克服建筑障碍的辅助用具的标准、费用承担及优惠:意大利政府为改善残障者融入社会而大力改造建筑障碍

2011-02-27ElisabettaTurinaCarloBelletti

Elisabetta Turina,Carlo Belletti

Disability because of a physical impairment is a permanent condition which completely involves the disabled person for the rest of his/her life and influences deeply his/her social life.

Though the subject of disability concerns all of us,because of the possibility of being disabled can happen to each and every one of us even if only temporarly,for example a broken arm or leg,or because of ageing.

Disabled people are different because of a physical impairment,but are people fully aware.Disability is not a synonymous of inferiority but indicates a social disadvantage that limits or prevents the individual of having a normal and autonomous life.

Integration of disabled people is a social task and can only happen if attendance to social life is made possible and not limited to ones'home,but creating interaction with the external world.

A way to grant this integration is to give free access to the constructed environment,also by eliminating all physical barriers that can have a profound psychological impact in disabled individuals since they represent obstacles to achive and fulfill fundamental daily activities.

Besides the adaptation of all public facilities,Government financial incentives represent a dirve to speed up the process of integration of people with physical impairment,to become an autonomous and an active part of society,with all the benefits for society itself.

The Italian Government has established various levels of incentives for the removal of architectural barriers in residential buildings and to improve accessibility.These incentives apply to all works including the installation of stairlifts and platform lifts,and consist in reduced VAT rates,tax credits and deductions,and money refund:

—Subsidized VAT rate,reduced to 4%(instead of conventional rate of 21%),it applies independently from the beneficiary(no need to be a disabled person).

—36%tax credit and deduction,applicable to all natural persons that implement any works aimed at the removal of archtectural barriers on residential buildings,including apratments buildings(no need to be a disabled person).The tax credit is calcualted on the total amount of the expenses and can be deduced from the an-nual income taxes,in equal quotas during a period of 10 years(5 years for people over 75 and 3 years for people over 80).

—19%tax credit and deduction calculated on the amount of the expenses for the purchase of lifting devices for people with impaired mobility,applicable only to people with recognized disability or to their family members holders of the parental authority.The tax credit can be deduced from the annual income taxes in one total quota and it is alternative to the 36%tax deduction.

—Money refund for the purchase of lifting devices to overcome architectural barriers such as stairlifts and platform lifts,including all necessary adaptations and works.The money refund is allocated as a percentage which is variable in decreasing steps(starting from 100%on expences up to 2,500.00 euro,down to 5%on expences from 12,900.00 to 51,000.00 euro),the refund is calculated on the amount of the total expenses that have to be previously authorised by the local authorities.The refund is issued only to people with recognized impaired mobility,because of disability or elderly individuals,or to their family members holders of the parental authority.The refund can be additional to the incentives issued as tax credits and reductions.

All these incentives have allowed people with disabilities to be able to afford all the necessary expences for the removal of architectural barriers.

Architectural Barriers—Stairlifts a way to make buildings and public facilities accessible to people with impaired mobility for a better social life

Autonomy of people with disabilities is granted when freedom of movement and freedom to access public and commercial facilities is achieved by:

External physical obstacles,usually constructions or environmental elements,are encountered during the course of everyday life.

For people with limited sensorial faculty or people with impaired mobility caused by a physical impairment or because of advanced age,these obstacles can represent a barrier and a limit to their autonomy.

These elements are usually called"architectural barriers"and can restrain,limit or cause difficulty to the mobility of people or to the fruition of services.

Architectural barriers are perceived by each individual with a level of intensity which is different according to the personal physical state,particularly if they are conditioned by a disability,whether temporary or permanent,or by advanced age.

An accessible,or barrier free element,is a site,building or facility,that can be approached,entered and used by physically impaired people.

Developed countries have been regulating design,construction and alteration or renovation of buildings by setting standards that provide all necessary requirements for an Accessible Design so that physically impaired people could have ready access to and use of buildings and public or commercial facilities to the maximum possible extent.

Italy has regulated building accessibility in the last 30 years with the national legislation DM 236 of 1989 which establishes all mandatory requirements for design,construction and alteration of buildings.All these requirements apply to all public and commercial facilities and newly designed or altered residential housing structures.It is important to specify that residential buildings with less than 4 storeys do not need to be accessible as long as they can be adapted,if and when necessary.

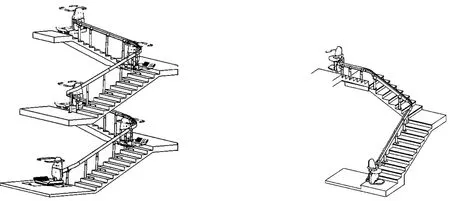

Wherever a barrier is represented by a stairway or by an inclined ramp with an over inclined slope,and where it is not possible to provide a vertical lifting apparatus between floors,such as a conventional lift or a platform-lift,or as an alternative to it,other lifting appliances such as stairlifts can be installed to overcome the difference between levels within a building.

"Stairlifts"are generally installed along the staircase or inclined ramp and do not need any modification or adaptation of the building structure since they are adapted by the manufacturer to the configuration of the site or staircase itself.They can be installed in short straight staircases or staircases serving different storeys made of several flights.

By not requiring any adaptation or construction works,stairlifts are cost effective and quickly installed and are especially suitable for all renovations of buildings.

The installation of a stairlift does not require any authorisation or licence by the local authorities since it does not change the structure of the building.

Stairlifts consist in a motorised carriage moving along a guide rail,straight or curved,that is installed directly on the stairs.The carriage can be fitted with a chair or with a platform.

The Chair Stairlift is an ideal means to carry a seated person along stairways,and it is usually destined to be used by elderly people or people with partial mobility impairment.

The Chair Stairlift is mainly suitable for private use in residential housing,where the dimensions of staircases are limited and generally too narrow to allow the installation of a platform stairlift.

The Platform Stairlift is installed in all situations,mainly in public places,where it is fundamental to grant accessibility to people with impaired mobility.

The Platform Stairlift is fitted with a platform suitable to carry a user with a wheelchair,and it should be designed with the maximum dimensions to grant access to all kind of wheelchairs.

Lifting Platforms for Persons with Reduced Mobility:Italian and European Situation

1 Technical and Legal Background

Lifting platforms are a system for lifting people in addition,or as an alternative,to lifts in the case of specific applications,such as in existing buildings,private houses or for the overcoming of architectural barriers.

In recent years there has been lively debate,now settled,on the legitimacy of lifting platforms and especially whether these should be regulated by the Machine Directive or by the Lift Directive and,consequently,on their safety requirements.

A brief summary of the chronological background is given below.

The European situation

During the 1980s lifting platforms were hand-crafted or manufactured by small companies,and in some cases they were even homemade,having a very limited market which did not draw much attention.They were mainly used in the Scandinavian countries and in Great Britain as home lifts.

At European level,they were the subject of legal provisions,since the 84/528/EEC Directive relating to lifting and mechanical handling appliances laid the bases for product certification through Notified Bodies(at the time the conformity mark was the letter stamped in a hexagon),and in some countries there were also specific technical standards(i.e.BS5900 and BS6440 in Great Britain).(The first part of the Directive number indicates the year it was issued,e.g.84/xxx indicates the year 1984).

Later the Machine Directive 89/392/EEC came into force(amended in 91/368/EEC,93/44/EEC and 93/68/EEC),which in the appendix IV part A16 included within its scope all the systems for lifting persons involving a risk of falling from a vertical height of more than 3 metres,and also confirming the exclusion from its own scope of lifts equipped,among other things,with a car.

A few years later the 95/16/EC Lift Directive adopted the same definition and added the car features(a container completely enclosed by a ceiling,fitted floor and full-length walls and accesses equipped with full-length doors).Therefore,the distinction between lift and machine was based on whether this was equipped with an enclosed car,on this basis either the Lift Directive or the Machine Directive was applied.

When the 98/37/EC version of the Machine Directive was published,which re-ordered the previous Machine Directive versions and obviously excluded lifts from its scope of application,the situation was ready for technical regulations guaranteeing the safety of lifting platforms.Therefore the European Committee for Standardisation set up a Working Group to assess whether the ISO9386-1 standard(at the time it was an FDIS—Final Draft of International Standard)fulfilled the Machine Directive and,if not,to draw up a technical standard.After a lengthy procedure,this standard became EN81-41,included in the Machine Directive(the standard was approved in January 2009 by the National European Standardisation Institutes and became a harmonised standard in April 2011—see the relevant chapter).Going back to the end of the 1990s,there was also a preliminary agreement,reached through the National Standardisation Institutes,which levelled out the different national positions and stated the maximum speed of platforms at 0.15 m/s.

After lengthy technical disagreements between platform and lift manufacturers on platform features(e.g.the maximum travel of 4 metres,or the various safety features),the resulting legal provision finally clarified the situation.In May 2006 the Machine Directive 2006/42/EC was issued,stating the difference between ma-chines and lifts is the speed(up to 0.15 m/s they are machines,beyond that threshold they are lifts),without imposing maximum lifting heights and without reference to the system features.The term"car"was replaced by the more general term"carrier adding the requirements that the"carrier of each lift must be a car",and the consequent reference to the said amendment of the Lift Directive 95/16/EC.

The new Machine Directive entered into force on 29th December 2009.

The situation in Italy

European Directives are obviously valid in Italy and enacted in Italy by adding the Italian administrative provisions to the technical details which are the same for all Europe.Furthermore,Italian laws overlapped over the time to the Directives.

Actually,in Italy the first market movements began at the end of the 1980s,more or less when Law 13 dated 9th January 1989,"Provisions for overcoming and removing architectural barriers in private buildings",was issued,as well as the relevant implementation decree,Min.Decree 236 dated 14th June 1989,detailing the technical features of stairlifts,but which skimmed swiftly over those of lifting platforms,perhaps also because of the preamble stating that the decree was applicable"until the issue of a specific standard",thus suggesting imminent evolution.This decree also states"height differences usually not exceeding 4 metres,with speed up to 0.1 m/s"and,just like for stairlifts,"hold-to-run"type controls.In Italy,at that time,there was a no man's land area regarding home lifts;Decree 587 dated 12th December 1987,for example,excluded from its scope"lifts installed for the use of a single family",which were still excluded from the standard UNI EN81-2 of 1989,and there was no indication of what reference standard had to be adopted(at that time,the so-called"old approach"was still in force,i.e.the technical standards EN81-1&2 for lifts were not optional but compulsory).

The following years passed without much change,with a small market only a couple of important Italian manufacturers.

The next important event was Italian Decree 459 dated 24th July 1996,i.e.,the Italian adoption of the Machine Directive 89/392/EEC and following amendments 91/368/EEC,93/44/EEC and 93/68/EEC,which became that"specific reference standard"for lifting platforms announced seven years before by Italian Decree 236/89.The explanatory Circular of Ministry of Industry no 157296/97 dated 14th April 1997 confirmed that lifting platforms should comply with Italian Decree 459,stating the administrative procedure for putting them into service,and that the safety components subject to declaration of conformity(but not subject to any type certification)were the devices for locking the doors,those against overspeed,lock valves,safety circuits with electronic components,safety gears and the safety buffers(excluding spring type safety buffers).Furthermore,every system had to be provided with EC conformity declaration,issued by the manufacturer after positive testing of the installation,the owner had to entrust maintenance to a qualified technician according to the same criteria in use for lifts,and the system had to be inspected every two years by a Notified Body;systems travels less than 2 metres were exempted from administrative procedures.

The following Machine Directive 98/37/EC issued for clarification reasons,grouped the previous 4 editions without modifying them,but was never formally enacted in Italy.

Therefore the Italian Decree 459 dated 1996 was in force until February 2010 when the Italian Decree No.17 was issued,i.e.the Italian implementation of the Machine Directive 2006/42/EC.

On that occasion acceptance of the European directive took place with only the transposition of the European technical text,without adding neither the administrative rules nor the amendment to the Lift Directive;these were introduced with the Italian Decree 214 dated 5th October 2010,amending the Italian Decree 162 dated 1999,which was the Italian decree for the implementation of the Lift Directive 95/16/EC.In practical terms,the administrative and maintenance rules for machines aimed at lifting persons,with speeds up to 0.15 m/s,were standardised in line with those already in force for lifts.

Meantime,the lifting platform market in Italy developed up to reaching about 7,000 platforms sold per year,and with at least a dozen important manufacturers.

2 The European Rules

In Europe,the general rules stated by the Machine Directive 2006/42/EC are applied.

In practice:

1-The devices for lifting persons involving falling from a vertical height of 3 metres are included in appendix IV point A17.

2-For these devices,in the absence of a harmonised provision,the manufacturer must carry out a risk assessment to identify all those concerning the device.

3-The manufacturer must then design and construct the platform taking into account the risks assessment and,obviously,the health and safety essential requirements included in the Directive as a whole and specifically in paragraphs 4 and 6 of appendix I,respectively relevant to lifting,and to lifting persons.

4-Successively,the technical dossier(indicating all the solutions adopted for the prevention of risks)and a prototype of the platform must undergo the assessment of a Notified Body which,after positive verification,issues the EC certificate of the model according to appendix VI.

5-The product can then be placed on the market.

6-On completion of every installation,the manufacturer must carry out the final tests and,if the result is positive,must draw up the declaration of conformity according to appendix IIA and can then apply the ECmark.

7-The lifting platforms with a travel less than 3 metres are exempt from the provisions of point 4.

In addition to these general rules,which are applicable in all cases,each country can establish its own national administrative rules;for example,it can establish in which cases a machine can be installed,in which cases a lift must be installed,which is the competent authority for the market surveillance,whether periodic maintenance is compulsory,and if so which subjects are qualified to carry out such maintenance,etc.

3 The Italian Rules

In Italy,since the end of 2010,the Decree 17/2010 has been applied;this contains the same technical rules and standards defined in the Machine Directive and in the Decree 214/2010,which defines the administrative aspects.

Points from 1 to 7 listed in the previous chapter remain valid(which are the rules of the Directive);in addition:after a communication to the Mayor documenting the maintenance mandate conferred on a qualified company and the acceptance by an Italian Notified Body for the periodic inspections and testing,the owner is automatically granted an operation licence.This information must be affixed in the platform carrier.

The operation licence is automatically renewed every two years,upon positive result of the periodical inspection by the Notified Body.

10-The lifting platforms with travel less than 2 metres are exempt from the provisions of points 8 and 9.

The provision of Decree 236 of 1989 also remains in force,limiting the possibility of the installation of a platform to existing buildings or to new buildings with no more than three levels;for new buildings with four or more levels,a lift must be installed.

4 The Scenario Opened by the Machine Directive 2006/42/EC

As mentioned above,in 2006 the new version of the Machine Directive 2006/42/EC was issued,entering into force on 29th December 2009.It has introduced specific amendments for platforms,also taking advantage of the above-mentioned discussions on the product and the development of the harmonised standard EN81-41.

The new Machine Directive states

· the speed of 0.15 m/s as the only discriminating element between lifts and machines(up to 0.15 m/s they are machines,if the speed exceeds this limit they are lifts).

Other essential safety requirements have been added for equipment for lifting persons,requiring:

· stopping accuracy

· safety spaces for the maintenance personnel above/below the carrier

· protection for persons outside the platform

· excess speed control.

Consequently,the distinction established only on the basis of the speed and not on the basis of the features of the carrier allows for the manufacturing of lifting platforms with an enclosed car and doors,and it is therefore possible to provide the device with automatic controls for movement and no longer with hold-to-run type controls.

5 THE HARMONISED STANDARD EN81-41

After about ten years of study(a couple of years spent on assessing more than 800 comments received in the public inquiry phase,and compliance with the requirements of the Directive 2006/42/EC which had been issued in the meantime),the standard was approved in January 2009 by vote of the National European Standardisation Institutes.

The procedure to become a harmonised standard was stopped immediately afterwards,due to the opposition of the German DIN Institute,which disagreed with some important points.After the failure of the conciliation attempts between the parties,in June 2010 the European Committee for Standardisation organised a new vote,which ruled that the standard had to be reviewed before its publication.However,because of the"fundamental disagreement"by Italy,France,Sweden and the United Kingdom,on the change introduced by the new vote,the European Standardisation Committee rejected the DIN opposition and decided in favour of the publication of the provision in its original version.

With the publication in the Official Journal of the European Community,the standard EN81-41 became"harmonised according to Directive 2006/42/EC"in April 2011.This means that the construction of a platform with full conformity to the standard EN81-41 automatically satisfies all the requirements prescribed by the Machine Directive 2006/42/EC,and it is no longer necessary to carry out a specific risk assessment procedure or certification of the model through a Notified Body(see points 2,3 and 4 of chapter 2).

Of course,the product must fall within the limits of the field of application indicated in the standard itself,which are stricter than those allowed by the Directive in as much as conceived successively.In practical terms,this simplified procedure can be used only in the cases of an open type carrier installed in an enclosed well and with hold-to-run type controls.

6 The Product and Its Technical Features

Let us now consider technical and safety details.

One feature common to all platforms,necessary to satisfy the requirements of the current Machine Directive 2006/42/EC(in force since December 2009),is that the carrier can be either of the open type,i.e.,without a significant element such as the door,the ceiling,or one or more walls,or of the enclosed type.

Another common feature,in the case of the open carrier,is the hold-to-run type controls which,together with the reduced speed,the safety elements at the entrance and on the open sides(if activated,these elements interrupt the electrical operation and stop all movements)and with the STOPbutton,protect passengers from the consequences of contact with the well.In fact,the absence of one or more walls on the carrier implies that either there is no well on that side(and a protection against falls from the carrier is therefore necessary,the type of protection depending on the lifting height),or the well wall must be perfectly smooth,hard and continuous and at a controlled distance(normally 15~20 mm)so as to avoid the possibility of anything remaining caught between the carrier and the well.

However,if the carrier is entirely enclosed(therefore also provided with car doors),controls may be of the automatic type,i.e.,not hold-to-run control type.

For all the other aspects,there are great differences between the products of the various manufacturers,with the development of widely varying solutions.

One of the main differences in the lifting platform features involves the lifting height.

For travels of up to 2 metres,almost all devices have an open platform moving in an open space,i.e.,without fixed walls surrounding the movement and enclosing occupied spaces.Users are protected against falling from the platform by liftgates,usually 1.1 m high.The traditional dimensions of the platform are 800×1200 mm(the minimum required by Italian Decree 236/89).The movement between the two stops is obtained by means of a single or double scissor-type pantograph,according to the length of the travel.The pantograph is operated upwards by a hydraulic piston,and lowered by the force of gravity thanks to the electro-valve which releases the piston.The speed is usually 0.05~0.10 m/s.Under the platform a folding protection encloses space and prevents access to the area under the platform.The platform is equipped with a gate which travels up and down with the platform and which gives access to the lower level.The gate faces onto a fixed wall of the well while the basket rises,until it coincides with the position of a door at the top of the well wall,giving access to the upper floor.The movement can be controlled from landings and from the platform by a hold-to-run type control

With a travel higher than 2 metres,the platform must travel inside a closed well,in order to fully isolate it from the surrounding environment and there is no risk of fall from the platform or crash against persons passing by.

The platform load is usually about 250~350 kilos,with a speed of up to 0.15 m/s.They are connected to a single-phase 230 V power line and require an installed power of about 1.5~2.5 kW which,in the case of the engaged power lower than 1.5 kW,is compatible with a standard home electricity supply.

The carrier may be without a door,and sometimes without one or more walls and ceiling.The dimensions are up to 1,100×1,400 mm,suitable for a motorised wheelchair;however,smaller platforms are very common,even 600×600 mm,in order to satisfy the installation requirements in the limited spaces of existing buildings.

A 100~150 mm pit or an access ramp is required if the structure is installed on top of a finished floor,and an headroom of about 2.5 m is required above.Extreme positions are protected with limit switches.Maintenance operations to be carried out in the pit or in the well are usually very limited and the safety space for the maintenance operator is obtained by mobile struts inserted when accessing the work area.

Landing doors are wing type,also with automatic powered movement and include the call pushbutton panel.Door locks are certified according to the harmonised standard EN81-1/2 applicable to lifts.After the enforcement of the Machine Directive 2006/42/EC,models equipped with automatic sliding doors were introduced,fully enclosing the car and allowing for the use of automatic operations.The car can be also enclosed by folding doors.In the case of an open car,or a car without doors,controls for upward and downward movements are always hold-to-run type.To call the platform from landings or for a person to move on the platform,the button of the desired floor must be pressed and hold pressed.The platform moves while the button is pressed,and stops within a few millimetres when released;the platform automatically stops when reaching the selected floor,guaranteeing a difference in the level of no more than a few millimetres.Obviously,platform controls have priority over the landing controls.

The platform is also provided with emergency stop and alarm buttons.Usually a system allowing for a controlled travel onboard is available,also in the case of a power failure.

The most common drive systems are worm screw and nut type(mainly used in North Europe and Scandinavia)and hydraulic(i.e.hydraulic using fluid,above all in South Europe and especially in Italy).Electrical systems are also being developed,with or without gear and with or without counterweight.In the latter case,the ropes are wound around a drum,and this solution is usually applicable for loads up to 250 kg.

In Italy the carrier is usually with a ceiling and all the walls except where access is given to the landing.This simplifies installation in a masonry well,since only this wall must be finished in order to assure a constant distance of 15~20 mm.There are many cases of metal shaft structures,also in aluminium,both inside and outside buildings.

Many applications also include a car door.

In the case of hydraulic drive,the hydraulic power unit controls a piston positioned to the side of the platform;a 2∶1 roping is used for travels of about 12 m,and a direct telescopic piston for smaller travels.In the case of roping systems,suspension is with ropes or chains,and the piston operates either by compression or traction.

The control panel is embedded in the hydraulic drive,in a single cabinet.

The noise operation is low,normally 50~55 dBA,and even less during descent which is achieved by the force of gravity thanks to the electro-valve which discharges the oil of the power unit.

Protection against excess speed during descent is guaranteed by two traditional systems:a lock valve on the cylinder and safety gear controlled for to loosen the suspension ropes/chains,with an electrical safety switch.

The platforms are also equipped with the traditional safety devices of hydraulic systems,such as overload pressure switches,overpressure valves,minimum pressure valves,electrical re-levelling during ascent and descent,a hand pump for emergency upward travel,and a button for emergency manual descent.

In the case of electric drive,the machine is positioned in the well,in the pit or in the headroom,thus resulting in a traditional machine-roomless solution.

7 THE SOCIAL AND ECONOMIC VALUE

Why use elevator platforms?

In an aging society,freedom of movement at home is,and will increasingly be,felt as a primary need;it is therefore necessary to offer everyone,especially those who have ambulation problems(the old and the disabled),a means of vertical transport which is safe and economic,and which can be installed into existing and new buildings.

In many single-family homes,the problem of vertical transport cannot be solved by a standard lift for various reasons:space,cost,installation,energy consumption,running costs.The solution offered today is that of lifting platforms:a safe solution,with low costs and reduced energy consumption,which can improve the quality of life and overcome architectural barriers(i.e.stairs).

Lifting platforms have been developed precisely with this need in mind and considering the relative restrictions:fast installation,requiring little space,usually suitable for existing buildings,limited speed,minimum power required,special accessories,maximum safety and reliability of the product and low cost.

Furthermore,there are no contraindications or overlapping in respect of existing lifts:the limit is of a practical nature,not relative to safety;the speed of 0.15 m/s is too low for the heavy use of a large building.

The risk assessments criteria and the requirements of the Machine Directive are carefully applied in the design and construction of the platforms;the product has been certified to guarantee the safety of users and of installation and maintenance workers.

The result is lifting platform which is easy to install,inexpensive,and which guarantees maximum safety.

ITALIAN SITUATION CONCERNING REIMBURSEMENT AND DEDUCTIONS IN FAVOUR OF LIFTING PLATFORM BUYERS

For the customer,the purchase of lifting platform allows for the possibility of a series of reimbursements and tax deductions,listed below:

1)Deduction of 36%of the total expense from income tax,pursuant to Italian Law 449/97.The sum can be recovered in the ways contemplated by the Law depending on the age of the owner of the building:

for owners of more than 80 years old,over a period of 3 years;

for owners of less than 80 years but more than 70 years old,over a period of 5 years;

for owners of less than 70 years old,over a period of 10 years.Alternatively:

2)19%of the total expense can be deducted from income tax pursuant to art.13-bis of the Consolidated Income Tax Act,for"expenses necessary for the ambulation,locomotion and lifting of persons afflicted with permanent functional deficiencies with reduced or impeded motor capacities".The necessary condition is invalidity.

In addition to the above,Law 13/89 also allows the possibility of access to a contribution which does not have to be paid back.

The conditions indicated under point 1)and point 2)are alternative to each other.

The special contribution indicated in point 3)can be granted as well as the tax deduction of either point 1)or point 2),if the customer is eligible according to the various provisions of law.