不同酶解工艺对鲜木薯块根粗多糖得率的影响

2025-02-09余厚美林立铭王琴飞姚庆群杜培旭张金泉张振文

摘""要:本研究以木薯块根为原料,采用单因素试验结合Box-Behnken响应面方法,优化超声波辅助木薯粗多糖的提取工艺,分析4种不同酶酶解鲜木薯块根的工艺,比较木薯粗多糖(crude"polysaccharide"of"cassava"root,"CPCR)得率的差异。结果表明:4种酶酶解最优工艺均有所差异,加酶提取CPCR得率显著高于不加酶,4种酶的CPCR得率大小为中温α-淀粉酶gt;普鲁兰酶gt;半纤维素酶gt;低温α-淀粉酶,其中低温α-淀粉酶酶解超声处理时间最长(360"min),但CPCR得率最低为7.02%;中温α-淀粉酶CPCR得率最高(20.25%),其最佳酶解提取工艺为超声功率300"W,超声温度70"℃,加酶量5"KU/g,料液比(g/mL)1∶2.5,超声时间240"min;普鲁兰酶酶解超声处理时间最短(60"min),CPCR得率为13.98%;半纤维素酶酶解条件下CPCR得率为7.99%。进一步对优化条件进行验证,结果表明,粗多糖得率和预测值接近,但是在仅加入酶不加木薯样本的条件下也检测到粗多糖含量,扣除酶的影响后中温α-淀粉酶的提取率仍然为最高(17.22%),可见,中温α-淀粉酶酶解木薯块根是一种高效率提取CPCR的方法。本研究有望为鲜木薯粗多糖的深入研究和开发利用提供技术基础。

关键词:木薯;粗多糖;响应面分析;酶解提取中图分类号:Q814.9,S533""""""文献标志码:A

Effect"of"Different"Enzymatic"Hydrolysis"Processes"on"the"Yield"of"Crude"Polysaccharide"from"Fresh"Cassava"Roots

YU"Houmei1,2,"LIN"Liming1,2,"WANG"Qinfei1,2,"YAO"Qingqun1,2,"DU"Peixu1,"ZHANG"Jinquan1,"ZHANG"Zhenwen1,2*

- Institute"of"Tropical"Crops"Genetic"Resources,"Chinese"Academy"of"Tropical"Agricultural"Sciences"/"National"Ramp;D"Center"for"Potato"Processing,"Haikou,"Hainan"571101,"China;"2.nbsp;Key"Laboratory"of"Germplasm"Resources"Conservation"and"Utilization"of"Cassava,"Ministry"of"Agriculture"and"Rural"Affairs,"Haikou"Hainan"571101,"China

Abstract:"Cassava"roots"were"used"as"the"raw"material."Single"factor"tests"combined"with"the"Box-Behnken"response"surface"method"were"used"to"optimize"the"extraction"process"of"cassava"crude"polysaccharide"(CPCR)"assisted"by"ultrasonic"wave,"and"the"process"of"enzymatic"hydrolysis"of"cassava"tuber"roots"by"four"different"enzymes"was"analyzed."The"results"showed"that"the"four"enzymatic"hydrolysis"processes"were"different."The"extraction"yield"of"CPCR"with"enzyme"was"significantly"higher"than"that"without"enzyme."The"CPCR"yield"of"the"four"enzymes"was"α-medium"temperaturegt;pullulanasegt;hemicellulasegt;α-low-temperature"amylase,"the"ultrasonic"treatment"time"of"α-low-temperature"amylase"was"the"longest"(360"min),"but"the"CPCR"yield"was"the"lowest"(7.02%)."The"α-medium"temperature"CPCR"yield"was"the"highest"(20.25%),"and"the"best"enzymatic"extraction"process"was"as"follows:"ultrasonic"power"300"W,"ultrasonic"temperature"70"℃,"enzyme"content"5"KU/g,"solid-liquid"ratio"(g/mL)"1∶2.5,"and"ultrasonic"time"240"min."The"ultrasonic"treatment"time"of"pullulanase"was"the"shortest"(60"min),"and"the"CPCR"yield"was"13.98%."The"yield"of"CPCR"under"hemicellulase"hydrolysis"was"7.99%."The"optimized"conditions"were"further"verified,"and"the"results"showed"that"the"yield"of"crude"polysaccharide"was"close"to"the"predicted"value."However,"the"crude"polysaccharide"content"was"also"detected"under"the"condition"that"only"enzyme"was"added"without"cassava"sample,"and"the"extraction"rate"of"medium"temperature"α-amylase"was"still"the"highest"(17.22%)"after"deducting"the"influence"of"enzyme."It"can"be"seen"that"medium"temperature"α-amylase"enzymatic"hydrolysis"of"cassava"tuber"roots"is"an"efficient"way"to"extract"CPCR."This"study"is"expected"to"provide"technique"basis"for"its"further"research"and"utilization"of"crude"polysaccharide.

Keywords:"cassava;"crude"polysaccharides;"response"surface"analysis;"enzymolysis"extraction

DOI:"10.3969/j.issn.1000-2561.2025.02.016

多糖是一类由单糖通过糖苷键连接在一起形成的生物大分子物质[1-2],广泛存在于自然界中,并因其独特的生物活性,如免疫调节、抗氧化、抗肿瘤、降血糖等备受关注,并在医药、食品和化妆品等领域具有广泛的应用价值[3-7]。木薯(Manihot"esculenta"Crantz)作为一种在全球热带地区广泛种植的粮食作物,为超过10亿人口提供了基本的营养来源[8],其块根含有淀粉、纤维素、蛋白质等营养物质,且已被证实是制备活性多糖的重要物质基础[9-11]。已有研究表明,木薯块根中的多糖不仅种类繁多,而且具有显著的生物活性。例如,CHARLES等[12]从木薯块根中分离出一种由蔗糖、果糖、葡萄糖、半乳糖和阿拉伯糖等组成的粘多糖,具有特定的分子量和组成,该粘多糖来自半纤维素;CHIA等[13]的研究则揭示了木薯多糖对大鼠耐力的积极影响;此外,木薯粉提取的粗多糖亦被证实具有抗氧化活性和对大鼠肝损伤的保护作用[14];UTHUMPORN等[15]进一步研究发现,木薯多糖的添加能够显著改善小麦粉面团的加工特性。

多糖的提取是多糖活性评价的前提,其方法的选择对于多糖的得率、性质及生物活性具有显著影响[16-19],传统的提取方法如热水提取、酸碱提取虽操作简单,但存在得率低、活性低等缺点。相比之下,超声提取和酶法提取因具有条件温和、提取率高、活性强等优势而逐渐受到重视[20-21]。超声波能够破坏植物细胞壁结构,促进多糖的释放,而酶法则具有专一性强、反应条件温和、活性强、成本低、环保等特点,特别是当把2种方法结合使用时,能够进一步提高多糖的得率和活性[22]。然而,值得注意的是,尽管超声辅助酶法在多糖提取领域展现出巨大的潜力,但该方法尚未被应用于木薯多糖的提取。因此,本研究旨在充分利用超声和酶解法的优点,通过响应面法优化不同酶解条件下的最佳提取工艺,以期为木薯多糖的深入研究和综合高效利用提供理论支持和实践指导。

1""材料与方法

1.1""材料

华南9号木薯(South"China"9,"SC9)块根采自中国热带农业科学院热带作物品种资源研究所国家薯类加工技术研发分中心(海南儋州);无水葡萄糖、葡萄糖醛酸、牛血清白蛋白(bovine"serum"albumin,"BSA)、四硼酸钠、考马斯亮蓝均购自北京索莱宝公司;低温α-淀粉酶、半纤维素酶均购自上海源叶生物公司;中温α-淀粉酶、普鲁兰酶、三氯乙酸均购自上海麦克林公司;无水乙醇、磷酸二氢钠、磷酸氢二钠、氯化钠、硫酸等所有分离用有机试剂均购自国药集团化学试剂有限公司。

KQ-600DE超声波清洗器(昆山舒美公司);TU-1810APC紫外分光光度计(北京普析公司);Simple-Q15超纯水系统(上海芷昂公司);Multiskan"FC酶标仪(美国Thermo公司);PHS-3E"pH计(上海仪电科学仪器公司);SRY-150生化培养箱(宁波赛福公司);IJXFSTPRP-24全自动样品快速研磨仪(上海净信实业公司);Z327K高速冷冻离心机(德国HERMLE公司)。

1.2""方法

1.2.1""木薯粗多糖提取样本预处理""采收生长期1年的华南9号木薯块根,木薯块根洗净泥沙、去掉外表皮和木薯内层皮,切块、研磨成浆、分装,‒20"℃冷冻待用。

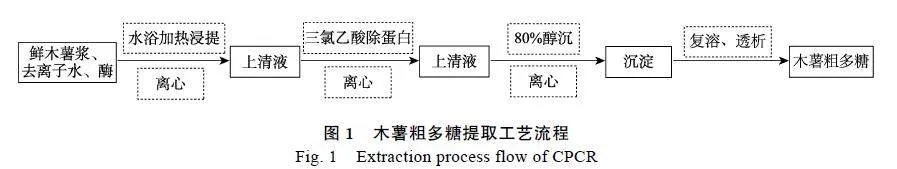

1.2.2""超声辅助酶解木薯粗多糖提取工艺""CPCR的提取参考CHARLES等[12]、CHEN等[23]的方法并优化,按照图1流程进行提取:在木薯样本中加入一定量的去离子水和酶,300"W条件下超声浸提,25"℃,8000"r/min离心10"min后取上清,加4%三氯乙酸去蛋白,离心后在上清中加无水乙醇至浓度为80%,混匀后室温静置2"h离心取沉淀,沉淀用去离子水复溶后使用截留量为3.5"kDa透析袋在去离子水中透析72"h。

1.2.3""单因素试验""低温α-淀粉酶:以CPCR得率为指标,在超声功率300"W、超声温度45"℃条件下,按照1.2.2提取CPCR,依次分别考察加酶量(0、0.1、0.3、0.5、0.7、0.9、1.1"KU/g)、料液比(g/mL)(1∶2、1∶3、1∶5、1∶8)、超声时间(60、120、180、240、300、360"min)对CPCR得率的影响。

中温α-淀粉酶:以CPCR得率为指标,在超声功率300"W、超声温度70"℃条件下,按照1.2.2提取CPCR,依次分别考察加酶量(0、1.0、2.0、3.5、4.5、6.0"KU/g)、料液比(g/mL)(1∶1.5、1∶2、1∶3、1∶5、1∶8)、超声时间(30、60、120、240、360、480"min)对CPCR得率的影响。

普鲁兰酶:以CPCR得率为指标,在超声功率300"W、超声温度55"℃条件下,按照1.2.2提取CPCR,依次考察加酶量(0、1.0、2.0、3.0、4.0"KU/g)、料液比(g/mL)(1∶1.5、1∶2、1∶3、1∶5、1∶8)、超声时间(30、60、120、240、360、480"min)对CPCR得率的影响。

半纤维素酶:以CPCR得率为指标,在超声功率300"W、超声温度50"℃条件下,按照1.2.2提取CPCR,依次考察加酶量(0、0.3、0.5、0.7、1.0、2.0、3.0"KU/g)、料液比(g/mL)(1∶2、1∶3、1∶5、1∶8、1∶10)、超声时间(15、30、45、60、80、100、120"min)对CPCR得率的影响。

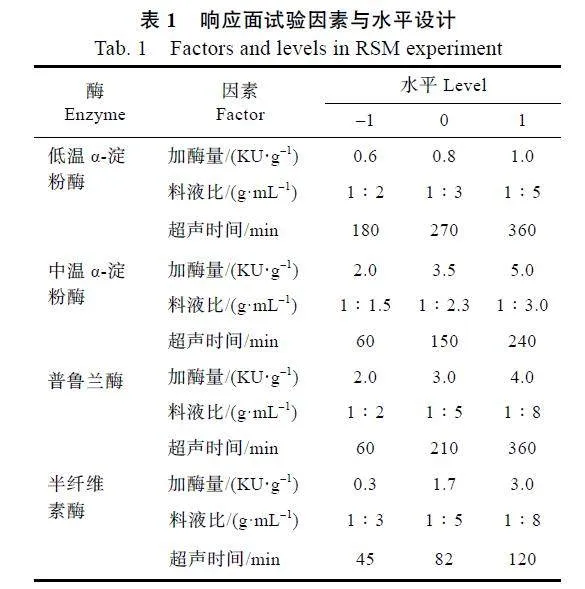

1.2.4""响应面优化""基于单因素试验结果,采用Design-Expert"12的Box-Behnken设计响应面组合试验方案[24],以加酶量、料液比和超声时间为正交因子,CPCR得率为响应值,优化木薯粗多糖的超声波辅助提取工艺参数,具体试验因素水平如表1所示。

1.2.5""粗多糖组成测定""采用苯酚-硫酸法测定木薯粗多糖总糖含量,采用间羟基联苯法测定酸性糖含量,采用考马斯亮蓝法测定可溶性蛋白质含量[25]。

1.3""数据处理

每个试验至少重复3次,采用Excel"2016软件计算试验数据平均值和相对标准偏差,响应面试验数据由Design-Expert"12软件处理,采用IBM"SPSS"Statistics"27软件进行单因素显著性统计分析,相关图形数据均由Origin"2021软件处理。

2""结果与分析

2.1""单因素试验

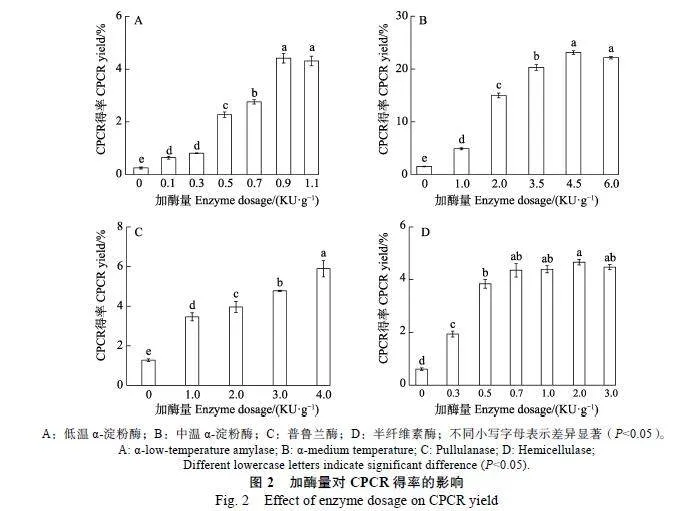

2.1.1""加酶量对CPCR得率的影响""4种酶的不同加酶量对CPCR得率的影响表明,在未添加和低剂量添加酶时,CPCR得率较低。随着加酶量的增加,CPCR得率逐渐升高,当加酶量达到一定程度时,CPCR得率不再显著增加,部分情况下反而有所降低(图2)。这可能是因为在加酶量较低时,酶可以充分与底物接触,随着加酶量增加底物被完全反应,进一步增加加酶量可能导致酶的活性被抑制[26]。低温α-淀粉酶在加酶量为0.9"KU/g时得率达到最高,进一步增加加酶量未显著提高CPCR得率(图2A),因此,选择0.6~"1.0"KU/g作为优化范围;中温α-淀粉酶加酶量达到4.5"KU/g时,粗多糖得率达到最高,为23.11%(图2B),其优化范围为2.0~5.0"KU/g。普鲁兰酶为液体型,加酶量增加会导致料液比相应增加,结合料液比数据(图2C),其优化范围选择为2.0~4.0"KU/g。半纤维素酶在加酶量达到2.0"KU/g时CPCR得率达到最大,但在0.7"KU/g后增加不显著(图2D),其优化范围为0.3~3.0"KU/g。

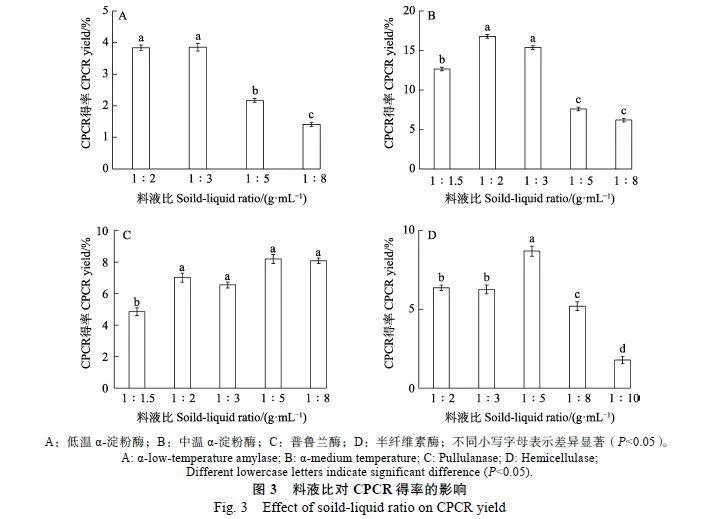

2.1.2""料液比对CPCR得率的影响""4种酶解条件下料液比对CPCR得率的影响见图3,随着溶剂增加,图3A、图3B、图3D中粗多糖得率均呈现先增加后减少的趋势。当溶剂较少时对木薯酶解不充分,随着料液比增加,可能杂质的溶出抑制了多糖的提取,使得多糖呈现先增加后减少的趋势[27]。从图3A中可知,料液比在1∶3"时粗多糖得率最高,与1∶2"的料液比无显著性差异,料液比1∶5"或1∶8"时,多糖得率显著下降,因此,料液比选择1∶2~1∶5"作为优化范围;图3B料液比在1∶2"时粗多糖得率最高,因此选1∶1.5~1∶3.0"作为其优化范围;图3C中料液比1∶2"后CPCR得率未显著增加,料液比选择1∶2~1∶8"作为其优化范围;图3D料液比在1∶5"时粗多糖得率最高,随着料液比上升粗多糖得率迅速下降,料液比选择1∶3~1∶8"进一步优化。

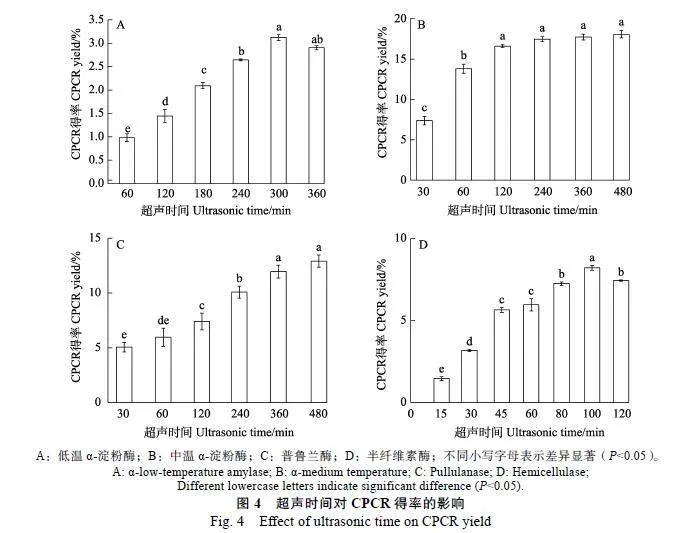

2.1.3""超声时间对CPCR得率的影响""超声时间对CPCR得率的影响如图4所示。随着超声时间延长,木薯粗多糖得率逐渐增加,说明适当延长超声时间可以提高CPCR得率,但时间过长,多糖得率呈现下降趋势,可能是粗多糖溶解到平衡后,会引起粗多糖结构的改变从而降低得率[28]。低温α-淀粉酶在超声时间60~300"min时CPCR得率和超声时间成正比,超过300"min后CPCR得率下降(图4A),可能是超声时间太长导致水温上升,超过了低温α-淀粉酶的最适温度45"℃导致酶失活,导致得率下降,因此提取时间选取180~360"min作为优化范围;中温α-淀粉酶在超声时间大于120"min后粗多糖得率并未显著增加(图4B),表明经过120"min的超声处理,大部分木薯粗多糖都已溶出[25],随着超声时间延长水温升高,但是仍然在中温α-淀粉酶的活性温度范围内,所以随着超声时间延长,CPCR得率未减少,因此提取时间选取60~240"min作为优化范围;普鲁兰酶超声时间对木薯粗多糖的得率如图4C所示,随着提取时间延长,CPCR得率逐渐增加,但超过360"min后未显著提高粗多糖得率,因此提取时间选取60~360"min作为优化范围;半纤维素酶在15~100"min随着超声时间延长,CPCR"得率逐渐增加,并在100"min时达到最大(图4D),说明适当延长超声时间可以提高木薯粗多糖得率,可能是超声能破坏细胞壁促进粗多糖溶出,但超声时间超过100"min后木薯粗多糖得率开始下降,可能长时间超声破坏了多糖结构并使其降解,导致得率下降[29-30],因此超声时间选取45~120"min作为优化范围。

2.2""响应面优化

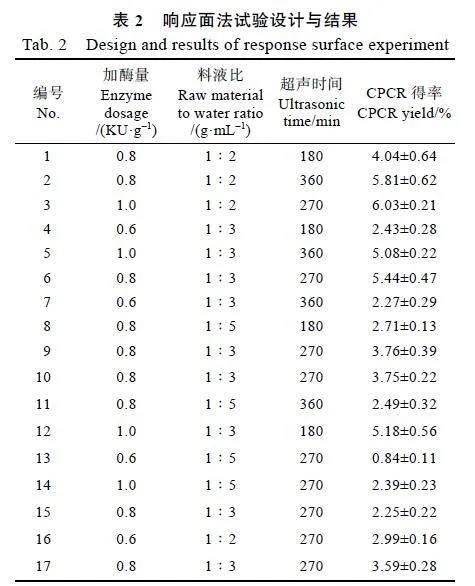

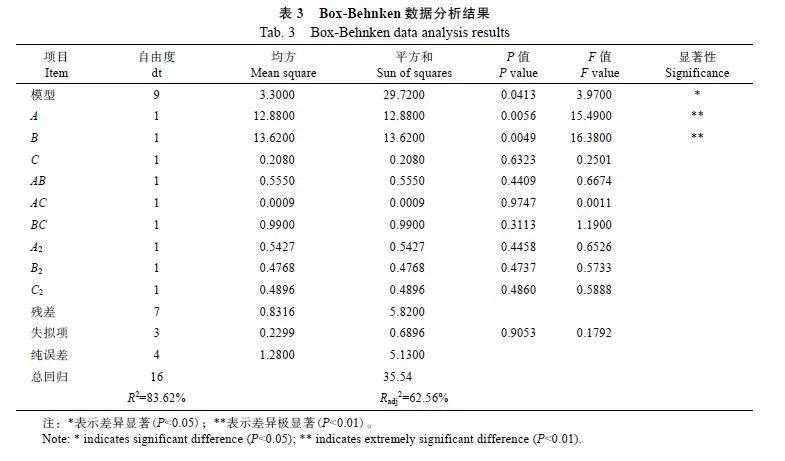

2.2.1""低温α-淀粉酶""应用Design-Expert"12软件对表2中的数据进行建模和分析,得到了粗多糖得率(R)的加酶量(A)、料液比(B)、和超声时间(C)的多元回归方程:R=3.7600+1.2700A‒1.3000B+"0.1613C‒0.3725AB+0.0150AC‒0.4975BC‒0.3590A2‒0.3365B2+0.3410C2。响应面试验数据的分析结果见表3,模型P=0.0413lt;0.05,R2=83.62%,说明此模型显著,失拟项P=0.9053gt;0.05,说明明显的失拟因素不存在,因此该回归方程可信。根据F值可判断3项因素对CPCR得率影响大小排序为B(料液比)gt;A(加酶量)gt;C(超声时间)。

根据回归模型分析结果,运用Design-Expert"12软件中的Optimization功能,以粗多糖含量最大为条件,求解回归模型优化得到最优参数:加酶量为1"KU/g,料液比(g/mL)为1∶2,超声时间为360"min,粗多糖得率为7.02%。

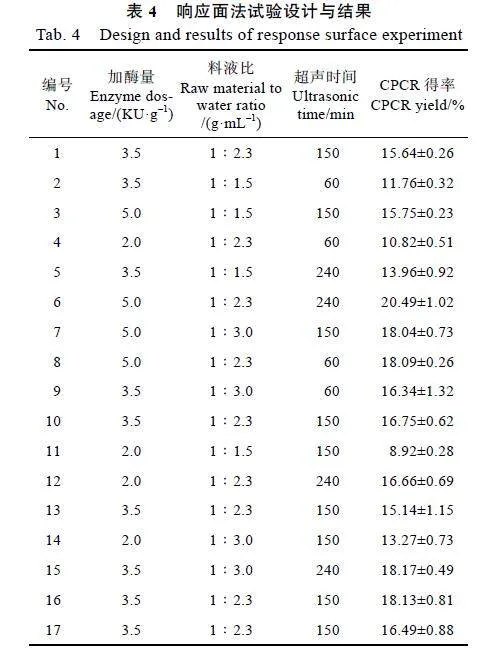

2.2.2""中温α-淀粉酶""应用Design-Expert"12软件对表4中的数据进行建模和分析,得到粗多糖得率(R)的加酶量(A)、料液比(B)、和超声时间(C)的多元回归方程:R=16.4300+2.8400A+1.9300B+"1.5300C‒0.5163AB‒0.8623AC‒0.0935BC‒0.4883A2‒1.9400B2+0.5730C2。响应面试验数据的分析结果见表5,P=0.0014lt;0.01,R2=94.34%,说明此模型极显著,失拟项P=0.5926gt;0.05,说明明显的失拟因素不存在,因此该回归方程可信。F值可评估判断自变量对因变量产生的影响,可知3个因素影响CPCR提取率的程度为A(加酶量)gt;B(料液比)gt;C(超声时间)。

根据回归模型分析结果,运用Design-Expert"12软件中的Optimization功能,以粗多糖含量最大为条件,求解回归模型优化得到最优参数:加酶量为5"KU/g,料液比为1∶2.5,超声时间为240"min,粗多糖得率为20.25%。

2.2.3""普鲁兰酶""应用Design-Expert"12软件对表6中的数据进行建模和分析,得到了粗多糖得率(R)的加酶量(A)、料液比(B)、和超声时间(C)的多元回归方程:R=8.4900+3.2100A+0.0072B‒"0.4989C‒0.1425AB‒0.3443AC+0.6830BC+0.3117A2‒0.0120B2+0.3152C2。响应面试验数据的分析结果见表7,Plt;0.01,R2=98.04%,说明此模型极显著,失拟项P=0.0564gt;0.05,说明该回归方程可信。由F值可知3个因素影响CPCR提取率的程度为A(加酶量)gt;C(超声时间)gt;B(料液比)。

根据回归模型分析结果,运用Design-Expert"12软件中的Optimization功能,以粗多糖含量最大为条件,求解回归模型优化得到最优参数:加酶量为4"KU/g,料液比为1∶2"g/mL,超声时间为60"min,粗多糖得率为13.98%。

2.2.4""半纤维素酶""应用Design-Expert"12软件对表8中的数据进行建模和分析,得到粗多糖得率(R)的加酶量(A)、料液比(B)、和超声时间(C)的多元回归方程:R=3.59000+0.72000A‒0.20250B+"0.86250C+0.13000AB+0.34500AC+1.82000BC‒1.11000A2+1.53000B2+0.06957C2。响应面试验数据的分析结果见表9,P=0.0060lt;0.01,R2=91.14%,说明此模型极显著,失拟项P=0.4365gt;0.05,说明该回归方程可信。由F值可评估3个因素影响提取率的程度为C(超声时间)gt;A(加酶量)gt;B(料液比)。

根据回归模型分析结果,运用Design-Expert"12软件中Optimization功能,以粗多糖含量最大为条件,求解回归模型优化得到最优参数:加酶量为2.4"KU/g,料液比为1∶8,超声时间为120"min,粗多糖得率为7.99%。

2.3""参数验证

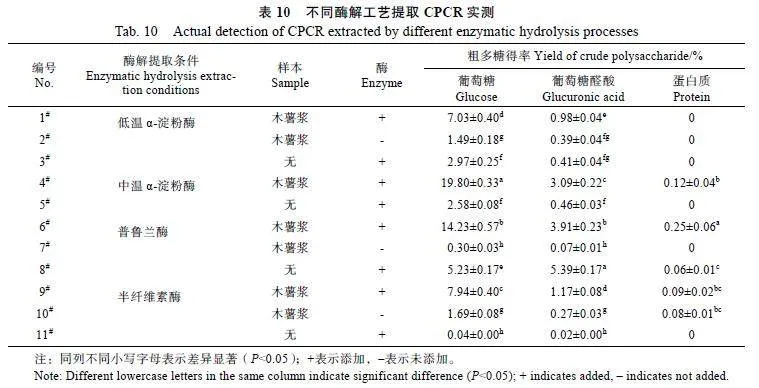

根据多元回归方程和模型,预测了4种酶法辅助超声波提取木薯粗多糖最优参数。经过5次平行试验,CPCR的得率如表10所示。结果显示,4种酶对木薯肉粗多糖得率大小:中温α-淀粉酶>普鲁兰酶>半纤维素酶>低温α-淀粉酶,中温α-淀粉酶酶解木薯浆时CPCR得率最高。进一步分析发现,所有加酶条件下的CPCR得率均极显著高于未加酶条件的得率,这证明了超声波辅助酶解能极显著提高CPCR的提取效率。此外,在仅加入酶而不加木薯样本的试验中也检测到了多糖成分,无样本只加酶提取的粗多糖得率大小为普鲁兰酶(5.23%)gt;低温α-淀粉酶(2.97%)gt;中温α-淀粉酶(2.58%)gt;半纤维素酶(0.04%),这可能是由于菌种自身的胞壁多糖,或者在酶的生产过程中菌种培养等原因而残留的能产生多糖的成分所致[31-33]。具体而言,在未加样本只加酶的情况下,普鲁兰酶的多糖得率最高,达到5.23%,而半纤维素酶的多糖得率最低,仅为0.04%。在扣除酶本身产生的多糖影响后,我们发现中温α-淀粉酶对木薯浆中CPCR的提取得率仍然为最高(17.22%)。值得注意的是,中温α-淀粉酶的最佳作用温度为70"℃,这与木薯淀粉的糊化温度相近[34],因此,不加酶的情况下,由于样本大部分已凝固,导致无法有效提取木薯粗多糖,所以,中温α-淀粉酶提取条件下不加酶无法获得木薯粗多糖。总的来说,建立的回归模型能准确反映3个因素对木薯粗多糖得率的影响,并且实际结果与预测值非常接近。经过响应面法优化的超声波辅助酶法提取的参数具有实际应用价值,为CPCR的提取提供了有效的技术方法。

3""讨论

木薯是世界重要的粮食作物,其块根富含淀粉和纤维素,是传统的植物基多糖提取制备的优质原料。传统采用热水浸提法提取多糖时,过高的提取温度(65"℃以上)会引起淀粉的糊化[34],进而影响非淀粉多糖的提取效率。而采用α-淀粉酶和糖化酶联合酶解处理山药的多糖得率为温水浸提的3.5倍左右[35],为此,常见能降解淀粉的酶类如α-淀粉酶、糖化酶、普鲁兰酶等常被用于高淀粉含量样本的粗多糖提取。本研究表明,中温α-淀粉酶提取的多糖得率最高,这可能中温α-淀粉酶的作用温度为70"℃,超声过程中温度会升高,导致实际作用温度高于70"℃,但是还是在中温α-淀粉酶的最佳作用温度范围内,在该范围内木薯淀粉已糊化,糊化的淀粉空间结构更松散,更易于被酶解,提高了粗多糖的得率[36]。

从提取工艺看,超声辅助提取多糖也是一种常用的物理提取方法,超声形成的空化效应具有高强度的冲击力和剪切力,能够穿透细胞壁,从而促进胞内物质的溶出[37],缩短时间,提高得率[38],使多糖分子量更小,活性更高[39]。本研究结果表明300"W超声波辅助酶解能显著提高CPCR得率,但不同的酶最适作用条件不同,所得产物也有差异。许多研究也表明,不同的酶解条件下所得到的多糖在含量、单糖组成、分子量、外观形态等方面有显著差异[40-42]。可见,超声波辅助酶水解植物基提取功能多糖可能是今后产业化应用的主流技术。本研究系统分析了CPCR的提取工艺,为后续CPCR的分离纯化及活性组分研究奠定基础,有助于进一步揭示其结构与生物活性之间的关系。然而,不同超声时间和酶是如何高效水解淀粉、CPCR主要来源于淀粉还是纤维或细胞壁等科学问题尚不清楚,这将是今后研究的重点。

参考文献

[1]"路欣彤,"齐欣,"高雪峰,"崔承弼."辐照处理对桦褐孔菌多糖抗疲劳作用的影响[J]."食品工业科技,"2022,"43(3):"351-357.LU"X"T,"QI"X,"GAO"X"F,"CUI"C"B."Effect"of"irradiated"process"on"anti-fatigue"activity"of"inonotus"obliquus"polysaccharide[J]."Science"and"Technology"of"Food"Industry,"2022,"43(3):"351-357."(in"Chinese)

[2]"SHI"L."Bioactivities,"isolation"and"purification"methods"of"pol y saccharides"from"natural"products:"a"review[J]."Interna tional"Journal"of"Biological"Macromolecules,"2016,"92:"37-48.

[3]"WANG"M"X,"FU"C"Y,"ZHANG"M"C,"ZHANG"Y"X,"CAO"L."Immunostimulatory"activity"of"soybean"hull"polysaccharide"on"macrophages[J]."Experimental"and"Therapeutic"Medicine,"2022,"23(6):"389.

[4]"HUANG"R"R,"WU"E"H,"DENG"X"L."Potential"of"lycium"barbarum"polysaccharide"for"the"control"of"glucose"and"lipid"metabolism"disorders:"a"review[J]."International"Journal"of"Food"Properties,"2022,"25(1):"673-680.

[5]"DENG"R,"WANG"F,"WANG"L"F,"XIONG"L,"SHEN"X"C,"SONG"H"Z."Advances"in"plant"polysaccharides"as"antiaging"agents:"effects"and"signaling"mechanisms[J]."Journal"of"Agricultural"and"Food"Chemistry,"2023,"71(19):"7175-7191.

[6]"WANG"A"Q,"LIU"Y,"ZENG"S,"LIU"Y"Y,"LI"W,"WU"D"T,"WU"X,"ZOU"L,"CHEN"H"J."Dietary"plant"polysaccharides"for"cancer"prevention:"role"of"immune"cells"and"gut"microbiota,"challenges"and"perspectives[J]."Nutrients,"2023,"15(13):"3019.

[7]"刘爽,"曲孟,"齐欣,"及长城,"崔承弼."辐照富硒木耳多糖对1型糖尿病小鼠的降血糖作用研究"[J]."食品工业科技,"2024,"45(18)":"334-343.LIU"S,"QU"M,"QI"X,"JI"C"C,"CUI"C"B."Hypoglycemic"effect"of"irradiation"Se-enriched"A."auricularia"polysaccharide"on"type"1"diabetes"mice[J]."Science"and"Technology"of"Food"Industry,"2024,"45(18)":"334-343."(in"Chinese)

[8]"LIN"L"M,"LUO"X"Q,"YU"H"M,"WANG"Q"F,"ZHANG"Z"W,"LI"K"M."The"effect"of"postharvest"water"migration"onnbsp;metabolism"of"cassava"root"by"hypobaric"storage[J]."Innovative"Food"Science"amp;"Emerging"Technologies,"2024,"93:"103609.

[9]"张振文,"李开绵."木薯及其加工利用100问[M]."北京:"中国农业出版社,"2017.ZHANG"Z"W,"LI"K"M."100"Questions"on"cassava"and"its"processing"and"utilization[M]."Beijing:"China"Agricultural"Publishing"House,"2017."(in"Chinese)

[10]"姜太玲,"刘光华,"周迎春,"熊贤坤,"刘超,"段春芳,"宋记明,"刘倩,"李月仙,"沈绍斌,"严炜,"易怀锋,"卢诚,"张林辉."不同品种木薯的主要品质特征与综合评价[J]."食品工业科技,"2019,"40(20):"251-255,"261.JIANG"T"L,"LIU"G"H,"ZHOU"Y"C,"XIONG"X"K,"LIU"C,"DUAN"C"F,"SONG"J"M,"LIU"Q,"LI"Y"X,"SHEN"S"B,"YAN"W,"YI"H"F,"LU"C,"ZHANG"L"H."Main"quality"characteristics"and"comprehensive"evaluation"of"different"varieties"of"cassava[J]."Science"and"Technology"of"Food"Industry,"2019,"40(20):"251-255,"261."(in"Chinese)

[11]"喻珊,"王友印,"邢晓东,"李开绵,"王志勇,"欧文军."木薯饲料化应用研究进展[J]."热带作物学报,"2023,"44(12):"2369-2383.YU"S,"WANG"Y"Y,"XING"X"D,"LI"K"M,"WANG"Z"Y,"OU"W"J."Research"progress"on"feed"application"of"cassava[J]."Chinese"Journal"of"Tropical"Crops,"2023,"44(12):"2369-2383."(in"Chinese)

[12]"CHARLES"A"L,"HUANG"T"C,"CHANG"Y"H."Structural"analysis"and"characterization"of"a"mucopolysaccharide"isolated"from"roots"of"cassava"(Manihot"esculenta"Crantz"L.)[J]."Food"Hydrocolloids,"2008,"22(1):"184-191.

[13]"CHIA"H"Y,"TE"H"T,"CHENG"U"H,"CHANG"B"Y,"CHUNG"S"K."Effects"of"sweet"cassava"polysaccharide"extracts"on"endurance"exercise"in"rats[J]."Journal"of"the"International"Society"Sports"Nutrition,"2013,"10(1):"18.

[14]"CHARLES"A"L,"HUANG"T."Sweet"cassava"polysaccharide"extracts"protects"against"CCl4"liver"injury"in"wistar"rats[J]."Food"Hydrocolloids,"2009,"23(6):"1494-1500.

[15]nbsp;UTHUMPORN"U,"NADIAH"I,"IZZUDDIN"I,"CHENG"L,"AIDA"H."Physicochemical"characteristics"of"non-starch"polysaccharides"extracted"from"cassava"tubers[J]."Saine"Malaysiana,"2017,"46(2):"223-229.

[16]"XI"T,"XIN"Z,"CHEN"H"G."Structure-activity"relationship"of"plant"polysaccharides[J]."China"Journal"of"Chinese"Materia"Medica,"2017,"42(21):"4104-4109.

[17]"陈超鹏,"全伟,"吴明亮,"张文韬."基于离散元法的油菜移栽垂直入土式成孔部件参数优化[J]."湖南农业大学学报"(自然科学版),"2019,"45(4):"433-439.CHEN"C"P,"QUAN"W,"WU"M"L,"ZHANG"W"T."Parameter"optimization"of"vertical"soil-filling"hole-forming"parts"for"rapeseed"transplantation"based"on"discrete"element"method[J]."Journal"of"Hunan"Agricultural"University"(Natural"Sciences),"2019,"45(4):"433-439."(in"Chinese)

[18]"陆建能,"麦碧仪,"刘义军,"赵雨诗,"陈云兰,"林丽静,"周大圣,"张明."梯度乙醇沉淀工艺对灵芝多糖结构特征及生物活性的影响[J]."热带作物学报,"2023,"44(4):"816-824.LU"J"N,"MAI"B"Y,"LIU"Y"J,"ZHAO"Y"S,"CHEN"Y"L,"LIN"L"J,"ZHOU"D"S,"ZHANG"M."Effect"of"gradient"alcohol"precipitation"process"on"the"structural"characteristics"and"biological"activity"of"ganoderma"lucidum"poly-saccharides[J]."Chinese"Journal"of"Tropical"Crops,"2023,"44(4):"816-824."(in"Chinese)

[19]"谭婉碧,"王琴飞,"余厚美,"何毅,"张振文."植物源功能活性多糖的提取及其研究进展[J]."热带农业科学,"2022,"42(7):"90-98.TAN"W"B,"WANG"Q"F,"YU"H"M,"HE"Y,"ZHANG"Z"W."Research"progress,"extraction"and"functional"activity"of"plant"polysaccharides[J]."Chinese"Journal"of"Tropical"Agriculture,"2022,"42(7):"90-98."(in"Chinese)

[20]"WU"H"Y,"SHANG"H"M,"GUO"Y,"ZHANG"H"X,"WU"H"X."Comparison"of"different"extraction"methods"of"polysaccharides"from"cup"plant"(Silphium"perfoliatum"L.)[J]."Process"Biochemistry,"2020,"90:"241-248.

[21]"LIAO"D"W,"CHENG"C,"LIU"J"P,"ZHAO"L"Y,"HUANG"D"C,"CHEN"G"T."Characterization"and"antitumor"activities"of"polysaccharides"obtained"from"ginger"(Zingiber"officinale)"by"different"extraction"methods[J]."International"Journal"of"Biological"Macromolecules,"2020,"152:"894-903.

[22]"董宇,"林翰清,"缪松,"卢旭."酶法提取多糖的研究进展[J]."食品工业科技,"2021,"42(3):"351-358.DONG"Y,"LIN"H"Q,"MIAO"S,"LU"X."Advances"in"enzymatic"extraction"of"polysaccharides[J]."Science"and"Technology"of"Food"Industry,"2021,"42(3):"351-358."(in"Chinese)

[23]"CHEN"X,"ZHANG"H,"DU"W"Q,"QIAN"L"Y,"XU"Y,"HUANG"Y"G,"XIONG"Q"P,"LI"H"L,"YUAN"J."Comparison"of"different"extraction"methods"for"polysaccharides"from"Crataegus"pinnatifida"bunge[J]."International"Journal"of"Biological"Macromolecules,"2020,"150:"1011-1019.

[24]"GUO"L,"TAN"D"C,"HUI"F"Y,"GU"F,"XIAO"K"M,"HUA"Y."Optimization"of"the"cellulase−ultrasonic"synergistic"extraction"conditions"of"polysaccharides"from"Lenzites"betulina[J]."Chemistry"amp;"Biodiversity,"2019,"16(11):"e1900369.

[25]"徐湘,"庞旭佳,"张名位,"张瑞芬,"贾栩超,"董丽红,"马勤,"赵东,"黄菲."不同提取工艺淮山多糖的理化性质及抗氧化活性分析[J]."现代食品科技,"2023,"39(10):"128-138.XU"X,"PANG"X"J,"ZHANG"M"W,"ZHANG"R"F,"JIA"X"C,"DONG"L"H,"MA"Q,"ZHAO"D,"HUANG"F."Physicochemical"properties"and"antioxidant"activity"of"chinese"yam"polysaccharides"extracted"by"different"methods[J]."Modern"Food"Science"amp;"Technology,"2023,"39(10):"128-138."(in"Chinese)

[26]"喻随,"邓霞,"陈思颖,"吴鹏,"占剑峰,"胡婷."纤维素酶法提取佛手山药多糖的工艺[J]."食品工业,"2020,"41(9):"60-63.YU"S,"DENG"X,"CHEN"S"Y,"WU"P,"ZHAN"J"F,"HU"T."Extraction"technology"of"polysaccharide"from"Foshou"yam"by"enzymatic"hydrolysis"of"cellulase[J]."The"Food"Industry,"2020,"41(9):"60-63."(in"Chinese)

[27]"张婷阳,"张伶,"蒋雨秦,"刘洋,"王新惠,"赵欣欣,"苗保河."玫瑰花渣多糖提取工艺优化及体外抗氧化活性分析[J/OL]."食品工业科技,"1-18"(2024-05-13)[2024-06-22]."doi:"10."13386/j.issn1002-0306.2023120256.ZHANG"T"Y,"ZHANG"L,"JIANG"Y"Q,"LIU"Y,"WANG"X"H,"ZHAO"X"X,"MIAO"B"H."Study"of"extraction"process"of"polysaccharides"from"rosa"residue"and"and"evaluation"of"antioxidative"activity[J/OL]."Science"and"Technology"of"Food"Industry,"1-18(2024-05-13)[2024-06-22]."doi:"10.13386/j."issn1002-0306.2023120256."(in"Chinese)

[28]"李晨京,"冯怡华,"王春玲."紫甘薯水溶性多糖的提取工艺优化及结构研究[J]."食品研究与开发,"2022,"43(24):"125-133.LI"C"J,"FENG"Y"H,"WANG"C"L."Extraction"optimization"and"structure"of"water-soluble"polysaccharides"from"purple"sweet"potato[J]."Food"Research"and"Development,"2022,"43(24):"125-133."(in"Chinese)

[29]"刘鑫,"陈香玉,"郭锐,"李旭娇,"寇宇星,"张俊爱,"吴艳."碧螺春多糖的超声辅助酶提取工艺优化、分离纯化及性质分析[J]."食品工业科技,"2021,"42(16):"138-146.LIU"X,"CHEN"X"Y,"GUO"R,"LI"X"J,"KOU"Y"X,"ZHANG"J"A,"WU"Y."Process"optimization"of"ultrasound-assisted"enzyme"extraction"of"Biluochun"polysaccharide"and"its"separation,"purification"and"property"analysis[J]."Science"and"Technology"of"Food"Industry,"2021,"42(16):"138-146."(in"Chinese)

[30]"陆源添,"刘迪."杨树桑黄与紫孢侧耳共培养胞内多糖提取工艺优化及抗氧化活性分析[J/OL]."食品工业科技,"1-19"(2024-05-31)[2024-06-22]."doi:"10.13386/j.issn1002-"0306."2024020046.LU"Y"T,"LIU"D."Optimization"of"intracellular"polysaccharide"extraction"process"and"analysis"of"antioxidant"activity"in"co-"cultures"of"sanghuangporus"vaninii"and"pleurotus"sap id us[J/OL]."Science"and"Technology"of"Food"Industry,"1-19"(2024-05-31)[2024-06-22]."doi:"10.13386/j.issn1002-0306."2024 0 20046."(in"Chinese)

[31]"韩宗辰."烟草专用α-淀粉酶的基因挖掘及其表达优化[D]."武汉:"华中农业大学,"2023.HAN"Z"C."Gene"mining"and"expression"optimization"of"tobacco-specific"alpha-amylase[D]."Wuhan:"Huazhong"Agricultural"University,"2023."(in"Chinese)

[32]"胡晓龙,"冯大鸿,"田瑞杰,"王永亮,"曹满堂,"魏涛,"韩素娜,"沈祥坤,"何培新."中温大曲产淀粉酶菌株的筛选鉴定及培养条件优化[J]."中国酿造,"2023,"42(1):"78-85.HU"X"L,"FENG"D"H,"TIAN"R"J,"WANG"Y"L,"CAO"M"T,"WEI"T,"HAN"S"N,"SHEN"X"K,"HE"P"X."Isolation,"identification"and"culture"conditions"optimization"of"amylase-pro du cing"strains"in"medium-temperature"Daqu[J]."China"Brewing,"2023,"42(1):"78-85."(in"Chinese)

[33]"YEKTA"G,"PÜRLEN"U,"SEVAL"D."Optimization"of"pullulan"production"from"hydrolysed"potato"starch"waste"by"response"surface"methodology[J]."Carbohydrate"Polymers,"2011,"83(3):"1330-1337.

[34]"谭婉碧,"王琴飞,"张金泉,"余厚美,"张振,"何毅."不同菌种发酵木薯粉品质和糊化特性比较分析[J]."食品科学,"2023,"44(10):"56-63.TAN"W"B,"WANG"Q"F,"ZHANG"J"Q,"YU"H"M,"ZHANG"Z"W,"HE"Y."Comparative"analysis"on"quality"and"gelatinization"characteristics"of"cassava"flour"fermented"by"different"strains[J]."Food"Science,"2023,"44(10):"56-63."(in"Chinese)

[35]"董义,"沈才洪,"曾里,"黄张君,"刘晓碧,"刘文虎,"何强,"曾凡骏."酶解辅助提取山药多糖的研究[J]."河南工业大学学报"(自然科学版),"2015,"36(3):"56-60.DONG"Y,"SHEN"C"H,"ZENG"L,"HUANG"Z"J,"LIU"X"B,"LIU"W"H,"HE"Q,"ZENG"F"J."Enzymolysis-assisted"extraction"of"polysaccharides"in"Chinese"yam[J]."Journal"of"Henan"University"of"Technology"(Natural"Science"Edition),"2015,"36(3):"56-60."(in"Chinese)

[36]"ZHANG"Y"T,"XU"F,"WANG"Q"F,"ZHANG"Y"J,"WU"G,"TAN"L"H,"ZHANG"Z"W."Effects"of"moisture"content"on"digestible"fragments"and"molecular"structures"of"high"amylose"jackfruit"starch"prepared"by"improved"extrusion"cooking"technology[J]."Food"Hydrocolloids,"2022,"133:"108023.

[37]"陈雪梅,"刘夏蕾,"林标声,"陈小红,"黎英."百香果果皮主要有效成分连续提取工艺[J].nbsp;热带作物学报,"2023,"44(2):"405-418.CHEN"X"M,"LIU"X"L,"LIN"B"S,"CHEN"X"H,"LI"Y."Continuous"extraction"technology"of"main"active"components"of"passion"fruit"peel[J]."Chinese"Journal"of"Tropical"Crops,"2023,"44(2):"405-418."(in"Chinese)

[38]"郭蒙,"郭纯,"蒋青,"高林晓."黄果茄中绿原酸超声辅助提取工艺优化及抗氧化活性[J]."热带作物学报,"2023,"44(4):"825-833.GUO"M,"GUO"C,"JIANG"Q,"GAO"L"X."Ultrasound-assisted"extraction"process"optimization"of"chlorogenic"acid"from"Solanum"xanthocarpum"fruits"and"its"antioxidant"activity[J]."Chinese"Journal"of"Tropical"Crops,"2023,"44(4):"825-833."(in"Chinese)

[39]"JIA"Y"N,"GAO"X"D,"XUE"Z"H,"WANG"Y"J,"LU"Y"P,"ZHANG"M,"PANICHAYUPAKARANANT"P,"CHEN"H"X."Characterization,"antioxidant"activities,"and"inhibition"on"alpha-glucosidase"activity"of"corn"silk"polysaccharides"obtained"by"different"extraction"methods[J]."International"Journal"of"Biological"Macromolecules,"2020,"163:nbsp;1640-1648.

[40]"XIAO"B,"HUANG"Q"Q,"CHEN"S,"YAO"J,"ZENG"J"Y,"SHEN"J"M,"WANG"G,"WANG"W"M,"ZHANG"Y"J."Comparison"on"chemical"features"and"antioxidant"activity"of"polysaccharides"from"Auricularia"auricula"by"three"different"enzymes[J]."Journal"of"Food"Biochemistry,"2022,"46(5):"e14051.

[41]"HONG"S,"ZHANG"Z"Q,"LI"Y"X,"ZHANG"Y,"YANG"L"N,"WANG"S"N,"HE"Y"T,"LIU"J,"ZHU"D"S,"LIU"H."Effects"of"different"enzyme"extraction"methods"on"the"properties"and"prebiotic"activity"of"soybean"hull"polysaccharides[J]."Heliyon,"2022,"8(11):"e11053.

[42]"张妮,"陶文扬,"罗梦帆,"周万怡,"郑晓杰,"李彦坡,"金火喜,"杨颖."酶解辅助提取对铁皮石斛多糖结构和菌群调节功能的影响[J]."浙江农业学报,"2024,"36(9):"2099-2109.ZHANG"N,"TAO"W"Y,"LUO"M"F,"ZHOU"W"Y,"ZHENG"X"J,"LI"Y"P,"JIN"H"X,"YANG"Y."Effects"of"enzyme-assisted"extraction"on"polysaccharide"composition"and"gut"microbiota"regulation"function"of"Dendrobium"officinale[J]."Acta"Agriculturae"Zhejiangensis,"2024,"36(9):"2099-2109."(in"Chinese)