Solid Material Formula of Small Fragrant Chicken Soup Stock and Improvement of Boiling Process

2023-10-28ChaohangCHENDandanLUMaozhaoWUHaiyanWANGJieXIEGuanghuiYANGShoumeiWANLinglingXIAOShengxianPANJinyuZHAO

Chaohang CHEN, Dandan LU, Maozhao WU, Haiyan WANG, Jie XIE, Guanghui YANG, Shoumei WAN, Lingling XIAO, Shengxian PAN, Jinyu ZHAO

1. Guizhou Qianweiwei Food Co., Ltd., Qiandongnan 556020, China; 2. Guizhou Leiage Ecological Agricultural Products Development Co., Ltd., Qiandongnan 556020, China; 3. Guiyang Customs Logistics Management Center, Guiyang 550002, China; 4. Guizhou Light Industry Vocational and Technical College, Guiyang 550025, China

Abstract [Objectives] To study the solid material formula and boiling process of Small Fragrant Chicken Soup Stock. [Methods] Small fragrant chicken and edible fungi were used as the main raw materials to prepare instant chicken and Morchella esculenta soup stock, and the influencing factors such as solid material ratio, ratio of liquid to material, time and temperature were studied, and the optimal formula and process of the soup stock were screened out through sensory and instrument evaluation experiments. [Results] The optimal formula and process of Small Fragrant Chicken Soup Stock were as follows: small fragrant chicken 40%, M. esculenta 6%, Lyophyllum decastes 3% and Lentinus edodes 1.5%; the ratio of liquid to material was 2.5:1, the boiling time was 2 h, and the boiling temperature was 120 ℃.Under these conditions, the sensory score of Small Fragrant Chicken Soup Stock was the best. [Conclusions] This study provided a theoretical basis for the industrial production of edible mushroom prepared dishes.

Key words Edible fungi, Instant heating type prepared dishes, Processing technology

1 Introduction

With the improvement in people’s consumption level and fast-paced life, instant heating type prepared dishes came into being. The instant heating type prepared dishes are a kind of convenient meal prepared, processed, packaged and transported in advance in a specific cold chain environment, such as pre-fried hairtail, stewed pig’s trotters and self-heating hot pot[1]. Based on its advantages of good taste, convenience and low price, prepared dishes are favored by more and more consumers, making them stand out in the fast-paced life of urban residents[2].Morchellaesculentabelongs to the genusMorchellaof Ascomycota, which is mainly distributed in the low altitude plain area to the high altitude range of 3 200 m in China, and the yield ofM.esculentaranks first in China[3]. In addition,M.esculentais a rare edible fungus with rich sources, unique flavor and precision. It has not only high nutritional value but also certain medicinal value, so it is generally considered as a natural, nutritious and multi-functional health food. In this study, chicken soup stockM.esculentawas prepared withM.esculentaas the raw material of prepared dishes. We explored the solid material ratio, ratio of liquid to material, time, temperature in the soup stock, the amount of water, edible mushroom powder and edible alkali in the edible mushroom noodle, and the cooking time, and determined the processing technology and the best formula of the chicken soup stockM.esculentanoodle, so as to provide a reference for the healthy development of prepared dishes industry.

2 Materials and methods

2.1 Main materials and instrumentsJianhe small fragrant chicken,M.esculenta,Lyophyllumdecastes,Lentinusedodes, salt, onion, ginger, pepper, sugar, Chinese prickly ash powder, cooking wine and oyster sauce (all of which are commercially available food grade). Kubei electronic scale; DHG-9070 A meat grinder; K35 Midea pressure cooker.

2.2 Methods

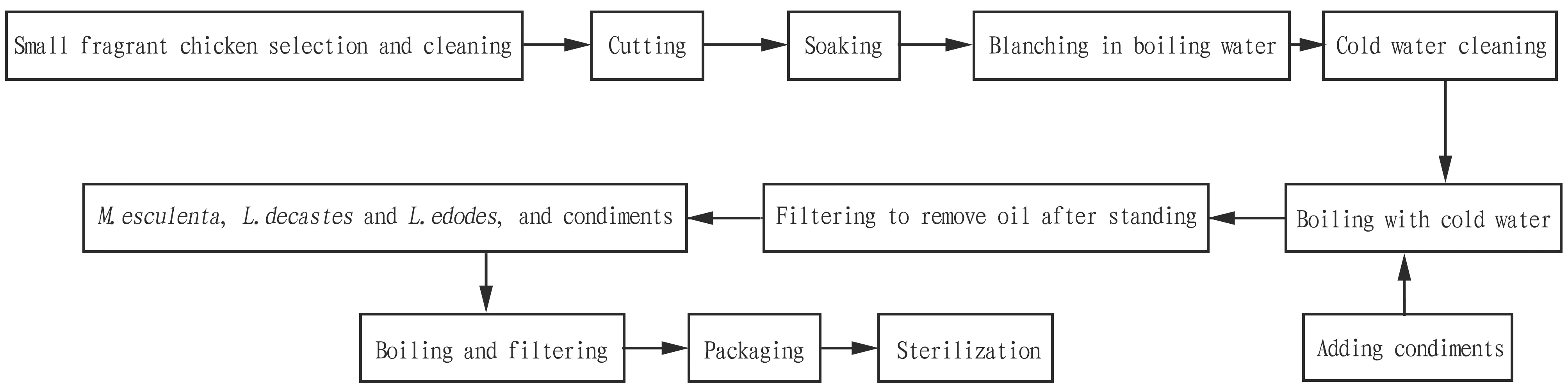

2.2.1Preparation of prepared mushroom soup stock. (i) Process flow of prepared mushroom soup stock (Fig.1).

Fig.1 Process flow of prepared mushroom soup stock

(ii) Key points of operation. Select small fragrant chicken produced in Jianhe, Guizhou, clean, cut into cubes, soak in water, put in boiling water, cool with cold water to lower the temperature, add cold water to boil small fragrant chicken. Then, add auxiliary raw materials such as salt, shallot, ginger, pepper, white sugar, Chinese prickly ash powder, cooking wine and oyster sauce. Filter the prepared small fragrant chicken raw material soup stock to remove oil. Finally, addM.esculenta,L.decastesandL.edodesto continue to boil in the pressure cooker 1 000 W. Filter the Small Fragrant Chicken Soup Stock, package and sterilize, and store the obtained finished product at the temperature of -18 ℃ for later use.

2.2.2Optimization of solid material formula parameters. The basic solid materials of the Small Fragrant Chicken Soup Stock include chicken,M.esculenta,L.decastes,L.edodes, yellow wine, ginger, onion, garlic,etc.According to the pre-test optimization, the small fragrant chicken solid material was divided into small fragrant chicken,M.esculenta,L.decastes, andL.edodes. The indicator was response value, and the suitable dosage range of solid material was determined by single factor and orthogonal experiment through sensory evaluation.

2.2.3Determination of boiling process parameters. (i) Boiling time. The soup stock was decocted using the method in Section2.2.1, in which the ratio of liquid to material parameter was set at 2.5:1, the boiling temperature was 120 ℃, and the boiling time was set at 1.0, 1.5, 2.0, 2.5, and 3.0 h, and the results of three parallel tests were taken. The sensory evaluation of the corresponding soup stock was carried out to determine the optimal boiling time. (ii) Boiling temperature. The soup stock was decocted using the method in Section2.2.1, in which the ratio of liquid to material parameter was set at 2.5:1, the boiling time was set at 2 h, and the boiling temperature was set at 110, 115, 120, 125, and 130 ℃, and the results of three parallel tests were taken. The sensory evaluation of the corresponding soup stock was carried out to determine the optimal boiling time. (iii) Ratio of liquid to material. The soup stock was decocted using the method in Section2.2.1, in which the boiling time was set at 2 h, the boiling temperature was set at 120 ℃, the ratio of liquid to material was set at 3.0:1, 2.5:1, 2.0:1, 1.5:1, and 1.0:1. The results of three parallel tests were taken. The sensory evaluation of the corresponding soup stock was carried out to determine the optimal ratio of liquid to material.

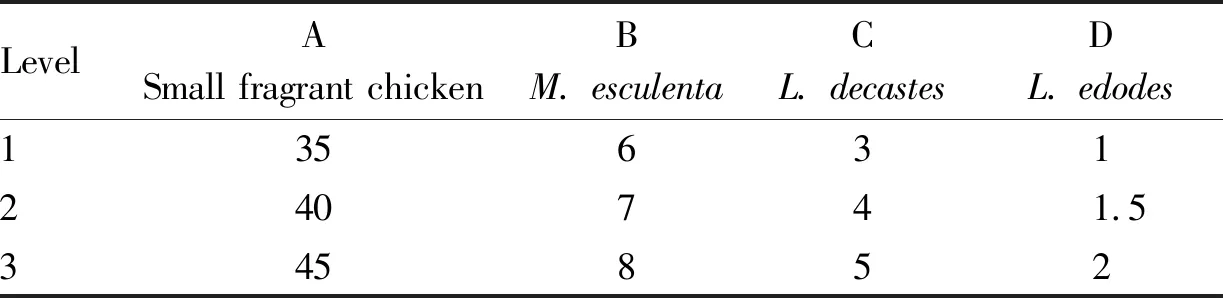

2.2.4Orthogonal experiment. (i) Solid material ratio. The addition amount (%) of small fragrant chicken,M.esculenta,L.decastes, andL.edodeswas used as a factor for the orthogonal experiment, and the sensory score was used as an evaluation indicator to determine the formula of the optimal soup stock solid material. The factor levels are shown in Table 1.

Table 1 Factor level of optimal formula for solid material ratio of small fragrant chicken M. esculenta soup stock %

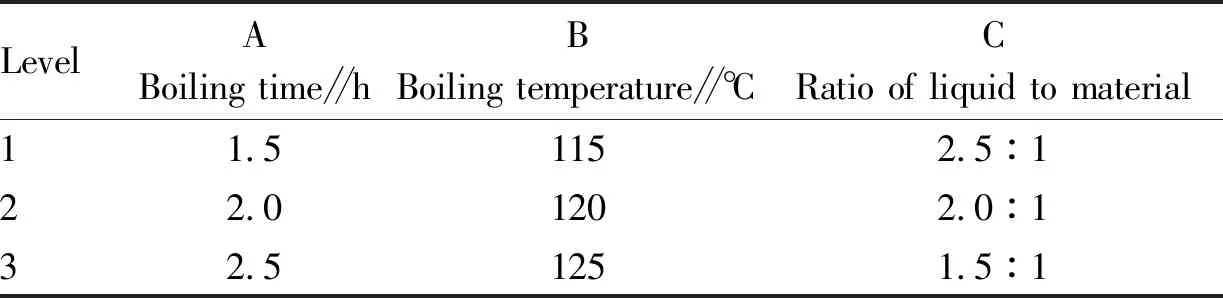

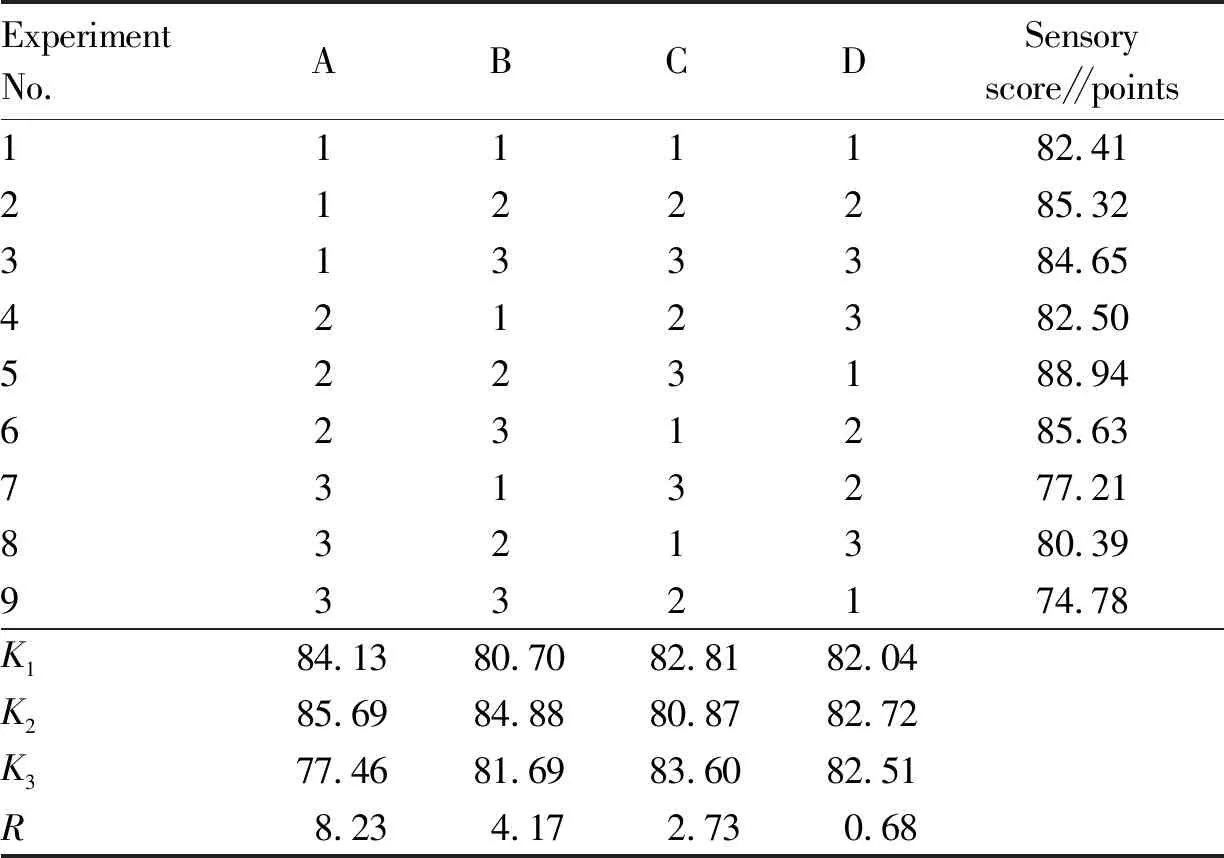

(ii) Processing parameters. The L9(34) orthogonal experiment was carried out with the ratio of liquid to material, boiling time and boiling temperature of the small fragrant chickenM.esculentasoup stock as the influencing factors. The sensory score is used as an evaluation index to determine the optimal process condition factor level, as shown in Table 2.

Table 2 Factor levels of optimal process parameters for soup stock preparation

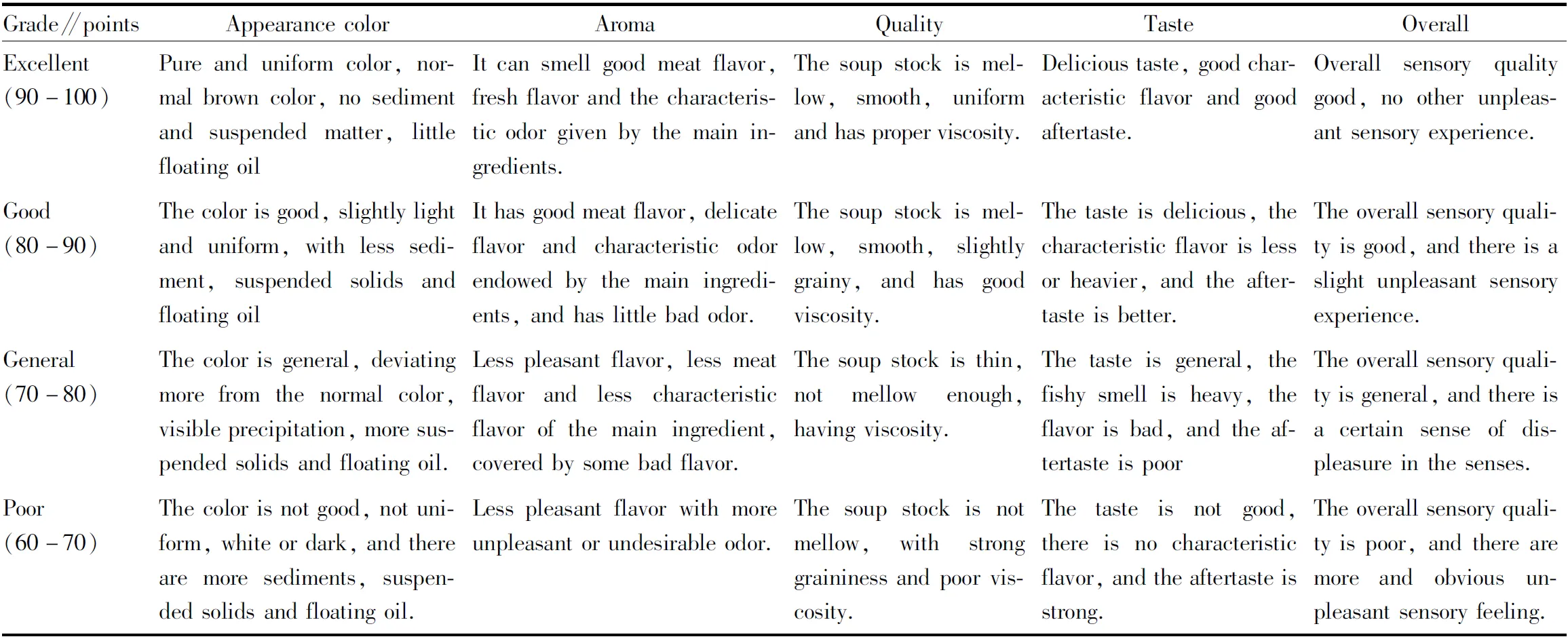

2.2.5Sensory evaluation. After adding seasonings, the boiled soup stock was packed into plastic bowls, each weighing 50 g, and the sensory evaluation of the soup stock was carried out by a 10-member team composed of laboratory researchers, production personnel and sales personnel. The sensory score of each group of samples was given after tasting, and the evaluation criteria used were formulated according to the sensory of the soup stock obtained by the traditional process, as shown in Table 3.

3 Results and analysis

3.1 Optimal formula of solid material ratio for the soup stock

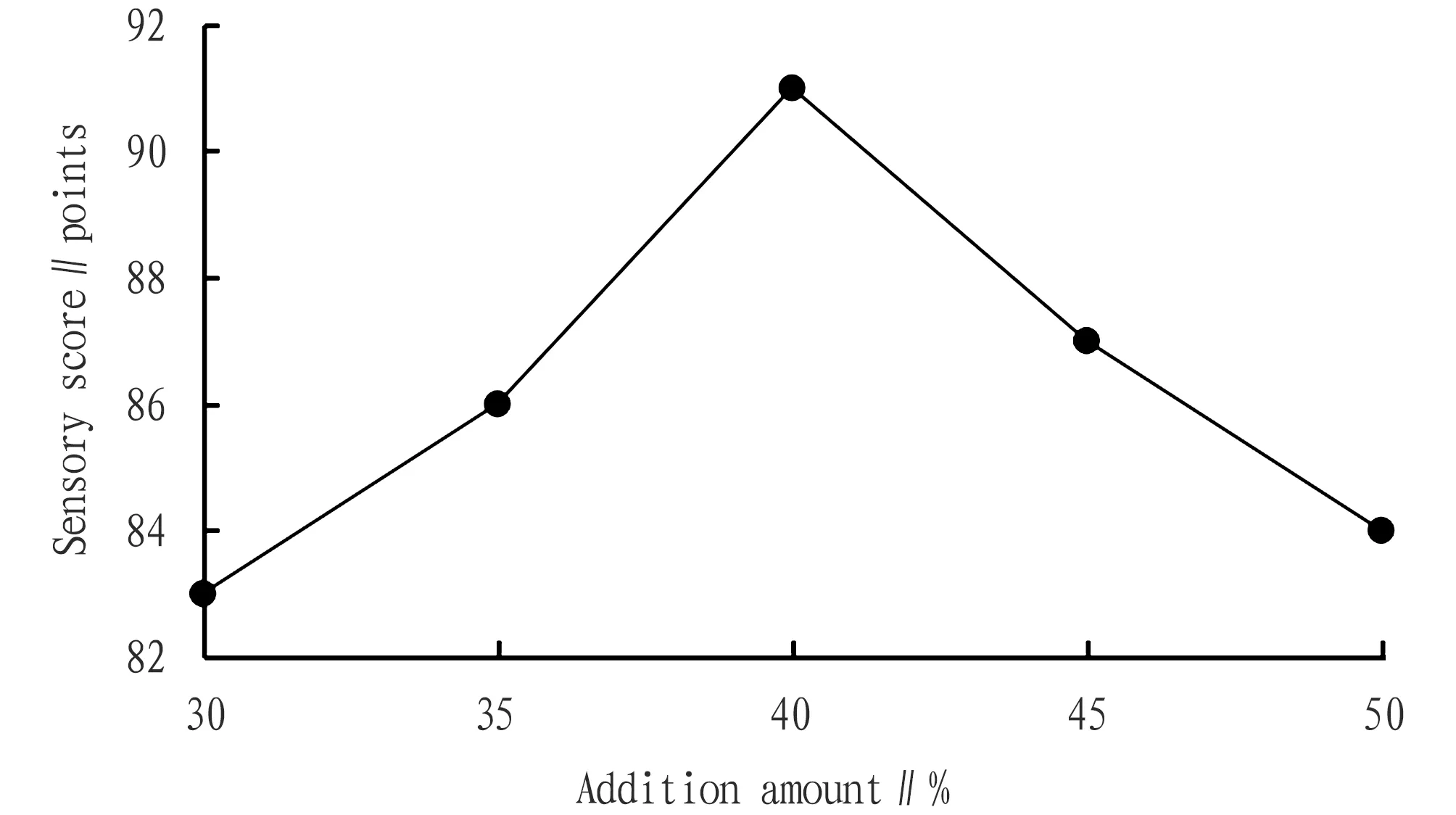

3.1.1Addition amount of small fragrant chicken. The soup stock was boiled in accordance with the method in Section2.2.1, wherein the addition amount of the small fragrant chicken was set at 30%, 35%, 40%, 45% and 50%, the addition amount of theM.esculentawas set at 6%, the addition amount of theL.decasteswas set at 3% and the addition amount of theL.edodeswas set at 1.5%, the results of three parallel tests were taken. Sensory evaluation was performed on each group of soup stock samples to determine the addition amount of small fragrant chicken, and the results are shown in Fig.2. The sensory score of the soup stock showed a trend of first increasing and then decreasing with the increase of the addition amount of small fragrant chicken. Before the addition amount of small fragrant chicken was less than 40%, the soup stock was delicious but the characteristic flavor was insufficient. When the addition amount of small fragrant chicken reached 40%, the soup stock not only tasted delicious and mellow, but also had appropriate characteristics and smooth entrance, showing the maximum sensory score. This may be due to the fact that the characteristic flavor substances in the small fragrant chicken are released after accumulating a certain amount at this time, so that the flavor quality of the soup stock is the best. With the continuous increase in the addition amount, the accumulation of flavor substances is excessive, resulting in negative sensory effects. Similar results were found in the addition amount of the Fotiaoqiang Chicken Soup studied by Wu Lizhen[4]. Therefore, the addition amount of small fragrant chicken was 40% in the subsequent experiments.

Table 3 Sensory scoring criteria of the soup stock

Fig.2 Effects of the addition amount of small fragrant chicken on the soup stock quality

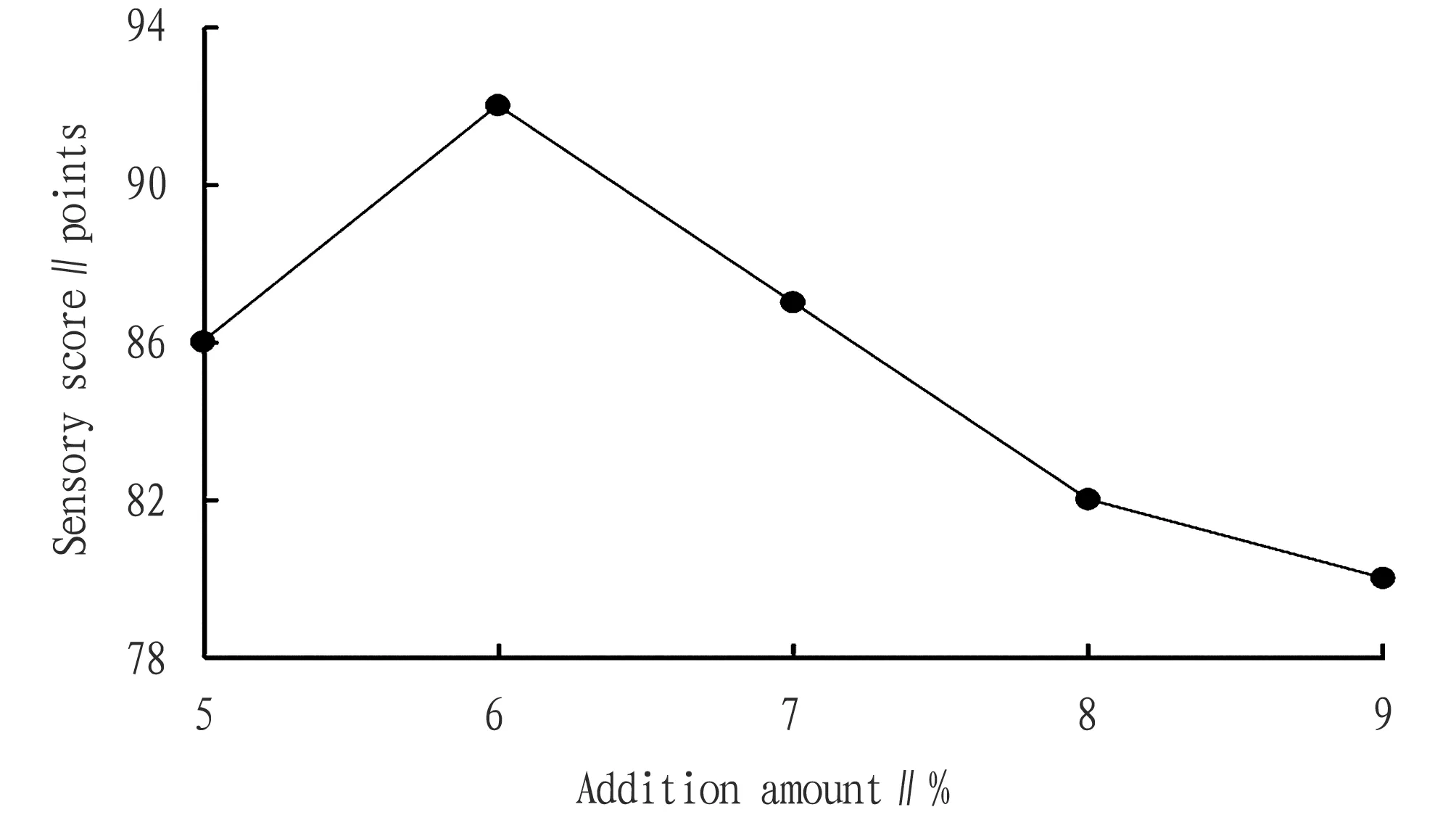

3.1.2Addition amount ofM.esculenta. The soup stock was boiled in accordance with the method in Section2.2.1, wherein the addition amount ofM.esculentawas set at 5%, 6%, 7%, 8%, and 9%, the addition amount of small fragrant chicken was set at 40%, the addition amount ofL.decasteswas set at 3%, and addition amount ofL.edodeswas set at 1.5%. The results of three parallel tests were taken. Sensory evaluation was performed on each group of soup stock samples to determine the addition amount ofM.esculenta. As shown in Fig.3, the sensory score of the soup stock increased first and then decreased with the increase of the addition ofM.esculenta. It is worth noting that the sensory score reached its peak when the addition ofM.esculentawas 6%, which was due to the degradation of various components ofM.esculenta, such as protein, fat and carbohydrate, during the boiling of the soup stock. In this process, an important Maillard reaction occurs inM.esculenta, resulting in the release of many aromatic components such as lactones, pyrazines and furans[5], which greatly improves the flavor quality of soup stock. Therefore, the addition amount ofM.esculentawas selected at 6% for the subsequent experiment.

Fig.3 Effects of the addition amount of Morchella esculenta on the soup stock quality

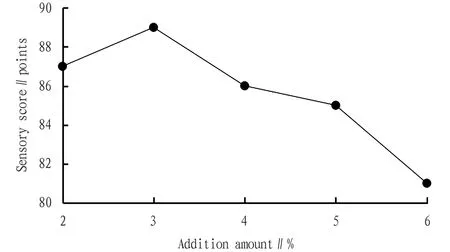

3.1.3Addition amount ofL.decastes.L.decastesis a kind of precious edible and medicinal fungus. It is rich in flavor, smooth in taste, crisp and silky in the mouth. It is rich in high nutritional value, and its fruiting bodies are also rich in minerals, dietary fiber and vitamins[6]. The soup stock was boiled in accordance with the method in Section2.2.1, wherein the addition amount ofL.decasteswas set at 2%, 3%, 4%, 5%, and 6%, the addition amount of small fragrant chicken was set at 40%, the addition amount ofM.esculentawas set at 6%, and addition amount ofL.edodeswas set at 1.5%. The results of three parallel tests were taken. Sensory evaluation was performed on each group of soup stock samples to determine the addition amount ofL.decastes. As shown in Fig.4, the sensory score of the soup stock increased slowly before the addition ofL.decasteswas 3%, and reached the maximum at 3%, and then the sensory score remained almost unchanged with the increase of the addition amount, indicating that when the addition amount was less than 3%, the flavor substances inL.decasteswere also released continuously until the accumulated concentration of flavor substances exceeded the threshold, resulting in a decrease in the sensory score. After that, it tended to be stable, so the addition amount ofL.decasteswas selected at 3% to continue the experiment.

Fig.4 Effects of the addition amount of Lyophyllum decastes on the soup stock quality

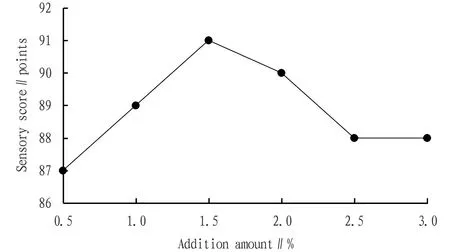

3.1.4Addition amount ofL.edodes. The soup stock was boiled in accordance with the method in Section2.2.1, wherein the addition amount ofL.edodeswas set at 0.5%, 1%, 1.5%, 2%, and 3%, the addition amount of small fragrant chicken was set at 40%, the addition amount ofM.esculentawas set at 6%, and addition amount ofL.decasteswas set at 3%. The results of three parallel tests were taken. Sensory evaluation was performed on each group of soup stock samples to determine the addition amount ofL.edodes. As shown in Fig.5, with the increase in the addition amount ofL.edodes, the sensory score showed a trend of first increasing and then decreasing, which may be due to the fact that when the addition amount ofL.edodesreached 1.5%, the dissolution rate of flavor substances was the best, which made the flavor reach the best at this time, and if the addition amount continued to increase, the concentration of flavor substances would be too high, which would have a negative effect on the sensory score. Therefore, in the subsequent experiments, we selected the addition amount ofL.edodesas 1.5%.

Fig.5 Effects of the addition amount of Lentinus edodes on the soup stock quality

3.1.5Results of orthogonal experiment. According to the results of the above single factor influence experiment, small fragrant chicken,M.esculenta,L.decastesandL.edodeshave greater influence on the flavor quality of the soup stock stock. Therefore, we selected these four factors as the factors of the orthogonal experiment, as shown in Table 4.

Table 4 Orthogonal experiment results of the optimal formula of small fragrant chicken Morchella esculenta soup stock solid material ratio

The factors affecting the sensory score of the soup stock were as follows: small fragrant chicken>M.esculenta>L.decastes>L.edodes, and the best formula combination of the soup stock was A2B2C3D2, that is, the addition of small fragrant chicken was 40%. When the addition amount ofM.esculentawas 6%,L.decasteswas 3% andL.edodeswas 1.5%, the soup stock was the best.

3.2 Determination of process parameters

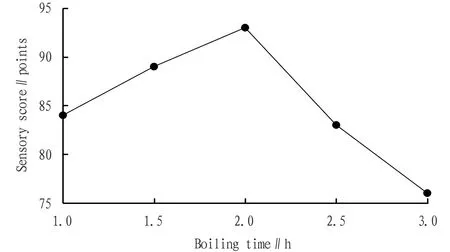

3.2.1Boiling time. The effect of the boiling time of the soup stock on the sensory score is shown in Fig.6. With the increase in boiling time, the sensory score of the soup stock showed a trend of first increasing and then decreasing. When the boiling time was 1.5 h, the nutrients in the raw materials were continuously precipitated during the boiling process, and gradually accumulated, but the upward trend was relatively slow, until the boiling time reached 2 h, the flavor substances and nutrients in the raw materials were the most abundant. At this time, the sensory score reaches the highest. With the increase in boiling time, the continuous boiling of the soup stock leads to the continuous vaporization of water to form water vapor, which reduces the amount of soup stock to a certain extent, resulting in the deepening of the appearance color of the soup stock and even the bitter taste, resulting in the gradual decrease of the sensory score[7]. Therefore, the boiling time was set to 2 h in subsequent experiments.

Fig.6 Effects of boiling time of the soup stock quality

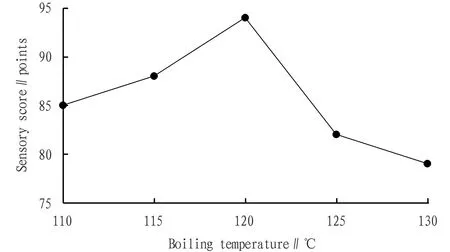

3.2.2Boiling temperature. The effect of boiling temperature on the sensory score of soup stock is shown in Fig.7. The sensory score of the soup stock was the highest at 120 ℃ and the lowest at 130 ℃, which may be due to the fact that the Maillard reaction produced before 120 ℃ promoted the caramelization of sugars, resulting in a large number of positive flavor substances, thus continuously improving the flavor quality of the soup stock. When the boiling temperature exceeded 120 ℃, the Maillard reaction continued to produce substances with bad flavor, and the proteins in the soup stock were also decomposed at high temperature to produce small molecules with bitter taste, resulting in the decline of the overall flavor of the soup stock. Therefore, the boiling temperature was selected at 120 ℃ in the subsequent experiments.

Fig.7 Effects of boiling temperature of the soup stock quality

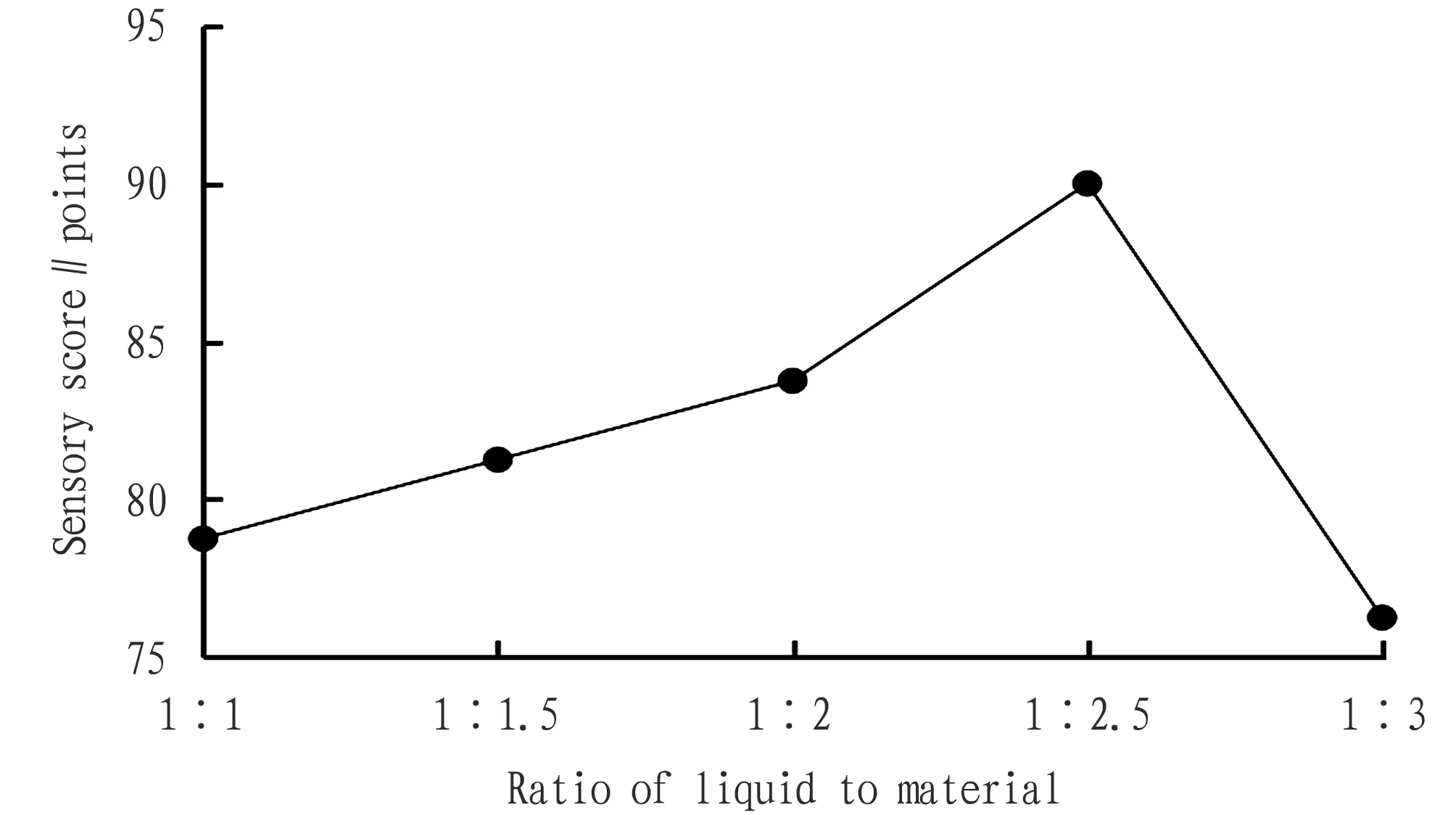

3.2.3Ratio of liquid to material. The effects of the ratio of liquid to material in the boiling process on the sensory score of the soup stock were shown in Fig.8. When the ratio of liquid to material decreased gradually, the sensory score of the soup stock showed a trend of first increasing and then decreasing. It is worth noting that when the value of ratio of liquid to material is 2.5:1, the sensory score is the best, which may be due to the fact that the concentration of flavor substances in the soup stock exceeded the threshold when the addition amount of water was small, thus causing negative effects on human senses. However, when too much water was added, the concentration of flavor substances in the soup stock will be insufficient. Therefore, the ratio of liquid to material in the subsequent experiments was selected at 2.5:1.

Fig.8 Effects of ratio of liquid to material on the soup stock quality

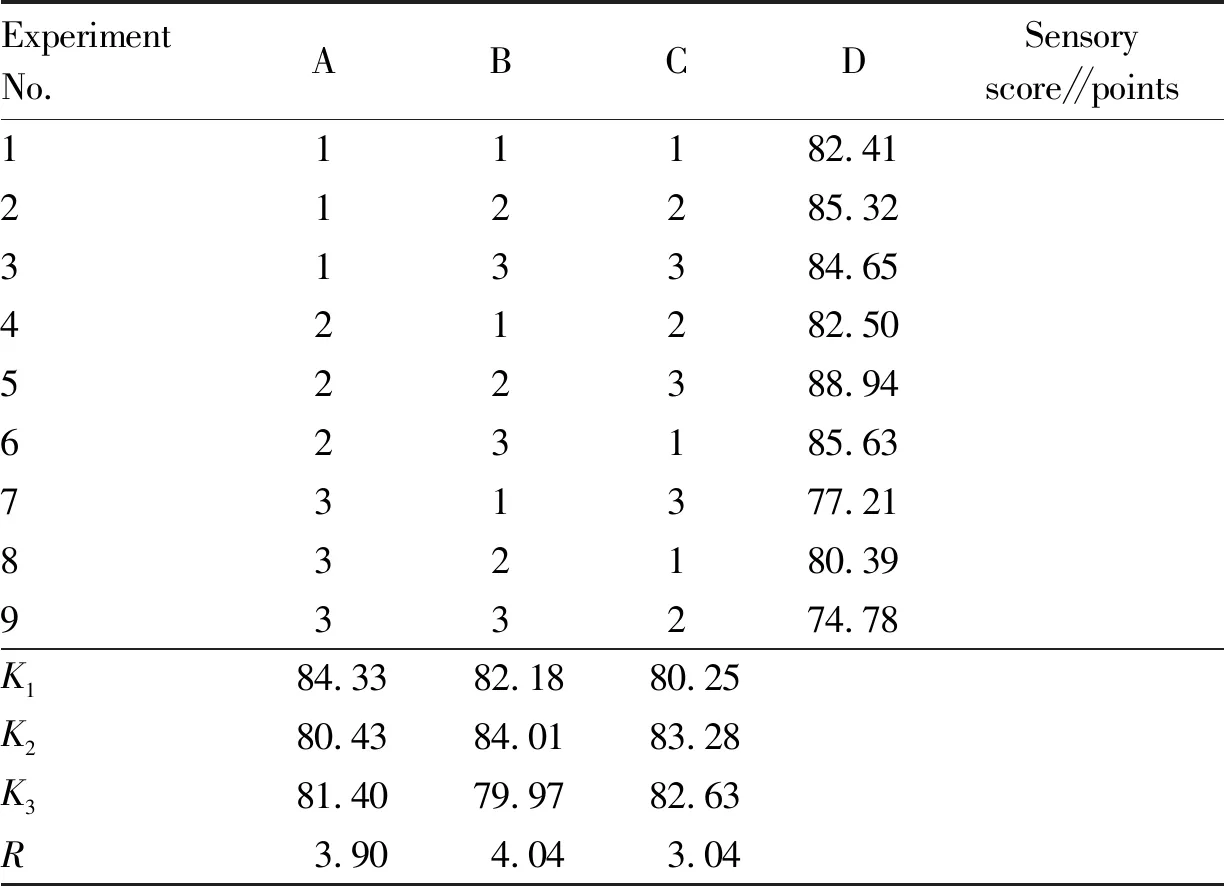

3.3 Results of orthogonal experimentOn the basis of the results of the single factor experiment, the boiling process of the Small Fragrant Chicken Soup Stock was determined through the orthogonal experiment, and the results are shown in Table 5. The order of the factors affecting the sensory score of the soup stock was B>A>C, and the best combination of process parameters was A1B2C2, that is, ratio of liquid to material 2.5:1, boiling time 2 h and boiling temperature 120 ℃. Under these conditions, the small fragrant chickenM.esculentasoup stock had the best taste.

Table 5 Orthogonal experiment results of optimal process parameters for soup stock preparation

4 Conclusions

Soup stock has the characteristics of balanced flavor, outstanding flavor and lasting fragrance, so it is popular in the catering industry. In this study, we determined the optimal formula and processing parameters of the soup by studying the solid material ratio, ratio of liquid to material, boiling temperature and time of the Small Fragrant Chicken Soup Stock. Finally, we reached the following conclusions: the addition amount of small fragrant chicken is 40%, the addition amount ofM.esculentais 6%, the addition amount ofL.decastesis 3% and the addition amount ofL.edodesis 1.5%. In addition, the optimum processing parameters were ratio of liquid to material: 2.5:1, and the boiling time and temperature are 2 h and 120 ℃, respectively. Under these conditions, not only the nutrients can be fully dissolved, but also the flavor is the optimal.

杂志排行

Asian Agricultural Research的其它文章

- Research and Application of Ecological Outdoor Ground Structure with Composite Water Storage and Drainage Function

- Extraction Conditions of Essential Oil from Eucalyptus Leaves by Distillation

- Bioinformatics Analysis of Q0D1P0 Gene of Mangrove Endophytic Fungus Aspergillus terreus

- Planting Adaptability of Four Kinds of Common Vegetables in Shanghai

- Problems and Countermeasures of Fruit and Vegetable Logistics Distribution Development in Guangxi Zhuang Autonomous Region

- Evaluation and Exploration of Citrus Germplasm Resources in the Origin of Shatangju (Citrus flamea Hort.ex Tseng Shiyueju)