不同偏压下DCMS和DCMS/HiPIMS共溅射铜薄膜的结构和性能

2023-11-03黄敏易勇刘艳松谢春平何智兵

黄敏 易勇 刘艳松 谢春平 何智兵

摘要:采用DCMS(直流磁控溅射)和DCMS/HiPIMS(直流磁控溅射/高功率脉冲磁控溅射)共溅射在不同负偏压下沉积铜薄膜,使用X射线衍射仪、场发射扫描电子显微镜、白光干涉仪、纳米压痕技术和四点探针法对薄膜的晶体取向、形貌、粗糙度、力学和电学性能进行表征。结果表明:与 DCMS 铜薄膜相比,随着负偏压增加,DCMS/HiPIMS共溅射铜薄膜晶粒尺寸先减小后增大,Cu(111)取向减弱,硬度逐渐增大,电阻率逐渐降低;高负偏压(100 V)下Cu(111)向Cu(220)转变,薄膜致密,表面粗糙度减小,硬度增大(约3.5 GPa),电阻率降低(约2 μΩ·cm)。铜薄膜的结构和性能强烈依赖于由HiPIMS和负偏压共同决定的铜离子通量和能量。

关键词:直流磁控溅射 高功率脉冲磁控溅射 铜薄膜 衬底偏压 硬度 电阻率

中图分类号:O484; TG174.444文献标志码:A文章编号:1671-8755(2023)03-0001-07

Structure and Properties of DCMS and DCMS/HiPIMS Cosputtered

Copper Films under Different Bias Voltages

HUANG Min1, YI Yong1, LIU Yansong2, XIE Chunping2, HE Zhibing2

(1. State Key Laboratory of Environmentfriendly Energy Materials, Southwest University of

Science and Technology, Mianyang 621010, Sichuan, China; 2. Research Center of Laser Fusion,

China Academy of Engineering Physics, Mianyang 621900, Sichuan, China )

Abstract: Copper films were deposited by DCMS (direct current magnetron sputtering) and DCMS/HiPIMS(direct current magnetron sputtering/highpower impulse magnetron sputtering) cosputtering under various substrate negative biases. The crystal orientation, morphology, roughness, mechanical and electrical properties of the films were characterized by X-ray diffraction, field emission scanning electron microscope, white light interferometer, nanoindentation technique and fourpoint probe method. The results show that compared with DCMS copper films, the grain size of DCMS/HiPIMS cosputtered copper films first decreases and then increases with the increase of negative bias, the Cu(111) orientation weakens, the hardness gradually increases, and the resistivity gradually decreases. Under high negative bias (100 V), Cu(111) transforms to Cu(220), the film is compact, the surface roughness decreases, the hardness increases (about 3.5 GPa), and the resistivity decreases (about 2 μΩ·cm). The structure and properties of copper thin films are strongly dependent on the copper ion flux and energy determined by HiPIMS and negative bias.

Keywords: Direct current magnetron sputtering; Highpower impulse magnetron sputtering; Copper films; Substrate negative bias; Hardness; Resistivity

銅(Cu)薄膜具有较高导电性和导热性,是制造业中应用最广泛的材料。随着超大规模集成电路(VLSI)等行业对新材料的需求不断增加,传统的铝及其合金已不能满足要求。铜薄膜具有比铝及其合金更优的导热性和延展性,更低的成本和体积电阻率(ρ=1.67 μΩ·cm),可满足VLSI中尺寸缩减和互连材料的需求[1-3]。但是,作为VLSI中的新型布线材料,Cu薄膜在标准芯片制造过程中易被破坏和腐蚀,传统制备方法(溅射沉积)和模式(反应离子蚀刻) 对改善集成电路质量并不现实,已不适用于制备Cu薄膜。因此,迫切需要改进沉积方法,获得更高质量、更高硬度及更低电阻率的铜薄膜[2, 4]。直流磁控溅射(DCMS)是制备铜薄膜的传统方法,具有高沉积速率、高放电稳定性和高附着力等优点。但是,DCMS薄膜具有不均匀、多孔、显著热负荷和阴影效应等缺陷。高功率脉冲磁控溅射(HiPIMS)是一种新型技术,具有高离化率和薄膜均匀性,但沉积速率低,放电可控性较差[5- 6]。因此,需要开发更有效的溅射方法来制备高密度、低粗糙度、良好力学性能和低电阻率的铜薄膜。DCMS/HiPIMS共溅射技术是一种新颖的镀膜技术。该技术结合两种技术的特点,可实现微米厚薄膜的晶粒取向,提高薄膜的结晶度、均匀性和性能等,有望在VLSI中制备高质量铜薄膜[7]。近年来,利用DCMS/HiPIMS共溅射技术制备TiAlCrN,TiAlN和TiC薄膜取得重大成就,这些薄膜具有高致密性、高结晶度、高硬度和低应力等特点[5, 7],但利用DCMS/HiPIMS共溅射技术制备铜薄膜的系统研究鲜有报道。磁控溅射中,达到生长薄膜的离子轰击特性是影响薄膜质量和性能的重要参数,也是磁控溅射行业的研究热点和重点[8-10]。离子轰击能量是影响薄膜特定微观结构、晶体取向和相生长等的重要因素,由衬底负偏压决定。有报道提出[9,11-12],离子轰击能量可有效控制生长薄膜的能量传递和表面吸附原子的迁移率,改善薄膜致密性、质量、力学和电学性能等[8-10,13-14]。为此,本文开展在不同负偏压(0 ~100 V)下DCMS/HiPIMS共溅射制备铜薄膜的研究。使用X射线衍射仪、扫描电子显微镜、白光干涉仪、纳米压痕测试仪、四探针电阻率测试仪对样品的择优取向、晶粒尺寸、形貌、粗糙度、力学和电学性能进行表征。

1实验

1.1铜薄膜的制备

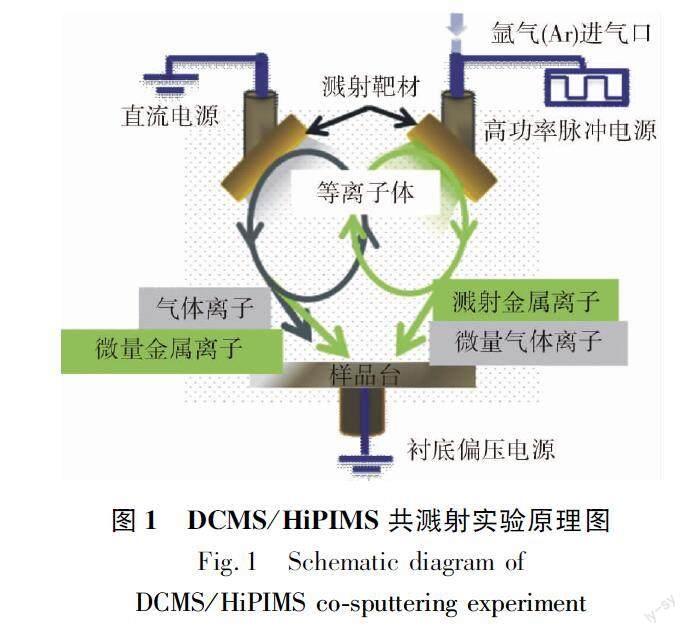

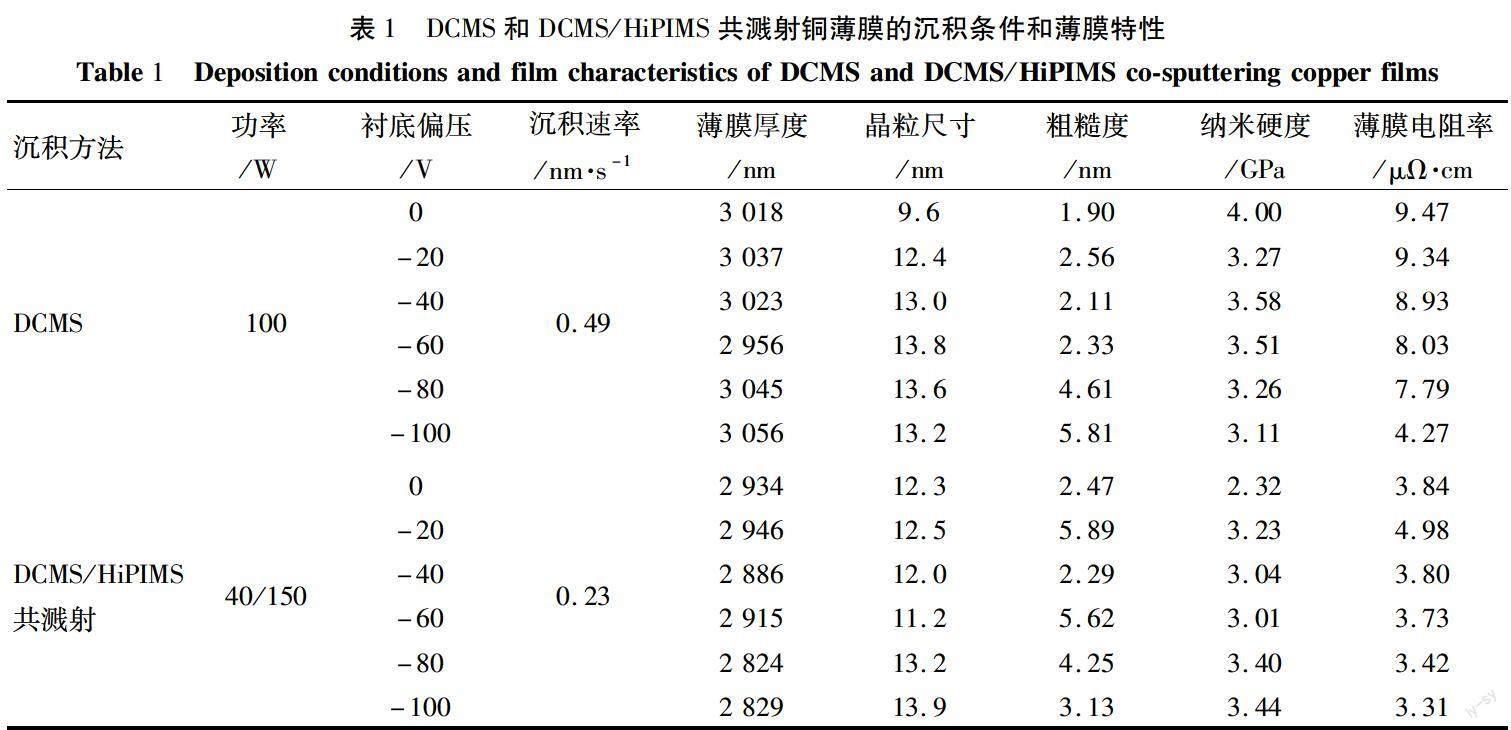

图1为DCMS/HiPIMS共溅射铜薄膜的实验原理图。如图1所示,采用JGP560超高真空镀膜设备在双面抛光硅片(111)上沉积3 μm厚的铜薄膜。硅片(10 mm×10 mm×0.5 mm)分別用丙酮和乙醇超声清洗20 min后用压缩空气吹干。实验本底真空约5×10-6 Pa,溅射气体为高纯氩气(纯度99.999 %,流量10 mL/min),工作气压约0.6 Pa。DCMS 实验的斜铜靶(纯度99.99 %,直径76 mm,厚度6 mm)直接连接100 W直流电源。耦合DCMS/HiPIMS 共溅射的两个铜靶分别接入直流电源和高功率脉冲电源。高功率脉冲电源保持恒定的脉冲直流电压(650 V)、功率(150 W)、脉冲宽度(100 μs)和重复频率(100 Hz)。表1为DCMS和DCMS/HiPIMS共溅射铜薄膜的沉积条件和薄膜特性参数。校准DCMS和HiPIMS沉积速率(分别为0.49 nm·s-1和0.23 nm·s-1)后,以50% 离化率计算共溅射所需直流功率(恒为40 W)。所有靶材距离衬底约15 cm,并与衬底中心法线成40°。为研究衬底负偏压的影响,依次向衬底提供0,20,40,60,80,100 V 的直流负偏压(标记为0,-20,-40,-60,-80,-100 V)。衬底保持正反10 r/min均匀转动以保证镀膜均匀性。

1.2薄膜的性能与表征

使用掠入射X射线衍射仪(GIXRD,0.5°,Rigaku SmartLab 9 kW)表征铜薄膜的晶体结构和择优取向;采用超高分辨率场发射扫描电子显微镜(FE-SEM,蔡司,德国,BRUKER XFlash 6130)研究铜薄膜的厚度、形貌;使用白光干涉仪(GT-O5X,10×目镜,50× 物镜)测量薄膜表面粗糙度;采用纳米压痕测试仪(U9820 A,G200压头,最大载荷8 mN,最大压入深度250 nm)连续刚度模式(CSM)测量薄膜的压痕硬度,为防止衬底干扰,压入深度不超过铜薄膜厚度的1/10[10];使用四探针测试仪(电流50 mA,电压 210 V,HRMS-800)测量铜薄膜电阻率。

2结果和讨论

2.1不同负偏压下铜薄膜的结构取向和晶粒尺寸

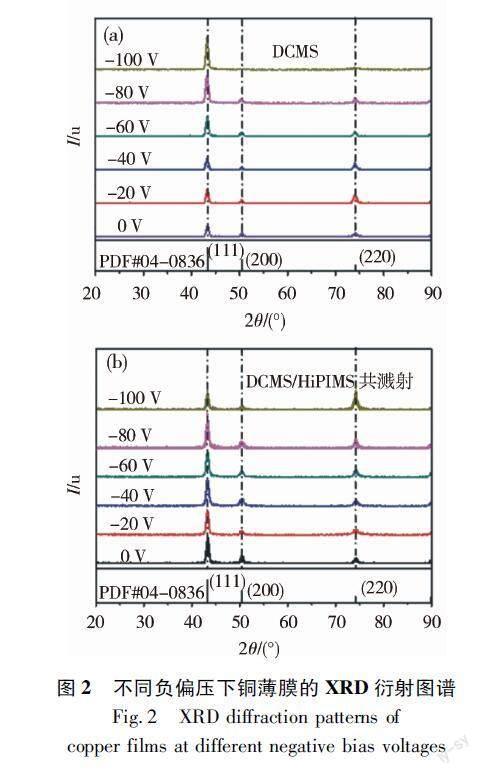

图2为不同负偏压下DCMS和DCMS/HiPIMS共溅射铜薄膜的XRD图谱。如图2(a)、图2(b)所示,薄膜所有衍射光谱均符合铜的标准卡片(JCPDS#04-0836)。图3表示Cu(111)和Cu(220)峰的相对强度,即I(111)/I(220),用于定义铜薄膜择优取向。因为密排Cu(111)晶面具有最低的表面能和最稳定的结构,所以铜薄膜在Si(111)衬底上优先以(111)晶面生长[15-16]。如图2(a)所示,DCMS铜薄膜均以Cu(111)晶面择优生长,并且Cu(111)强度随负偏压的增加呈递增趋势。如图2(b)所示,除了-100 V外,与DCMS铜薄膜类似,DCMS/HiPIMS共溅射铜薄膜以Cu(111)择优生长,且Cu(111)强度随着负偏压的增加而增大,薄膜结晶度提高。Mukherjee等[17]认为,等离子体能量随着负偏压的增加而增加,导致薄膜表面吸附铜原子迁移率增加[8, 14]。然而,在-100 V时,铜薄膜择优取向从(111)变为(220),表明该偏压下较高的离子能量促进Cu(220)晶面生长。类似于Cemin等[4, 8]和Engwall等[6]的研究,随着轰击离子能量增加,可实现Cu薄膜的织构转变。

用谢乐(Scherrer)方程计算了不同负偏压下铜薄膜的晶粒尺寸[3, 14],结果如图4所示。对于 DCMS 薄膜,平均晶粒尺寸在9.5 nm和13.5 nm之间。低负偏压(<60 V)下,晶粒尺寸增大与薄膜表面微量铜离子的有效能量转换和吸附原子的扩散有关。高负偏压(>60 V)下,晶粒尺寸减小归因于再溅射和热负荷导致吸附原子的扩散能损失[16, 18-19]。DCMS/HiPIMS共溅射薄膜的晶粒尺寸为11~14 nm,-60 V下形成最细晶粒。研究发现,较低或较高的负偏压环境下,富铜离子的共溅射薄膜晶粒尺寸略大,这与吸附原子迁移率和表面扩散能增加有关。然而,在-40 V至-80 V的偏压下,晶粒尺寸较小且低于DCMS薄膜的主要原因是二次成核出现并成为主导,这也反应在扫描电镜观察到的不均匀的颗粒形貌中[3,15,17]。

2.2不同负偏压下铜薄膜的微观结构和粗糙度

图5为DCMS和DCMS/HiPIMS共溅射铜薄膜的微观结构。铜薄膜表面均表现为大小不一的块状颗粒,并利用Nanomeasure软件统计铜薄膜表面颗粒的平均尺寸为86~190 nm,均大于XRD中计算的晶粒尺寸。根据Ma等[15]的报道可知,较大颗粒形态是由小晶粒聚集而成,这导致表面粗糙度增加。与Cemin等[4]的研究结果类似, 图5(a)-图5(f)中DCMS薄膜主要是纤维柱状结构且从表面突出,铜膜厚度接近3 μm(表1所示)[15]。与XRD结果相同,负偏压增大,薄膜表面吸附原子扩散加快,促进晶粒不断聚集,使表面颗粒尺寸增大。与DCMS薄膜不同,DCMS/HiPIMS共溅射铜薄膜厚度略小于3 μm,因为共溅射的沉积速率受HiPIMS影响。共溅射铜薄膜是多孔纤维结构(图5(g)-图5(l)),因为原子迁移率和微晶边界都受到严格动力学限制[13, 20],这严重影响薄膜的粗糙度和硬度。与XRD类似,-40 V至-80 V下,共溅射薄膜的颗粒尺寸低于DCMS薄膜,但较低或较高负偏压下尺寸较大,表明不同偏压对具有高通量铜离子的共溅射铜晶粒生长有不同的影响[14-15,19,21]。

图6是DCMS和DCMS/HiPIMS共溅射Cu薄膜的表面粗糙度(Ra)变化曲线和3D形貌图,其Ra值如表1所示。与SEM结果一致,DCMS铜薄膜Ra较大(图6(b)-图6(g)),因为晶粒生长并在表面聚集成大颗粒[3, 19]。然而,DCMS/HiPIMS共溅射铜薄膜的表面粗糙度受到内部多孔结构、晶粒尺寸和表面颗粒影响(图6(h)-图6(m))。结合XRD图谱和SEM形貌图,负偏压小于80 V时铜薄膜中具有丰富孔隙,导致共溅射薄膜粗糙度大于DCMS薄膜[13],大于80 V时,共溅射表面粗糙度减小,因为大量铜离子的有效能量转换和吸附原子扩散加快,促进晶粒生长并使薄膜结构相对致密[3,16,18]。最小粗糙度出现在粒径最小的铜薄膜中。以上结果表明,溅射金属离子通量和能量对薄膜生长和微观结构起主导作用。

2.3不同負偏压下铜薄膜的硬度和电阻率

图7所示是铜薄膜的纳米压痕硬度和电阻率。与其他研究相比[2, 15, 22],所有薄膜都显示出相对较高的硬度。由于施加负偏压形成大颗粒导致表面粗糙,DCMS薄膜硬度逐渐下降。DCMS/HiPIMS共溅射时,由于薄膜孔隙减少和致密度增加,硬度增加。此外,共溅射铜薄膜在高负偏压(>60 V)下的硬度较高,因为较高能量的离子轰击效应增加了薄膜的表面致密性,粗糙度降低。由于孔隙和表面粗糙度的影响,低负偏压(<60 V)下较小晶粒尺寸的铜薄膜硬度较低[22]。DCMS铜薄膜在0 V时出现的最大硬度(4 GPa)主要与细晶粒强化效应有关[1- 2]。该结果表明,共溅射中的铜离子的入射能量较大,可以有效观察到更光滑的表面和更高的硬度[20]。

如图8所示,随着离子轰击偏压的增加,薄膜电阻率降低。晶界效应和内部杂质、位错等缺陷是影响金属薄膜电阻率的主要因素[23]。DCMS薄膜电阻率下降的主要原因是晶粒长大减小了晶界密度、减少了电子散射[3,15,22]。然而,DCMS/HiPIMS共溅射薄膜的电阻率不完全取决于晶粒尺寸。在-40 V和-80 V之间,电阻率取决于丰富孔隙产生的大量位错。此外,施加负偏压后,因为高通量铜离子产生的晶界和位错效应对电阻率的影响大于DCMS中的中性原子,所以DCMS/HiPIMS共溅射Cu薄膜的电阻率低于DCMS薄膜[15]。

3结论

本文采用DCMS/HiPIMS磁控共溅射法在Si(111)衬底上制备铜薄膜,研究衬底负偏压(0~100 V)对DCMS/HiPIMS共溅射Cu薄膜的晶体取向、晶粒尺寸、微观结构、粗糙度、硬度和电阻率的影响。与DCMS相比,等离子体中铜离子通量和能量对薄膜的结构、形貌、力学和电学性能有显著影响。施加衬底负偏压可有效改变离子轰击能量,从而改变生长薄膜表面的能量扩散和吸附铜原子的迁移率。负偏压增加,共溅射铜薄膜晶粒尺寸有先减小后增加的趋势,最小粒径为11.2 nm。负偏压增加,薄膜致密性和光滑度增加,硬度增加,电阻率降低。高负偏压(100 V)下,共溅射中的高通量铜离子具有高能量,使铜薄膜生长取向改变,即从Cu(111)转变为Cu(220)。较高的离子轰击能量促进表面能量转换和吸附原子的扩散、迁移,导致铜薄膜具有更高的硬度(约3.5 GPa)和更低的电阻率(约2 μΩ·cm)。

参考文献

[1]KHODABAKHSHI F, KAZEMINEZHAD M. The effect of constrained groove pressing on grain size, dislocation density and electrical resistivity of low carbon steel[J]. Materials & Design, 2011, 32(6): 3280-3286.

[2]KURAPOVA O Y, GRASHCHENKO A S, ARCHAKOV I Y, et al. The microstructure and mechanical properties of twinned copperbismuth films obtained by DC electrodeposition[J]. Journal of Alloys and Compounds, 2021, 862: 158007.

[3]VILOAN R P B, HELMERSSON U, LUNDIN D. Copper thin films deposited using different ion acceleration strategies in HiPIMS[J]. Surface and Coatings Technology, 2021, 422: 127487.

[4]CEMIN F, LUNDIN D, CAMMILLERI D, et al. Low electrical resistivity in thin and ultrathin copper layers grown by high power impulse magnetron sputtering[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2016, 34(5): 051506.

[5]GUI B H, ZHOU H, ZHENG J, et al. Microstructure and properties of TiAlCrN ceramic coatings deposited by hybrid HiPIMS/DC magnetron cosputtering[J]. Ceramics International, 2021, 47(6): 8175-8183.

[6]ENGWALL A M, SHIN S J, BAE J, et al. Enhanced properties of tungsten films by highpower impulse magnetron sputtering[J]. Surface and Coatings Technology, 2019, 363: 191-197.

[7]ZOITA N C, DINU M, KISS A E, et al. A comparative investigation of heteroepitaxial TiC thin films deposited by magnetron sputtering using either hybrid DCMS/HiPIMS or reactive DCMS process[J]. Applied Surface Science, 2021, 537: 147903.

[8]CEMIN F, ABADIAS G, MINEA T, et al. Benefits of energetic ion bombardment for tailoring stress and microstructural evolution during growth of Cu thin films[J]. Acta Materialia, 2017, 141: 120-130.

[9]MBIOMBI W M, WAMWANGI D, MATHE B A, et al. Tuning structural, electrical and mechanical properties of diamondlike carbon films by substrate bias voltage[J]. Materials Today Communications, 2021, 28: 102501.

[10]BOBZIN K, BROGELMANN T, KRUPPE N C, et al. Pulse synchronized substrate bias for the High Power Pulsed Magnetron Sputtering deposition of CrAlN[J]. Thin Solid Films, 2021, 732: 138792.

[11]SAHU B P, DUTTA A, MITRA R. Influence of substrate bias voltage on structure and properties of DC magnetron sputtered Ni-Zr alloy thin films[J]. Journal of Materials Research, 2020, 35(12): 1543-1555.

[12]MIRZAEI S, ALISHAHI M, SOUCEK P, et al. Effect of substrate bias voltage on the composition, microstructure and mechanical properties of W-B-C coatings[J]. Applied Surface Science, 2020, 528: 146966.

[13]KUO C C, LIN C H, CHANG J T, et al. Effect of voltage pulse width and synchronized substrate bias in highpower impulse magnetron sputtering of zirconium films[J]. Coatings, 2021, 11: 7.

[14]DU H, ZANSKA M, BRENNING N, et al. Bipolar HiPIMS: the role of capacitive coupling in achieving ion bombardment during growth of dielectric thin films[J]. Surface and Coatings Technology, 2021, 416: 127152.

[15]MA D L, JING P P, GONG Y L, et al. Structure and stress of Cu films prepared by high power pulsed magnetron sputtering[J]. Vacuum, 2019, 160: 226-232.

[16]WU B H, WU J, JIANG F, et al. Plasma characteristics and properties of Cu films prepared by high power pulsed magnetron sputtering[J]. Vacuum, 2017, 135: 93-100.

[17]MUKHERJEE S K, JOSHI L, BARHAI P K. A comparative study of nanocrystalline Cu film deposited using anodic vacuum arc and dc magnetron sputtering[J]. Surface and Coatings Technology, 2011, 205(19): 4582-4595.

[18]LIM J W, ISSHIKI M. Effect of substrate bias voltage on the texture and microstructure of Cu thin films deposited by ion beam deposition[J]. Metals and Materials International, 2003, 9(2): 201-205.

[19]AVINO F, FONNESU D, KOETTIG T, et al. Improved film density for coatings at grazing angle of incidence in high power impulse magnetron sputtering with positive pulse[J]. Thin Solid Films, 2020, 706: 138058.

[20]ZHU X G, CHENG X L. Symmetric tilt grain boundary evolution during the growth of copper thin films: molecular dynamics simulation[J]. Physica B: Condensed Matter, 2020, 578: 411838.

[21]LATIF R, JAAFAR M F, AZIZ M F, et al. Influence of tantalums crystal phase growth on the microstructural, electrical and mechanical properties of sputterdeposited tantalum thin film layer[J]. International Journal of Refractory Metals and Hard Materials, 2020, 92: 105314.

[22]MLADENOVIC I O, MIKOLIC N D, LAMOVEC J S, et al. Application of the composite hardness models in the analysis of mechanical characteristics of electrolytically deposited copper coatings: The effect of the type of substrate[J]. Metals, 2021, 11: 111.

[23]LEE Y Z, ZENG W Y, CHENG I C. Synthesis and characterization of nanoporous copper thin films by magnetron sputtering and subsequent dealloying[J]. Thin Solid Films, 2020, 699: 137913.