Extraction Conditions of Essential Oil from Eucalyptus Leaves by Distillation

2023-10-28ShengjieWANGZongchenWEIShimingQIU

Shengjie WANG, Zongchen WEI, Shiming QIU

Guangxi Minzu Normal University, Chongzuo 533200, China

Abstract [Objectives] To explore the extraction conditions of essential oil from eucalyptus leaves. [Methods] The essential oil of eucalyptus leaves was extracted by steam distillation, and the yields of essential oil from eucalyptus leaves under different extraction times, soaking times and different solid-liquid ratios were analyzed through orthogonal test with three factors and three variables. [Results] The effects of various factors on extraction results were: distillation time >solid-liquid ratio>soaking time. When the extraction time and soaking time were 1.5 and 2 h, and the solid-liquid ratio of eucalyptus leaves to distilled water was 1:10, the yield of essential oil was the highest (0.8%). The yield of essential oil increased with the increase of extraction and soaking time, but when reaching the optimal value, the yield decreased with the extension of time. Increasing the solid-liquid ratio can improve the yield of essential oil, but beyond a certain value the yield increased gradually while the cost performance decreased. [Conclusions] The results will provide some reference for the recovery and utilization of eucalyptus leaves.

Key words Eucalyptus essential oil, Process conditions, Oil yield, Orthogonal test

1 Introduction

Eucalyptus essential oil is a mixture secreted by oil gland cells of eucalyptus leaves, which has complex components, rich varieties and special aroma, and is usually colorless or yellowish oily liquid[1]. The planting area, climate, soil conditions and varieties ofEucalyptusspp. all affect the chemical composition of eucalyptus essential oil, but the basic components of eucalyptus essential oil are terpenoids, aliphatic compounds and aromatic compounds, mainly terpenoids[2-3].

At present, the separation and extraction methods of plant essential oils at home and abroad mainly include distillation, ultrasonic (microwave) assisted extraction, organic solvent extraction, supercritical extraction and molecular distillation,etc.[4]. Distillation is the most commonly used method featured by simple equipment and low cost, which is convenient and easy to extract eucalyptus essential oil. Compared with ultrasonic and supercritical methods, it has less equipment input and low operation difficulty[5]. Compared with organic solvent method, distillation method is more environmentally friendly and greatly reduces the emission of VOC substances. In addition, distillation can use eucalyptus bark, branches and biomass fuel as power, which has little pollution to the environment and little input to production equipment, being a practical and efficient extraction technology of eucalyptus essential oil[6-7].

Guangxi is rich in germplasm resources ofEucalyptusspp., and is the breeding base ofEucalyptusspp. in China[8]. SinceEucalyptusspp. in Guangxi is mainly used for wood production, there is a lot of waste of eucalyptus leaves[9]. Therefore, this paper studied the extraction technology of eucalyptus essential oil by distillation, and discussed the yield of essential oil under different process conditions, in order to provide some reference for the recovery and utilization of eucalyptus leaves.

2 Materials and methods

2.1 MaterialsFresh leaves of different maturity were collected from 3-5 years oldEucalyptusglobulus,E.grandis×E.urophylla,E.urophyllaandE.tereticornis.

Deionized water (Panike); Anhydrous sodium sulfate (Tianjin Baishi Chemical Industry Co., Ltd.); Distillation equipment (DXY-SA); FY130 drug crusher (Tianjin Taisite Instrument Co., Ltd.).

2.2 MethodsThe above materials were weighed in equal amounts and mixed well, and broken by a drug crusher. A total of 30.00 g of eucalyptus leaf powder was soaked in appropriate proportion of deionized water. After soaking for different time, the essential oil of eucalyptus leaves was extracted by steam distillation method with distilled water as the extraction solvent. A micro-boiling state was maintained during the extraction process, and the heat source was turned off after reaching the set extraction time. As the oil and water were stratified after being left undisturbed for a few minutes, the distilled essential oil was collected. The collected essential oil should be dried by adding anhydrous sodium sulfate, and the yield of eucalyptus essential oil (oil yield) should be calculated after obtaining the product.

2.3 Data processingAll data were sorted by Excel and plotted by Origin.

3 Results and analysis

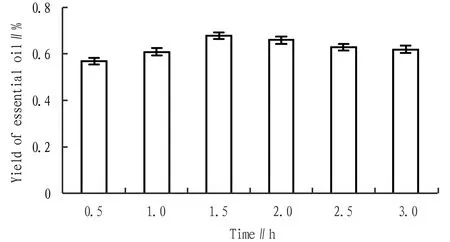

3.1 Effect of extraction time on the yield of essential oil from eucalyptus leavesWhen eucalyptus leaves were soaked for 2 h and the solid-liquid ratio of eucalyptus leaves to distilled water was set at 1:10 (g/mL), the yield of essential oil was determined after being extracted for 0.5, 1, 1.5, 2, 2.5 and 3 h (Fig.1). The yield of eucalyptus essential oil increased with the extension of extraction time, reached the maximum at 1.5 h, and then decreased.

Fig.1 Effect of distillation extraction time on the yield of essential oil from eucalyptus leaves

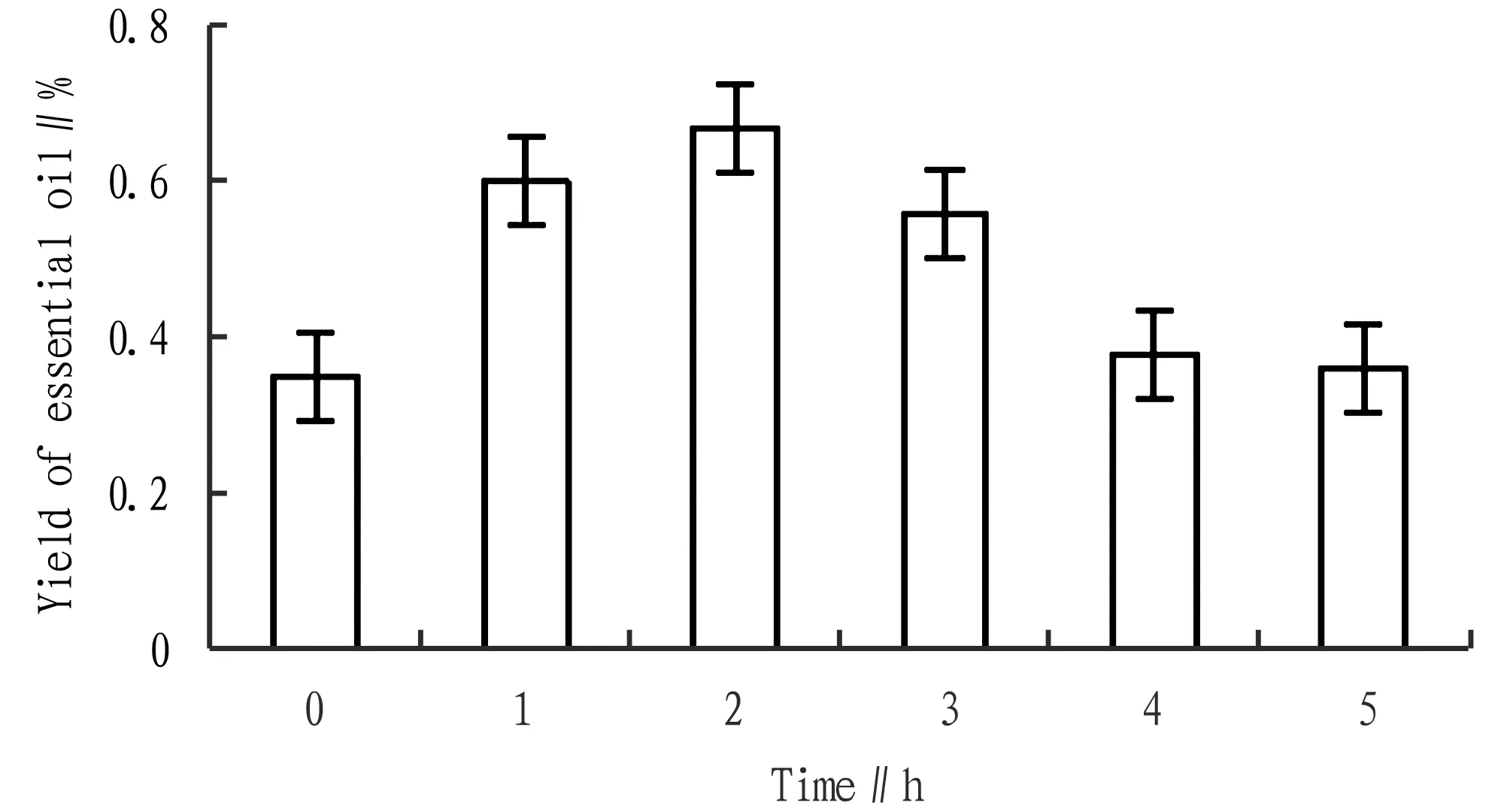

3.2 Effect of soaking time on the yield of essential oil from eucalyptus leavesAfter the extraction time was set to 1.5 h and the solid-liquid ratio of eucalyptus leaves to distilled water was set to 1:10 (g/mL), the effects of soaking time on the yield of essential oil from eucalyptus leaves were analyzed at 0, 1, 2, 3, 4 and 5 h. As shown in Fig.2, the yield of essential oil was the highest when eucalyptus leaves were soaked for 2 h. When eucalyptus leaves were soaked for 0-2 h, the yield of essential oil increased with the increase of soaking time, but when eucalyptus leaves were soaked for more than 2 h, the yield of essential oil decreased instead of increasing. It might be attributed to the fact that the volatile components of eucalyptus essential oil volatilized too much with too long soaking time, resulting in the loss of essential oil components, thereby reducing the yield of essential oil.

Fig.2 Effect of soaking time on the yield of essential oil from eucalyptus leaves

3.3 Effect of solid-liquid ratio on the yield of eucalyptus essential oilUnder the conditions of 1.5 h extraction and 2 h soaking in distillation, the solid-liquid ratios of eucalyptus leaves to distilled water were set as 1:5, 1:6, 1:7, 1:8, 1:9, 1:10 (g/mL). As shown in Fig.3, the yield of eucalyptus essential oil increased with the increase of solid-liquid ratio. More polar water molecules entered the cells of eucalyptus leaves, and the distilled water heated up rapidly after heating, which speeded up the time of cell rupture and allowed more volatile components to be carried out by water vapor, thus increasing the yield of essential oil. However, when the solid-liquid ratio was 1:10, the yield flattened out.

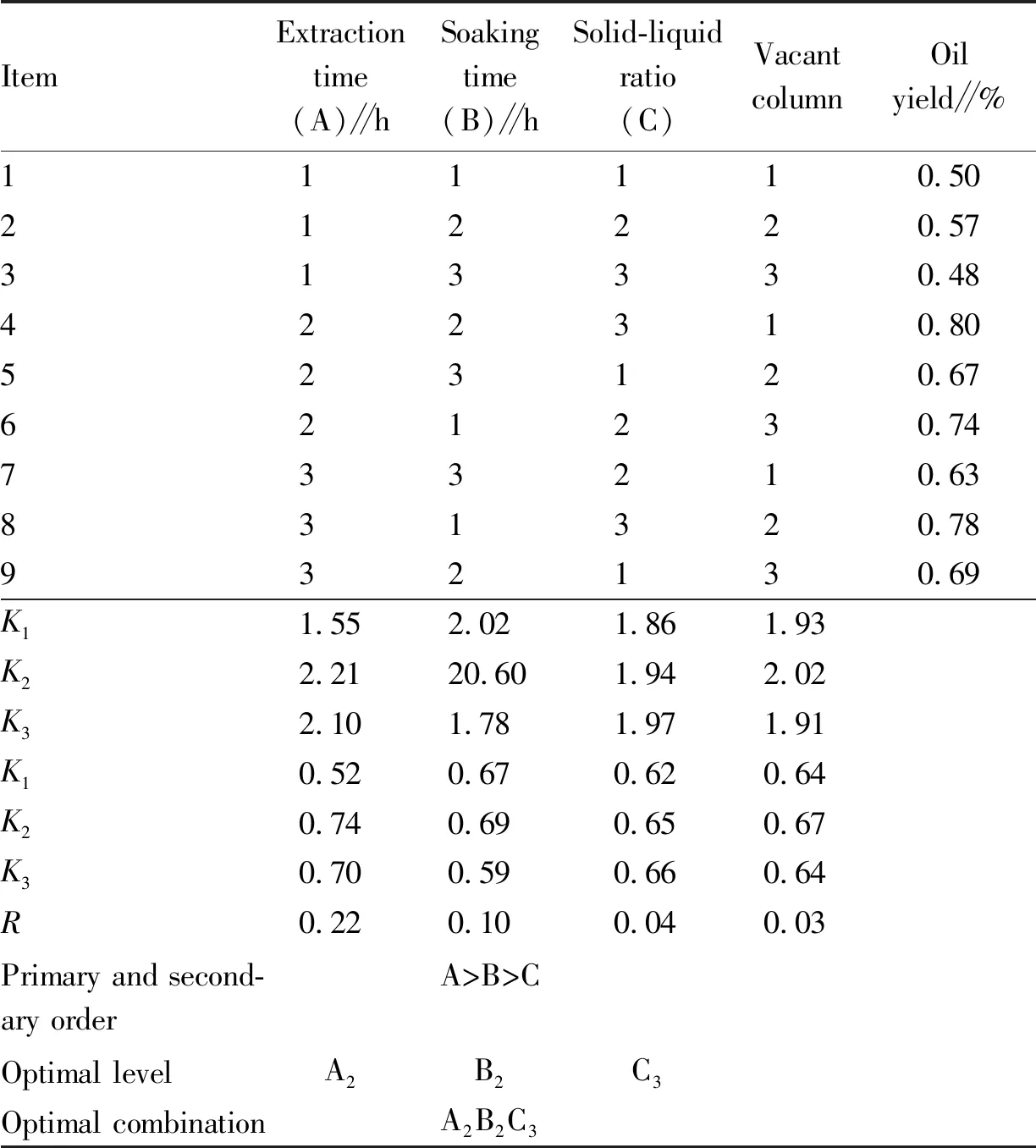

3.4 Orthogonal test resultIn order to obtain the best process parameters, orthogonal test was designed. The yield (%) of essential oil from eucalyptus leaves was used as the evaluation standard, and the extraction time (h), soaking time (h) and solid-liquid ratio were compared (Table 1). Three horizontal tests were conducted, and the average value was calculated. As shown in Table 2, extraction time had the greatest effect on the yield of essential oil from eucalyptus leaves, followed by soaking time. The optimal parameter combination of extraction process was A2B2C3, that is, extraction time 1.5 h, soaking time 2 h and solid-liquid ratio of eucalyptus leaves to distilled water 1:10, and the yield of essential oil reached 0.8%, receiving the best effect.

4 Conclusions and discussion

Eucalyptus essential oil is featured by aromatic odor, inhibition and killing effect against bacteria and fungi, obvious antioxidant ability, anti-inflammatory and analgesic effect, as well as certain insecticidal effect, and has been widely used in medicine, food, cosmetics and preservatives and other production industries. Studies have shown that with the yield of eucalyptus oil as the evaluation index, the optimal extraction process of eucalyptus oil can be obtained through ultrasonic assisted steam distillation method and single factor and orthogonal test: solid-liquid ratio 1:4, ultrasonic time 25 min, ultrasonic power 200 W, distillation time 5 h, and yield of eucalyptus oil 1.51%[4]. In this paper, the technical conditions of extracting essential oil from eucalyptus leaves by distillation were studied. The results were as follows.

Table 2 Results and analysis of orthogonal test

(i) Extraction time, soaking time and solid-liquid ratio had impacts on the yield of essential oil. The yield of essential oil increased with the increase of extraction and soaking time, but the yield of essential oil decreased with the extension of time after exceeding the optimal value.

(ii) The increase of solid-liquid ratio would increase the yield of essential oil, but when exceeding a certain value, the increase of yield became smooth, and the cost performance decreased.

(iii) The optimal extraction parameter combination was A2B2C3, that is, extraction time 1.5 h, soaking time 2 h and solid-liquid ratio of eucalyptus leaves to distilled water 1:10, and the yield of essential oil was the highest of 0.8%.

杂志排行

Asian Agricultural Research的其它文章

- Research and Application of Ecological Outdoor Ground Structure with Composite Water Storage and Drainage Function

- Solid Material Formula of Small Fragrant Chicken Soup Stock and Improvement of Boiling Process

- Bioinformatics Analysis of Q0D1P0 Gene of Mangrove Endophytic Fungus Aspergillus terreus

- Planting Adaptability of Four Kinds of Common Vegetables in Shanghai

- Problems and Countermeasures of Fruit and Vegetable Logistics Distribution Development in Guangxi Zhuang Autonomous Region

- Evaluation and Exploration of Citrus Germplasm Resources in the Origin of Shatangju (Citrus flamea Hort.ex Tseng Shiyueju)