Effect of Storage Time on Main Quality Indicators of Cotton

2023-09-26YuxiGUJinWANGGangYUANJunweiJIAWeiWANGJinyingCHEN

Yuxi GU, Jin WANG, Gang YUAN, Junwei JIA, Wei WANG, Jinying CHEN*

1. Sinograin Chengdu Storage Research Institute Co., Ltd., Chengdu 610091, China; 2. China Reserve Cotton Management Co., Ltd., Beijing 100000, China

Abstract The quality indicators of cotton will change during storage. Taking the 5.89 million t of Xinjiang cotton from 2016 to 2021 as a sample, this paper analyzed the main fiber quality indicator data of warehouse-in and warehouse-out cotton for storage of 1.5, 3.0, 4.0, 5.0, 6.0, and 7.0 years. It was found that the color grade of cotton decreased with the extension of storage time. The cotton with storage time of 5.0 years mainly changed from white cotton grade 2 and white cotton grade 3 to light yellow stained cotton grade 1 and yellow stained cotton grade 1. Among them, the increase of light yellow stained cotton grade 1 was the largest, and the change to yellow stained cotton grade 1 was the largest at the storage 6.0-7.0 years. In addition, there were no significant changes in moisture regain, Micronaire value, upper half mean length, length uniformity index and fiber strength.

Key words Cotton, Storage time, Fiber quality, Quality indicator, Color grade

1 Introduction

Cotton is an important strategic material related to the national economy and the people’s livelihood, and it is also one of the main raw materials of the textile industry[1]. China continues to implement the national reserve cotton policy, which has played an important role in protecting the interests of cotton farmers, stabilizing the cotton market, and ensuring the supply of textile raw materials and military materials[2]. In recent years, with the strong support of the state, China’s cotton industry has developed rapidly, and cotton storage has become an important research topic[3]. Due to the influence of multiple factors such as its own characteristics, high moisture regain and storage conditions, cotton will have unstoppable quality change during storage, and with the extension of storage time, cotton is more likely to have internal quality changes. Quality variations such as hardening and yellowing of cotton fibers reduce its use value and cause economic losses[4-5]. The central reserve cotton is stored in the warehouse for at least one year, most of them are stored for 3-4 years, and some are stored for 6-7 years or even longer before they are rotated out or put onto the market. Most of the reserve cotton stored in the warehouse for such a long time will be at a discount, so paying attention to the quality of cotton and exploring its variation rules will help to better grasp the opportunity for rotation, and lay a theoretical foundation for scientific cotton storage, reducing economic losses and establishing a long-term mechanism in the future.

TheCottonQualityInspectionSystemReformPlanapproved by the State Council in 2003 has clearly regarded cotton color grading as an important part of the reform of the cotton quality inspection system. In this study, we mainly selected the key quality indicators of cotton in 2016-2021, including color grade, moisture regain, Micronaire value, upper half mean length, length uniformity index, fiber strength[6], analyzed the data of cotton quality indicators during warehouse-in and warehouse-out, visualized the change trend, analyzed the changes in various indicators such as color grade of reserve cotton, and explored the change rules of cotton quality under different storage times.

2 Materials and methods

2.1 Research objectWe took the 5.89 million t of Xinjiang cotton from 2016 to 2021 as a sample. Among them, there were 4.93 ten thousand t of Xinjiang cotton with storage time of 1.5 years (the difference between each bale was not more than 10 d, the same below), 56.8 ten thousand t with storage time of 3.0 years, and 37.1 ten thousand t with storage time of 4.0 years, 2.221 million t with storage time of 5.0 years, 2.022 million t with storage time of 6.0 years, and 65.9 ten thousand t with storage time of 7.0 years.

2.2 Cotton quality indicator detection data source and data processingThe data were selected from the instrumental notarial inspection of the fiber inspection agency, based on the average inspection results of the batch formed by the bale inspection, including the quality indicators of the whole batch of cotton when warehouse-in/warehouse-out, including color grade, moisture regain, Micronaire value, upper half mean length, length uniformity index, fiber strength. We made a statistic of the warehouse-in percentage (%) and warehouse-out percentage (%) of each color grade, and subtracted the warehouse-in percentage from the warehouse-out percentage to obtain the change (percentage) in the proportion of each color grade. The change in the proportion of each color grade in cotton storage from 1.5 to 7.0 years was made into a histogram. The variation value of other indicators was the difference between the warehouse-out value and the warehouse-in value.

3 Results and analysis

3.1 Changes in color gradeThe analysis results of color grade percentage are shown in Fig.1. The most significant changes in the percentage of color grade are white cotton grade 2, white cotton grade 3, light yellow stained cotton grade 1 and yellow stained cotton grade 1, followed by white cotton grade 1, light yellow stained cotton grade 2, yellow stained cotton grade 2, the rest of the color grade did not change significantly. The variation of color grade of cotton stored for 1.5 to 5.0 years was similar, mainly changed from white cotton grade 2 and white cotton grade 3 to light yellow stained cotton grade 1 and yellow stained cotton grade 1, the increase in light yellow stained cotton level 1 was the main factor. The largest increase in storage time was 6.0-7.0 years for cotton in grade 1 yellow stained cotton.

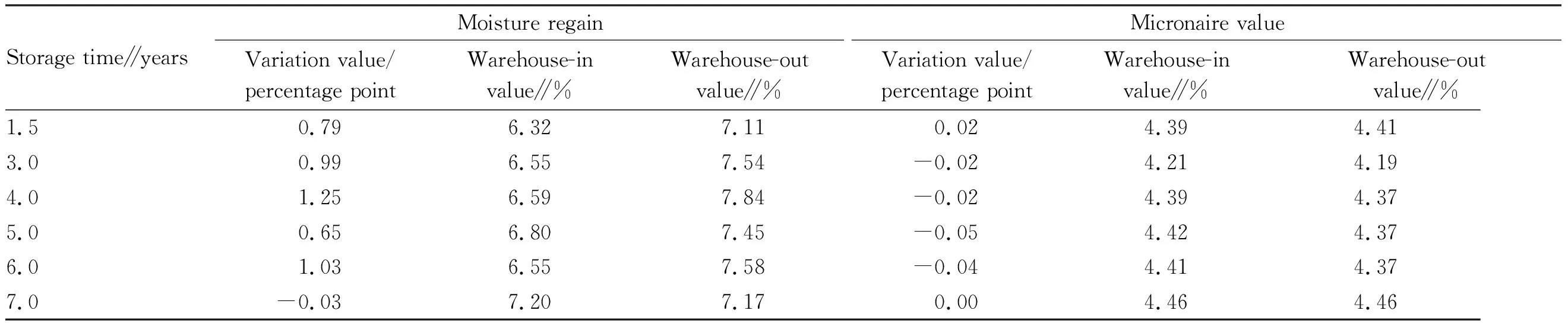

3.2 Changes in moisture regainThe average moisture regain of the cotton warehouse-out with the storage time of 1.5, 3.0, 4.0, 5.0 and 6.0 year was increased by 0.65-1.25 percentage point than that of the warehouse-in. The moisture regain of cotton stored for 7.0 years was basically unchanged, with a decrease of only 0.03 percentage points (Table 1).

Table 1 Changes in moisture regain and Micronaire value of cotton after different storage times

3.3 Micronaire valueThe variation range of Micronaire value after the storage time of cotton 1.5, 3.0, 4.0, 5.0, 6.0 and 7.0 years was -0.04-0.02, which is within the allowable error range ±0.28 (Table 1).

3.4 Changes in upper half mean length and length uniformity indexThe upper half mean length and length uniformity index are essentially a class of indicators, which can reflect the length characteristics of cotton fibers[7]. The variation range of the upper half mean length is -0.16--0.02 mm, which is within the allowable error range of ±0.9 mm. The length uniformity index varied in the range of -0.21-0.01 percentage points, within the allowable error ±1.9 percentage points (Table 2). The results indicate that the upper half mean length and length uniformity index did not change significantly during storage.

Table 2 Changes in cotton upper half mean length and length uniformity index after different storage times

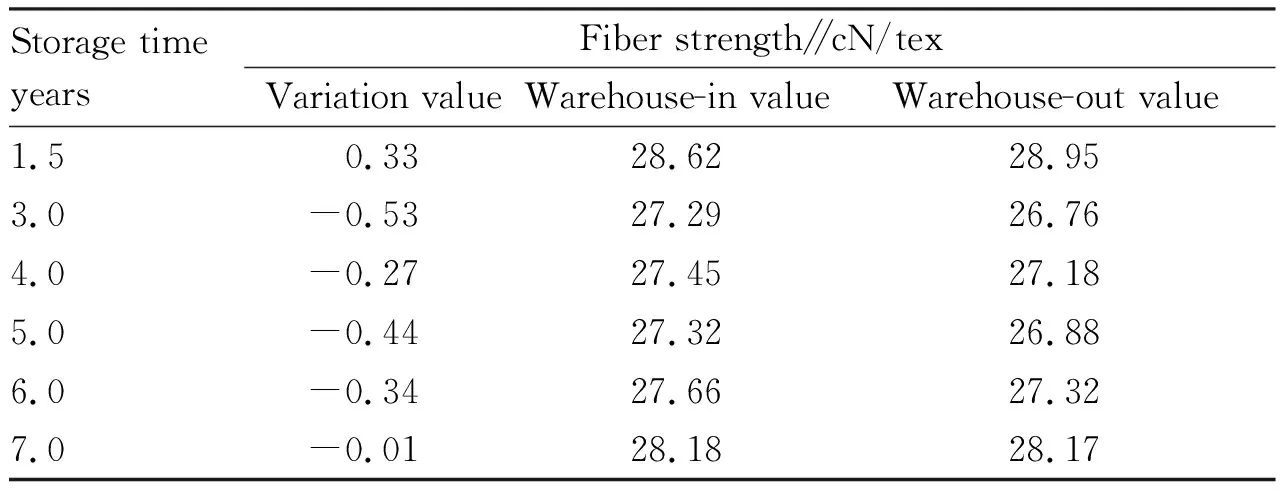

3.5 Changes in fiber strengthThe variation range of fiber strength was-0.53-0.33 cN/tex, which is within the allowable error ± 1.9 cN/tex (Table 3). The results indicate that there was no significant change in fiber strength during storage.

Table 3 Changes in cotton fiber strength after different storage time

4 Discussion and conclusions

Through the analysis of the current historical data, it is known that the color grade of cotton in the warehouse changed significantly with the increase in storage time, and with the storage time of 5.0 years as the dividing line, the color grade of cotton with storage time of 1.5 to 5.0 years changed similarly. However, after exceeding 5.0 years, the change in color grade was more serious. The changes in color grade is one of the key parameters reflecting the variation of cotton quality and even mildew[8], which directly affects the selling price of cotton, so it should be rotated within 5 years to avoid causing greater economic losses. The conventional moisture regain of cotton is 8.5%, with a maximum limit of 10.0%[9]. The level of moisture regain will affect the calculation of cotton weight and cotton consumption, as well as the subsequent spinning process. If the moisture regain is too high, it will cause problems such as difficulty in opening and removing impurities, and if the moisture regain is too low, it will cause problems such as static electricity[10]. Previous studies have suggested that Micronaire value has little to do with moisture regain[11]. However, some studies have shown that the Micronaire value of cotton is related to moisture regain. When the moisture regain was between 6.5% and 8.5%, the cotton fiber was in the balance of moisture absorption and moisture release, and the Micronaire value varied within ± 0.1[12]. In this study, the change of Micronaire value was within ± 0.05 when moisture regain was between 6.32% and 7.84%, which was similar to the results of the latter[12]. The upper half mean length and length uniformity index of cotton were mainly affected by factors such as cotton seed, growth environment and ginning process, and there are no factors that may cause the variation of these two indicators during storage[13]. In this study, the variance values of upper half mean length and length uniformity index were within the allowable error range, so it was speculated that most of the differences were caused by uncontrollable factors, such as test bias. The fiber strength of cotton is affected by varieties, planting climate[14], planting patterns[15], fertilization methods[16], cotton picking methods[17]and other factors, and there is no report that the fiber strength of cotton is affected by storage time or conditions. In this study, the fiber strength did not change significantly with the extension of storage time, and it was considered that this indicator was not affected by storage time.

杂志排行

Asian Agricultural Research的其它文章

- Analysis on the Problems and Strategies of Marketing Channels of Agricultural Products:Taking Liujun Lotus Root as an Example

- Species Composition and Diversity of Fagus longipetiolata in Leigong Mountain, Guizhou Province

- Removal Effect of Coagulating Sedimentation Method on Polyethylene Microplastics in Water

- National Protection Zone for Rapeseed Production and Industrial Cluster of Rape in Hubei Province

- Bird Resources and Avifauna of Zijin Mountain in Nanjing