Obvious advantages of optical fiber for sensor application

2022-11-15ByZhaoXinhua

By Zhao Xinhua

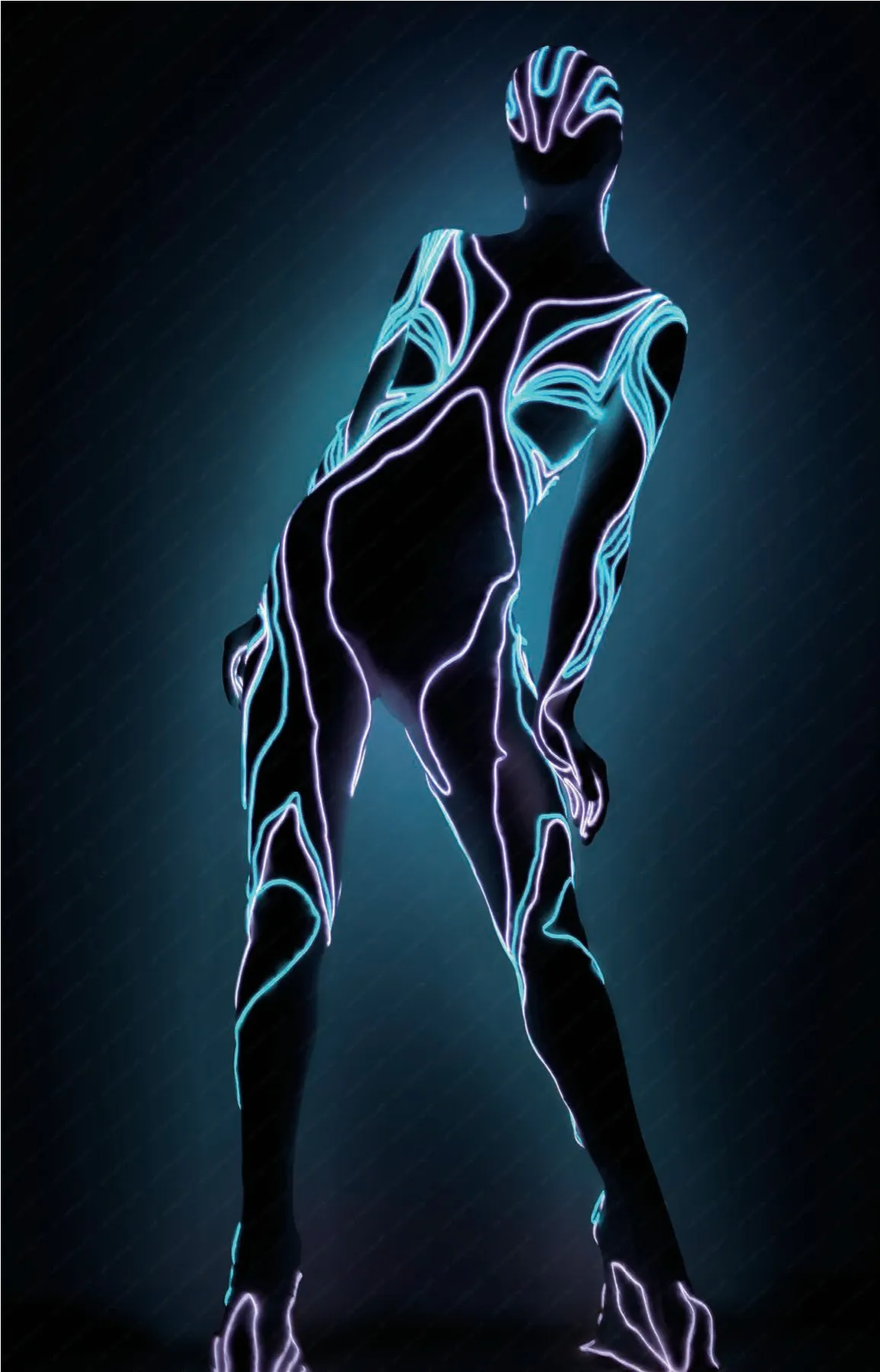

Different optical materials used in textiles will show different effects of light response.Fiber optic fabric is a blend of optical fiber and textile fiber.By adding light—emitting diode at the end of fiber with high permeability,it can become self—luminous fiber fabric after electrification.During the day,the effect is the same as ordinary fabric.After being energized in the dark,it will emit dazzling light.

Optical fibers have been developed using glass and polymers.The polymer made optical fibers are flexible and have lightweight properties that are demanded by textile products.Connected to an external light source,polymer optical fibers (POFs)incorporated in textile allow light transmission not only to selected locations but also holohedral on the textile surface.Textiles seem to be ideal substrates for 2D arrangements to fulfill specific photometric or radiometric requirements.

The POF textiles having external light source allow varied and easy—to handle illumination.Their specific benefit is that the light source and emitting surface can be separated.The luminosity of POFs depends on POF specifications such as diameter,the light source,optic leakage method,and pro—cessing of the fibers.In addition to the flexibility and lightweight feature of POFs,other properties such as durability,transmission capacity,easy handling,simple connections,robustness,and biocompatibility make them compatible with textile structures.

With the integration of light in textiles,many companies followed the trend to combine mod—ern design and functionality,and patented,for example,a light distribution system,flexible flat panel displays,and automotive solutions with fabric—like behavior and optic fiber fabric display.A textile—based display is created using the opti—cal fibers in a fabric made of classic yarns.The display matrix is created during weaving or knit—ting,using the texture of the fabric.These flexible textile—based displays have a very thin size and are ultra—lightweight.Integrating optical fibers into a woven fabric requires bending because of the crimping that occurs as a result of weave interlacing.However,standard POF materials like polymethylmethacrylate,polycarbonate,and polystyrene are rather stiff compared to standard textile fibers and therefore their integration into textiles usually leads to stiffening of the woven/knitted fabric and the textile touch is getting lost.Alternative fibers with appropriate flexibility and transparency are not commercially available yet.

Today,the processing of optical fibers in different textile technologies brought up a wide range of applications such as in displays and communication devices,or as sensing in a broad field of applications,such as medi—cals,healthcare,architecture,public premises,stage,fashion design,security and military devices,data communication,or automotive engineering.When integration of sensors into textiles is considered,optical fibers have a serious advantage over other kinds of sensors due to their fibrous nature.

The smart walker system consists of a 3D printed handle with an oximetry sensor and smart clothes equipped with the polymer opti—cal fiber sensors.The smart walker system iscapable of measuring oxygen saturation,gait ca—dence,breathing and heart rates with an accuracy of 99%.The system is proposed to be applied in the remote healthcare and robotics applications.

Dyeing and printing and embroidery are the main traditional crafts.But so far,these traditional crafts have been unable to meet people's ever—changing needs for fashion innovation.Fiber laser marking machine can be carved on all kinds of fabric cutting,multi—angle,multi—level performance of different layers of three—dimensional carving ef—fect.Processing does not add any pigment,do not produce chemical pollution.This unique,natural and plain style really makes the fabric return to nature.

POF sensors and devices integrated in textiles comply with an increasing request for flexible and flat structures,which are required for many dif—ferent sensing applications.In most cases,woven structures that incorporate POFs are used,but embroidery or weft—knitted devices have also been developed.Dimensions of textiles rank from small embroidered structures to large woven fabrics or knitted webs.Some of the main advantages of tex—tile products are their thin and lightweight structure,their drapability and bendability,and their manifold 2D design possibilities.