial robot(IRB 2400,ABB,Sweden)controlling the spray gun moved in x and y directions.Argon and hydrogen were used as plasma gas.Before deposition process,the pretreatment of the Cu substrate,including grit blasting and ultrasonic cleaning,was made in order to strengthen the adhesion of the coating with the substrate.Table 1 shows the deposition parameters.During the plasma spraying,water cooling to the substrate was adopted in order to avoid coating detachment from the substrate.After the deposition,the samples were cross-sectioned and polished for microstructure analysis.

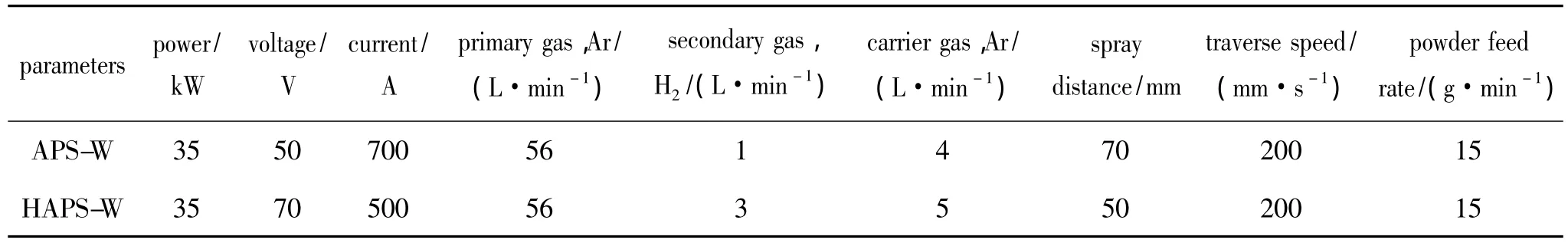

Table 1 Plasma spraying parameters表1 等离子喷涂参数

A scanning electron microscopy(SEM;S4700,Hitachi,Japan)was used to characterize the microstructure of the coatings,and porosity was measured by means of mercury porosimeter instrument(AutoPore 9500,USA).The oxygen content of the coating was detected by EDS(EDAX,USA),and the bonding strength was tested by Adhesion Tester(PosiTest AT,USA).

2 Result and discussion

2.1 Microstructure

Fig 2 shows the cross-section morphologies of APS-W and HAPS-W sample.

Generally,a dense and layered distribution deposit was observed.As shown in Fig 2,the pores are small in size(less than 1 ~2 μm),and they are mainly scattered in the vicinity of the coating's lamellar layers.Most of the sprayed tungsten particles were completely melted and deposited,but a few unmelted powders remain.Since the powder particle size is inconsistent(Fig 1 shows a wide size distribution of the tungsten powder)and it is hard to feed all the powders into the core area of the plasma flame,these unmelted powders may be peeled off in the cutting,grinding and polishing process,resulting in holes.Several holes found in Fig 2 may have arisen from this.

2.2 Tungsten oxidation

Fig 3 shows the phase constituents of the APS-W,HAPS-W coatings and tungsten powder before spraying.Diffraction peaks of tungsten oxide were not obvious in the XRD patterns.

The oxygen contents measured by means of EDS are shown in Fig 4.The mass fraction of oxygen content in the coatings were about w(O)=1.25%,w(O)=0.41%respectively,corresponding to the APS-W and HAPS-W.

Overall,the oxygen contents are smaller.The oxygen content of the HAPS-W is closed to w(O)=0.35%that of the VPSW coating which was reported by CHONG,etc[11].It seems that only very few tungsten particles have been oxidized in the highspeed atmospheric plasma spraying process.The HAPS-W technique is able to reduce the oxidation of tungsten mainly due to the high velocities of the powder particles and the rapid solidification of the droplets.There is not enough resident time for the formation of tungsten oxide.

Fig.2 Cross-section morphologies of APS-W and HAPS-W图2 APS钨涂层和HAPS钨涂层的截面形貌

Fig.3 XRD patterns of APS-W,HAPS-W coatings and tungsten powder图3 APS钨涂层、HAPS钨涂层和钨粉的XRD图谱

2.3 Mechanical properties

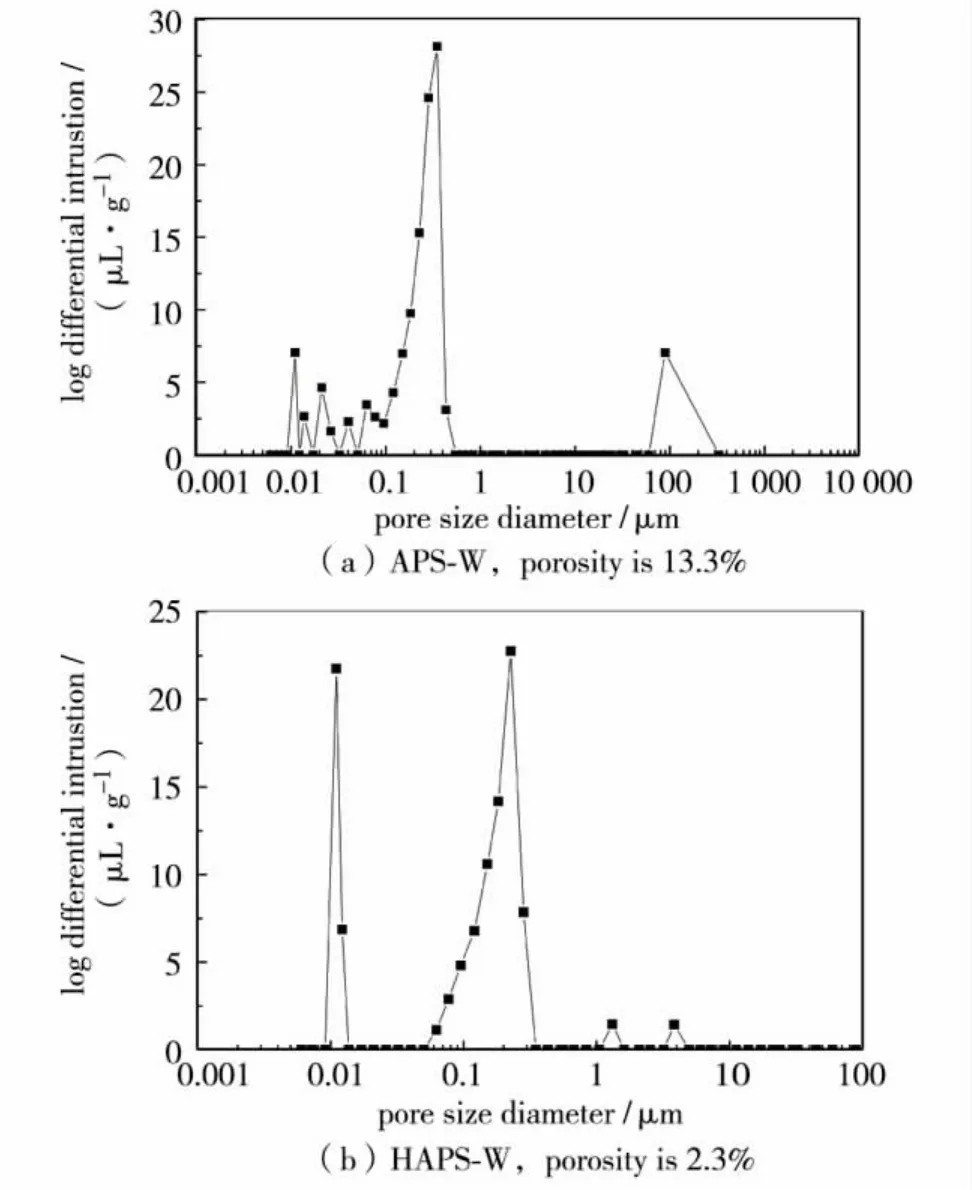

Fig 5 shows their distributions of pore diameter and the porosity,which were measured by means of a mercury porosimeter at RT.The porosity of HAPS-W is 2.3%,and the porosity of APS-W is 13.3%.The former has the narrow pore size distribution of 0.01 ~0.4 μm and has fewer pores that are greater than 1 μm.However,the latter is so different,it has much more pores at a size greater than 80 μm except the pores with the of 0.01 ~ 1 μm,which was also the main reason why APS-W coating had more porosity than the HAPS-W coating.

The bonding strength tests of the coatings reveal that the bonding strengths of the APS-W and HAPS-W coatings are almost equally close to 15 MPa.They exhibited a slightly poor adhesion in comparison with the reported result of the VPS-W coating which was about 22 ~40 MPa[10-14].In theory,HAPS-W should be able to get a better coating adhesion because of the faster flight speed of particles.However,the result show this is not the case.The main reason that the tungsten powder particle size is too small,and the small particles have lower kinetic energy and higher residual stress which decrease the bond strength.

Fig.4 The oxygen contents of the APS-W and HAPS-W coatings图4 APS钨涂层和HAPS钨涂层的氧含量

Fig.5 The distribution of pore diameter and the porosity图5 孔径分布和孔隙率

3 Conclusions

Tungsten coatings have been deposited on the copper substrate via APS and HAPS techniques.The HAPS-W coating shows a better performance than that of the APS-W coating and exhibits a good microstructure and relatively low oxygen content even compared with that of VPS-W.The high-speed atmospheric plasma spray technique can accelerate the tungsten powders to a higher velocity.Coupled with the rapid solidification of the droplets after impinged the substrate,the HAPS-W technique greatly reduces the possibility of the oxidation of tungsten.In addition,under the same conditions,a higher particle velocity corresponds to a greater kinetic energy,and is,therefore,more likely to obtain a dense coating.Compared with the complexity and cost of the VPS-W technique,HAPS-W provides a convenient and low cost alternative to getting a good-quality coating,and it has great feasibility and practicality in the engineer ing fields.

† This work was supported by the Development of Excellent Youth Creative Talents of Guangdong Colleges and Universities(LYM09119).

[1] Smid I,Akiba M,Vieider G,et al.Development of tungsten armor and bonding to copper for plasma-inter-active components [J].Journal of Nuclear Materials,1998,258:160-172.

[2] Federici G,Skinner C H,Brooks J N,et al.Plasmamaterial interactions in current tokamaks and their implications for next step fusion reactors[J].Nuclear Fusion,2001,41(14):1967-2137.

[3] Yoshida N.Review of recent works in development and evaluation of high-Z plasma facing materials[J].Journal of Nuclear Materials,1999,266:197-206.

[4] Tokunaga K,Yoshida N,Kubota Y,et al.High heat flux test of actively cooled tungsten-coated carbon divertor mock-ups[J].Fusion Engineering and Design,2000,49:371-376.

[5] Davis J W,Slattery K T,Driemeyer D E,et al.Use of tungsten coating on iter plasma facing components[J].Journal of Nuclear Materials,1996,233:604-608.

[6] Merola M,Akiba M,Barabash V,et al.Overview on fabrication and joining of plasma facing and high heat flux materials for ITER [J].Journal of Nuclear Materials,2002,307:1524-1532.

[7] Riccardi B,Montanari R,Casadei M,et al.Optimisation and characterisation of tungsten thick coatings on copper based alloy substrates[J].Journal of Nuclear Materials,2006,352:29-35.

[8] KANG Hyun-Ki.Thermal properties of plasma-sprayed tungsten deposits [J].Journal of Nuclear Materials,2004,335(1):1-4.

[9] Döring J-E,Vaßen R,Pintsuk G,et al.The processing ofvacuum plasma-sprayed tungsten-copper composite coatings for high heat flux components[J].Fusion Engineering and Design,2003,66-68:259-263.

[10] WANG T G,CHEN J L,CHEN Y,et al.Thermal properties of VPS-W coatings on CuCrZr alloy with Ti bonding layer[J].Journal of Nuclear Materials,2007,363:1294-1298.

[11] CHONG F L,CHEN J L,LI J G,et al.Heat load behaviors of plasma sprayed tungsten coatings on copper alloys with different compliant layers[J].Journal of Nuclear Materials,2008,375(2):213-217.

[12] LIU Xiang,ZHANG Fu,TAO Shun-yan,et al.Research and development of plasma sprayed tungsten coating on graphite and copper substrates[J].Journal of Nuclear Materials,2007,363:1299-1303.

[13] Yahiro Y,Mitsuhara M,Tokunakga K,et al.Characterization of thick plasma spray tungsten coating on ferritic/martensitic steel F82H for high heat flux armor[J].Journal of Nuclear Materials,2009,386:784-788.

[14] NIU Ya-ran,ZHENG Xue-bin,JI Heng,et al.Microstructure and thermal property of tungsten coatings prepared by vacuum plasma spraying technology[J].Fusion Engineering and Design,2010,85(7/8/9):1521-1526.