Research on knowledge-based design of complex mechanical product

2010-03-20ZHANGXiaoliHUDongmingWUBaogui

ZHANG Xiao-li,HU Dong-ming,WU Bao-gui

(1.School of Mechanical Engineering,Dalian University of Technology,Dalian 116024,China;2.China University of Petroleum,Dongying 257061,China)

0 Introduction

In recent years,CAD technology has been rapidly applied to design and manufacturing domain.However,the problem existing generally in the product design system is that researchers pay much more attention to the capacity of geometry treatment rather than the capacity of knowledge treatment[1].To meet the demands of engineering design,a new engineering design method,knowledge-based engineering is presented,which is an intelligent system based on product model aiming to capturing product and process information through modeling to the engineering design processes[2,3].

In this paper,the theories and methods of knowledge engineering are integrated into complex mechanical product design.In general,a multi-element and multi-size mechanical structure can be viewed as a complex product,which is incapable to be analyzed by manual way and the computer analysis technology is necessary.In this system,the experiences and knowledge are formalized and saved in knowledge base;case-based reasoning mechanism is designed to make decisions.Based on knowledge engineering,a design system of crane is developed to aid designers to develop crane.

1 Design model of complex mechanical product

Product family case tree is a model which can be used to present complex product[4].As shown in Fig.1,it is expressed by the hierarchy-decomposition tree.In this case tree,every node expressed by object has a common structure,and it stands for elements of products at all levels,such as product,sub-assembly,component and part,etc..The AND node that can be divided is called a composition tree.Its child nodes are AND relations.Father node and child nodes are combination (a-part-of)relations;the OR node that can be selected is called an optional tree.Its child nodes are OR relations.Anyone of the child nodes can be substituted by another,but only one node can be selected.Father node and child nodes are optional(a-kind-of)relations.Moreover,if one optional child node needs to be divided,it still can be re-divided into sub-nodes further as a father node of the lower composition nodes,as shown in the lowest level of Fig.1.

Fig.1 Structure model of product family case tree

The product family case module can be realized by object-oriented technology[5,6].Every node is regarded as an object,and a common element node class is defined to represent product,sub-assembly,component and part in different layers.Relative element function class,element structure class,element parameter class and element knowledge rule class are also defined and embedded in the common element node class.Every specific product case is the instance of the node class.Fig.1shows the structure of knowledge presentation based on object-oriented technology.

2 Knowledge reasoning based on case

CBR is a theory and research method in artificial intelligence domain[7,8].Its main spirit lies in solving new problems using the problem-solving methods of the past.Nearest neighbor technique is the method used most widely in CBR domain.Nearest neighbor algorithms do work by calculating similarity degree between the target case and source cases in the case-library.This measure may be multiplied by a weighting factor.Then,the sum of the similarities of all attributes is calculated to provide a measure of the similarity of that case in the library to the target case.This can be represented by the following equation,and Tab.1 shows some common functions of similarity degree.

WhereTis the target case;Sis the source case;nis the number of attributes in each case;iis an individual attribute,i=1,…,n;andwiis the importance weighting of attributei.

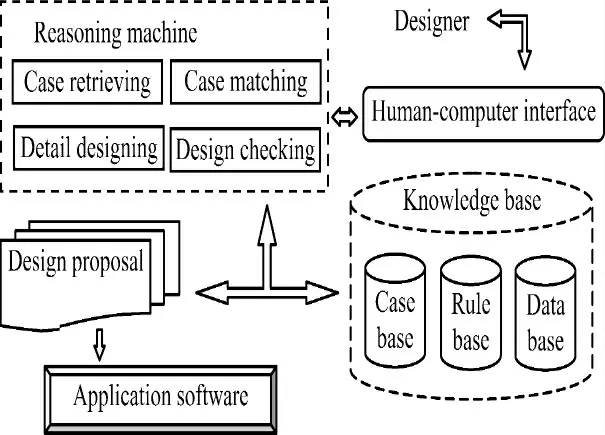

3 Construction and realization of the product design system

As shown in Fig.2,it is the construction strategy of the knowledge collaborative management system.The top of the system is human-computer interface,designers can submit parameters and read results from the interface.Knowledge base is the bottom of the system,which describes cases,rules,and data at each level of the family case tree.The core of the system construction is reasoning machine,as is discussed above,it is used to retrieve and calculate the similarity degree between primitive designs and target cases,and do some other reasoning for generating the design proposals.Finally,post treatment model is used to print BOM and calculation sheet and draw graphics.

Tab.1 Common functions of similarity degree

Fig.2 Structure mode of product family case tree

This system adopts Windows XP Server operating system,Microsoft Visual Basic.NET development tool,SQL Server 2003 database management system.Meanwhile,it also integrates the related modules of office and Solid works software by using the ADO.net technology to access to the knowledge base and ActiveX technology to drive office and Solid works to finish post treatment.

4 Application of the system

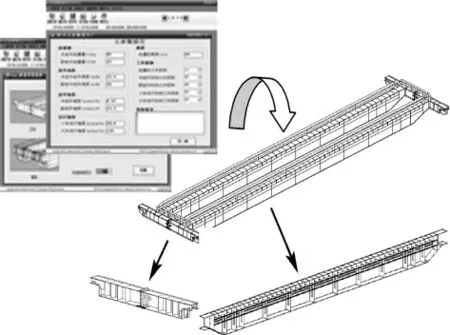

First,the designers type the main parameters submitted by customers to the design system.After the calculation of similarity degree between target designs and primitive cases,the system provides a most similar component to the designers.Next,the system retrieves cases through the case database.After the calculation of similarity degree between target designs and primitive cases,the same or the similar cases are searched and retrieved.If matching cases are found,the best cases are selected and provided to the designers,and then,designers finish detail design to conform to the new product′s specifications.On the contrary,if no matching case is found,an entirely new design is made afterwards.Finally,after finishing the design,some document should be printed and the product′s structure and performance should be assessed.According to the assessment,if the design satisfies the design requirements,the design results will be stored in the case library as a new case;otherwise,the system will return to the phase of detail design and start a redesign process.Fig.3shows a product example based on the structure mode shown in Fig.2.

Fig.3 Assembly case of bridge crane girder

5 Conclusions

In this paper,a knowledge-based system for complex mechanical product design is brought forward.The construction strategy of the system is studied.Using CBR driven method,taking the product family and object-oriented technology as knowledge-based organization,and adopting engineering database technology and ActiveX technology,intelligent crane design platform is developed.The platform is verified by application cases as follows:it can provide lowered cost,improved quality,and rapidly developing product approach to designers.

[1] WANG Ya-liang,JI Shi-ming,JIN Shou-song,etal.Upgrading the enterprise efficiency by integrating the knowledge of the industrial engineering and project management[C]//The 14th International Conference on Industrial Engineering and Engineering Management.Beijing:China Machine Press,2007

[2] YAN Chu-liang,YANG Fang-fei.New Technologies of Mechanical Digital Design [M].Beijing:China Machine Press,2007(in Chinese)

[3] XIAO Ren-bin,TAO Zhen-wu,LIU Yong.Theory and Technology of Intelligent Design [M].Beijing:Science Press,2006(in Chinese)

[4] TAI Li-gang,LI Dian-qi,ZHONG Ting-xiu,etal.Research on integrating customization design for mechanical product[J].Journal of Machine Design &Research,2006,22:6-8

[5] XU W L,KUHNERT L,FOSTER K.Objectoriented knowledge representation and discovery of human chewing behaviors [J].Engineering Applications of Artificial Intelligence,2007,20(7):1000-1012

[6] WILLIAMS M A,KOCHHAR A K,TENNANT C.An object-oriented reference model of the fuzzy front end of the new product introduction process[J].International Journal of Advanced Manufactural Technology,2007,34:826-841

[7] SLONIM T Y,SCHNEIDER M.Design issues in fuzzy case-based reasoning [J].Fuzzy Sets and Systems,2001,117:251-267

[8] VONG C M,LEUNG T P,WONG P K.Case-based reasoning and adaptation in hydraulic production machine design [J].Engineering Applications of Artificial Intelligence,2002,15:567-585