Laser Ignition of Four Types of FOX-7 Powders Mixed with Different Carbon Materials:Experiments and Simplified Calculations of Ignition Delays

2023-03-11LIHengZHAOFengqiXUSiyuJIANGHanyuPEIQingWANGChangjianZHANGRuiZHANGYangMAXiaoxunHAOHaixia

LI Heng,ZHAO Feng-qi,XU Si-yu,JIANG Han-yu,PEI Qing,WANG Chang-jian,ZHANG Rui,ZHANG Yang,MA Xiao-xun,HAO Hai-xia

(1.Science and Technology on Combustion and Explosion Laboratory,Xi′an Modern Chemistry Research Institute,Xi′an 710065,China;2.Science and Technology on Applied Physical Chemistry Laboratory,Shaanxi Applied Physical-Chemistry Research Institute,Xi′an 710061,China;3.College of Chemical Engineering,Northwest University,Xi′an 710069,China)

Abstract:The ignition experiments of four types of FOX-7 (1,1-diamino-2,2-dinitroethene) powders mixed with different carbon materials were carried out by a CO2 laser over a certain range of power density to study the trend of ignition delay times,aiming at the relatively difficult ignition performance of FOX-7 hindering extensive applications.The calculations and analysis of ignition delay times were conducted by two simplified ignition models to gain insight into the ignition mechanism and guide the ignition performance improvement of FOX-7.It is experimentally observed that the ignition delay time of FOX-7 powder reduced to different extents due to the addition of carbon materials.Graphene and graphene oxide exhibit relatively strong promoting role in shortening the ignition delay time and graphite has a slight effect.The calculation results show that Model 1 is more suitable for effectively predicting the ignition delay time of FOX-7 powder than Model 2.The mechanism analysis indicates that the addition of graphene could efficiently improve the absorption of radiation energy by FOX-7 powder and reduce energy loss.The main ignition induced process of FOX-7 sample was intensively affected by the heat transfer properties under laser irradiation.

Keywords:physical chemistry;FOX-7;carbon material;laser ignition;ignition delay;simplified calculation

Introduction

FOX-7(1,1-diamino-2,2-dinitroethene,DADE),as a relatively insensitive nitramine material,has been attracted more attention from researchors for a certain potential to improve the comprehensive safety performance of energetic composites[1-5].The significant insensitivity properties of FOX-7 suggest that it would have a bigger ignition threshold than the typical nitramines such as RDX,HMX and CL-20,which prevented FOX-7 from being easily ignited by conventional stimulus under atmosphere[1,6-8].

Some methods can improve the ignition performance of FOX-7,including heating and sensitizer addition[9-12].The preheating treatment has been demonstrated to exert a sensitizing effect on FOX-7 and the heating stimulation from rapid compression machine can facilitate auto-ignition of the FOX-7 mixture due to the lower ignition threshold[9-10].Besides,carbon-material additive is another possible route to improve the ignition performance of FOX-7.Graphene oxide (GO) and graphene (G) with high thermal conductivity have been found to assist in catalyzing the thermal decomposition of FOX-7,RDX,HMX and NC/NG propellants contributing to ignition enhancement[12-15].Graphite (Gt) and fullerene soot (FS) also have some advantages to promote ignition.The presence of Gt in RDX based propellant decreases the ignition energy threshold[16].The addition of FS in NG can accelerate its liquid-phase decomposition[17].

The ignition enhancement features from the above four carbon materials are not only affected by their physical properties for heat transfer,but also possibly by their optical parameters[18-20].The optical properties of carbon material additives may also play a non-negligible role in the laser ignition process of nitramine.However,it was found that the introduction of carbon black into HMX had little effect on the reflectivity and absorption coefficient under 10.6μm laser irradiation[21].A similar situation may also exist in the factors controlling the ignition delay of FOX-7.Unfortunately,there are very few studies on the combined effects of the optical and heat transfer properties of the above four carbon material additives on the ignition delay of FOX-7 powder under 10.6μm laser irradiation.The different effects of Gt,FS,G and GO additives on the ignition delay of the FOX-7 powder under 10.6μm laser irradiation is still unclear,which limited the in-depth understanding of the ignition control mechanisms of FOX-7-based mixed powders and restricted the effective adjustment of corresponding ignition performance.Furthermore,the different effects of four carbon material additives on the ignition delay of FOX-7 need to be analyzed by the corresponding theoretical prediction and some simplified models based on one-dimensional ignition theory were proved to able to simulate the laser ignition delay of solid materials with different physical properties[22-24].In addition,the relatively complex ignition regime and reaction mechanism caused by an overall two stage heat release behavior of FOX-7 thermal decomposition made the reason of shortened ignition delay and confined conditions cannot be determined explicitly,which may result in empirical mix with some safety risk[25-27].

Therefore,the experiments and reduced calculations of ignition delays for FOX-7 powders under 10.6μm laser irradiation were conducted to obtain a more comprehensive understanding of the mechanism governing ignition process in this work.Four types of carbon materials (CMs) were selected to compare the effects from some important physical properties on facilitating FOX-7 ignition.The ignition behaviors and controlling factors were analyzed to capture more insights of irradiation ignition for FOX-7 powders.

1 Experimental

1.1 Samples

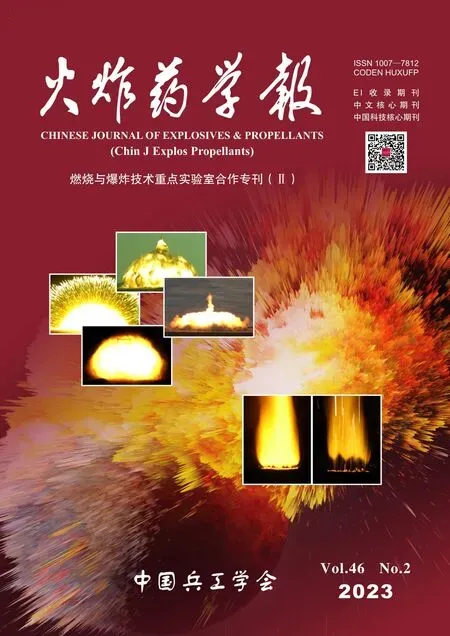

FOX-7 used in experiment was provided from Xi′an Modern Chemistry Research Institute,with purity higher than 99.5%.Graphite (Gt) was purchased from Fuchen Chemical Reagent Co.,Ltd.of Tianjin.Fullerene soot (FS) was obtained from Southwest University of Science and Technolog of Mianyang.Graphene (G) and graphene oxidation (GO) were purchased from Xianfeng Nano-material Technology Co.,Ltd.of Nanjing.Each CM powder weighted 3% was mixed with FOX-7 in a centrifuge tube which then was shook for 20min to make a physically mixed sample powder.The particle size distribution (d50=28μm) of FOX-7 was measured by a Malvern Mastersizer 2000 and the micro morphology of FOX-7 and CMs were characterized by a JEOL JSM 5800 SEM,as shown in Fig.1 and Fig.2.

Fig.1 The particle size distribution and SEM image of FOX-7 sample

Fig.2 SEM images of CMs

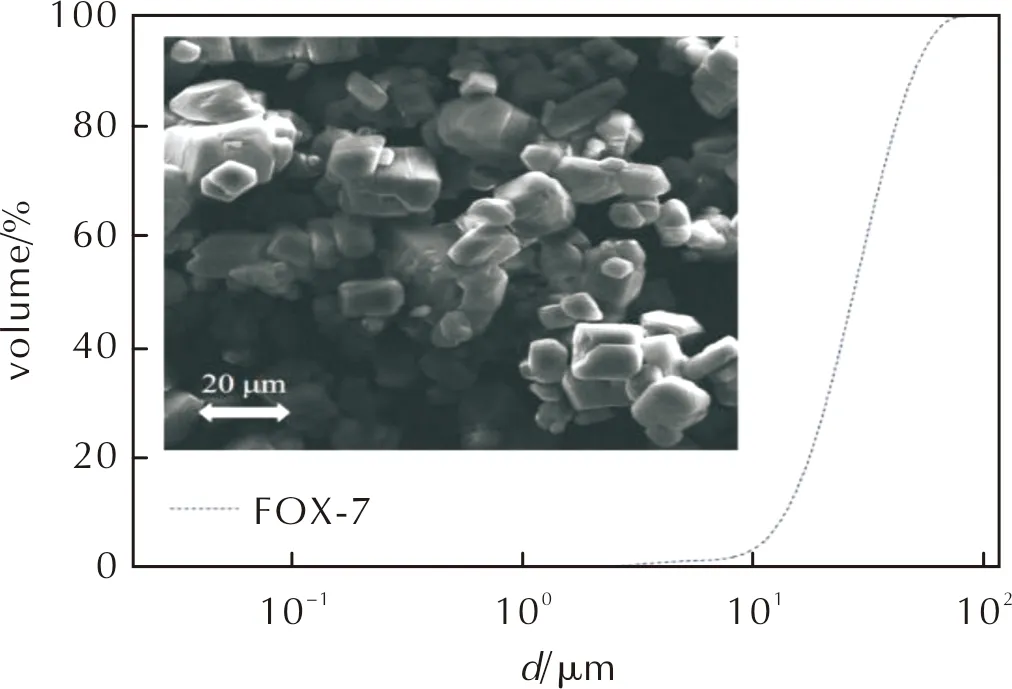

1.2 Laser ignition test

The experimental equipment is shown in Fig.3.A coherent J5 CO2laser apparatus (1),10.6μm wavelength,1000Hz frequency and 7mm laser beam diameter,was employed as the radiation source to heat FOX-7 samples (7).The flame signal from sample ignition in a combustion chamber (3) was detected by a photoelectric sensor (4) and recorded by a data acquisition apparatus (5).The laser operating parameters were set by the computer control system (2).The irradiation power was measured using a laser power meter (Ophir Nova II).The ignition test were conducted in continuous radiation mode at room temperature (298K) in air.Each sample was placed into a ceramic crucible of 5mm diameter and 4mm depth without pressing.The crucible almost full of sample was weighed by an analytical balance.The apparent sample density listed in Table 1 was calculated based on the average sample mass and crucible volume.

Fig.3 The experimental apparatus of laser ignition

The combustion behaviors during ignition process were recorded by a Canon high-speed camera (6) at 2000frames/s.The temporal characteristics of ignition are recorded by following two distinct signals locations at the start of ignition signal and 90% signal maximum described from Fang et al.[1]corresponding to the ignition delay and full burn delay respectively.

The instantaneous output laser signal was recorded as the initial timet0,which determined the ignition delay timeti=t*-t0,and the period from laser starting output until arriving at the surface of material was omitted for relatively minor.

2 Calculation Methods

(1)

(2)

(3)

(4)

(5)

The second model (Model 2) is from the approximate theoretical solutions of a one-dimensional heterogeneous radiant ignition model,which calculated ignition delay time equaling to the addition of the in-depth radiation absorption and heat conduction time,as shown in equation (6)[24,29].TsandRλare the surface temperature and reflection coefficient.

(6)

The thermal conductivity of FOX-7 mixtures was calculated by equation (7) from Maxwell theory[31-32].λF,λcandλmixare the thermal conductivity of FOX-7,CM and mixed powders.The heat capacity of mixture was calculated by equation (8)[33].cmixandciare the thermal capacity of mixed powder and componentiin powder.Yiis the mass fraction of componenti.

(7)

(8)

The kinetic parameters (z=1.3×1016s-1,E=192.5kJ/mol) of FOX-7 condensed-phase reaction were derived from Sinditskii et al[5,34]and the corresponding thermophysical parameters of FOX-7,CM and mixed powders for the above equations are listed in Table 1.The initiation and surface temperature of FOX-7 are 298K and 624K respectively.The thermal diffusivityαof FOX-7 is about 10-3cm2/s.The absorption and reflection coefficients (kλandRλ) were estimated to be 170cm-1and 0.1 respectively[21].

Table 1 The thermophysical properties of FOX-7 powders and components using in the numerical calculation

3 Results and Discussion

3.1 Measured delay times

Two kinds of delay time data were determined in laser ignition tests,seen Fig.4.One was the ignition delay time (ti) and the other was the full burn delay time (tFb) which correspondingly related to the first light and subsequent sustained burning behaviors as described similarly in some previous studies[1,44].The experimental ignition signals from first-light appearance in the form of luminous spot or IR emission contributed by condensed and gaseous reactions can be recorded by high-speed camera or photoelectric detector[44].Besides,another time data for full ignition delay (tFi) in Fig.4 is defined by equation (9).

Fig.4 The experimental ignition signals of FOX-7 in laser ignition test

tFi=ti+tFb

(9)

As illustrated in Fig.5(a),the measured ignition delay time decreases as increasing laser energy flux and all four FOX-7 mixed powders show shorter ignition delay time than that of neat FOX-7 in the studied energy flux range.FG and FGO containing graphene exhibit much shorter ignition delay times than FGt and FFS.The ignition delay times of FGt are closest to that of FOX-7.The ignition delay time of FFS is significantly shorter than that of FOX-7 and FGt in the higher laser energy flux range.Fig.5(b) shows that the overall order of measured full ignition delays for sample powders is similar to that of ignition delays.All four CM mixing can largely shorten the full ignition delay while G and GO show relatively stronger boosting effects.The full burn delay times of sample powders calculated by equation (9) are shown in Fig.5(c).All four mixed powders have shorter full burn delays than FOX-7 and the different full burn delay behaviors may be influenced by the complex conditions of flame growth process.

Fig.5 Ignition delay time vs. laser energy flux curves of FOX-7 powders mixed with differents of CMs.

3.2 Analysis and calculation of ignition delays

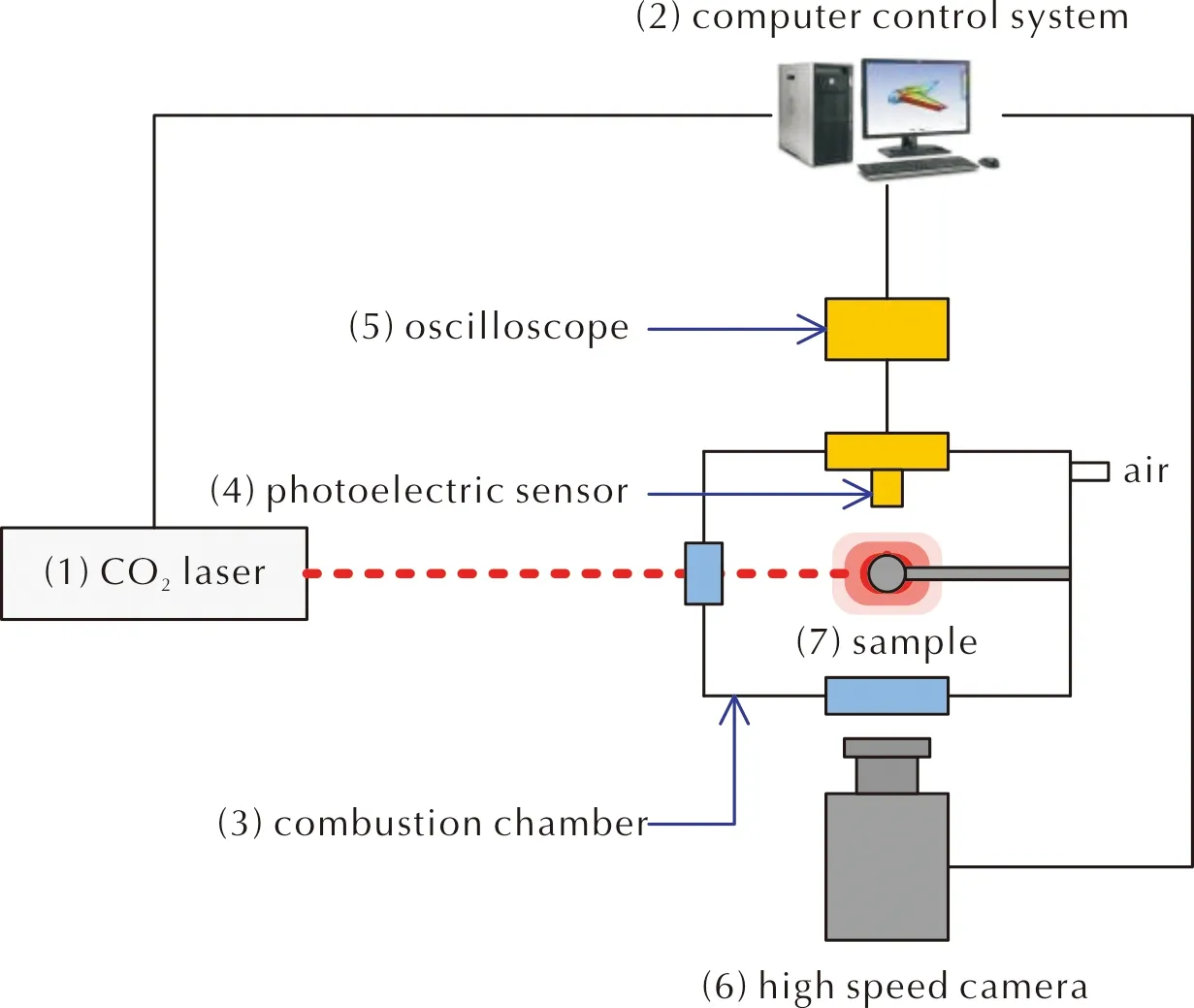

The fitting power law exponents of experimental ignition curves at the studied range of 130—560W/cm2related to first light onset and full ignition delay time are listed in Table 2.The exponents show the overall rate variety characteristics of an energetic material system achieving ignition threshold condition under a range of constant radiation flux[45].The power-law exponents of two types of delay time curves for FOX-7 and FG powders are both nearly closed to -1,which indicated that their ignition delay behaviors were both inclined to correspond to the fixed energy region[46-47].

Table 2 The fitting power law curve parameters of ignition delay time vs. laser energy flux for FOX-7 and its mixture samples (t=A×qB)

In the fixed energy region,the ignition criterion of energetic material is driven by a threshold energy flux[45,47].In this case,the approximate condition for ignition behavior to occur is given by equation (10),since the preheating layer thickness of steady burning becomes the main controlling factor and the ignition temperature would be met and exceeded during relatively rapid heating.

ti=Qc/q

(10)

Fig.6 shows the calculated laser ignition delay times of FOX-7 and mixed powders by two simplified ignition models which given different prediction performances compared with the experimental data.

The predicted results of FOX-7 ignition delays employing Model 1 agree well with the experimental data indicating that Model 1 could reproduce the ignition delay of FOX-7 under continuous 10.6μm laser irradiation reasonably,as seen in Fig.6(a).But the lower predicted results from Model 2 against experimental data may be caused for missing consideration of chemical reaction term in the approximate reduction treatment of conservation equations for radiant ignition,as seen in equation (6).The dominant mechanism of the ignition process embedded in Model 2 cannot match that of actual induced process of FOX-7 ignition well,which should be explained by theoretical analysis.

Fig.6 The predicted laser ignition delay time against the experimental data for FOX-7 and four mixed powders

The better prediction results of FGt from Model 1 indicate that the dominant mechanism of ignition process may probably be similar to that of FOX-7,as given in Fig.6(b).On the other hand,when CM was added,especially FS,G and GO,the reaction rate would be accelerated,resulting in that the ignition delay time was mainly controlled by heat transfer and absorption,which may be an important reason why Model 2 predicts better for FFS FG and FGO than model 1,as shown in Fig.6(c)—(e).

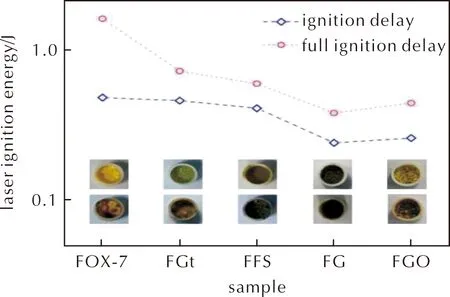

The calculated ignition energies of samples using the formulaEi=P×tare shown in Fig.7.Ei,Pandtare energy,laser power and ignition time (tiortFi) respectively[49-51].The ignition and full ignition energies of FOX-7 powders are all decreased due to the mixing of CM.The laser ignition energies of FG and FGO are smaller than that of FGt and FFS.The comparison of sample photos before and after ignition test suggests that FOX-7 would burn more completely with CM mixing.

Fig.7 The laser ignition energy and the observed images of sampless before and after irradiation

3.3 Effect of CMs mixing on ignition delay

The decreased ignition delay time under 10.6μm laser irradiation for FOX-7 powder mixed with CM cannot be explained analogously by the general sensitized effect of CMs on energetic materials under the irradiation in the smaller laser wavelength range due to the varying optical properties[11,52].Although laser energy absorption is one of the distinct factors influencing ignition delay,the relatively slight effects of adding Gt and FS in FOX-7 on the ignition delay are observed along with the increasing laser energy flux in Fig.5(a).This phenomenon may be consistent with that introducing carbon black to explosives would hardly affect the reflection and absorption properties at the wavelength 10.6μm[21,53].

As shown in Fig.5,Gt and FS do not appear to have notable effects on reducing the ignition delay until the power density exceeds about 350W/cm2,which is mainly due to the fact that the thermal conductivity advantage of Gt and FS contributed weakly to reducing the ignition delay of FOX-7,especially at the lower power density range of 130—250W/cm2.Gt and FS mixing significantly reduced the full ignition delay,indicating that the thermal conductivity properties of Gt and FS mainly accelerated the ignition development process from weak flame kernel to full ignition.G and GO can shorten ignition delay and full ignition delay more effectively,but their influences on full burn delay are not significantly different from that of Gt and FS.

Therefore,all four CMs can improve the energy transfer efficiency to a certain extent and reduce the actual energy loss caused by the apparently discontinuous exothermic reaction during the energy release process of FOX-7[2,54].The energy transfer abilities of G and GO not only promote the both two ignition stages of FOX-7 powder,but also has a more significant acceleration effect on the first ignition stage.

Furthermore,the density variation of FOX-7 powder caused by adding carbon material is also one of the factors affecting ignition delay,which could be described by an approximate equation (11) illustrating the effect of density on laser heating rate[49-50].Since the apparent density difference between FGt and FOX-7 powders is relative small,the laser heating rate of FOX-7 powder with graphite addition does not change much,resulting in an insignificant reduction of ignition delay time,as shown in Table 1 and Fig.5(a).While the addition of graphene materials greatly decreases the powder density leading to a significantly faster laser heating rate and the earlier appearance of ignition signals for FG and FGO.

(11)

The laser ignition moment images recorded by high-speed camera are shown in Fig.8.The size order of different sample flames in first-light pictures is FGt>FFS>FGO>FG corresponding roughly to the ignition delay and energy in Fig.5 and Fig.7.The smallest flame may be probably formed from a minimum ignition kernel relating to the lowest energy transfer loss during the ignition induction period of FG,which could reduce the apparent energy threshold of ignition and flame propagation[54-55].Therefore,graphene-based carbon material is able to decrease the energy transfer resistance increasing the overall rate of laser ignition process for FOX-7 powder.Furthermore,the subsequent flame evolution after first-light for the four samples indicates that FG and FFS with relatively smaller growing flames would tend to have shorter full burn times exhibited in Fig.5(c).

Fig.8 The laser ignition behaviors of four kinds of samples by using high-speed camera

4 Conclusion

Laser ignition experiments of four FOX-7 powders mixed with different carbon materials have been conducted to study the ignition delay behaviors under atmosphere condition.The corresponding ignition delay times were predicted by two reduced physical models.

(1) It was found that carbon-material mixing could both decrease the ignition and full ignition delay of FOX-7 powder significantly and G and GO exhibited better ignition-promoting effects than that of Gt and FS.

(2) The part of calculation results of ignition delays are in good agreement with the experimental values indicating that Model 1 is more suitable for predicting the ignition delay time of FOX-7 powder than Model 2.

(3) The ignition mechanism analysis suggested that the ignition delay could be greatly affected by the density and heat conductivity of bulk powder.The ignition processes of FOX-7,FGt and FFS powders under 10.6μm irradiation are mainly controlled by the coupling effects of three factors including optical absorption,heat diffusion and reaction kinetics while that of FG and FGO powders are inclined to be dominated by the first two factors.

Acknowledgments

In particular,we want to thank ZHOU Wen-jing and ZHAO Juan for the characterization experiments.