The personal protective equipment(PPE)based on individual combat:A systematic review and trend analysis

2023-11-11QinrnHuXingyuShenXinmingQinGungynHungMengqiYun

Qin-rn Hu , Xing-yu Shen , Xin-ming Qin , Gung-yn Hung ,**,Meng-qi Yun ,b,*

a State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing,100081, China

b Chongqing Innovation Center, Beijing Institute of Technology, Chongqing, 400044, China

Keywords:Personal protective equipment (PPE)Individual combat Material and structure Equipment application Intelligent devices Wearable technology

ABSTRACT With the development of ordnance technology,the survival and safety of individual combatants in hightech warfare are under serious threat, and the Personal Protective Equipment (PPE), as an important guarantee to reduce casualties and maintain military combat effectiveness, is widely developed.This paper systematically reviewed various PPE based on individual combat through literature research and comprehensive discussion, and introduced in detail the latest application progress of PPE in terms of material and technology from three aspects: individual integrated protection system, traditional protection equipment, and intelligent protection equipment, respectively, and discussed in depth the functional improvement and optimization status brought by advanced technology for PPE, focusing on the achievements of individual equipment technology application.Finally, the problems and technical bottlenecks in the development of PPE were analyzed and summarized, and the development trend of PPE were pointed out.The results of the review will provide a forward-looking reference for the current development of individual PPE, and are important guidance for the design and technological innovation of advanced equipment based on the future technological battlefield.

1.Introduction

With the intertwined impact of once-in-a-century global changes and unprecedented pandemic, the current forms of economic globalization have encountered an increasingly fluid and the world is gradually entering a new period of instability[1].Although the world military security situation has remained generally stable,but, the number of unstable factors affecting the world military security situation has increased significantly, adding uncertainty increases to the international security, major power relations and regional situations, and posing unprecedented risks to human development [2].At present, the military war situation is still severe, and some countries are still at war, causing serious human casualties and economic losses.More than 300,000 people have died in the Syrian conflict from 2011 to 2021, according to the United Nations [3].At the beginning of 2022, Russia and Ukraine had a military conflict [4].Soldiers, as the people who face the brutal war directly,suffer even more casualties.Since the two sides fought,100 to 200 soldiers have died every day in the Donbas region of Ukraine alone [5].With the rapid development of technology,the traditional combat unit will take a qualitative leap,and the safety of soldiers will be seriously threatened, thus having an essential impact on the overall war situation [6].Therefore, the safety of soldiers on the battlefield plays an important role in maintaining the overall combat power and the evolution of the war situation.As the life barrier of soldiers, Personal Protective Equipment(PPE)has significant value in protecting their own safety and improving combat effectiveness [7].

PPE mainly includes protective clothing and other protective systems and accessories, which protect the safety and health of soldiers, without affecting the basic requirements of normal operation, and enable soldiers to reduce the harm caused by various ordnance [8].It is the last line of defense to ensure the safety of soldiers.The development history of soldiers'PPE is closely related to the development of various ordnance.In the cold ordnance era,soldiers wore armor to prevent simple physical penetration [9].With the development of science and technology, various thermal ordnances have emerged as the times require, and the PPE of soldiers has also made considerable progress [10].At present, according to the protection function, a single set of PPEs is mainly divided into hard protection components and soft protection components[11].The hard protection components include helmet,bulletproof clothing, stab-resistant clothing, explosion-proof suit and other protective equipment against mechanical injury[12].Soft protection components include gas masks, anti-toxic clothing,noise-proof ear-wear, anti glare and anti laser glasses, high temperature fireproof insulation clothing, nuclear radiation and nuclear pollution protection clothing, etc., which are mainly used to prevent various physical, chemical and biological violations.However, with the development of scientific and technological ordnance, the threats faced by soldiers are complex and diverse(Table 1).On the one hand, combat soldiers may be injured by traditional ordnance such as gunfire, explosive fragments, nuclear ordnance, biological ordnance and chemical ordnance, hightemperature flame, blade stabbing, and by new concepts such as radiation,high-speed pulse,laser and acoustics.Therefore,the use of various high-power and high-energy new ordnance will lead to the loss of some functions of traditional defense equipment.At present, the soldier's protective equipment still needs to adapt to the combat tasks, provide effective protection for soldiers facing various threats, and improve the performance of PPE will become more and more vital.

With the development of science and technology, IoT technology provides new ideas for PPE development and promotes the revolution of intelligent PPE [13].Combining the IoT technology with clothing design, to improve the communication between individual soldiers and the digital world, enhancing the life protection capabilities.Through the exploration in a long period, the integrated protection system for soldiers has gradually entered the vision of national armies.The design concept is basing on arms,combining various equipment through integrated and systematic design,and use the soldier's body as a carrying platform to form a protection unit to greatly enhance the soldier's integrated protection capability, battlefield situational awareness capability and information processing capability [14].In the late 1980s, the U.S.Army first proposed the concept of “Individual Integrated Protection System” for soldiers to perform precision strikes, reconnaissance, combat coordination and other tasks under informationbased combat conditions [15]; In 1996, the French Army proposed the future individual integrated protection system.Since then,more than 20 countries such as Australia,Britain,Germany,Russia,South Korea, and India have also put forward their soldier system development plans[16],and the protection system technology has become increasingly mature and will play an important role in the future information battlefield.The individual integrated protection system has become an important element in the construction of 2lth century armies in western countries.

With the progress of artificial intelligence, big data and cloud computing [17], modern warfare form has transformed from information technology to intelligent, networked, data.The development of PPE for preserving military forces and win the future technological warfare has great significance in the new era [18].This paper mainly focuses on the progress of PPE applications based on individual combat through the systematic review, providing a systematic overview of the progress of new technologies currently used in PPE.In order to provide the reader with a clear understanding of the progress on equipment,the paper first provides an overview of individual integrated protection system,followed by an overview of traditional protection equipment,and finally describes in detail the progress of intelligent protection equipment.The results of the overview will provide forward-looking thinking on the status and development of today's individual PPE, and are of great reference significance for the new trends, levels, principles, and technologies for future PPE development.

2.Individual integrated protection system

2.1.Basic composition and functional characteristics

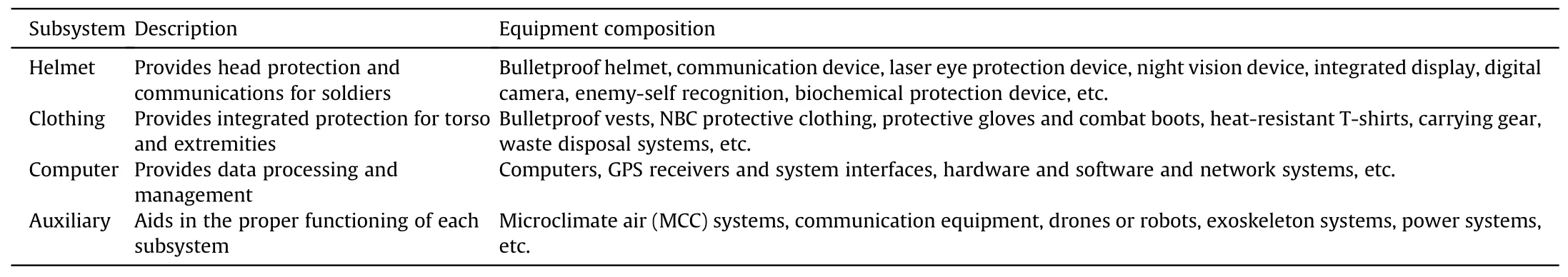

In 1989,the U.S.Army formally proposed the Soldier Integrated Protective Ensemble (SIPE) [19].Since then, countries around the world have followed suit, and the basic components of the soldier integrated protective ensemble are similar.At present, the international advanced the soldier integrated protective ensemble mainly consists of helmet subsystem, mask subsystem, clothing subsystem and auxiliary subsystem [20], as shown in Table 2.The helmet system ensures protection for the soldier's head, the mask system ensures protection for the soldier's face and respiratory tract, and the clothing system ensures protection for the soldier's body and extremities.The auxiliary system is based on the platform of the first three systems and uses modern technology to construct an integrated offensive and defensive effectiveness.

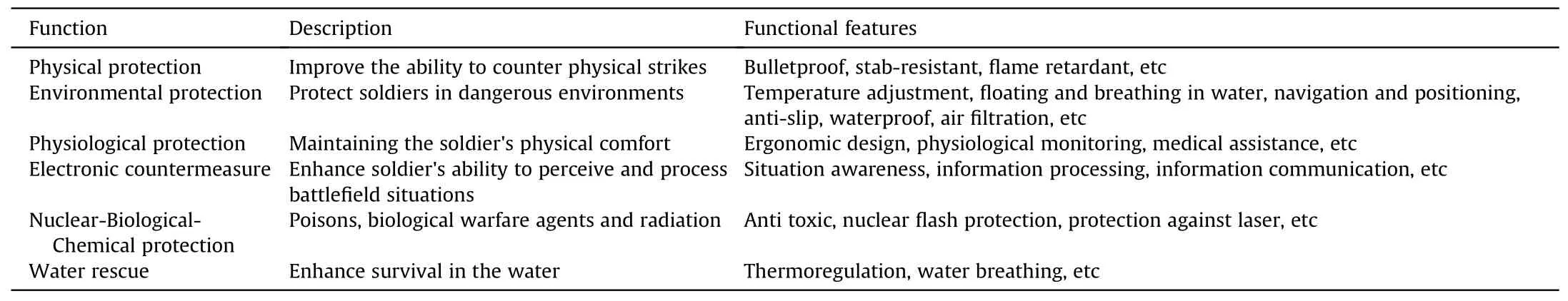

The SIPE based on reducing battlefield casualties, emphasizing multifunctional integrated design, promoting soldier protection and combat effectiveness [21].Based on Western military powers,the basic functions of the SIPE are divided into six types, mainly including physical protection, environmental protection, physiological protection, electronic information countermeasures,nuclear-biological-chemical protection,and water rescue(Table 3).Protection, information, command and control of integrated equipment has landed on the stage of modern warfare [22].

The integrated protection system realizes the perfect combination of soldiers and equipment by integrating,miniaturization and modular design, integrating various functions and reasonabledeployment.Functional integration and informationization are the most obvious features of integrated protection system.The protection system optimizes the entire system by treating all items carried by the soldier as a whole and integrating the various functions required.

Table 2The basic components of the SIPE.

Table 3The functions of the SIPE.

Informatization is a key part of connecting soldiers to the digital battlefield and providing them with an information advantage.With the intensification of the digital battlefield,the requirements for the informatization of protective equipment are increasing.At present,the U.S.,UK and other countries have incorporated the SIPE into the digital battlefield [23].The British Army will increase the digital test content of the individual system after launching the digital master plan[24].The U.S.Land Warrior system,based on the subsystem of computer helmets and sensors, connects soldiers to the digital battlefield,enabling them to rapidly discover targets and understand the battlefield situation, greatly improving their decision-making ability, reaction time, and overall combat effectiveness [25-27].Therefore, the development of information technology will significantly improve the active protection capability of the individual system.

2.2.Development overview

In 1989, the U.S.Army developed the “Integrated Soldier Protection System” program, and then launched the “Land Warrior”,“Future Force Warrior”, “Ground Soldier System” and “Knight Warrior” and other systems.In the U.S.Army's “Soldier Integrated Protective Clothing Advanced Demonstration Program”,for the first time, soldier protection is treated as a system, and the “Soldier Integrated Protective Ensemble” is proposed, which consists of three parts: the advanced clothing subsystem, the overall helmet subsystem, and the microclimate regulation subsystem.With the development of the world military revolution and new technologies [28], countries around the world have invested a lot of resources to seize the military high ground in modern warfare, and have strengthened the development of soldier protection systems,as shown in Fig.1.

The German soldier system started early, with the first generation of the IdZ-ES system(Fig.1(e))having been mass-produced in 2009 and more than 3500 soldiers already equipped with the system.IdZ-ES system uses a new design of combat clothing:inside is breathable,anti-bacterial underwear and socks,and its outside is not only waterproof, fireproof, insect bite resistant, scratch resistant, but also able to not be sensed by visible light and infrared detection equipment.The head protection is a helmet weighing approximately 1.6 kg, capable of defending against artillery fragments and 5.56- and 7.62-mm rifle rounds.The IdZ-ES soldier C4I system is at the heart of the German Army's drive to digitization.It is an electronic tactical undershirt of modular design,weighing 4 kg and with a front zipper, with functions such as organizing and receiving information,acquiring images,and checking positions.In 2020, Germany is actively advancing the development of the 4th generation IdZ soldier system (IdZ-ES VJTF 2023), with future for modular equipment with open architecture.

In 2011, the French 1st Infantry Regiment made public for the first time the FELIN Future Soldier System (Fig.1(f)), an integrated infantry system developed by Sagem in conjunction with 25 contractors.The core function of FELIN is the integration capability to integrate soldiers into the broader digital networked battlefield.Each soldier is equipped with a Bone-guide transmitter, allowing clear calls in a noisy battlefield environment.The FELIN system is also equipped with JIMMR target detectors and surveillance scopes with a maximum detection range of 3500 m against enemy forces.However,the FELIN system has a mass specification of 25 kg,which is a large load for soldiers to wear.In 2019,the French Army plans to integrate the FELIN system into the “Scorpion” modernization program and conduct research on new goggles using augmented reality technology.The goggles display a range of data such as friendly and enemy positions, tactical layouts, and munitions information, further improving the soldier's situational awareness.

Fig.1.Evolution of individual integrated protection system: (a) America-soldier intergrated protective ensemble; (b) Ameica-land warrior; (c) Britain-future integrated soldier technology system(FIST);(d)Israel-ruler soldier system(DAP);(e)Germany-IDZ extended system(IDZ-ES); (f)France-equipment and communication integrated infantry system;(g) Ameica-torso and extremities protection; (h) Russia-soldier-3 soldier system (Ratnik-3).

In 2019, the U.S.Army introduced a new lightweight soldier system,the TEP(Torso and Extremities Protection)(Fig.1(g)),which is lighter, more flexible, more comfortable, and more functional.The TEP system integrates more advanced technology to ensure protection while improving man-machine ergonomics.The special leader in U.S.Soldier Program Executive Office stated that the mass of the vest in the TEP is 10.4 kg,which is 26%less than the Army's current Improved Outer Tactical Vest(IOTV),which protects against fragmentation kills and 9 mm gunshot wounds [29].

Ratnik-3 is a 3rd generation soldier system(Fig.1(h)),developed by the Russian Precision Machinery Manufacturing Company and scheduled to be completed in 2022,the mass of the system will be reduced by 30%.The helmet will be equipped with a new communication system, enemy identification system, capable of exchanging many types of information in real time, and can transmit data to other soldiers and command centers, as well as continuously collecting data on the health status of soldiers.In addition,the system will be equipped with a wearable exoskeleton system.The next-generation Ratnik system will integrate medical sensors to monitor soldiers'physiological and psychological status[30].

At present, the integrated protection system has become increasingly perfect, but also faces many challenges, of which the load has become the primary problem [31].Currently, a soldier in Iraq needs to carry a load of 45.4 kg,and if the soldier is equipped with electronic systems,the load will be even greater,thus affecting the soldier's mobility and sustained combat capability, so the weight reduction is the biggest problem facing the application of the integrated protection system.In addition, the development of information technology follows the trend of the world's new military revolution,and will occupy an important position in the future of individual combat.In summary,the development of information technology, lightweight, modularity and miniaturization of equipment will become the inevitable trend of the future integrated protection systems.

3.Traditional PPE

3.1.Bulletproof

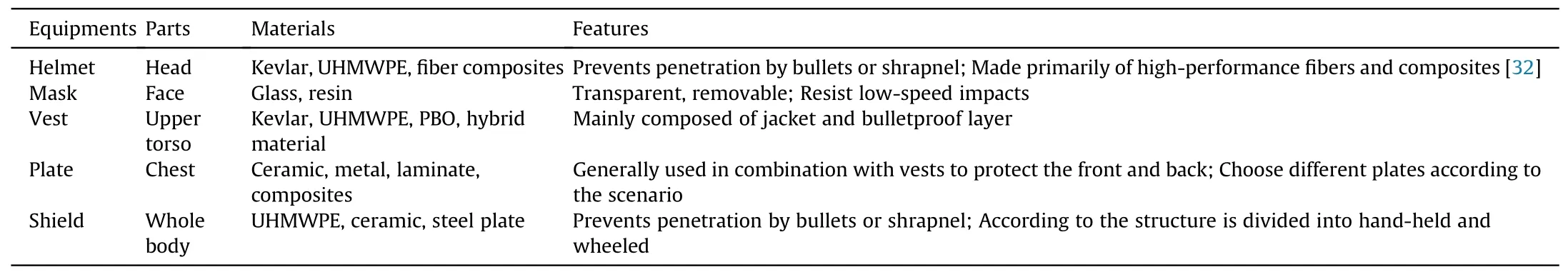

Protection from physical damage caused by bullets and shrapnel to soldiers has always been the primary element of protection for individual equipment.At present, individual bulletproof equipments have been gradually improved and has achieved bullet and shrapnel protection for all parts of the soldier,as shown in Table 4.

The bulletproof equipment is usually divided into soft and hard,soft bulletproof vest is the earlier applied protective equipment,which is multi-layer woven or laminated fabric structure to resist the high-speed impact of fragments,soft material and high ballistic resistance to ensure the flexibility and basic protection of soldiers[33].Flexible materials against ballistic impact have made significant progress in the last few decades, and currently, the main materials used in body armor are ultra-strong fibers such as Kevlar,ultra high molecular weight polyethylene(UHMWPE),and Poly-pphenylene benzobisoxazole (PBO) [34].

In 1972, DuPont introduced Kevlar, a para-aromatic polyamide fiber product, which is considered to have the highest energy absorption capacity and is therefore the most widely used material for ballistic applications.Kevlar is a new high-tech synthetic fiber[35,36],which has excellent properties such as ultra-high strength,high modulus and high temperature resistance, acid and alkali resistance, light weight, etc.The strength of Kevlar is 5-6 timesthat of steel wire, modulus is 2-3 times that of steel wire or glass fiber, and toughness is 2 times that of steel wire.

Table 4Individual bulletproof equipments.

In 1986, United Signal corporation produced a higher strength UHMWPE fiber body armor (Fig.2(a)), accelerating the development of bulletproof materials toward light weight and comfort.UHMWPE fiber has high strength and modulus,and is the strongest fiber among high-performance fibers[37].The specific modulus of UHMWPE fiber is 2.5 times higher than that of aramid, and its energy absorption and stress wave transfer in protection against bullet impact are better than other fibers.However, UHMWPE fibers have disadvantages such as poor heat resistance and poor adhesion.

Polybenzoate (PBO) is known as the super fiber of the 21st century,with high strength,high modulus,high heat resistance and high flame retardant, and is one of the best performing organic fibers found so far [38].However, the fiber is less used in military individual protection because it is not resistant to acid and light,has poor compression resistance, and is expensive.

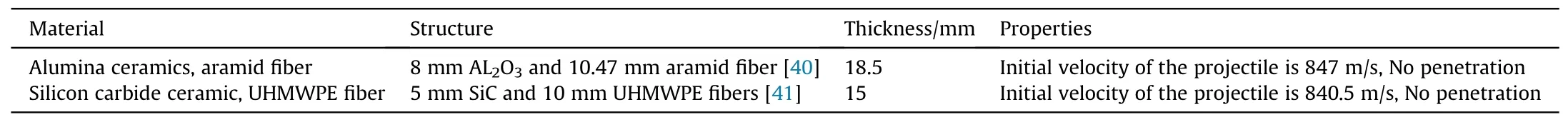

Hard bulletproof equipment corresponds to a higher level of protection and includes bulletproof helmets,plates,masks,etc.It is mainly composed of materials or structures such as laminates, ceramics and resins.Laminates are generally monolithic structural panels consisting of multiple layers of single-layer materials bonded together and used primarily as an intermediate layer or backing material in high-speed impact environments [39].More used in the field of ballistic protection is a rigid laminate made of various high-performance fiber composites, and together with ceramics to form a bulletproof plate that can defend against the impact of 800 m/s bullets,as shown in Table 5.The bulletproof plate composed of UHMWPE laminate and alumina ceramic is shown in Fig.2(b).

With the rise of high-tech industry, ceramics have gradually become excellent structural and functional materials [42,43].The U.S.spike armor company launched a “dragon scale armor” body armor, is made of small pieces of ceramic ballistic tiles and new ballistic fiber woven into a fish scale protective equipment, as shown in Fig.2(c).The “Dragon Scale Armor” body armor is unprecedented in its ability to protect against all kinds of bullets,and will not be penetrated by 7.62 mm military ammunition hit 40 times at 6 m.

Resins are usually organic polymers that soften when subjected to heat.The resin matrix used in ballistic composites can be divided into thermosetting and thermoplastic,and the main thermosetting resins are epoxy resins, which have good mechanical properties and thermal stability and corrosion resistance [44].Thermoplastic resins have better ductility, toughness, but are more difficult to process [45].Resin-based composites are more widely used in bulletproof mask and helmets.BATlskin's bulletproof mask(Fig.2(d))can withstand a 9 mm FMJ round impacting at 432 m/s,and a pounding of over 70 J.

Bulletproof equipment of lightweight, comfort and further improvement of protective performance is the inevitable trend of future development.With technological advances, bulletproof equipment must develop in the direction of new materials(bionicbased ballistic materials,electronic bulletproof vest materials)and structural design (comfort design, lightweight design, modular design).The protective performance of bulletproof equipment can be improved by developing new or modified materials, such as graphene materials, nanomaterials [46], liquid bulletproof materials [47], and 3D fabric-reinforced materials.In addition, it is necessary to strengthen the basic research of modular functional design and structural bionic technology [48] to achieve simultaneous improvement of bulletproof equipment in three aspects of light weight, comfort and protection performance by improving fabric materials, process technology and structural design [49].

3.2.Flame retardant

Fig.2.Some examples of bulletproof equipment.(a) Bulletproof vest made of UHMWPE fiber; (b) Bulletproof plate consisting of UHMWPE laminate and alumina ceramic; (c)“Dragon scale armor” bulletproof vest; (d) Bulletproof masks made by BATlskin.

Table 5Two bulletproof plates composed of composite laminates and protective properties.

The protection of soldiers against high-temperature heat sources on the battlefield has always been an important part of individual combat protection [50].At present, military flameretardant equipment is mainly through heat-resistant fabric or coating to achieve the role of flame retardant, in which highperformance fibers are widely used in flame retardant camouflage training uniforms, flame retardant overalls, explosion-proof blankets, explosive evacuation clothing and other equipment because of their high flame-retardant insulation properties.In 1969, DuPont developed Nomex, a military flame-retardant fiber that took into account the strength and industrial production, and was widely used in U.S.military clothing because of its excellent flame-retardant properties [51,52], which greatly promoted the development process of military flame-retardant fabrics and equipment in the world.At present, flame retardant fabrics are mainly made of two materials, namely, inherent flame-retardant fiber and modified flame-retardant fiber [53].Internationally, military flame retardant fabrics are mainly divided into several categories: aromatic polyamide fiber (Kevlar and Nomex produced by DuPont[54],Conex and Technora produced by Teijin in Japan[55],Fenilon produced in Russia [56] and Newstar produced in China,etc.), polybenzimidazole fiber (PBO and Zylon made by Toyo Spun in Japan, PBI made by NASA in the USA) and polyimide fiber (Kermal made by Rhodia in France,Anilon made by Gaoqi in China[57]and P84 made by Evonic in Austria), etc.All the above-mentioned fibers are high-performance fibers with excellent performance in flame retardant and thermal insulation properties and mechanical properties.

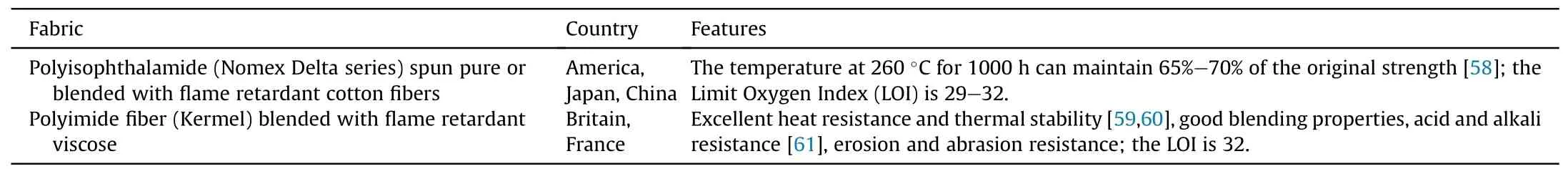

Currently, the world's mainstream flame-retardant fiber products are mainly made by blending, and their classic matching and application generally use two or more fiber blends to obtain fabrics with better protective properties such as flame retardant, heat resistance and chemical resistance at a reasonable price.The two more typical international blended flame-retardant fiber products are shown in Table 6.

Poly fiber is purely spun or blended with flame retardant cotton fiber (blending ratio of 65/35) and is the main flame-retardant fabric for the U.S.and Japanese armies.Flame retardant, heat resistant performance, good acid and alkali resistance, chemically stable [62]; easier to dye; higher price and decomposition temperature of 427°C.It has good resistance to hydrolysis and hightemperature steam, as well as good radiation resistance [63], but does not have the ability to resist ultraviolet light,and is stuffier and more impermeable to wear.The new camouflage combat uniform for the Army developed by the Japanese Army in 1992 used a fabric blended from 65%aromatic polyamide fibers and 35%cotton fibers,which can withstand temperatures of 800°C in 12 s [64].

Polyimide fiber (Kermel) with dope dyeing technology is blended with flame retardant viscose (blending ratio of 50/50),which is widely used as the main fabric for special military uniforms in European countries.Firefighting suits in Italy and riot suits in the UK and France use blended fabrics with a Kerml/flame retardant viscose(50/50)fiber pairing[65].The most typical flameretardant viscose fiber blended with Kermel fiber is FR Viscose flame-retardant viscose fiber from Lenzing (Lanjing) Co., Austria.The fabric made of 50/50 mixture ratio of the two can provide excellent comfort and permanent flame retardant.When exposed to high temperature and flame, the fabric will be carbonized and thickened,and the barrier between skin and fire will be enhanced.Kermel/Viscose FR 50/50 blending method, flame retardant performance can be better than Nomex fiber in the vertical burning test, even at 260°C high temperature can still maintain soft.This blend also has good moisture absorption and is comfortable to wear in hot and humid climates, making it a classic ratio [66].

Polybenzimidazole (PBI) flame retardant fiber is developed by NASA in the U.S, with the limiting oxygen index of 41, a fracture temperature of 550°C and a high moisture return rate of 1.5%.Most international PBI mateix fabrics(40%PBI,58%Kevlar,2%conductive fiber), PBI Gold and PBI Maz, mostly used in firefighting clothing,high temperature resistant work clothes and flight suits of flameretardant materials [67,68].

With the development of new technologies and materials, the comprehensive performance of military flame-retardant clothing and thermal protective clothing will be further improved,and will also gradually develop in the direction of production of environmental protection and intelligence.For example,diversified flameretardant systems based on bio-based materials have the advantages of degradability and non-pollution, and are the trend of flame-retardant clothing research.Phase change material(PCM) is highly promising in the development of smart thermal protective clothing.Paraffin-loaded organic PCM can modify the thermal insulation properties of fabrics, and by incorporating a PCM layer with smart bi-directional thermal regulation into thermal protective clothing,the high heat capacity of PCM increases the potential of thermal protective clothing to accumulate heat during thermal contact [69], thus improving thermal performance.In summary, a lot of research and innovation is still needed in the future to enhance the application fields of flame-retardant materials and provide a solid foundation for the future development of military intelligent flame-retardant protective clothing.

3.3.Stab resistant

Cold ordnance such as daggers often become commonplace in close quarters engagements, so protection of soldiers should focus on the damage caused by sharp ordnance to combatants.Stab-proof equipment is protective equipment that effectively protects against attacks from various stabbing angles by basic sharp objects such asdaggers,thereby reducing the threat of stab wounds to body parts,protecting the wearer from cuts, and is suitable for use by the military in environments where there is a risk of being cut.Research into stab-proof equipment can be traced back as far as prehistoric leather woven armour,from the rattan armour of a 19th century South Pacific island aborigine to the later Chinese Warring States period metal sheet armour and wire hauberk,and on to the current stab-proof clothing woven from high strength fibers [70].Currently, stab-proof materials on the market are mainly divided into two categories according to their strength: rigid metal structures and flexible stab-proof fibers.The more widely used stabproof equipment includes helmets, stab-proof clothing, stab-proof vests and stab-proof gloves [71].

Table 6Mainstream international military flame retardant materials.

3.3.1.Hard stab-resistant

In the early days, hard stab-resistant clothing was constructed much like the armour worn by ancient soldiers.During the First World War,soldiers wore fully hard stab-resistant clothing,mostly made of metal.At present, the main puncture-proof structure of hard stab-resistant suit is usually made of a rigid material such as metal or ceramic,with the stab-resistant layers of material mostly arranged closely in plates or blocks.Table 7 summarizes the Hard stab-resistant materials developed by various institutions or scholars.

Natural organisms have evolved unique protective systems against predator attacks and environmental damage, their biological materials are often optimized for their properties and organisation, and the protective structures of individual organisms are often a combination of flexibility, strength and lightness.Many scholars have gradually tried to seek inspiration from the protective systems of natural organisms for the bionic design of stab-resistant materials.Based on the bionic principle, Yuan et al.[72] have designed a titanium substrate with a trigonal structure based on the morphological structure of pangolin armour and lizard(Fig.3(a)).This structure can disperse the impact of the knife more effectively compared to the flat structure, avoiding the concentration of kinetic energy damage,and can withstand an impact of 24 J,and the weight is significantly reduced to achieve a better protective effect; The hard stab-resistant clothing produced by the Chinese company Dragon Valley is widely used in the market.Its inner material is small pieces of tungsten steel sheets shown in Fig.3(b),which are arranged closely in the shape of fish scales and connected together by stitching or riveting,with a stab-resistant area of about 0.3 m2and a mass of about 2.4-2.6 kg,with excellent performance against stabbing, cutting and slashing; Based on the bionic design principle,Yu et al.[73]have researched and produced a hard stabresistant suit made from a fish scale arrangement and lap joint pattern(Fig.3(c)).The stab-resistant suit is flexible and can be used for stab-resistant purposes.

In addition, researchers have experimented with changing the geometry and arrangement of rigid materials to design stabresistant clothing.Howard et al.[74] place metal geometries of a specific structure in a puncture-proof material in the form of a nonwoven fabric, for example, with the bottoms of the geometries interconnected.In the event of tool impact, this structure changes the tool's trajectory and thus acts as a puncture guard.Zhang et al.[75]glues hexagonal stab-resistant sheets to a soft base fabric in a honeycomb mesh structure, leaving certain gaps between the hexagonal stab-resistant sheets,thus giving the stab-resistant suit a certain degree of curvature and facilitating human movement.Xie et al.[85] arranged specific shaped protective modules on both sides of the base fabric in a certain pattern and fixed these modules to the fabric by means of double-sided riveting to achieve puncture resistance.Dong et al.[76] investigated the influence of the shape and arrangement of resin sheets on the puncture protection effect.Through theoretical analysis of resin sheets of different shapes,such as hexagonal, circular and triangular, it was found that the inter-sheet gap of hexagonal resin sheets was the smallest under the same porosity of the fabric surface, and the hexagonal arrangement could make the gaps not connect into a straight line,and the puncture protection performance of the resulting material was more stable.Yuan et al.[77] used 3D printing technology to mix carbon fiber and polyamide(PA)materials to make a punctureproof sheet,and the resulting puncture-proof material was reduced in mass by 30%-40% compared to metal sheets.

The addition of flexible rigid materials such as wire and metal rings to stab-resistant clothing has resulted in a semi-rigid suit with a lower surface density,greater flexibility and greater dexterity.At present, the representative semi-hard stab-resistant clothing on the market include the TurtleSkin MFA stab-resistant clothing from Warwick Mills and the semi-hard stab-resistant vest from Chongqing Shield King Company; The TurtleSkin MFA stabresistant clothing combines high-performance fibers with stabproof metal panels that are thin, less than 3.5 mm thick, with soft textiles for added flexibility and metal fasteners for stab-resistant protection; The semi-hard stab-resistant vest developed by Shield King Co.is made of a variety of new materials according to a special composite new process, which not only has the function of stabresistant, but also can effectively block the general explosives and fragments, and has the functions of waterproof, acid and alkaliresistance, UV protection, etc.Wang et al.[78] used interlocking spirals of metal wire to create a stab-resistant suit that is lighter and softer than traditional hard stab-resistant suits by weaving metal layers through the interlocking filaments.Bachner et al.[79]made interlocking metal rings from metal wire and placed them in the sandwich of a stab-resistant suit to achieve the stab-resistant effect.Du et al.[86]used corespun yarns containing metal wires to make puncture-proof fabrics and found that an increase in yarn twist could improve the puncture resistance of the fabrics.

Fig.3.Stab-resistant substrate using:(a)Three-pronged cone-shaped stab-proof substrate,the original reference is from Ref.[72];(b)Tungsten Steel Sheet,the original reference is from Ref.[83]; (c) Fish scale barb-proof structure, the original reference is from Ref.[73]; (d) Other bionic structures, the original reference is from Ref.[84].

Impregnated resin stab-resistant clothing usually combines a resin material with a base fabric to improve the stab-resistant effect of the base fabric through the application of resin[84].At present,the resins commonly used for puncture protection are epoxy resins with good adhesion and low shrinkage, phenolic resins which are hard and abrasion resistant but slightly less tough,impact resistant sarin resins,soft polyacrylates and polyurethane resins.Li et al.[80]found that the puncture resistance of the fabric was highly dependent on the fabric's surface density and alignment structure during puncture resistance tests of UHMWPE weft-free fabrics impregnated with resin [87].Mayo et al.[82] used thermoplastic resins to impregnate aramid fabric and found that the resins filled the inter-fiber voids well, resulting in a more compact structure;After the resin impregnation treatment, the static and dynamic puncture resistance of the aramid material is superior to that of pure aramid fabrics [88].Li et al.[89] combined polyurethane material with aramid fabric to produce a stab-resistant material and compared the effects of three coating methods on the stabresistant material.They found that the stab-resistant material made by coating the front and back sides of the aramid fabric has better stab-resistant effect and can effectively prevent the impact of 24 J energy.Xu et al.[90]produced a stab-resistant garment using weft-free fabric relying on adhesive material and found that the more adhesive used, the better the stab-resistant effect.Ma et al.[91]used injection moulding technology to prepare puncture-proof materials, achieving a combination of impact- and punctureresistant engineering plastics and fiber aggregates for punctureproof purposes.

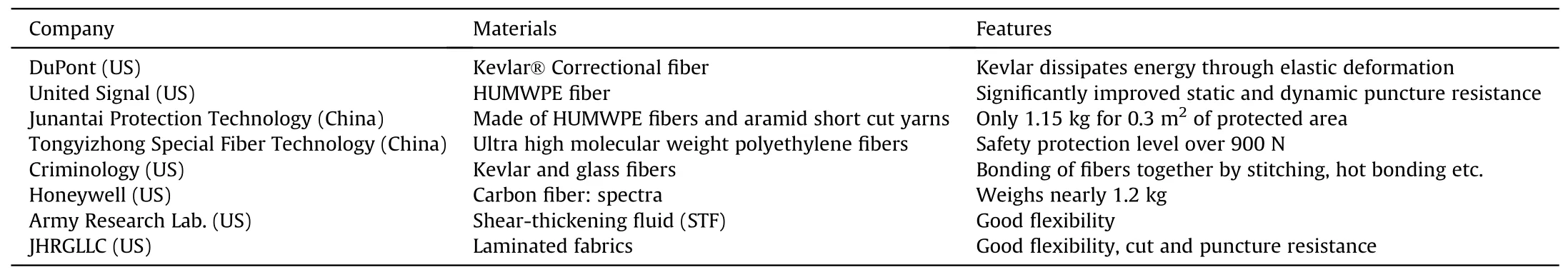

3.3.2.Flexible stab-resistant

Flexible stab-resistant materials have good flexibility and concealability, and can meet the requirements of special occupations such as police and military personnel,but can also be used as daily wear clothing to protect personal safety, so flexible stab-resistant materials have become the mainstream direction of research and development today.Currently, flexible stab-resistant suits with an area of 0.3 m2are made in the laboratory and have a mass of approximately 1 kg,which is much lighter than hard stab-resistant suits.With the development of science and technology, high performance fibers with high strength and low density have been developed,and Table 8 summarizes the flexible puncture-resistant materials developed by various companies.In the current development of puncture resistant clothing, composites produced by combining thermoplastic films such as polyethylene and ethyleneacrylic resins with Kevlar fabrics offer significant improvements in static and dynamic puncture resistance[92,93].In 2017,Honeywell,one of the world's leading manufacturers of personal protective equipment,launched a new generation of carbon fiber material for stab-proof clothing called “spectra”.This material offers a higher strength and safer performance, with a breaking strength 6-15 times higher than other materials,while being only 0.2-0.85 times denser.Its puncture resistance meets the Chinese national standard for puncture resistance(24 J/11 layers)and weighs only 1.2 kg and is approximately 2 cm thick.

The flexible stab-resistant clothing currently on the market is representative of the knitted anti-penetration vests produced by Cirminology in the U.S.and the high relative molecular mass polyethylene stab-resistant clothing produced by Beijing Junan Tai.Junan Tai's stab-resistant clothing is made from a blend of ultrahigh-strength polyethylene short-cut yarn and aramid short-cut yarn, which can effectively block stabbing, cutting and slashing attacks by knives, daggers and other cold ordnance, and fully protect the human torso and internal organs from injury.

One of the most promising studies on the puncture resistance of multilayer protective textiles is shear thickening fluid (STF) [94].The invention of STF by the US Army Laboratory provides a new rawmaterial for liquid stab-resistant clothing, which is made by laminating STF with a base fabric such as woven and non-woven fabrics.The STF is normally liquid in form and will change to a solid when subjected to a momentary impact,returning to its initial liquid state and becoming very soft when the external impact wears off.Thus,compounding STF with high performance fibers results in flexible,puncture resistant clothing [95].For example: Kevlar fabrics impregnated with STF can pass through only 3 layers at an energy impact of 17 J, whereas ordinary Kevlar fabrics can pass through 5 layers at an energy of only 4 J;Aramid woven fabrics impregnated with STF have significant puncture resistance compared to pure fabrics of equal area density [96].

Table 8Flexible stab-resistant materials developed by various companies.

In hydrogel composite fabrics, the space between the yarn and the fibers is filled with hydrogel [97], which provides a tight bond between the fibers and the yarn and substantially improves the puncture resistance [98].Compared to pure aramid fabrics, nanocomposite hydrogel aramid fabrics have a 201.34% increase in knife-puncture force without reducing the flexibility of the fabric.The composite can be used as a stab-resistant layer for soldiers'stab-resistant clothing, cut-proof gloves and a stab-resistant base.

At present,hard stab-resistant clothing is still mainly local stabresistant,the practical application of stab-resistant effect in various complex environments has yet to be tested, the comfort is not enough and the cost is still high.Liquid stab-resistant clothing is emerging as a new research hotspot.The unification of functionality and comfort will be the future trend for flexible stab-resistant equipment.

3.4.Nuclear, biological and chemical protection

Nuclear, Biological and Chemical (NBC) ordnances occupy a special place in security deterrence and military-strategic competition, therefore, countries around the world attach great importance to the protection of personnel from nuclear, chemical and biological ordnances.Since the First World War chemical warfare,military battlefields accordingly appeared to protect soldiers from skin poisoning anti-gas suits, then national armies began to use impermeable tarpaulin,rubber and plastic film,etc.to manufacture isolated anti-services suits[99],with good anti-gas properties,but not breathable, impermeable to moisture, in the temperature conditions above 30°C only allowed to wear time 20-30 min.In the 1960s, the British Army successfully developed and equipped its troops with breathable gas-proof clothing containing activated carbon for the first time,and various countries and armies began to develop their own distinctive gas-proof clothing containing activated carbon.After more than 40 years of research and development, forces in various countries have developed and equipped many different types of NBC protective clothing containing activated carbon, the more typical of which are micro spherical activated carbon, fibrous activated carbon, microporous PTFE,membrane layer fabrics and activated carbon cloth combinations[100].The “Salatoga” suit, developed jointly by Germany and the United States, which was used in the 1991 Gulf War, is considered to be the best suit after the British suit(Fig.4(a)).Its most important feature is that the activated carbon is processed into very small spheres, which can absorb the most pollutants with the smallest area and can expel sweat from the body,making it suitable for use in deserts, tropical and cold areas.

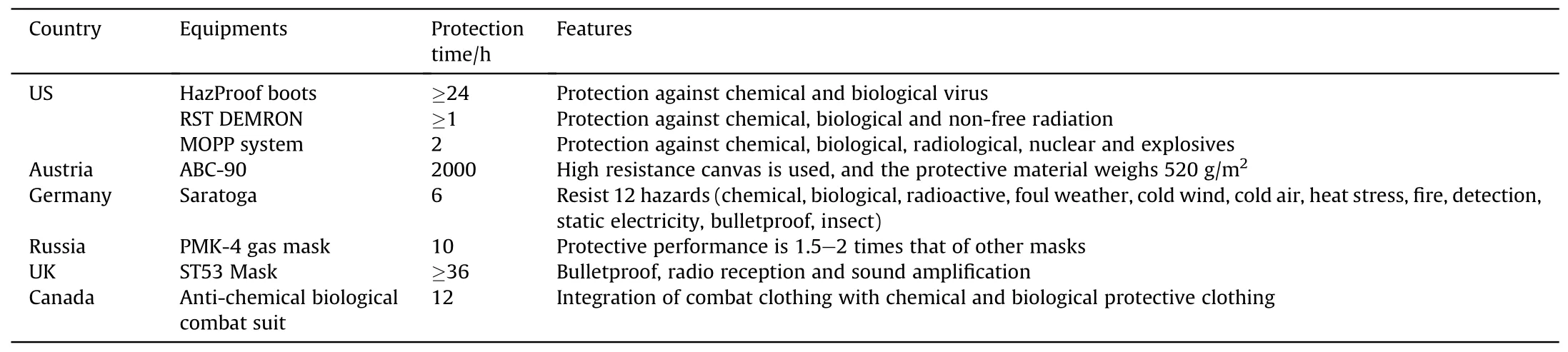

NBC PPE is the equipment used by individuals to avoid and mitigate harm from toxic agents, biological warfare agents and radioactive contamination with the basic protective functions of avoiding contamination,protection and decontamination.The NBC suit ABC-90-HR developed by J.Blaschke Wehrtechnik GmbH,Austria is an isolation suit (Fig.4(b)), which is made of high resistance canvas, weighs 520 g/m2of protective material and offers increased protection against biological warfare agents up to 2000 h.The ABC-90-HR complete kit consists of a gas mask (filtered and insulated),gas suit(insulated and breathable),gas gloves,gas cape and gas boots.Currently, in response to the environment and requirements of operational use, research institutes have developed different NBC protective equipments, as shown in Table 9.The US Naval Air Development Center has proposed a series of improvements aimed at improving the integration of chemical protection equipment and developing more advanced integrated chemical and biological protection equipment.

Western countries have made the transition from NBC protection to CBRN protection, specifically to deal with “chemical, biological, radiological, nuclear and explosive” hazards.CBRN protective clothing tailored to research based on US military standards and Canadian national standards is an important sign of a high level of technology [101].A full-body coverall CBRN suit developed by a German company, capable of protecting against chemical warfare agents at any concentration and in any form of application,protecting the skin from damage,made of high-quality activated charcoal, waterproof, fire and oil resistant, and with a degree of protection against infrared detection; Task-guided protective measures are those used by the military in hazardous environments such as chemical, biological, radiological or nuclear strikes[102].JSLIST is part of the MOPP range of protective clothing,known as Joint Service Lightweight Integral Clothing Technology(Fig.4(c)).JSLIST protective clothing allows maximum air circulation for cooling while preventing chemical and biological agents from encountering the wearer's skin, and was used extensively in the Gulf War.

Today, nuclear, biological and chemical protective equipment has made great strides and the use of bio-fiber materials that actively degrade biological and chemical warfare agents to make protective clothing will be a key research direction in the future for countries such as the US and UK.

4.Intelligent PPE

Fig.4.Nuclear, biological and chemical (NBC) protective clothing: (a) “Sarah Toga”; (b) ABC-90-HR; (c) JSLIST.

Table 9NBC protective equipment developed by various countries.

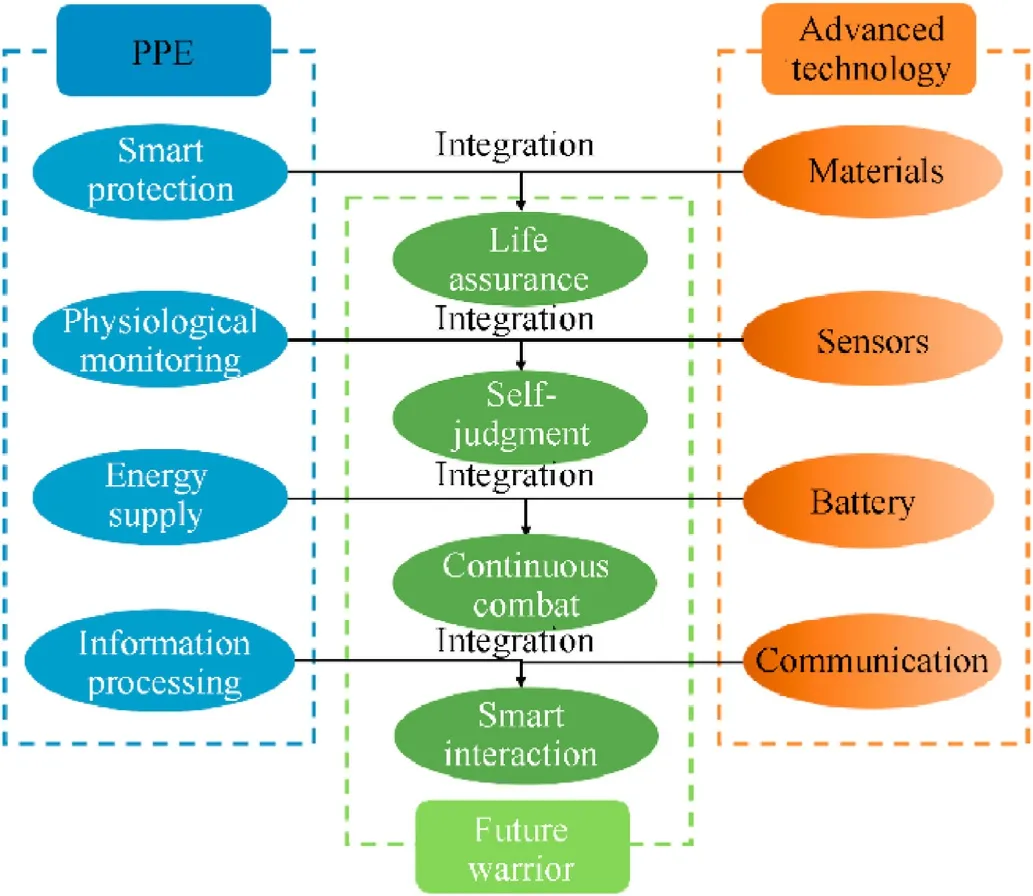

As a product of the integrated application of materials,physics,biology disciplines, intelligent individual protective equipment connects isolated combat individuals with the digital world and continues to develop in the direction of intelligence and refinement, playing an important role in the harsh battlefield environment.Through literature research and summary, the research progress of intelligent PPE in four aspects of situational awareness,performance enhancement, physiological monitoring and environmental adaptation is as follows.

4.1.Situational awareness

Situational awareness is the premise and basis for the realization of equipment intelligence.In the face of the multi-dimensional battlefield environment of future intelligent warfare, individual protective equipment must establish a multi-level, all-weather,three-dimensional situational awareness network to achieve realtime accurate mastery of the battlefield situation and provide reliable information and data support for intelligent decisionmaking and combat operations.Situational awareness is an environment-based, dynamic, and holistic insight into security risks, and with complex information and rapidly changing situations on the battlefield, enhancing soldiers' situational awareness capabilities will undoubtedly be related to their operational safety[103].In October 1996,the U.S.Land Warrior system conducted its first operational suitability test, and the battlefield visualization format significantly improved collaborative communications among soldiers and improved their situational awareness[104].

Helmets, as the main equipment for perceiving battlefield hazards in maneuver, can significantly improve soldiers' situational awareness on the battlefield by integrating various pendants into the helmet system.Currently, a summary of wearable pendants applied in various countries is shown in Table 10.In 1983, the U.S.Army began to equip a man-portable combat display system (C3),one of the features of which is a detachable earpiece and embedded camera mounted on the helmet (Figs.5(a) and 5(b)).The earpiece uses signal processing technology to intelligently process different sounds, which can help soldiers determine the location and distance of the sound source, and has the effect of sound filtering,slowing and suppression; the embedded camera monitors the surrounding environment through sensors, enabling soldiers to observe the scene beyond their line of sight.These miniature cameras are lightweight and compact, easily fixed to a soldier's helmet,and can transmit undetectable targets on the battlefield to the display, enabling soldiers to quickly eliminate threats and hidden dangers around them.In modern warfare, miniature cameras mounted on helmets are gradually gaining popularity among soldiers and are an essential piece of equipment in modern combat[105].

The flat panel display is a modular display system worn by soldiers on their hands,which integrates a micro-optical digital TV that can effectively improve soldier mobility at night by wirelessly linking data and displaying infrared or TV video images.In addition,the device can display digital maps,emergency messages and alertsin a timely manner in silent mode,enabling soldiers to clearly grasp and judge the battlefield situation and enemy positions in the first instance.In the Iraq War,the U.S.entered“enemy targets,”“friendly forces,” “our vehicles” and other content information into a flatpanel display, which not only significantly reduced the rate of misfire, but also improved strike efficiency.

Table 10Situational awareness equipments based on key technology.

Night vision devices are important tactical equipment in modern combat,and their main features are high definition,durability,and concealability.Night vision devices are divided into two types:active and passive, the former using infrared searchlights to illuminate the target and receive reflected infrared radiation to form an image, and the ability to observe through fog, rain, etc.; the latter does not emit infrared light, relying on the target's own infrared radiation to form a “thermal image” [106].In 1945, the U.S.Army was the first to put night vision devices into combat and achieved significant operational results.

Night vision glasses belong to the third generation of binoculars,which can display all the information and map data received from the command and control system on the lenses, and are equipped with a camera, using advanced visual enhancement wearable technology to perceive and understand the battlefield environment that cannot be directly observed in a timely manner, allowing soldiers to become“clairvoyant”[107].In 2011,the DARPA“Soldier Vision Enhancement System”project developed a contact lens that provides the human eye with a 2.8x optical zoom capability.In November 2018,the U.S.Army partnered with Microsoft to develop a prototype of HoloLens augmented reality glasses.In the future,the United States will conduct research on the Integrated Visual Augmentation Systems (IVAS) to enhance soldier situational awareness through advanced perception technologies and virtual reality[108].

In the field of single-armed equipment,the world's mainstream direction is currently biased toward the direction of intelligent helmets that integrate single-armed night vision goggles/scopes,battlefield command systems and other equipment, in the field of helmet display systems have not seen large-scale equipment single-armed.The core of helmet display system is the application of virtual reality technology [109], which uses 3D graphics generation technology, multi-sensing interaction technology, and highresolution display technology to generate a 3D realistic virtual environment,thereby improving the visibility of soldiers in adverse conditions.Virtual reality technology focuses on real-time information delivery, immersion, and interactivity, providing soldiers with a personalized, highly realistic 3D scene interaction experience.In 2018, the U.S.Army announced a development study of next-generation military smart helmet displays, the finished product of which will integrate a single soldier night vision goggle,digital command system, single soldier helmet display, and detachable fuel cell powered devices.With the development of virtual reality and computer technology, helmet display systems are bound to develop in the direction of smaller size, higher resolution, lower cost, lower power consumption, and lighter weight.

In addition, smart combat suits are widely used in the field of situational awareness.Intelligent combat clothing will be small sensor smart chip woven into the standard clothing,can sense the surrounding environment and collect relevant information to achieve specific functions, real-time awareness of the battlefield environment.Columbia Lemur Design Studio has developed a smart protective shoe called “Save One Life” (Fig.5(c)), which is installed with a metal detection sensing circuit on the sole of the shoe.When a suspected mine is found with a metallic magnetic response,the smart watch connected to the shoe will send an alarm message to indicate the location of the suspect, which greatly ensures the safety of the deminer's life.The Institute of Nanotechnology at MIT has developed an intelligent enemy-versus-us recognition combat suit(Fig.5(d))that incorporates special optical fibers in the fabric.Military uniforms made of this fabric can be irradiated to emit“friendly”signals that can be identified by lasers,and combatants can quickly identify the enemy and us based on whether a signal is returned, thus greatly reducing the probability of accidental injury.

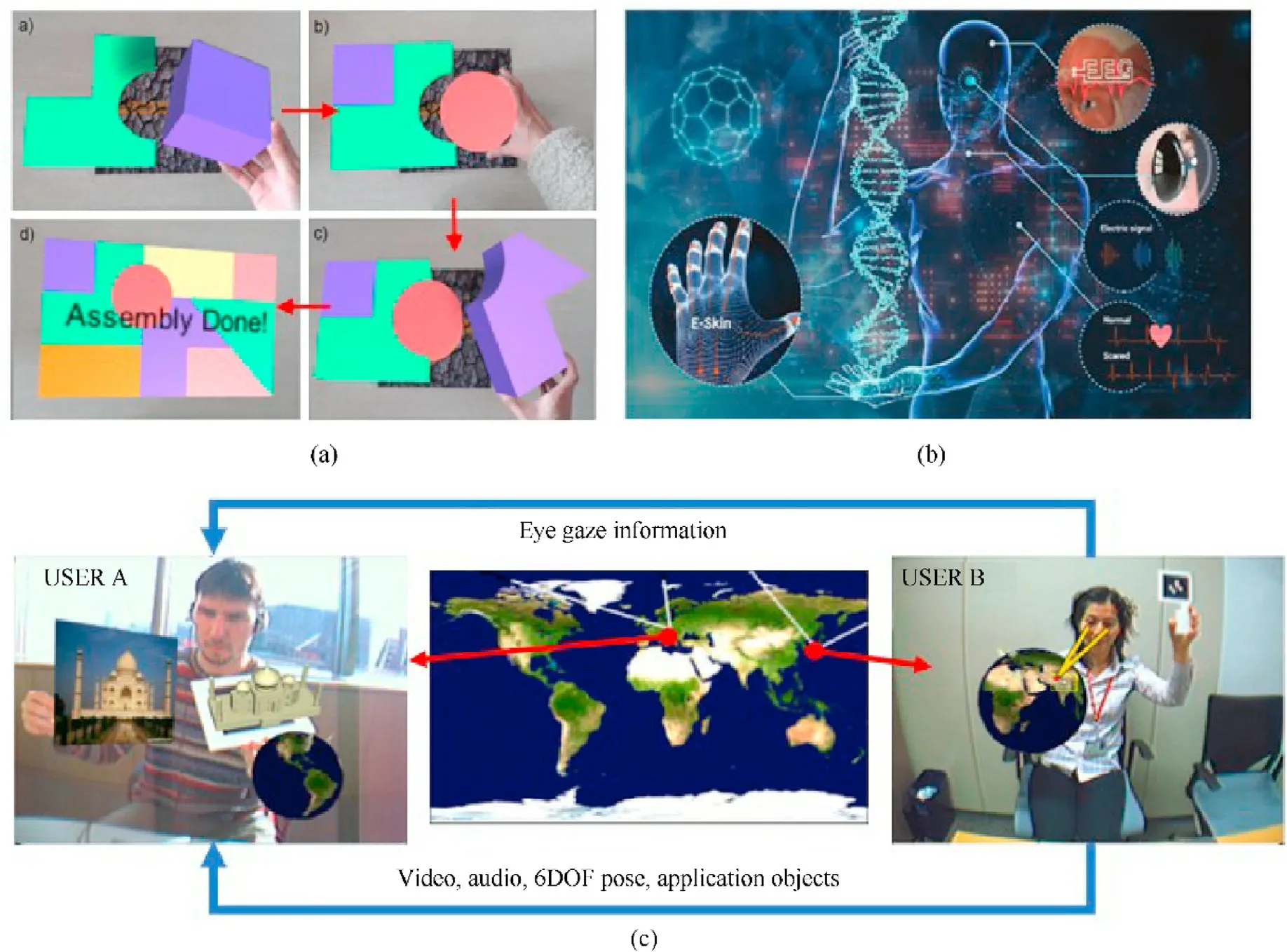

The situational awareness data in modern battlefield presents the characteristics of Volume,Variety,Value,Velocity and Veracity.The difficulty and complexity of battlefield information acquisition will bring challenges to soldiers' safety.Therefore, there is an urgent need to break through and apply key technologies to significantly improve situational awareness capabilities.The purpose of audiovisual augmentation technology (Fig.6(a)), a key element in enhancing situational awareness, is to enhance the processing of battlefield information using virtual reality technology, GIS, and multimedia,with the advantage of allowing soldiers to analyze and display critical information hidden behind trivial data regardless of the harsh audiovisual environment.Currently,the technologies and methods of audiovisual enhancement include retinal implants,cochlear implants, and visual field enhancement systems.The Defense Advanced Research Projects Agency (DARPA) is focused on the need to expand the operational dimension of modern warfare and has conducted research projects on visualization enhancement technologies such as “XDATA”, “PLAN X′′, and “HIVE” to develop superior equipment and software platforms that will provide soldiers with valuable situational information.

Advanced human-computer interaction technology is an important part of improving the efficiency of situational awareness.The Army Concept of Operations manual issued by the U.S.Army Command,states,“Adapt the machine to the soldier,not the soldier to the machine.”Soldiers have a central energetic role in situational awareness, and their behavior is difficult to describe in a precise way.With the development of virtual reality,holographic imaging,wearable technologies, “immersive” situational awareness is gradually emerging.By setting up dual-functional interfaces and protocols, it enables soldiers to immerse themselves in display manipulation, gestures, voice and other interactive functions to enhance their situational awareness.Geuss et al.[110] proposed a method to apply mixed reality (MR) technology to battlefield command and decision making, envisioning a command and control model in which soldiers interact with various holographic projection images,and by wearing mixed reality devices,operators can receive situational information in all dimensions to improve decision making efficiency (Fig.6(b)).Dennison et al.[111]extended the effectiveness of common operational picture with the help of cross-reality (XR) technology, which can further establish team situational awareness and help warfighters maintain a proper perception of the overall dynamic situation.

Data mining technology is one of the key technologies for understanding battlefield posture,which can mine more information about enemy's characteristics from the complex, multi-scale, information-rich mass data, to analyze the direction of enemy's intention and provide the next course of action for our own side.Deep learning can be applied to nonlinear, high-capacity, multidimensional battlefield situational analysis by simulating the human brain learning approach to extract and cluster analysis of autonomous features of big data.Peng et al.[112]proposed a convolutional neural network (CNN)-based YOLO model for obtaining the location and class of targets directly from the input image to improve the efficiency of target detection (Fig.6(c)).However, one of the bottlenecks facing deep learning is that large numbers of training samples are often difficult to obtain in uncertain battlefield environments.Therefore, the meta-learning approach represented by less sample learning provides ideas to solve such problems.Fewshot Learning is a technique typically applied in meta-learning[113], where the goal is to accomplish a learning task using only a small number of samples,and to construct new neural networks by combining information from previous experience and current training samples to avoid fitting on new data.Therefore, lesssample learning techniques have important implications for operational situational understanding.

Fig.6.Key technologies for the application of situational awareness equipment.The original references in Fig.6(b) are from Refs.[110,111];The original references in Fig.6(c) are from Refs.[112,113]; The original references in Fig.6(c) are from Refs.[114,115].

Information fusion technology is a multi-level and multicategory data processing method that makes data results more accurate and reliable by detecting and analyzing data and clarifying the correlation between data.Multi-platform, multi-sensor resource management and real-time information processing are particularly important to the overall information fusion process on the battlefield of the future.Hao et al.[114]proposed a cloud-based information fusion system to address the problems of limited computing power and limited information processing capability of traditional information fusion systems, and explored a new direction for the development of battlefield information fusion by using its super computing power, powerful information processing capability, and flexible cloud architecture to compensate for the shortcomings of traditional information fusion systems (Fig.6(d)).Jenkins et al.[115]developed a human observation error alignment model that combines human observation data with sensor data to enhance the accuracy and reliability of fusion results and to reduce the heterogeneity and complexity of the amount of data evaluated and correlated by the fusion system.

With the development of artificial intelligence, the Internet of Things and other technologies, future quantum technology for enemy-seeking imaging in complex environments, terahertz wave technology for detecting explosives and metamaterials for enhancing infrared detection capabilities will gradually join the research and development of emerging perception equipment to further enhance the situational awareness capabilities of individual soldiers.

4.2.Performance enhancement

The extreme multi-dimensional environment of the future battlefield will have a significant impact on the physical abilities,skills, and intelligence of the individual combatants as well as the overall combat effectiveness of man and machine.In 1990,General Paul Gorman of the Defense Advanced Research Projects Agency(DARPA)first proposed the“super soldier”,and gradually expanded to “effectiveness enhancement” research, aiming at adapting and mastering future warfare through the overall enhancement of human capabilities.

4.2.1.Exoskeleton

The wearable exoskeleton is an accompanying intelligent system that conforms to the structural characteristics of the human body and can be worn outside the body of a single soldier, which can enhance the functions of carrying power,movement speed and endurance of a single soldier by sensing the intention of human movement and by using energy and mechanical power, and is a strategic high-tech for building “super soldiers” in future warfare[116].Since 2000, the U.S.Defense Advanced Research Projects Agency (DARPA) launched the Exoskeletons for Human Performance Augmentation(EHPA)grant program,developing both fullbody and lower-extremity exoskeletons to enhance soldiers' loadbearing and military combat capabilities.The most representative ones are Raytheon's Sarcos XOS full-body exoskeleton (Fig.7(a))and Lockheed Martin's HULC lower-extremity exoskeleton(Fig.7(b)).The Sarcos XOS full-body exoskeleton consists of various complex mechanical structures,sensors,actuators, and controllers that are hydraulically actuated to enable the wearer to easily lift 90 kg [117].In 2013, the U.S.Special Operations Command developed the Tactical Assault Lightweight Operating Suit (TALOS), an advanced exoskeleton system that integrates full-body light armor,boosted exoskeleton, built-in displays, situational awareness,physiological monitoring systems and other comprehensive capabilities to enhance vision and improve situational awareness.A variety of exoskeleton robot prototypes were born later,including a hydraulically driven lower extremity assisted Berkeley Lower Extremity Exoskeleton (BLEEX) developed by the Robotics and Human Engineering Laboratory at the University of California,Berkeley, as shown in Fig.7(c).With the impetus of Lockheed Martin, BLEEX evolved into the Human Universal Load Carrier(HULC), a mechanical exoskeleton with enhanced lower limb capabilities [118].

With the development of technology, military and civilian institutions in other countries have also developed exoskeleton system equipment extensively and achieved fruitful results, as summarized in Table 11.The second-generation exoskeleton system developed by China Institute of Ordnance 202 weighs 24 kg,travels at a speed of 4-4.8 km per hour, is rated at 50 kg and can work continuously for 4 h, and its functions and technical indexes have basically reached the relevant indexes of the HULC.

Exoskeleton systems can be divided into active powered exoskeletons and non-powered exoskeletons according to the power source, with the former providing the power source through traditional drive methods (electric motors, hydraulic systems,pneumatic systems),or new drive methods(shape memory alloys,textile drives, artificial muscles).Active type power exoskeleton involves mechanical, sensing, control, energy and other systems,stability, reliability, and adaptability need to be improved, but controllability and scalability is stronger.Representative results such as Soft Exosuit from Harvard University [120].Non-powered exoskeletons often use elastic elements for assistance, such as common springs, rubber bands, carbon fibers, etc.Since only mechanical structures are involved,the system is simple and reliable,but usually requires customized design according to individual wearer differences.Representative products include the UPRISE military exoskeleton from MAWASHI Canada (Fig.7(d)).

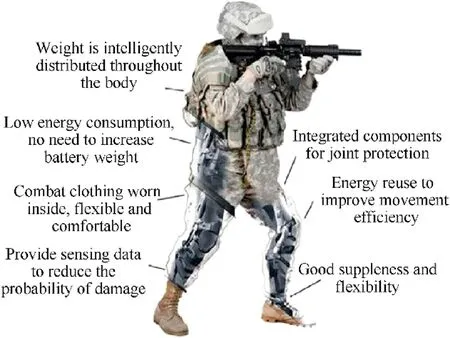

Currently,exoskeleton systems used in the military field can be divided into two categories: rigid exoskeleton and flexible exoskeleton systems according to their structures.The working mechanism of rigid exoskeleton is to transfer the load weight of soldiers' back to the ground through rigid skeleton, thus relieving the physical exertion of soldiers on heavy marching.However,rigid exoskeletons, while significantly increasing a soldier's weightbearing capacity, can alter gait characteristics, leading to increased metabolic energy expenditure and reduced functional joint range of motion [121].Therefore, the flexible exoskeleton system was developed, which uses flexible materials for the construction of the body, with the help of flexible Bowden wire for power drive, and has the advantages of light weight, comfort, and high adaptability of the system.In September 2011,the U.S.Defense Advanced Research Projects Agency (DARPA) invested in the development of the“Warrior Web”intelligent combat suit research project.“Warrior Web” flexible exoskeleton is a new type of internal wear combat suit (Fig.8), which can weight-bearing intelligent distribution throughout the soldier's body to reduce and prevent soldier injury, enhance muscle function to reduce the fatigue loss of soldiers marching in rugged terrain for a long time,with light weight,good flexibility,good comfort and other technical performance characteristics.Therefore, the “Warrior Web” intelligent combat suit can not only improve the combat effectiveness of soldiers, but also protect their health and safety.

Fig.7.The exoskeleton systems: (a) Sarcos XOS; (b) HULC; (c) BLEEX; (d) UPRISE.

Fig.8.Intelligent combat clothing “Warrior Web” using bionic technology.

The future application of exoskeleton equipment on the ground is to work with soldiers to form a human-machine coupled system,requiring a high degree of human-machine compatibility,cognitive coupling and movement consistency, the core of which lies in the human musculoskeletal function mechanism bionic, external environment, and the wearer's intention to sense, adaptive precision control, human-machine intelligent interaction and collaboration.In 2019, the U.S.Department of Defense Biotechnology Council's report 《Cyborg 2050: Human-Machine Integration and Its Future Implications for Defense Policy》 stated that it plans to provide real-time interfaces between humans and external systems in the future, enabling rapid recovery and control of wearable optoelectronic musculoskeletal control systems and allowing dynamic adaptive coupling of warfighters to external systems.Currently, wearable exoskeleton technology has made breakthroughs in microprocessors and bioelectric sensors, and its development still faces technical challenges such as gait stability control, multi-sensor data fusion, energy and power drive technology, lightweight advanced materials, and optimized control algorithms, so the overall exoskeleton technology is still in the R&D trial stage,and there is still a gap between the overall performance and the actual requirements of combatants.The development of future exoskeleton system needs to break through common key technologies such as efficient drive,accurate perception,intelligent control, etc., to gradually enhance the efficiency of assistance,improve the comfort and convenience of exoskeleton wear under the premise of ensuring the safety of wear, to develop multicategory new exoskeleton systems for specific task scenarios, and to comprehensively promote the application of exoskeleton systems in the field of military individual protective equipment.

4.2.2.Artificial muscle

Artificial muscles are actuator materials that use dimensional changes driven by voltage,magnetic fields,light,or temperature to produce complex morphological changes such as stretching,bending,bunching,or swelling.Small and light in weight,they are very similar to biological muscles and can achieve a significant increase in a soldier's base strength and further enhance the loadcarrying effectiveness of combatants.Artificial muscles can also be applied to the adaptive size adjustment of protective equipment such as airtight helmets, oxygen supply masks, ejection seats,etc.,which greatly improves the protective performance of equipment and system integration, and is of great significance to the development of intelligent active protection of individual equipment.In the last decade, artificial muscle technology has been rapidly developed due to the birth of special polymeric and smart materials, and a wide range of achievements have been made by institutions in various countries and have provided the scientific basis for the translation of artificial muscle technology to applications in the field of soldier effectiveness enhancement, as shown in Table 12.

The current research on artificial muscle technology is centered on the following four directions.

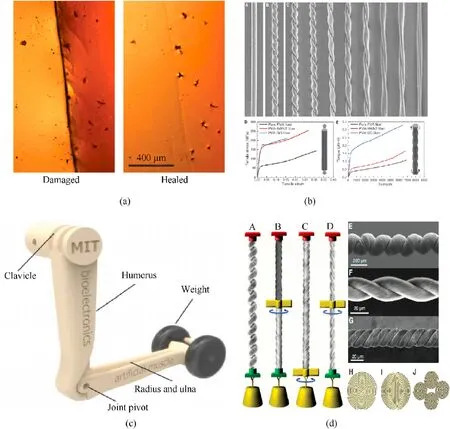

(1) Stretching and contraction are achieved based on the twisting of fibrous structures to mimic human muscles.A breakthrough in the field of self-repairing elastomeric materials has been achieved by Bao's team at Stanford University, which has developed PDMS materials (Fig.9(a)) with extremely high stretchability and excellent self-repairing ability [123].The above research will be expected to be applied in the field of artificial muscles.

(2) High torque and energy density are achieved through the“shape memory effect” of the polymer.Zhennan Bao's team discovered a method to achieve high energy density, unidirectional shape memory polymers based on strain-induced supramolecular nanostructure formation.Recently, Philippe Poulin and Jinkai Yuan's team at the University of Bordeaux,France, prepared rotating artificial muscle fibers (Fig.9(b))and substantially improved their mechanical and driving properties by doping them with carbon nanotubes and graphene, almost 60 times that of natural skeletal muscle.The trigger temperature can be adjusted and programmed to achieve up to 600 rpm in 2 s when the programmed temperature is reached[129].2021,Bao Zhenan team at Stanford University discovered PPG-MPU, a shape memory polymer based on supramolecular nanostructures,with a record high energy density(19.6 MJ/m3)and over 90%shape fixation and recovery[29],which will have significant applications in the field of artificial muscle research.

(3) Based on the different thermal expansion coefficients of the two materials to enhance the strength and weight-bearing capacity of the artificial muscle.Polina Anikeeva's group at MIT has developed artificial muscles made of a combination of single strands of fibers of two different polymers, cyclic olefin copolymer elastomer (COCe) and high-density polyethylene (Fig.9(c)).The COCe elastomer is stretched by a“cold drawing” technique, which subsequently bonds the two fibers and places them in a polymethylmethacrylate(PMMA) coating.After releasing the stretch, it retracts to form a spring-like structure that can lift objects more than 650 times its own weight and withstand tensions greater than 1000% [128].

(4) The novel“sheath-driven”structure allows for greater power density.Ray Baughman's group at the University of Texas at Dallas has proposed a novel artificial muscle drive mode,sheath-run artificial muscles [122] (SRAMs), as shown in Fig.9(d).The design has a sheath-core double-layer structure, in which CNT yarn is used for the muscle core and a mixture of poly (ethylene oxide) and tetrafluoroethylene,vinyl ether sulfonyl fluoride (SFVE) copolymer (PEO-SO3),etc., is selected for the shell.This artificial muscle provides driving force through the stretching and twisting of carbon nanotubes and can achieve 29 times the contractile work of human muscle [125].

As technology continues to evolve, artificial muscles will become the closest strength-assisting enhancement equipment to a soldier's physiological characteristics, and their military use is of great interest.Currently,the U.S.Department of Defense has spent$50 million to begin research and development“muscle uniforms”for future soldier equipment, artificial muscles will be fitted intogloves, uniforms, and boots, can mimic and expand the soldier's athletic ability,to have superb protection and combat effectiveness.A “Bio-Suit System” developed by MIT enhances human strength and endurance by embedding artificial muscle fibers powered by electricity, and can determine the physiological state of combat soldiers based on the feedback from the muscle fibers.

Table 12Research teams and technical features of artificial muscles.

Fig.9.Typical artificial muscles.(a)Optical microscope images of damaged and healed PDMS,Reproduced with permission from Ref.[123],©Macmillan Publishers Limited 2016;(b) Rotating shape memory polymer (SMP) fibers, Reproduced with permission from Ref.[129]; (c) A printed model of a polymer-based artificial muscle, Reproduced with permission from Ref.[128]; (d) Muscle configurations and yarn structures for sheath-actuation, Reproduced with permission from Ref.[122], © AAAS 2012.

Currently, laboratory research has been completed on artificial muscle technology, but there are few reports on military system equipment applied to the soldier's body surface; therefore, the transformation from basic research to the application of military equipment will become an important link to enhance the effectiveness of the warfighter in the future.How to solve the problems of high voltage of artificial muscle application, deformation stimulation can not meet the soldiers' work scenarios, and integration with soldiers' physiology will be the key to the application of laboratory research results in the field of military protection, while solving the practical application of artificial muscle in the abovementioned fields requires deep cross-collaboration of materials,chemistry, electronic biology, military medicine, and other disciplines.

4.3.Physiological monitoring

Physiological monitoring has important applications in the military, where it can provide important assistance to soldiers'physiological health and sustained operational effectiveness by monitoring information on combatants' thermal work limitations,alertness, adaptive states, musculoskeletal fatigue limits, neuropsychological and physiological states, and by combining it with medical aid and environmental monitoring.

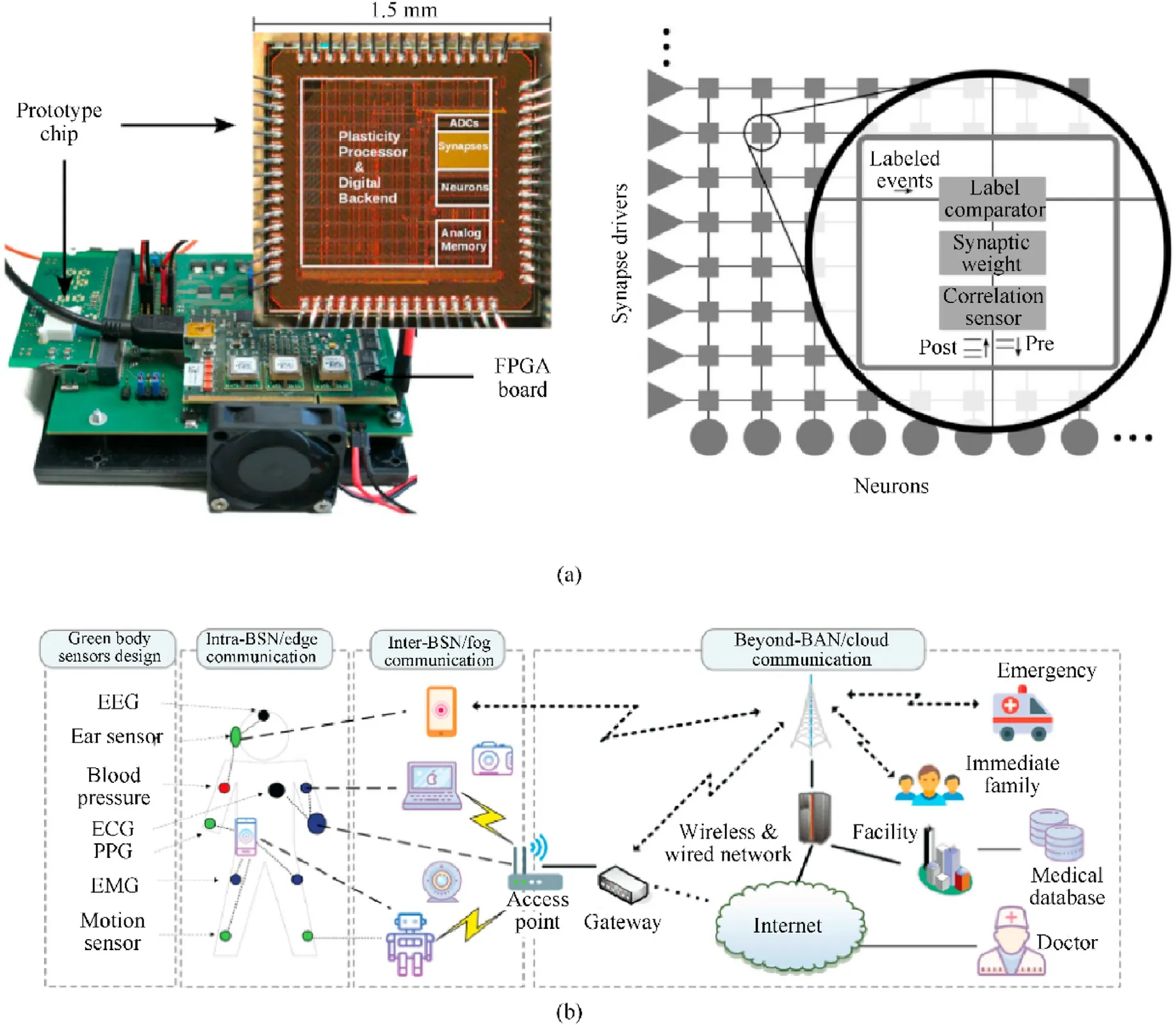

At present, the U.S.Army Medical and Medical Devices Command is working to develop a new technology that can be used to monitor soldiers' physiological status in real time, and has developed the “Real-Time Soldier Physiological Status Monitoring System” (RT-PSM) (Fig.10), which consists of wireless sensors distributed around the soldier's body, and its monitoring data will be transmitted to the sub-nodes under the system control center through the wireless local area network, and the sub-nodes will immediately transmit the received information to the manned digital system, thus providing a valuable basis for soldier service support and proper command operations.The “Real-Time Soldier Physiological Status Monitoring System” in Fig.10 can be divided into eight subsystems,of which the most critical part of RT-PSM is the algorithms and models that transform the data into useful and actionable information.Power management subsystem provides the RT-PSM with a smaller size, weight and power battery that is critical to the acceptability of the soldier's carrying weight; Wearable sensor subsystem as the basic unit for collecting physiological signals and information from soldiers; The body area network subsystem enables real-time monitoring of the soldier's health and physiological changes through sensors and transmits the information to an external processing unit; Cyber security subsystem ensures that the data of hardware and software in RT-PSM are not damaged, changed and leaked, and that the system can operate continuously and normally; Data management subsystem utilizes computer hardware and software technologies for effective data collection, storage, processing and application to ensure the effective utilization of data; Open architecture subsystems that reduce the computational and life-cycle costs of RT-PSM and enhance the commonality and reusability of system components; The human factor subsystem takes into account the relationship between human and system, human and program, human and environment,and human and human,thus ensuring the rationalization of system functions and humanized design.The above subsystems work together to ensure and enable the proper operation and core functions of RT-PSM.

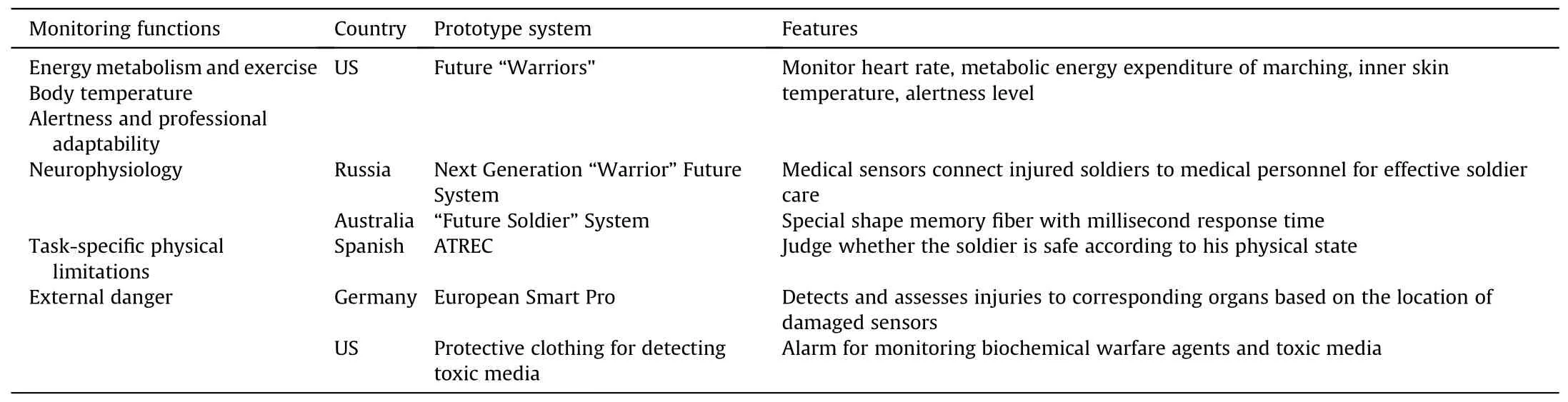

Soldier physiological monitoring systems have been extensively developed in various countries or research institutions, and six monitoring functions of soldier physiology have been gradually implemented based on sensing technology and algorithmic processing(Table 13)to be fully informed of the physiological status of the combatants [132].

The U.S.Army Soldier Systems Center and the Army Environmental Medicine Institute have proposed a Warrior Physiological State Monitoring(WPSM)program to develop a sensor system that can be embedded in uniforms to monitor the physiological state of'Warriors',and the next generation of combat uniforms may have a cluster of miniature wireless sensors embedded in them.Current WPSM test sensors monitor heart rate, metabolic energy expenditure on foot(marching),internal skin temperature,and alertness or sluggishness [133].The sensors worn on the soldier's belt provide information on the soldier's physical exertion,physiological stress,and alertness level,and the data will be stored or transmitted to the command communications network.WPSM sensors will provide medical treatment when a soldier is wounded and allow for accurate battlefield casualty identification and classification.WPSM researchers have also studied additional sensors that measure physical fatigue, body weight, hydration and blood oxygenation,which will enhance the system's ability to predict a soldier's physical condition under a variety of conditions.

Russia's next-generation “Warrior” future soldier system will integrate Ratnik medical sensors[134]to monitor combat soldiers'physiological and psychological information,including pulse,blood pressure,and emotional state,and to transmit this data to medical units and emergency commanders.Medical sensors can connect wounded soldiers on the battlefield with medical personnel,so that medical personnel can provide effective treatment to the wounded according to their type of injury and overall condition; Australia's“Future Soldier” System, disclosed in October 2018, is equipped with a new combat suit that combines camouflage, ballistic protection and ambulance functions, and can use special shaped memory fibers with millisecond response time, which can apply pressure to the wounded part of the body to stop bleeding and effectively reduce the amount of blood loss [135].

To perform a real-time assessment of the mission-specific physiological limitations of combatants, the Spanish Ministry of Defense launched the ATREC project [136], which aims to achieve the goal of determining the suitability of a soldier to perform a certain military mission based on the mental state he or she is in and whether there is a risk of endangering the life of the individual or others.At present,researchers have developed wearable testing systems consisting of sensing garments and fabric-based noninvasive devices.Among them, the sensing clothing is mainly composed of functional components such as gloves with built-insensors, upper armbands and chestbands with fabric electrodes.The non-invasive device includes a skin galvanometer,a respiratory recorder with a single-channel ECG amplifier,and two sensors used to measure skin and ambient temperature,respectively.The data of heart rate,respiratory rate,skin electrical response and peripheral temperature can be collected in real time, and used for the establishment and analysis of subsequent evaluation models.

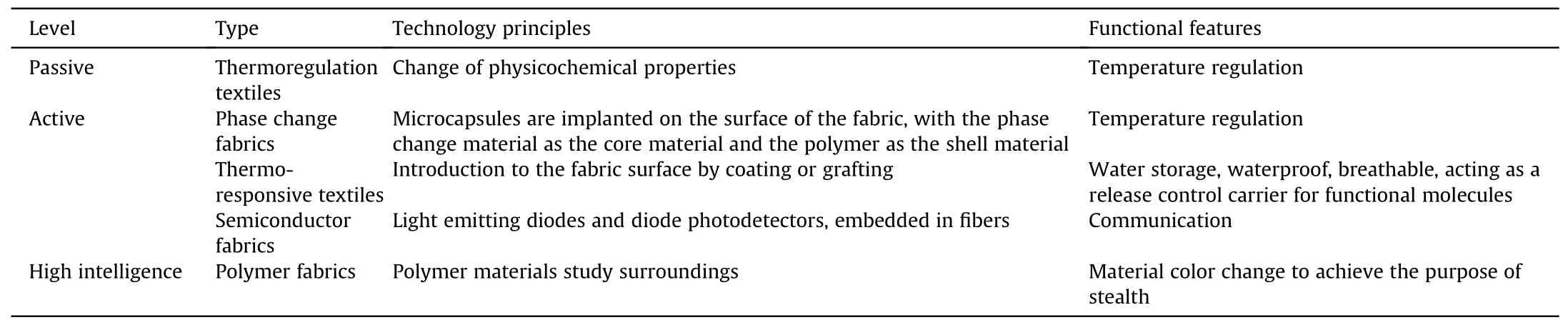

Table 13Major soldier physiological monitoring functions and typical equipment systems.