3D technology integrates textile production and garment manufacturing

2023-09-18ZhaoXinhua,ZhongMengxia

The availability of 3D technologies is driving the efficiency of textile manufacturing and design.3D printing allows experiments with imaginative structures, shapes, and prototypes.The technology also enables the production of different materials ranging from soft polymers to rigid ceramics.It also contributes to zero-waste goals by enforcing green materials.Besides, 3D design software virtually visualizes garments before producing any fabric and waste.This way, startups not only resolve overproduction issues but also increase sales speed and minimize operating costs.

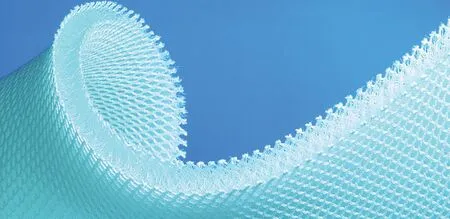

3D woven clothing for a zero-waste future

Weffan 3D weaves the garment shape while weaving the fabric by merging textile production and garment manufacturing into one step.Weffan’s 3D woven production method reduces production steps, time, and waste using existing scalable infrastructure.Weffan aims to align fashion industry incentives with sustainability goals by creating manufacturing efficiency and cost effectiveness using existing loom technology for easy adoption.Weffan production method’s low cost of adoption could support near-shore manufacturing in the UK, lowering a garment’s carbon footprint and the risk of supply chain interruption on labour and business.

Shapeshift prints 3D sports equipment

Canadian startup Shapeshift prints sports and medical equipment using AI technology for 3D printing.The platform scans the human body to fully customize products from prostheses to bicycle helmets.Then, intelligent algorithms reconstruct users’ 3D scans in terms of form,function, and fit.Based on them, 3D printers quickly produce items on large scale.Thus, Shapeshift’s 3D technology democratizes mass-scale production of custom-fit personalized wearables.

New Industrial Order manufactures 3D knitwear

Dutch startup New Industrial Order manufactures 3D printed knitwear to reduce fast fashion waste.The startup’s 3D machines produce clothes in one piece without cutting and sewing.Further, this technique allows one to unravel the yarn and re-use it for knitting.Besides that,the Knitcloud platform in combination with digital manufacturing automates the 3D knitwear supply chain and contributes to the circular economy in fashion.

杂志排行

China Textile的其它文章

- The global fire-resistant fabrics market is anticipated to garner US$ 6 billion in 2033

- AI and data analytics are in full swing in the textile sector

- Desalting? Reversible dyeing? Dyeing and printing industry ushers in big changes!

- The Innovation of Global Start-ups from ITMA 2023

- FISH’s new technology makes the management of textile enterprises smarter

- Maredamare 2023: The international beachwear show