STUDY OF YELLOW-OLEDS WITH DIFFERENT AlQ THICKNESS

2010-02-23ZHANGMailiZHANGFanghui

ZHANG Mai-li, ZHANG Fang-hui

(School of Electrical & Information Engineering, Shaanxi University of Science & Technology, Xi′an 710021, China)

0 Introduction

In the last few years, white organic light-emitting displays(WOLEDs) have attracted particular attention due to its application, such as full-color displays and light[1,2]. Various types of white OLEDs have been reported i.e. red-green-blue system and blue-yellow system etc[3,4]. So the preparation of high-performance yellow-OLEDs is very important. At present the key problem to be resolved is how to improve the electroluminescent efficiency and lifetime. The electroluminescent efficiency of OLEDs is improved by improving holes′ and electrons′ effective injection and balance. So hole transport layer (HTL) and ETL are differently prepared between ITO/emitting layer (EML) and EML/metal electrodes[5-7]. The thickness of transmission layer is an important parameter on the performance of OLEDs[8], so the research of effect of transmission layer's thickness is necessary.

In this paper, yellow-OLEDs were fabricated by vacuum evaporation method. The effect of the OLED with different thickness of AlQ as ETL was researched and have achieved the optimal thickness.

1 Experimental

The sheet resistance of ITO was used about 10 Ω/square, the ITO substrate was cleaned by ultrasonic in ethylalcohol, acetone and distilled water and oxygen plasma treatment to remove surface contamination and improve surface morphology. The structure is as follows: ITO/2T-NATA(15 nm)/NPB (50 nm)/ADN(20 nm):2% DCJTB:2% TBPe/AlQ(x)/LiF (5 nm)/Al (100 nm)(x=10 nm, 15 nm, 20 nm, 25 nm, 30 nm)(Fig.1). On the device, the AlQ was used as ETL, ADN:DCJTB:TPB was used as EML, the LiF/Al was used as cathode, the 2T-NATA was used as hole injecting layer and the NPB was as HTL. The base main chamber pressure was kept under 2×10-4Pa. Quartz crystal resonator was used to watch thickness and deposition rate of film.

Fig.1 The structure of OLED

The electroluminescent spectra, efficiency and CIE were measured with PMS-80UV-VIS-near IR spectrophtocolorimeter. The luminescent brightness, current-voltage(I-V) and the luminescence-voltage(L-V) characteristics was measured with ST-900B photometer and DC power supply PS-3003D. All measurements were carried out at room temperature under ambient atmosphere.

2 Results and Discussions

Fig.2 and Fig.3 shows the absolute and relative electroluminescent spectrum of OLEDs with different AlQ thickness, respectively. The measurement has been done with the current 0.12 A. From Fig.3, it is illuminated that the color don′t change with change of AlQ thickness, which prove that the location of emitting layer don′t change. From the Fig.2, we can know that EL intensity is the biggest when the thickness of AlQ layer is 20 nm.

Fig.2Electroluminescent spectrum of devices with different thickness of AlQ layer (I=0.12A)

Fig.3Relative electroluminescent spectrum of devices with different thickness of AlQ layer(I=0.12A)

The luminescence-voltage curves and efficiency -current of OLEDs with different thickness AlQ layer are shown in Fig.4 and Fig.5. Fig.4 shows that luminescence brightness is the best in the same voltage when the thickness of AlQ is 20 nm. When AlQ is more thinner, biggish disfigurement and pinhole exist in the thin film. The carriers are captured by these defects and diminish the probability of collide between holes and electrons, as well as the composite odds. So the brightness will decrease. When AlQ is more thicker, the increase of resistance reduces the current density of the device. Consequently, the device luminous brightness will decrease.

Fig.4 Luminescence-voltage(L-V) curve of devices with different thickness of AlQ layer

Similarly, the efficiency is the best in the same current when the thickness of AlQ is 20 nm in Fig.5, beacause the number of holes and electrons injected is balanceable. When the thickness of AlQ is thinner, the compositeness of holes and electrons is in the organic layer/electrode interface, which includes a mass of disfigurement. So the exciton is abrupt quenched and the efficiency reduce. When the thickness of AlQ is thicker, it is difficult for the electrons to enter the emitting layer through the AlQ layer. Correspondingly the efficiency reduce.

From the Fig.5, we can know that the efficiency is the best in the 0.1 A. Because the number of injected electrons adds with the increase of the current, the efficiency improve, but the produced joule fever in the device will aggrandize. Corresponding, the organic material will crystallize and the performance of the material will fall off. The interface performance of organic layer/electrode will letdown.

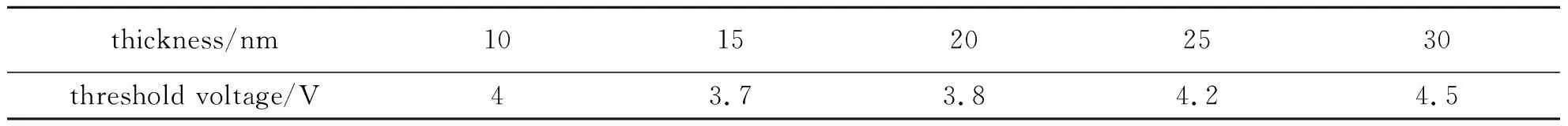

Tab.1 The threshold voltage with different thickness of AlQ3 film

Tab.1 shows the threshold voltage with different AlQ thickness. It can be seen in Tab.1 that the threshold voltage will correspondingly increase when the thickness of AlQ adds because AlQ is an insulator and the resistance of AlQ film improves with the increase of thickness of AlQ. But if the thickness of the organic layer is too small, the disfigurements of the organic layer are likely to be more. Thereby, the threshold voltage will increase. Similarly, the uniformity and stability of the device may become worse.

3 Conclusion

We have successfully fabricated an excellent yellow-OLED, and the structure is as follows: ITO/2T-NATA(15 nm)/NPB(50 nm)/ADN(20 nm):2% DCJTB:2% TBPe/AlQ(20 nm)/LiF(5 nm)/Al(100 nm), the effect of the thickness of AlQ on the performance of OLED is researched. We can see that when the thickness of AlQ layer is 20 nm, electroluminescent intensity, efficiency and bright is the best, but the peak position of light-emitting is near to change.

[1] JungBae Song, Sunghun Lee. Degradation of white light emitting OLEDs[J]. SID, 2008,(4):2 060-2 063.

[2] Tien-Shou Shieh, Jin-Sheng Lin, Pey-Ching Liu. Color stability of white-light-emitting organic electroluminescent device based on three phosphorescent emission peaks[J]. SID, 2008,(3):2 028-2 031.

[3] Dong-Eun Kima, Won-Sam Kimb, Byoung-Sang Kim .Characteristics of white OLED using Zn(phen) as a yellowish green emitting layer and BCP as a hole blocking layer[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2008,313 (1):320-323.

[4] J. T. LIM, C.H.JEONG, J.H.LEE. White organic light-emitting diodes using bis(2,4-dimethyl-8-quinolinolato)(triphenylsilanolato) aluminum(Ⅲ) as a new hole-blocking layer[J]. Japanese Journal of Applied Physics, 2006,45(3A): 1 826-1 828.

[5] Musubu lchikawa, Kenta Wakabayashi. New tris bipyridyl derivative as hole-blocking and electron-transporting materials for organic light-emitting devices[J]. SID,2008,(4): 2 053-2 055.

[6] Manju Rajeswara, Thomas N. Blanton, Ching W. Tana. Structural, thermal, and spectral characterization of the different crystalline forms of AlQ3, tris(quinolin-8-olato)aluminum(Ⅲ), an electrolumine-scent material in OLED technology[J]. Polyhedron, 2009, 28(4): 835-843.

[7] Fangcong Wang, Su Liu, Jianlin Zhou. Bright green organic light-emitting devices having a composite electron transport layer[J]. Microelectronics Journal, 2006, 37(9):916-918.

[8] Soo-Kang Kim, Young-ll Park, Jong-Wook Park. High quantum efficiency of new deep-blue EML materials in OLED[J]. SID,2008,(3): 2 001-2 004.