飞机除冰液对高性能混凝土抗冻性的影响

2010-05-05麻海燕1曹文涛3康4鹏5韩丽娟6

麻海燕1, 2 曹文涛3 白 康4 周 鹏5 韩丽娟6

( 1.南京航空航天大学航空宇航学院,南京, 210016,中国; 2.解放军理工大学工程兵学院,南京, 210007,中国;3.江苏省交通科学研究院股份有限公司道桥规划设计二所, 南京, 211112,中国;4.江苏省交通科学研究院股份有限公司道路工程研究所,南京, 211112,中国;5.南京市长安建筑规划设计有限公司结构室,南京, 210002,中国;6.抚顺市规划设计研究院道路交通室,抚顺, 113100,中国)

INTRODUCTION

Before air plane takes off,ice covered on the airfield pavement and on the air plane must all be removed.Main composition ofthe commonly used airfield pavement dicer is ethylene glycol or propylene glycol. According to the report of British Transport Research Laboratory[1], for concrete exposed to air plane dicer,of which the main composition was ethylene glycol,surface scaling and degradation of specimens were observed after just 50 freeze-thaw cycles.Ref.[2]drilled core samples from the apron of an airport in Northeast China,and investigated the freeze-thaw durability of those samples by slow freeze-thaw test exposed to aircraft deicer.The results showed that when the samples undergo 270 freeze-thaw cycles, severercrackswere developed,and the compressive strength was reduced by 20.6%. According to the investigation of Ref.[3],ethylene and propylene glycol are the most frequently used deicer in Airports of USA.Scaling and spalling of the concrete pavements in Springs Airport and Denver International Airport are studied.Surveys of civil airports[1,4-5]in Northeast China,North China and Northwest China have also revealed that surface scaling of apron cement concrete was directly related to the presence of aircraft dicer.This paper investigates the durability of civil airport pavement in North China.It is revealed that different degrees of spalling occur for apron surface exposed to aircraft deicer in Airports of Beijing,Shenyang,Harbin,Changchun and Xi′an,and the situation is especially serious in Changchun Airportand the No.2 terminal building of the Capital Airport,as shown in Fig.1.Researchers in USA and Canada are currently focusing on the impact of propylene glycol on airfield infrastructures[6-8], while research on freeze-thaw durability of concrete exposed to aircraft deicer is rather limit in China,and little literatures[3,9-10]are available.Ref.[11]revealed thatforordinary Portland concrete (OPC)exposed to 3.5% ethylene glycol solution,the deterioration is similar to that of OPC exposed to 3.5% NaCl solution,of which the main character is denudation.The paper investigates the freezethaw durability of HPC exposed to aircraft deicer.

Fig.1 Deterioration of apron surface in North China after using aircraft deicer

1 EXPERIMENT

1.1 Raw materials

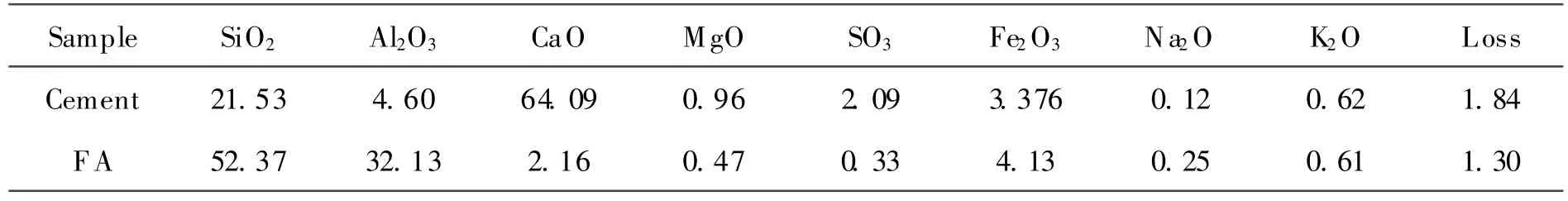

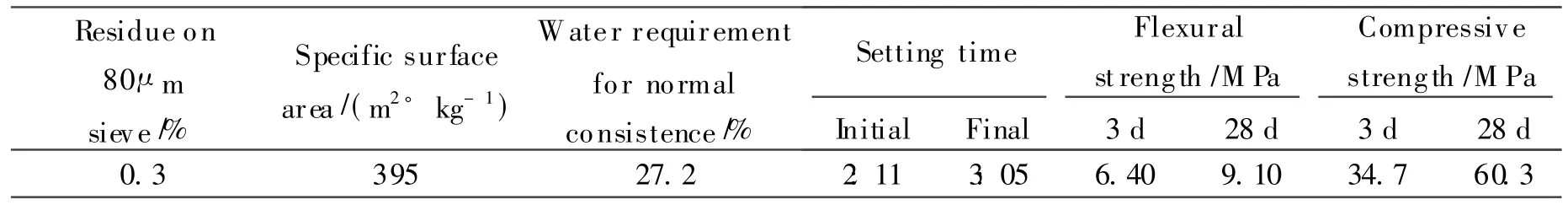

The cement used in the paper is P.II 52.5R Portland cement,the chemical compositions and the physical and mechanical properties are given in Tables 1,2, respectively. The mineral compositions of cement are:C3S∶55.5%,C2S∶19.9%,C3A∶6.6%,C4AF∶10.2%.The fly ash(FA)used is grade I FA from Zhenjiang.The fineness is 6.8%,water content is 0.04%,its loss on ignition is 2.04%,water demand ratio is 93%,and SO3content is 1.22%.The chemical compositions of FA are given in Table 1.Fine aggregate used is natural river sand with fineness modulus of 2.72.Its apparent density and bulk density are 2 500 kg/m3and 1 615 kg/m3,respectively.The mud content is 1.0%.Coarse aggregate is continuous grade crushed basalt aggregate with 5— 10 mm.Its apparent density,bulk density and mud content are 2 820 kg/m3,1 435 kg/m3,and 0.3%,respectively.The ratio of flat and elongated particles is 11.4% and the crushing index is 6%.High-ranger water reducer(HRWR)is naphthalene type superplasticizer powder with water-reducing percent above 20%,in which alkali content is below 2% and Clcontent is below 0.01%.Air-entrained agent is JM-2000c from Jiangsu Research Institute of Building Science Co., Ltd., and the recommended dosage is 0.005%—0.01%.The mixture water is tap water.

Table1 Chemical composition of Portland cement and fly ash %(in weight)

Table2 Physical and mechanical properties of Portland cement

1.2 Mixture proportions

According to the technical requirements of airfield pavement concrete, strength grade of HPC samples is C50.Cement content is 384 kg/m3.FA contentis 96 kg/m3, the mix proportion is 1∶2.08∶3.42.Water-cementitious materials ratio is 0.32.Dosage of HRWR and airentrained agent is 0.65% and 0.008%,respectively.The measured slump is 160 mm.Air content is 5.2%.After 28 d standard curing,the compressive strength and flexural strength are 58.4 and 4.75 MPa,respectively.

1.3 Preparation and cure of sample

The cement,sand and coarse aggregate are mixed firstly for 1 min in a blender,then water is added and mixed for another2 min. Before casting,the slump and air content of mixtures are measured.Afterwards,concrete prisms with size of 40 mm× 40 mm×160 mm are prepared and cured under the sealed condition for 24 h.Then,they are demoulded and moved into a standard chamber with(20± 3)°C and 95% RH,and cured till 150 d.At the time,the freeze-thaw tests begin,the tested compressive strength is 88.6 MPa and the flexural strength is 7.11 MPa.

1.4 Freeze-thaw test

CDR-2 type freeze-thaw apparatus for concrete is employed.The cycling rule of freezethaw obeys Chinese Standard GB/T50082-2009,similar to ASTM C666.Four kinds of solutions,i.e.,tap water,NaCl solution,glycol solution,and a LBR-A type commercial aircraft deicer are employed as the freeze-thaw medium. The commercial aircraft deicer is diluted to simulate the practical situations,and the content is 25%.Three concentrations of glycol solution are included,which are 3.5%,12.5% and 25% in mass. According to GB/T50082-2009,if its relative dynamic modulus drops to below 60%,or its mass loss exceeds 5.0%,the specimen is regarded as failure,and the determination method of relative dynamic modulus and mass loss is explained in Refs.[12-13].At the moment,the numberoffreeze-thaw cycles isregarded as maximum freeze-thaw cycles,or the end of its service life.The mass and the relative dynamic elastic modulus of the specimens are determined by electronic balance and NM-4B type nonmetallic ultrasonic detector,respectively.

2 RESULTS AND DISCUSSION

2.1 Influence of types of freeze-thaw medium on HPC durability

Fig.2 gives the evolution of relative dynamic elastic modulus and mass loss of HPC specimens exposed to tap water,3.5% NaCl solution and 3.5% glycol solution.Results show that though HPC fails in all of the three solutions,the failure modes are different.The failure modes in 3.5%NaCl solution and 3.5% glycol solution are identical in thatthe relative dynamic elastic modulus evolution curves are similar forHPC exposed to these two solutions. The main difference between these two curves is the ultimate freeze-thaw cycles;the number is 525 and 475 for HPC exposed to 3.5% NaCl and 3.5% glycol solution,respectively.And since the freezing points of those two deicer solutions are both lowerthan water,the relative dynamic elastic modulus of HPC exposed to the abovementioned solutions is always higher than that exposed to water.The mass loss evolution curves are also parallel for HPC exposed to these two deicer solutions,except mass loss for HPC exposed to NaCl solution is faster.It is shown in Fig.2 that mass loss ofHPC exposed to tap water,3.5% NaCl and 3.5% glycol solution are initially identical,when freeze-thaw cycles reach 275 and 400,for NaCl and glycol solution,respectively,the mass loss of HPC exposed to deicer solutions begins to exceed that exposed to water.Conclusions can be drawn that though the freeze-thaw deterioration ofHPC exposed to 3.5% glycol solution is different from that exposed to tap water,it is similar to that exposed to 3.5% NaCl solution,and both are caused by surface denudation.Influence of aircraft deicer,of which the main ingredient is glycol solution,on the durability of concrete is similar to that of NaCl solution,and will accelerate the freeze-thaw degradation,only the degree is milder.

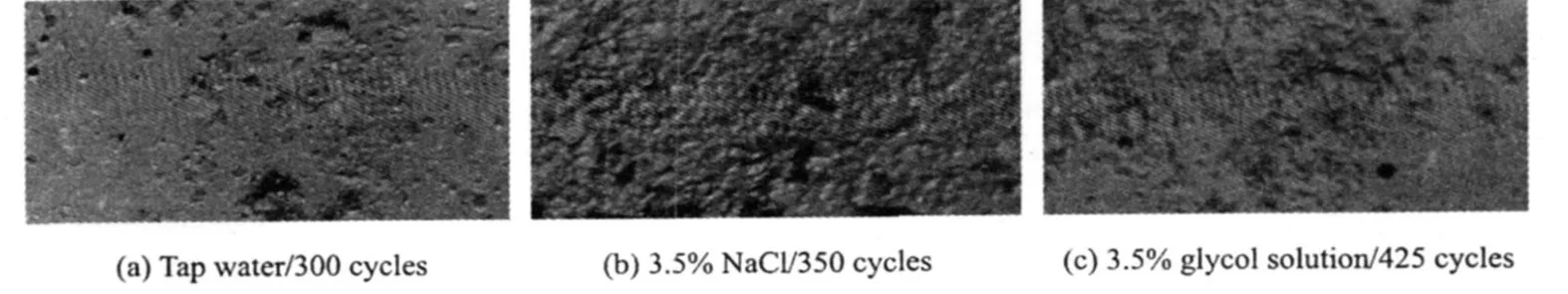

Fig.3 gives the photos of HPC samples that subjected to maximum freeze-thaw cycles.Integrating Figs.2,3,it is found that for the samples exposed to tap water,its relative dynamic modulus drops to below 53% after 300 freeze-thaw cycles,and the ultimate freez-thaw cycleis only 275.But when its maximum freezthaw cycle is reached,it shows minor surface deterioration,indicating that damage of those samples is resulted from the propagation of inner cracks.For samples exposed to 3.5%NaCl solution or 3.5% glycol solution,serious surface deterioration is observed, and the failure is dominated by surface denudation.When their masses lose reaches 5%,the relative dynamic elastic modulus remains above 90%.The maximum freeze-thaw cycles of samples exposed to 3.5% NaCl solution and 3.5% glycol solution are 350 and 400—425 cycles,and the remained relative dynamic elastic modulus are 81% and 77%, respectively. Surfacedenudation is responsible for the freeze-thaw failure for thesamples exposed to 3.5% NaCl solution and 3.5% glycol solution.Glycol is usually believed to be a kind of environmental friendly deicer,and do no harm to concrete.

Fig.2 Durability of HPC exposed to tap water,3.5%NaCl solution and3.5% glycol solution

Fig.3 Photos of HPC specimens subjected to freeze-thaw cycles

2.2 Influence ofglycolsolution on HPC durability

The evolution ofrelative dynamic elastic modulus and mass change of HPC exposed to glycol solutions with different concentrations are shown in Fig.4.It is demonstrated that higher concentration of glycol solution results in slower decrease of HPC dynamic elastic modulus and a higher dynamic elastic modulus. The ultimate freezing-thawing cycle of HPC exposed to 3.5%glycol solution is 400,which is 125 more than that of HPC exposed to tap water.When exposed to 12.5%and 25% glycol solution,no mass loss is observed till700 freeze-thaw cycles are completed and the relative dynamic elastic modulus remain higher than 80%.Therefore,the freeze-thaw damage of HPC exposed to glycol solution is closely related to the solution concentration.Higher concentration leads to a relatively less serious denudation,so the damage is practically postponed.The result indicates that in the practical usage,attention should be paid to the negative effects of diluted glycol solutions to HPC.

2.3 Influence of commercial aircraft deicer on HPC durability

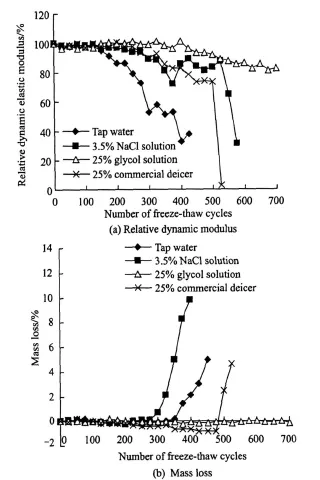

Fig.5 gives the evolution of relative dynamic elastic modulus and mass loss of HPC specimens exposed to 3.5%glycol solution and a 25% LBRA type commercial aircraft deicer,of which the main composition is propylene glycol. Results show that for HPC exposed to 25% LBR-A type commercial aircraft deicer,the relative dynamic elastic modulus shows an abrupt decrease when 500 freeze-thaw cycles are reached,and the corresponding mass loss is also significant.This hinge point is25cycles less than of HPC exposed to3.5% NaCl solution.While for HPC exposed to 25% glycol solution,the relative dynamic elastic modulus shows a much slower decrease,and no denudation is observed and the relative dynamic elastic modulus remains 83% even when 700 cycles are completed. This implies that commercial aircraft deicer illustrates much seriously freeze-thaw damage to HPC than glycol solution.Compared with HPC exposed to 3.5%NaClsolution, the hinge pointofseriously surface denudation occurred is postponed but the degradation of the relative dynamic elastic modulus is even more serious.This is due to the minor corrosion inhibitor in the commercial aircraft deicer.Results prove that commercial aircraft deicer is detrimental to HPC.

Fig.5 Durability of HPC exposed to commercial deicer and25% glycol solution

3 CONCLUSIONS

(1)Similar to the broadly studied NaCl deicer,commercial aircraft deicer,of which the main composition is glycol,is seriously harmful to the freeze-thaw durability of HPC,and the influence is depended on the solution concentration. Lower concentration of commercial aircraft deicer accelerates the freezethaw damage of HPC while higher concentration can mitigate the damage.

(2) Freeze-thaw deterioration of HPC exposed to glycol solution is closely related to the solution concentration. Higher concentration leads to less surface denudation and less damage.

(3)Freeze-thaw damage of HPC exposed to NaCl and glycol solution features surface denudation,and the ultimate freeze-thaw cycles are 350 and 400,respectively.

(4)Compared with glycol solution,the commercial aircraftdeicerdemonstrates much more negative effect to HPC freeze-thaw durability,and the degree even exceeds 3.5%NaCl solution.

[1] LancasterI E.Assessment of alternative deicing chemicals to rock salt[R].Project Report PR/H/11/93,1993.

[2] Zhao Xiaolong,Ba Hengjing.Damage mechanism of runway concrete in cold region[J].Journal of Harbin University of Civil Eenineering and Architecture,2002,35(5):81-83.(in Chinese)

[3] Rangaraju P R.Mitigation of ASR in presence of pavement deicing chemicals[R],IPRF-01-G-002-04-8,2007.

[4] Shi X.Impact of airport pavement deicing products on aircraft and airfield infrastructure [M].Washington D C:National Academies Press,2008.

[5] SongYuxiu,Liu Xuesong. An inquiry intothe damage of concrete pavement for airport in’the three Northern region’in China[J].Civil Aviation Science& Technology,2000(3):74-75.(in Chinese)

[6] Hu Shangke.Frost injury on cement concrete road surface and the prevention measures in Gobi desert,Northwest areas [J]. Ningxia Engineering Technology,2003,2(2):177-180.(in Chinese)

[7] Van Dam T J,Peterson K R,Smith K D,et.al.Concrete mixes and pavementconstruction for aircraft deicing facilities[R].IPRF-01-G-002-03-3,2006.

[8] Van Dam T J,Peterson K R,Sutter L L,et al.Durability of concrete pavements used for aircraft deicing facilities[C]∥ Transportation Research Board Annual Meeting.Washington D C,USA:[s.n.],2008.

[9] Michigan Tech Transportation Institute. The deleterious chemical effects of concentrated deicing solutions on portland cement concrete—executive summary[R].SD2002-01-X,TPF-5(042)-X,2008.

[10]Zhao Hongduo,Yao Zukang,Zhang Changan,et al.Influence of aircraft deicer on apron cement concrete[J]. Journal of Traffic and Transportation Engineering,2004,4(2):1-5.(in Chinese)

[11]Ma Haiyan,Yu Hongfa,Cao Wentao,et al.Freezethaw durability of Portland cement concrete subjected toaircraftdeicer[C]∥ International Conference on Advances in Materials and Manufacturing Processes (ICAMM P 2010).Shenzhen,China:[s.n.],2010:1856-1861.

[12] Ababneh A N.The coupled effect of moisture diffusion,chloride penetration and freezing-thawing on concrete durability[D].Denver:Department of Civil,Environmental and Architectural Engineering,University of Lolorado,2002.

[13]Yang Quanbing.Effects of salt and snow-thawing agent types on salt-scaling damage of concrete[J].Journal of Building Materials,2006,9(2):464-467.(in Chinese)