The Skyscraper Crop Factory: A Potential Crop-Production System to Meet Rising Urban Food Demand

2023-03-22LiZhngLnHungToLiToWngXioYngQihngYng

Li Zhng, Ln Hung, To Li, To Wng, Xio Yng,*, Qihng Yng,*

aInstitute of Urban Agriculture,Chinese AcademyofAgricultural Sciences (IUA-CAAS),Chengdu National Agricultural Scienceand Technology Center (NASC), Chengdu 610213,China

b Institute of Environment and Sustainable Development in Agriculture, Chinese Academy ofAgricultural Sciences,Beijing100081,China

cChengdu Institute of Biology, Chinese Academy ofSciences, Chengdu 610041, China

Keywords:Vertical farming system Cereal crop production Plant factory technology Skyscraper crop factory

ABSTRACT Vertical farming systems, such as sky farms, are a potential type of agricultural system for stable and effective food production.Here, we highlight the potential of the sky farm, denoted as the ‘‘skyscraper crop factory” (SCF), for cereal crop production and discuss some nascent technologies that would be applied in this production system.SCFs are ideal crop-production systems for increasing the effective arable area for crops and ensuring food security in times of crises that cause a shock in global trade.They can also provide food in urban areas to meet producers’and consumers’demands for the increased nutrition,taste, and safe production of cereal crops.Moreover, as their use can reduce greenhouse gas emissions,SCFs could be a sustainable addition to conventional agricultural crop production.

1.Introduction

Due to rapid urbanization, more than 56% of the world’s population was living in urban areas as of the end of 2022,and this proportion will reach 67% by 2050, with a total global population of 9.7 billion[1].In this context,traditional crop production and supply chains face unprecedented challenges in the tension between increasing food demand due to the population boom and agricultural resource scarcity in urban and peri-urban areas.By disrupting global food-supply chains and severely impeding the flow of food in global markets, the coronavirus pandemic has further aggravated food security issues,emphasizing the importance of improving food security on a more localized scale and promoting local food-supply systems through innovative approaches [2,3].For example, the Food and Agriculture Organization speculated that 20%-30% of crops could not be harvested in the summer of 2022[4].To address such issues in future, effective crop-production and delivery systems should be developed for urban areas to meet the growing food demand, especially in times of crisis.

Sky farms,which use high-rise buildings to grow crops,are considered to be an innovative solution for supplying food to cities in a reliable, environmentally friendly, highly productive, and highquality manner.To date, several ideas have been proposed for sky farms.For example, the construction of a sky farm in downtown Toronto, Canada, has been proposed, in the form of a 59-floor vertical tower that utilizes the hydroponic technique for developing food, with a total area of approximately 743 224 m2[5,6].It has been estimated that a single hectare of land in a 10-layer wheat sky farm could produce a maximum of 1940 t·a-1of grain, containing 2.37 × 109to 6.56 × 109kcal of energy, which could feed approximately 4000-12 000 people annually [7].Another sky farm, Plantscraper, has been proposed for development in Stockholm, Sweden; it would consist of a 12-story,mixed-use tower with a farmers’ market on the ground floor and offices for research on urban agriculture[5].Plantscraper’s possible production is estimated to be 500 t·a-1of leafy greens.This building would also enable the collection and reuse of all wastewater,as well as automatic monitoring and control of pesticides, fertilizers,and soil pollution.A sky farm is currently under construction in Chengdu,China;it is 36 m high and consists of a seven-floor vertical farm, including a 20-layer plant factory with artificial light(PFAL) used for vegetable production, aquaponics, edible fungi cultivation, functional plants, multifunctional zones, and a roof garden [8].

To date,no sky farm has been successfully run in operation.It is challenging to operate indoor crop farming in a way that is economically competitive with current market prices.However, sky farms could play an essential role in hedging against future climate change or unexpected disruptions to the food system.

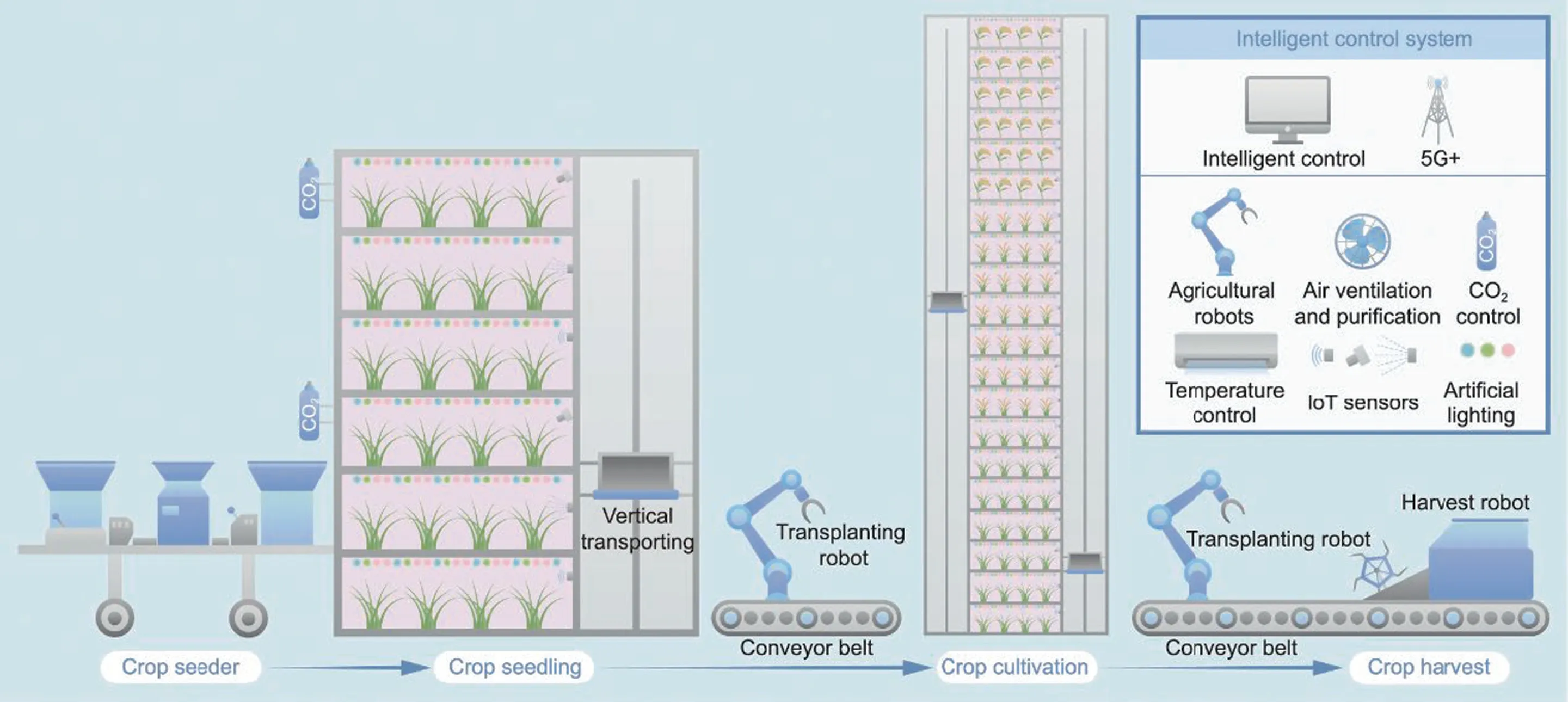

Here, we highlight the potential of sky farms for cereal crop production, such as rice, corn, and wheat.The skyscraper crop factory (SCF) is a potential crop-production system aimed at increasing the effective arable area for crops by building a highrise structure with multiple levels on the same land footprint to continuously provide safe, nutritious, sustainable, and sufficient food regardless of war, pandemics, and natural disasters (e.g.,drought).In addition, with the application of PFALs, green, sustainable, and energy-conserving technologies, SCFs can enable the year-round, highly efficient, and environmentally friendly cultivation of cereal crops (Fig.1).An SCF can be built in a metropolis with several multilayer PFAL units deployed vertically for crop production.Each PFAL unit contains crop seeders, seedling nursery rooms, transplanting robots, conveyor belts for seedling trays and seedling transfer, multilayer cultivation systems, artificial lighting systems, aeroponics systems, air ventilation and temperature control systems, purification systems, smart sensor-based control systems, and accessory machines for crop harvesting(Fig.2).

2.Technologies applied to SCF

2.1.PFAL technology

As an indoor vertical farming system for efficient and highquality food production units in an SCF, a PFAL includes several advanced automatic and intelligent systems, such as multilayer cultivation systems, indoor environmental-control systems for temperature, humidity, and CO2; air ventilation and purification systems; artificial lighting; fertigation systems; intelligent control systems; and indoor-farming robot operations [9].A PFAL enables crop productivity using vertical cultivation technology, regardless of geographical and climatic conditions.A well-designed SCF should be equipped with an automated climate-control system that uses sensors and real-time data collection to control automated valves and switches in order to precisely maintain optimal environmental conditions(e.g.,light quality,photoperiod,temperature, and CO2enrichment) and nutrient solutions (e.g., irrigation cycles and nutrient mix) for crop growth and development.This can reduce the time needed for crop growth and ensure that a consistent supply of crops can be raised throughout the year.

Fig.1.The proposed SCF model.PFAL, green and sustainable, and energy-conserving technologies enable the year-round, highly efficient, and environmentally friendly cultivation of cereal crops in SCFs.5G+: integrating artificial intelligence, Internet of Things (IoT), and the fifth generation mobile communication technology (5G);N: nitrogen; P: phosphorus; K: potassium.

Fig.2.The proposed module of crop production in an SCF.Each PFAL unit contains a crop seeder,a seedling nursery room,transplanting robots,conveyor belts for seedling trays and seedlings transfer, a multilayer cultivation system, an artificial lighting system, an aeroponics system, air ventilation/temperature control systems, a purification system, a smart sensors-based control system, and accessory machines for crop harvesting.

2.2.Energy-conservation technology

Utilizing energy-conservation technology may reduce operating expenses, increase economic benefits, and promote ecologically sustainable industrial growth.The selection of appropriate thermal insulation, sunlight conduction lighting technology, and energystorage system technology is at the core of energy-conservation solutions for skyscraper farming [10].Thermal insulation of the peripheral building structure, including the roof, building walls,doors, and windows, will effectively reduce the energy consumption for heating or cooling in an SCF.Recently developed thermal insulation coatings (e.g., nanoscale thermal insulation coating)for exterior walls have played an increasingly powerful role in realizing building energy conservation,due to their advantages of thermal insulation, energy conservation, convenient construction, and strong adaptability [11,12].Moreover, as the energy consumption of artificial lighting accounts for 70%-75% of a PFAL’s energy consumption, sunlight conduction lighting technology is considered to be an effective energy-conserving approach [13].For example,a full-spectrum-utilization solar indoor-lighting system can be used to effectively separate solar light into visible and nonvisible light; the visible light is then transmitted to the PFAL via optical fibers to provide illumination for crop production, while the non-visible light is converted into thermal energy.This indoor lighting system allows for a solar energy utilization efficiency of 50% [10].In addition, the use of energy-storage systems, such as ice-storage systems, can help reduce peak energy loads during the cool-down period, as these systems store energy during offpeak hours and use it during peak cooling periods.Furthermore,our previous study investigated a light-temperature coupling energy-conserving thermal regulation strategy that shifts the lighting period of crops inside the PFAL from daylight to night and inputs a cooling source from outdoors by taking advantage of low temperatures at night [14].Establishing energetic fluxes and developing a functional energy model of a vertical farming system could also be used to simulate the energy balances and optimize the specific energy consumption, which could be further used for optimization algorithms of the energy-conserving strategy in a vertical farming facility [15].Moreover, it will be crucial to lower the electricity consumption by implementing a smart energy-control system built using a smart sensing network,as well as by developing the Internet of Things(IoT)and cloud computing infrastructure,to permit the intelligent monitoring, analysis, and control of energy consumption using artificial intelligence algorithms.

2.3.Green and sustainable technology

Green and sustainable technologies enable the maximization of internal resources.For example, the use efficiencies of water, CO2,and inorganic fertilizers (e.g., nitrogen (N), phosphorus (P), and potassium (K)) in a closed system are 95%-98%, 87%-89%, and 85%, respectively [16,17].The SCF system has an estimated water use efficiency of 95%-98%,because water is recycled in the fertigation system, and evaporated water can be reused for irrigation,thereby minimizing water losses due to exfiltration and ventilation[16].Production in this closed system can reduce water use by up to 95% compared with a greenhouse [18].PFAL-based skyscraper farming can reduce water and CO2use by as much as 95% and 92%, respectively, in comparison with a greenhouse [18].In addition,previous research has shown that using CO2capture and storage technology can reduce CO2emissions by storing high concentrations of CO2in PFALs, where the CO2can be used to enhance plant photosynthesis [19].The crops in an SCF are cultivated in a high-purity,pesticide-free environment,free from heavy metal and pesticide contamination.The use of amino acids to partially replace inorganic fertilizers has also been proposed, in order to improve the yield and reduce nitrate levels [20,21].Fungal fertilizers are used to enrich beneficial microorganisms in the rhizosphere in order to increase the nutrient-use efficiency of crops[22].Also,a variety of clean and renewable energy sources,including solar, wind, geothermal, hydroelectric, biofuel, and biomass energy, are available worldwide, allowing SCFs to produce yields in a sustainable, affordable, and cost-effective manner.In the last few decades, significant advancements have been made in various effective renewable energy systems in agricultural practice,such as ground source-and solar-based systems[23,24].For example,several solar-based systems store energy, while other photovoltaic systems convert solar energy into electricity, which can meet the heating and cooling needs of an SCF.According to previous investigations,the most promising composite system is the earth-to-air heat exchanger system, which uses the ground as a heat sink/source.This system consists of several pipes buried in the ground,through which heat is transferred from or dissipated to an SCF[5,25].Compared with traditional farming, an SCF can reduce the use of fossil fuels for tractors,plowing,or shipping.In parallel,the SCF can reduce the food travel distance, resulting in lower emissions and a smaller carbon footprint.

3.How are crops grown in an SCF?

3.1.Breeding specialized crops for skyscraper farming

Compared with the aim of crop breeding for field use,the ideal crop architecture of the crops used for skyscraper farming requires a dwarf crop with high space utilization and less occlusion in its aboveground parts, which is thought to be beneficial for minimizing the space needed for cultivation[9,26,27].The development of gene-editing technology, such as clustered regularly interspaced short palindromic repeats (CRISPR)/CRISPR-associated protein 9(Cas9), has made it possible to develop gene-edited crops with specific phenotypes or metabotypes for cultivation in SCFs [9].Thus far, several germplasms with dwarf traits and genes related to this phenotype (e.g., Rht1 and AINTEGUMENTA) have been reported [28-31].Rice germplasm (Xiaowei) is considered to be perfect for indoor research,because 1200 individuals can be grown in 20 m2with a plant height of only 22 cm [30].In addition, fast growth,a high yield,and a short growth period are essential characteristics of crops grown in SCFs, which require crop roots with high nutrient use efficiency.For example, previous studies have highlighted the importance of the root system architecture in nutrient acquisition, which is critical for cereal crop production[9,26].Therefore, designing an optimal crop root system architecture with high nutrient use efficiency under soilless cultivation conditions could shorten the crop’s growth duration from seed to harvest[32].In parallel,the artificial lighting environment in SCFs requires crops with low light-intensity tolerance and high light use efficiency.Editing leaf angle-related genes,such as INCREASED LEAF ANGLE 1 or OsbHLH98, could regulate the plant architecture and hence increase canopy light interception and plant photosynthesis[33,34].Long-term efforts should also be directed toward developing cultivars with crop architecture characteristics that facilitate robotic handling, such as breeding maize cultivars with a consistent ear height and flowering period [26].High-quality and nutrition-rich crops are under continuous development due to their high market value, such as rice with increased carotenoid levels (β-carotene, lycopene, lutein, and astaxanthin) and maize with increased vitamin content(vitamin C,vitamin E,and provitamin A) [35].Overexpression of OsGLK1 can significantly increase carotenoid production in rice (~50-fold) [36].Researchers have also obtained a six-fold increase in vitamin E in corn seeds [37].These transgenic plants could be cultivated in SCFs with higher quality and shorter growth periods.

3.2.Multilayer cultivation

As an essential component of skyscraper farming, the multilayer cultivation technique has tremendous productivity when combined with light emitting diode (LED) lighting and a highperformance hydroponic system [26].To summarize, a 20-layer SCF will be the mainstream design,considering the optimal height of existing automated logistics equipment and the optimal price/performance ratio of the structural strength of the layer frame(mainly due to the materials used).This will enable a large increase in production for the same amount of available land.Hydroponic technology, either with (e.g., static solution culture) or without(e.g.,continuous flow solution culture and aeroponic systems)soilless substrates to provide physical support, is already widely used for growing crops, including rice, maize, and wheat [7,38-40].Among these hydroponic technologies, aeroponics shows great potential for reducing fertilizer and water use, thereby enabling increased productivity.An aeroponic system allows crop roots to hang in the open air without being mechanically constrained by soilless substrates, which enables the roots to flourish and is beneficial for crop growth.In addition, aerosol culture can effectively alleviate root hypoxia-induced absorption and transport of water and nutrients, as well as growth retardation.It also allows for the ideal design of plant-microbial interactions, which promotes crop production with high yield and quality.Therefore,aeroponics is considered to be an efficient hydroponic system for crop production.

3.3.Optimizing appropriate environmental conditions for crop cultivation

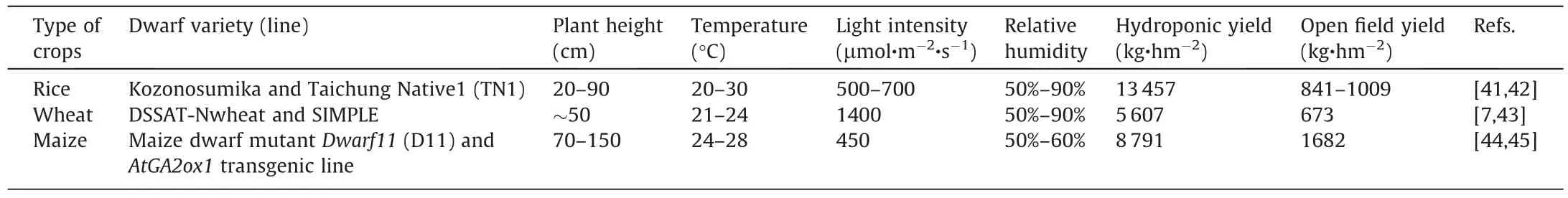

In a closed system, appropriate environmental conditions—including photosynthetic photon flux density,vapor pressure deficit,air temperature, CO2concentration, light intensity, light quality(i.e., spectral distribution), lighting cycle (photoperiod/dark period),air currents,and surrounding crops—are vital for crop growth and development.Moreover, appropriate oxygen levels, root temperature,and flow-rate conditions in the crop root zone are critical for a crop’s absorption of nutrients and water.Setting appropriate conditions for the environment and the crop root zone in an SCF enables the crops to grow quickly and produce a high yield(Table 1[7,41-45]).For example, according to Asseng et al.[7],wheat was cultivated on a single hectare of land in a ten-layer vertical indoor facility, with an annual grain yield from 700 t·a-1(measured) to 1940 t·a-1(estimated)under optimized environmental conditions.This yield is 220-600 times higher than the current world average annual wheat yield for wheat cultivated in an open field.Another example is provided by our earlier study,in which the transplanting of ZF802M rice seedlings to harvesting under optimized environmental and fertigation conditions took only 63 days, with a yield of 0.98 kg·m-2in a single layer of PFAL.Under these conditions, it would be possible to grow five to six generations of rice per year,for an annual production of 568 t·ha-1in a ten-layer PFAL[46].

3.4.Machine-learning-based phenotyping for regulating crop growth and development

Using visible light, near-infrared, infrared, and multispectral imaging,along with other imaging technologies,the SCF inspection system, which is equipped with phenotyping monitors, can beutilized to obtain the morphological, physiological, and biochemical characteristics of crops in a nondestructive manner[47,48].For example, the crops’ leaf area, plant height, anthocyanin content,number of inflorescences, and number of fruits can be acquired in real time using non-destructive phenotyping monitors [48].In an SCF, phenotypic, metabolic, and environmental factors can be monitored by means of phenotype monitors and then analyzed using machine learning algorithms, resulting in models that can predict the optimal agronomic cultivation and configuration combination of the crop environmental parameters.A smart control system can be used to construct a virtual SCF crop model using phenotype monitoring combined with digital twin technology.Interactive comparative analyses of plant phenotype indicators during the actual cultivation process can be used to rectify cultivar and environmental parameters,predict crop yield and quality,and detect early signs of crop diseases in real-life growing situations.This greatly improves the smart control of growing situations by accurately predicting the growth and developmental features of cultivated crops in SCFs.

Table 1Appropriate environmental conditions for crops production in SCFs [7,41-45].

3.5.IoT-based smart control systems and agricultural robots

SCFs also require automation and the development of intelligent equipment to boost productivity and reduce labor costs.Automation of the environmental control, illumination, and fertigation in SCFs is well understood at present [49] and greatly benefits from the combination of sensor technology, crop modeling,and artificial intelligence.However, biosensors for plant growth and development and high-precision digital simulation technology are still bottlenecks for smart control use, requiring further investigation [26].To complete the deep integration of agricultural machinery and agronomy in unmanned SCFs, agricultural robots require standardized automatic crop-production processes such as sowing, nutturing seedling, transplanting, vertical conveying,and harvesting[9].Unfortunately,agricultural robots are currently unavailable for most crop-production processes in SCFs.

4.Perspectives

The industrial and green revolutions have resulted in massive improvements in crop production per unit of arable land.Despite these advances, enormous challenges still remain in feeding a rapidly expanding population, while accelerating urbanization and reducing arable land area [50-52].Greenhouse gas emissions are the most important cause of global warming.To realize carbon neutrality,greenhouse gas emission mitigation is an important target in agriculture, because the agricultural supply chain—which includes land use change, crop production,processing,transportation, retail, and packaging—contributes a large proportion of the world’s greenhouse gas emissions[53].Moreover,it will be considerably more challenging in the coming decades to meet producers’and consumers’ demands for the increased nutrition, taste, and safe production of cereal crops.Since Dr.Dickson Despommier[54]first came up with the innovative concept of vertical farming,which has been defined as ‘‘a fundamental solution,” this concept has been gaining increasing attention.

In this study, we propose a sustainable, innovative, and community-based cereal crop-production system for high-rise buildings in urban areas.SCFs offer producers, transporters, and consumers a green, high-yield, high-quality, and food-safety solution for cereals.SCFs enable soilless cultivation in multiple layers,high production density, and extensive control, which allow local production, prevent pollution, and decrease the land footprint and greenhouse gas emissions.An SCF provides high quality local food, reuses gray or black water, and recycles organic waste for energy and nutrients.In addition, establishing SCFs in urban areas could shorten the distance food travels to reach the pantry of consumers and ensure a ‘‘local-for-local” food chain supply, particularly in the contexts of war, pandemics, or natural disasters.

SCFs bring crop production to cities through vertical farming and provide a green urban landscape that enables multifunctional real estate development.These green,transparent,high-rise buildings could be new iconic structures inserted into the cityscape,demonstrating the possibility of achieving a sustainable and healthy future for citizens.Moreover, SCFs could serve a variety of functions by integrating with other buildings in urban agriculture [9].For example, SCFs could allow citizens to farm on and inside buildings and could be associated with leisure and recreational functions, such as workshops, catering, and entertainment activities.Therefore, it may be beneficial to establish a number of well-functioning SCFs in urban areas.

However, the development of SCFs remains challenging.To the best of our knowledge, the environmental sustainability of SCFs has not yet been thoroughly quantitatively assessed and requires further study.This includes weighted assessments of air, water,and soil pollution; of resource use such as land, water, and nutrients;and of energy and emission balances[26].In addition,further investigations should be aimed at improving light efficacy and energy use efficiency, which are crucial for the environmentally sustainable development of SCFs and will contribute to reducing SCFs’ high demand for electrical energy and high production costs[9,26].Another major hurdle for industrial applications is the high initial cost of SCFs,which includes the costs associated with building construction, cultivation systems, accessory machines, and smart control systems.The use of prefabricated and prefinished volumetric construction technology will effectively reduce the start-up cost of skyscraper farming by dividing the construction of SCFs into several modules and enabling the completion of all equipment and pipelines,and the decoration of each module,prior to assembling it as a building block.Moreover, electricity costs account for more than 50% of the running costs of an SCF, and the cost of artificial lighting and air conditioning accounts for 95%of the total.Therefore,it is imperative for further investigation to be conducted to enhance the efficiency of SCFs’ use of light and energy.Policy changes could also serve as a catalyst for the promotion of vertical farming.According to relevant estimates,the return on investment of a ten-layer vertical farm is approximately 8%,which is unacceptable for most venture capital investors [55,56].In this case,government capital should directly support SCFs,such as by providing infrastructure, priority planning regulations, budgets, or supplementary allowances, because SCFs have public benefit and are forward-looking.The indoor cultivation of crops using artificial lighting makes an SCF a very energy-intensive production method in the present fossil fuel-based economy.However, with the transition to nuclear and renewable energy sources,SCFs might become a sustainable addition to conventional agricultural crop production that will improve the safety and security of food for the growing urban population and can reduce food transport requirements, agricultural inputs, and greenhouse gas emissions.

Acknowledgments

The authors warmly thank our colleague Dr.Shulang Fei for the thoughtful and productive advice.We also appreciate the constructive suggestions from Dr.Bin Liu of the Xinjiang Academy of Agricultural Sciences.This work was supported by the National Key Research and Development Program (2022YFB3604600), the Local Financial Project of the National Agricultural Science and Technology Center (NASC2023TD01 and NASC2023TD10), the Central Public-interest Scientific Institution Basal Research Fund(S2022006), the Sichuan Science and Technology Program(2022NSFSC1719), and the Agricultural Science and Technology Innovation Program of CAAS (ASTIP-34-IUA-01 and ASTIP-IUA-2023002).

Compliance with ethics guidelines

Li Zhang,Lan Huang,Tao Li,Tao Wang,Xiao Yang,and Qichang Yang declare that they have no conflict of interest or financial conflicts to disclose.

杂志排行

Engineering的其它文章

- Global Top Ten Engineering Achivements 2023

- 2023 Global Engineering Fronts

- Will Massive Appetite for Minerals Stall Clean Energy Transition?

- Optical Microscopy Advances Reach Sub-Nanometer Resolution

- International Correlation Research Program: Cross-Fault Measurement for Earthquake Prediction

- A Systematic Perspective on Communication Innovations Toward 6G