废旧风电叶片粉体/聚丙烯复合材料力学性能及润湿性能研究

2024-10-14于勐张爱玲邢作霞张雨晴葛靖怡范雨亭李立石王睿涵金垚均

摘 要: 针对废旧风电叶片粉体材料(WWTB)回收加工高值化利用问题,以WWTB(平均粒径尺寸<2 mm)为原料,采用三种不同的改性剂对其进行活化改性修饰,选择出较佳的改性剂及用量,得到改性修饰废旧风电叶片粉体材料(GWWTB)。采用熔融共混方式制备改性修饰废旧风电叶片粉体/聚丙烯复合材料(GWWTB/PP),考察GWWTB含量对GWWTB/PP复合材料力学性能、热稳定性能、润湿性能和断裂面微观形貌的影响。结果表明:采用质量分数4wt%的Z-6173改性效果最佳,活化指数提高了78.6%。当GWWTB含量质量分数为6wt%时,GWWTB/PP复合材料热稳定性最高,拉伸强度和冲击强度最大,热失重5%分解温度提高了11.7%,拉伸强度和冲击强度分别提高了22.89%和178.54%,GWWTB/PP复合材料的润湿性能随着GWWTB含量的增加而提高,GWWTB/PP复合材料亲水性增强。

关 键 词:废旧风电叶片粉体材料; 改性剂; 聚丙烯; 力学性能; 润湿性能

中图分类号:TQ314.262文献标志码: A文章编号: 1004-0935(20202024)0×9-1351-04

风电叶片作为风电能源产业装置必不可少的核心部件之一,一般的使用寿命为20~30年,在未来的十几年内,将会出现风电叶片的“下线潮”,风电叶片复合材料的回收问题亟待解决[1-3]。目前国内主要以焚烧和填埋的方式处理[4-5],这两种回收方法都很难将废弃物再资源化,废弃物焚烧和填埋处置造成大量可循环资源的流失,而且还会占用土地资源,对环境造成二次污染,周边可供处置的土地面积大量减少[6-7]。物理回收方法相对于前两种回收方式具有低碳环保、节约资源、操作简单的优势,它主要是通过研磨粉碎方式获得复合填料,所以常用于废弃材料的回收和处理[8]。

基于健全风电产业全生命周期循环,为了将WWTB清洁回收和高值化利用,本文将对WWTB进行改性修饰,选择出较佳的改性剂及含量,然后制备GWWTB/PP复合材料,研究GWWTB含量对其力学性能、热稳定性能和润湿性能的影响。同时将WWTB填充引入PP体系中文章鲜有报道,可以为提高PP性能提供新思路和新方法。

1 实验部分

1.1 实验材料

WWTB;γ-氨丙基三乙氧基硅烷(KH550,上海耀华化工厂);γ-(2,3-环氧丙氧)丙基三甲氧基硅烷(KH560,上海耀华化工厂);Z-6173(美国道康宁公司);邻苯二甲酸二丁酯(DBP,天津市大茂化学试剂厂);聚丙烯(PP,北欧化工)。

1.2WWTB改性修饰及GWWTB/PP复合材料制备

将WWTB通过湿法改性与含有不同官能团的改性剂发生化学反应得到GWWTB。将GWWTB与PP采用熔融共混的方式挤出造粒,得到GWWTB/PP复合原料,进行性能测试与表征。

1.3测试与表征

质量法测定活化指数;用IR Prestige-21型红外光谱仪分析WWTB改性修饰前后官能团结构变化;用Q50型热重分析仪分析GWWTB/PP复合材料热稳定性;拉伸强度和冲击强度分别按照GB/T 1040.1—2006、GB/T 1843—2008测试;使用JC2000D8型接触角测量仪对样品进行水接触角测量;使用EVO MA-10型扫描电子显微镜分析GWWTB/PP复合材料标准测试样条拉伸断裂面微观形貌。

2结果与讨论

2.1 WWTB改性修饰研究

2.1.1活化指数

改性剂可以改变粉体表面性质,以改善WWTB与其他材料间的相容性,通过活化指数可以简单直观地反映样品的改性修饰效果[9]。改性剂质量分数对WWTB活化指数影响见图1,WWTB经过质量分数4% Z-6173改性修饰活化指数最高,从未改性的3%提高到81.6%;说明经过改性修饰后,WWTB的疏水性有所提高,与其他材料或者基体相容性更好。这与改性剂中的疏水基团有关,疏水基团与WWTB结合导致复合材料呈现良好的疏水性。

2.1.2表面结构分析

图2为Z-6173改性修饰前后红外光谱图,Z-6173红外光谱中2 960 cm-1处为烷基官能团,1 080 cm-1和808 cm-1处为Si-O键特征吸收峰,改性修饰后红外光谱在2 962.66 cm-1处出现-CH的反对称伸缩振动峰,在1 263.37 cm-1和1 035.77 cm-1处出现脂肪醚C-O键吸收峰。说明Z-6173中的Si-O键与WWTB中的环氧基团发生开环交联反应,烷基官能团也有效与WWTB相结合,Z-6173改性剂的引入提高了WWTB与其他材料的相容性问题,使其与其他基体材料能够更好相容。

2.2 GWWTB/PP复合材料研究

2.2.1 GWWTB质量分数对GWWTB/PP复合材料热稳定性影响

图3为GWWTB质量分数对GWWTB/PP复合材料热失重影响。PP初始分解温度为341.0 ℃,PP热失重5%,分解温度为380.6 ℃。当GWWTB质量分数为6%时,GWWTB/PP复合材料初始分解温度最高为348.0 ℃,热失重5%,分解温度最高为425.1 ℃,此时GWWTB/PP复合材料的热稳定性最好,两者相容性最好,GWWTB可以提高GWWTB/PP复合材料的热稳定性。GWWTB/PP复合材料的残余量应该归因于GWWTB中的玻璃纤维含量,随着GWWTB含量增加,GWWTB/PP复合材料残余量增大。

2.2.2 GWWTB质量分数对GWWTB/PP复合材料力学性能影响

GWWTB质量分数对GWWTB/PP复合材料力学性能影响见图4。

当GWWTB质量分数为6%时,拉伸强度最高为34.63 MPa,冲击强度最高为12.59 kJ·m-2,分别提高了22.89%和178.54%。说明GWWTB中的玻璃纤维可以增强PP,PP与GWWTB相容性较好,随着GWWTB含量的增大,会有更多的粉体来承担基体传递的载荷,GWWTB/PP复合材料强度会增加,但随着粉体质量分数大于6%时,粉体会出现团聚现象,不能很好地分散在PP表面,不能形成有效包覆,两者相容性变差,从而导致GWWTB/PP复合材料力学性能下降。

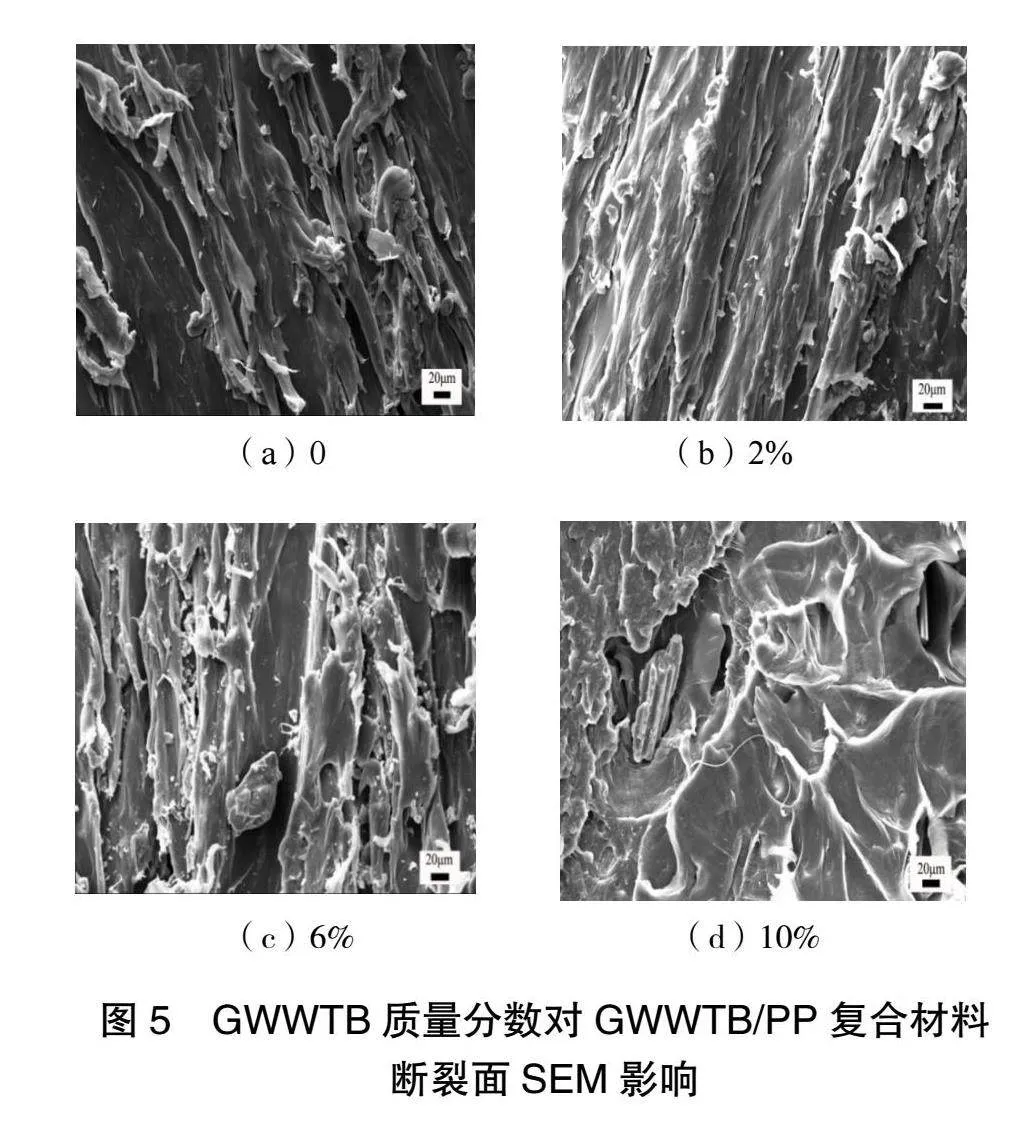

2.2.3 GWWTB质量分数对GWWTB/PP复合材料断裂面微观形貌影响

GWWTB质量分数对GWWTB/PP复合材料断裂面SEM影响见图5。

随着GWWTB少量加入,GWWTB/PP复合材料测试样条拉伸断裂面比较粗糙,断面呈褶皱状,表明其拉伸断裂为较强的韧性断裂,因此GWWTB/PP复合材料有很高的拉伸强度。当GWWTB添加质量分数超过6%后,GWWTB/PP复合材料拉伸断裂面开始变得逐渐光滑平整,断裂面褶皱变小,表明GWWTB/PP复合材料韧性断裂减弱,分散相开始增多,说明GWWTB与PP相容性开始变差,从而导致GWWTB/PP复合材料的力学性能降低。

2.2.4 GWWTB质量分数对GWWTB/PP复合材料润湿性能影响

采用热压法将GWWTB/PP原料制成复合薄膜,测定其水接触角,从而判断GWWTB/PP复合薄膜的润湿性能。GWWTB质量分数对GWWTB/PP复合材料润湿性能影响见图6。

随着GWWTB质量分数的增加,GWWTB/PP复合薄膜的接触角逐渐变小,从110.72°降低到64.52°,说明GWWTB/PP复合薄膜润湿性能增强,GWWTB/PP复合薄膜从疏水性变成亲水性。原因可能在于随着GWWTB含量的增加,GWWTB中的改性剂具有较低的表面能,较高的润湿能力,从而提高非均质材料之间的相容性和分散性,使两者紧密结合,从而完成非均质材料之间的偶联过程,使GWWTB/PP复合薄膜表面亲水,表面张力变大。

3 结论

采用含有不同官能团的改性剂对WWTB进行改性修饰,Z-6173改性修饰效果最好,较佳质量分数为4%。当GWWTB质量分数为6%时,GWWTB/ PP复合材料热稳定性、力学性能最好;热失重5%时分解温度提高了11.7%,拉伸强度提高了22.89%,冲击强度提高了178.54%;随着GWWTB含量的增加,GWWTB/PP复合薄膜接触角由110.72°降低到64.52°,GWWTB/PP复合材料从疏水性材料变成亲水性材料。

参考文献:

[1] FANTIN IRUDAYA RAJ E, APPADURAI M, LURTHU PUSHPARAJ T, et al. Wind turbines with aramid fiber composite wind blades for smart cities like urban environments: Numerical simulation study[J]. , 2023, 10(1): 139-156.

[2] SAKELLARIOU N. Current and potential decommissioning scenarios for end-of-life composite wind blades[J]. , 2018, 9(4): 981-1023.

[3] CAPRILE C, SALA G, BUZZI A. Environmental and mechanical fatigue of wind turbine blades made of composites materials[J]. , 1996, 15(7): 673-691.

[4] CHEN J L, WANG J H, NI A Q. Recycling and reuse of composite materials for wind turbine blades: an overview[J]. , 2019, 38(12): 567-577.

[5] 刘雪辉,徐世美,王玉忠.热固性树脂及其复合材料的升级回收新方法[J].中国材料进展,2022,41(1):7-13.

[6] ZHAO X, LONG Y W, XU S M, et al. Recovery of epoxy thermosets and their composites[J]. ,2023, 64: 72-97.

[7]许冬梅,张兴林,荆涛.废旧热固性复合材料绿色回收利用关键技术研究——以风电行业废弃风叶片为例[J].环境保护,2019,47(20):54-56.

[8]雷蕊英,齐锴亮.热固性树脂基复合材料的化学回收方法及再利用现状[J].工程塑料应用,2018,46(11):134-137.

[9]曹笑宁,马亚丽,岳岩,等.改性氢氧化镁的制备及在HDPE中的应用[J].塑料工业,2022,50(1):38-43.

Research on Mechanical Properties and Wettability of Waste

Wind Turbine Blade Powder/Polypropylene Composite

YU Meng1a, ZHANG Ai-ling1,*a, XING Zuo-xia2b, ZHANG Yu-qing1a, GE Jing-yi1a,

FAN Yu-ting1a, LI Li-shi1a, WANG Rui-han1a, JIN Yao-jun1a

(1a.Schoolof Environmental and Chemical Engineeringof Shenyang University of Technology, Liaoning Shenyang 110870,China;

2b. New Energy Research Instituteof,Shenyang University of Technology, ShenyangLiaoning Shenyang110870,,China)

Abstract:Aiming at the high value utilization of waste wind turbine blade powder material (WWTB) recycling and processing, WWTB (average particle size < 2 mm) was used as raw material, it was activated and modified by three different modifiers, and the better modifier and dosage were selected to obtain modified waste wind turbine blade powder material (GWWTB).The modified waste wind turbine blade powder/polypropylene composite (GWWTB/PP) was prepared by melt blending. The effects of GWWTB content on the mechanical properties, thermal stability, wettability and fracture surface morphology of GWWTB/PP composite were investigated.The results showed that mass fraction 4% Z-6173 had the best modification effect, the activation index was increased by 78.6%.When the mass fraction of GWWTB was 6%, the thermal stability, tensile strength and impact strength of GWWTB/PP composite material were the best. The thermal decomposition temperature of 5% weight loss was increased by 11.7%,the tensile strength and impact strength were increased by 22.89% and 178.54%, respectively.using different modifying agents as raw materials, the modified waste wind turbine blade powder material (GWWTB) was obtained by selecting the best modifier and dosage. Modified waste wind turbine blade powder/polypropylene composite (GWWTB/PP) was prepared by melt blending method. The effects of GWWTB content on mechanical properties, thermal stability, wetting property and fracture surface microstructure of GWWTB/PP composite material were investigated. The results show that 4wt% Z-6173 has the best modification effect, the activation index is increased by 78.6%. When the content of GWWTB is 6wt%, the thermal stability, tensile strength and impact strength of GWWTB/PP composite material are the best. The thermal decomposition temperature of 5% weight loss is increased by 11.7%,the tensile strength and impact strength are increased by 22.89% and 178.54%, respectively. The wettability of GWWTB/PP composite material increases increased with the increase of GWWTB content, enhancing the hydrophilicity of GWWTB/PP composite material.

Key words:Waste wind turbine blade powder material;Modifying agent; Polypropylenel; Mechanical property; Wetting property