Effects of deformation twins on microstructure evolution,mechanical properties and corrosion behaviors in magnesium alloys -A review

2022-10-24LianhuiLiWenhongLiuFugangQiDiWuZhiqiangZhang

Lianhui Li ,Wenhong Liu ,Fugang Qi ,Di Wu ,Zhiqiang Zhang,**

aKey Lab of Electromagnetic Processing of Materials,Ministry of Education,Northeastern University,Shenyang 110819,China

bEngineering Research Center of Advanced Materials Preparing Technology,Ministry of Education,Northeastern University,Shenyang 110819,China

c College of Information Science and Engineering,Northeastern University,Shenyang 110819,China

d School of Materials Science and Engineering,Xiangtan University,Xiangtan 411105,China

e Key Laboratory of Nuclear Materials and Safety Assessment,Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

Abstract Due to lattice reorientation,grain segmentation,induced recrystallization,twins play a very important role in regulating texture,refining grains,improving mechanical properties and corrosion resistance,and has received more extensive attention.Numerous studies have shown that {10-12}<10-11> tensile twins (TTWs) are easily activated in large quantities due to the lower critical resolve shear stresses (CRSS).Introduction of TTWs under uniaxial compression improved the strength,ductility,and formability of magnesium (Mg) alloys.Moreover,TTWs produced by multi-directional impact forging (MDIF) can optimize the microstructure by dividing grains and promoting recrystallization,resulting in significant improvement of mechanical properties.Although {10-11}<10-12> compressive twins (CTWs) and {10-11}-{10-12}double twins (DTWs) can promote dynamic recrystallization (DRX),they are also favorable nucleation sites for cracks.In addition,the type and volume fraction of twins can affect the corrosion resistance,and they also play different roles in the corrosion process of different Mg alloys.Twins have shown great potential for improving structure and properties,but a comprehensive and critical discussion of twins in Mg alloys is still lacking.Therefore,based on previous studies,this article reviews the common types and variants of twins in Mg alloys,influencing factors,and their effects on the microstructure,mechanical properties and corrosion resistance.In addition,some interesting ideas are being proposed for further research.

Keywords: Twins;Mg alloy;Microstructure;Mechanical properties;Corrosion resistance.

1.Introduction

Mg and its alloys have the advantages of low density,high specific strength,good damping and shock absorption,excellent machining performance,and easy recycling,which make them have broad development prospects in the fields of aviation,aerospace,automobiles,and military industries [1–6].In recent years,biodegradable Mg alloys have attracted great attention from researchers due to their excellent biocompatibility and elastic modulus matching with human body [7–11].Moreover,Mg and Mg-based materials have the advantages of high hydrogen storage capacity,low cost and good reversibility,so they are considered as hydrogen storage materials with broad development prospects [12–16].

Currently,more than 80% of Mg alloy components are manufactured by die casting[17,18].However,die casting Mg alloys have the defects of coarse grains and dendrite segregation,which lead to poor mechanical properties and corrosion resistance.Through reasonable plastic deformation methods(extrusion,rolling,forging and equal channel angle processing,etc.),wrought Mg alloys can have a finer microstructure and better mechanical properties [19–21].Unfortunately,unlike face-centered cubic lattice and body-centered cubic lattice,Mg alloys generally exhibit unsatisfactory ductility and formability due to the lack of easily activated slip systems in their hexagonal lattice structure [22,23].At the same time,the yield asymmetry of Mg alloys is often serious during thermo-mechanical processing,which is closely related to the strong texture [24].The high yield asymmetry makes Mg alloys potential safety hazards in the application of some structural parts that simultaneously bear tensile and compressive stresses.In plastic deformation,basal slip and prismatic slip are more easily activated,while pyramidal

As an important deformation mechanism at RT or high strain rate,twinning can not only coordinate plastic deformation,but also optimize the microstructure by inducing DRX[33–37].Guo et al.[38]showed that pre-twinning greatly promoted DRX during hot rolling,increasing the yield strength(YS)of AZ31 alloy without sacrificing elongation(EL).Some research has shown that the accumulation of high strain energy promotes the generation of DRX in the twin region.Compared with {10-12}<10-11>tensile twins (TTWs) with low Schmid factor (SF),DRX mainly occurs in {10-11}CTWs and{10-11}-{10-12}DTWs[39–41].Furthermore,the division of the matrix by twin boundary (TB) and the reorientation of crystals both play a very important role in the evolution of the microstructure and the improvement of the properties.Lu et al.[42]demonstrated that the introduction of a large amount of TTWs not only promoted DRX,but also greatly refined the grains of Mg-Gd-Y alloys,and the ultimate tensile strength (UTS) after 110 passes of MDIF was 354 MPa.At the same time,the activation of many twins led to a weak non-basal texture,which made the tensilecompression YS ratio of the alloy close to 1 along the forging direction.Cui et al.[43] also found that the activation of numerous twins resulted in a significant grain refinement of the as-extruded ZK60 alloy,and the unique<0001>//FFD(first forging direction) and<11-20>//FFD four-peak texture enhances the yield symmetry.The stretch formability of hotrolled AZ31 alloy sheets was significantly improved by 50%at RT by pre-twinning [44].However,it should be cautious that not all twin types are beneficial to the mechanical properties of the alloy.{10-11} CTWs and {10-11}-{10-12} DTWs are often the source of cracks due to large internal stresses[45].In addition,the micro galvanic corrosion of twins and Mg matrix will promote the formation of surface film,and the dense film layer is profitable to the corrosion resistance of Mg-RE alloy [46].Therefore,twinning has attracted the interest of many researchers in recent years due to its outstanding contributions in coordinating deformation,refining microstructure,regulating texture,and improving comprehensive mechanical properties and corrosion resistance [47–49].

Before this,some researchers have summarized and reviewed some related content of twinning.Liu et al.[19] summarized the effects of internal stress,crystal defects,solute segregation,and twin-dislocation interaction on the stress stability of twinning,and also described the thermal stability of twinning affected by the segregation of solute atoms,the activation of slip,the relative contribution of twinning/slip to plastic strain,and initial dislocations.In addition,Gerashi et al.[11] elaborated the role of twins and texture in the corrosion behavior of Mg alloys.However,these reviews only focus on a certain part of the twins.In this review,the types and variants of twins in Mg alloys,the influencing factors of twins,and the effects of twins on the microstructure and properties are systematically introduced to help novices easily enter the field,and it is also expected that some interesting ideas can be motivated to further enhance the formability and mechanical properties of wrought Mg alloys,develop new processing technologies with high efficiency and low cost,and promote large-scale application of Mg alloys.

2.Overview of twins

2.1.Types of twins

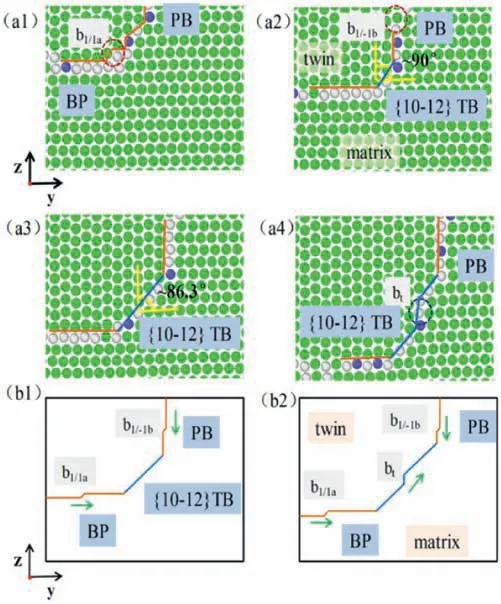

Twinning is a very important plastic deformation mechanism in the hexagonal close packed (HCP) metals [50].There are four common types of twins in Mg alloys: {10-12}<10-11>TTWs,{10-11}<10-12>CTWs,{10-11}-{10-12} DTWs and {10-12}-{10-12} DTWs.Among them,the CRSS of TTWs is about 2–5 MPa,which is the easiest twins to be activated [51].In general (regardless of polycrystalline strain coordination),they follow the Schmid law and are prone to occur when pulled along the c-axis direction or compressed perpendicular to the c-axis direction.For twin embryo with coherent basal-prismatic (BP)/coherent prismatic-basal (PB)boundary,the misorientation angle of the twins and its matrix is 90° [52].With the widening of {10-12} TB,the positions of atoms near TB are adjusted to match the neighboring atoms,resulting in the orientation difference gradually shifting to 86.3°,as shown in Fig.1 [53].

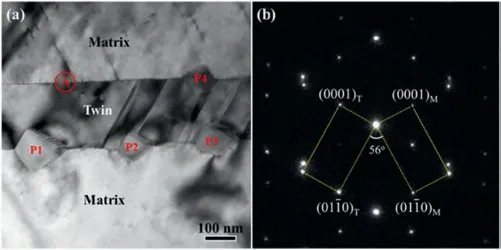

{10-11}CTWs provide compressive strain along the c-axis and are usually seen at higher strains than{10-12}TTWs due to its relatively high CRSS.As shown in Fig.2,CTWs are found in the cold-rolled and annealed AZ80 alloy.It can be clearly found by the selected area electron diffraction(SAED)pattern that the misorientation angle of the twin and its parent lattice along the<2-1-10>αdirection is 56°[54].CTWs have a relatively thinner thickness than TTWs because of the lack of low-energy mobile interfaces and a higher energy barrier against the nucleation and propagation of twin dislocations on {10-11} TB [55].

Fig.1.The formation of a {10-12} TB.(a) The transformation from BP/PB interface to{10-12}TB through the diagonal pile-up of disconnections,strain increases from a1 to a4.(b) Schematics of the transformation from BP-PB interfaces (orange solid line) to {10-12} TB (blue solid line) [53].

Fig.2.(a) Bright field Transmission Electron Microscope (TEM) image showing the microstructure of a {10-11} twin in the sample cold rolled by 10% and annealed for 8 h at 200 °C,(b) the SAED pattern taken from the area marked by A.The electron beam is taken along the common<2-1-10>α direction of the matrix and twin [54].

With the further increase of plastic deformation,secondary{10-12} TTWs will appear in the {10-11} CTWs to form{10-11}-{10-12} DTWs [56,57].Through dissociation of lattice dislocations,the{10-11}-{10-12}DTWs mechanism may be related to the separation of basal

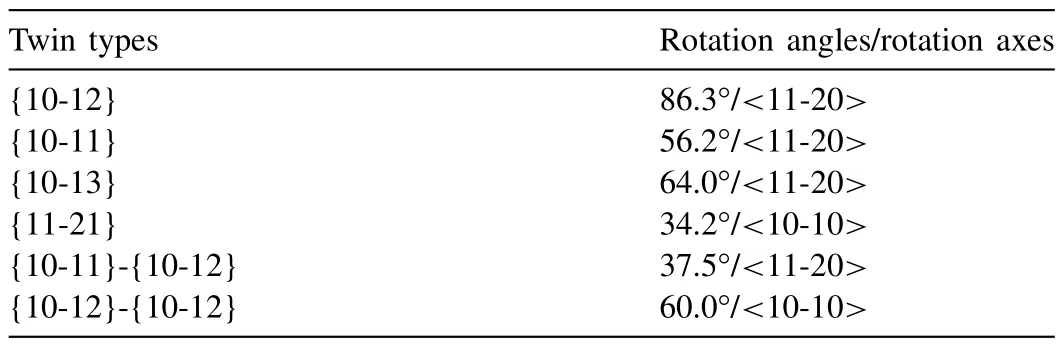

It can be seen that the selection of the type of twins in the Mg alloy is not only affected by the relationship between the external stress and the c-axis of the crystal grains,but is also related to the local stress state.For multi-directional loading,SF and strain adaptation should be considered to better predict the twin selection after the strain path changes [37].Since other twin types are not common in Mg alloys,they will not be introduced in detail.The types of twins and the rotation angle/rotation axis appearing in Mg alloys are shown in Table 1.

Table 1 The type and orientation of twins [51].

2.2.Geometry of twins

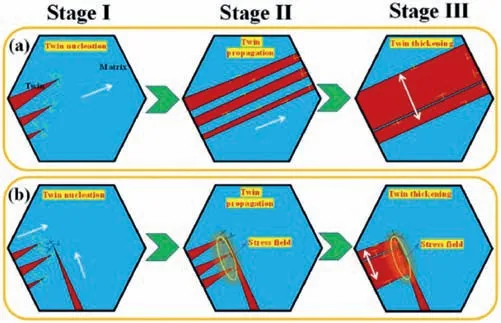

There are two main types of twin geometry in Mg alloys,namely “parallel structure” and “cross structure”.For a“parallel structure” (as shown in Fig.3a),twins will grow up quickly after nucleation and will not stop until they hit grain boundary (GB).In addition,twins can be thickened to accommodate further plastic deformation.In some loading situations,multiple twin variants can be activated at the same time and influence each other,resulting in twin-twin interaction,that is,a “cross structure”.For the “cross structure” (as shown in Fig.3b),twin variants in different directions nucleate and grow rapidly until they are in contact with each other.The dislocations at the tip of the incident twin interact with the dislocations of TB,resulting in stress concentration and dislocation accumulation,which affects further growth of twins[68].Some studies revealed that the interaction between twins had an important influence on the twin propagation,detwinning and twinning-induced strain hardening effects of Mg alloys[69,70].Shi et al.[69]researched the effect of different twin geometry on twinning in AZ31 alloy byin-situelectron backscattered diffraction (EBSD) and found that the “cross structure” of the twins would hinder twin growth and promote the nucleation of new twins near the cross region,and eventually drew the conclusion that the “cross structure” of twins induced hardening.Therefore,it is of great significance to study the geometry of twins in Mg alloys.

Fig.3.Schematic maps of the two types of twin-twin growing behaviors mechanisms: (a) “parallel structure”,(b) “cross structure” [68].

Fig.4.The codes,crystallographic indices and illustration of six {10-12}twin variants [37].

2.3.Variants of twins

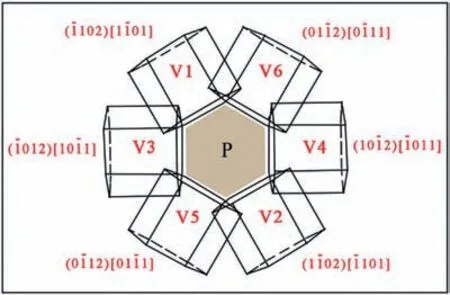

Each twin model has six equivalent twin planes and twin directions due to crystal symmetry,corresponding to six twin variants.Taking {10-12} TTWs as an example,by establishing a coordinate system (x// [10-10],y// [-12-10] and z//[0001]),a schematic diagram of the six variants of twins is shown in Fig.4.It can be seen that there are mainly three orientation relationships for twinning variant pairs in Mg alloys:ortho-position relationship (V1 and V3),meta-position relationship (V1 and V5) and para-position relationship (V1 and V2).The theoretical orientation relations of these three variant pairs ((10-12)-(01-12),(10-12)-(0-112),(10-12)-(-1012)) are:60°/<10-10>,60°/<8-1-70>and 7°/<11-20>,respectively[71].

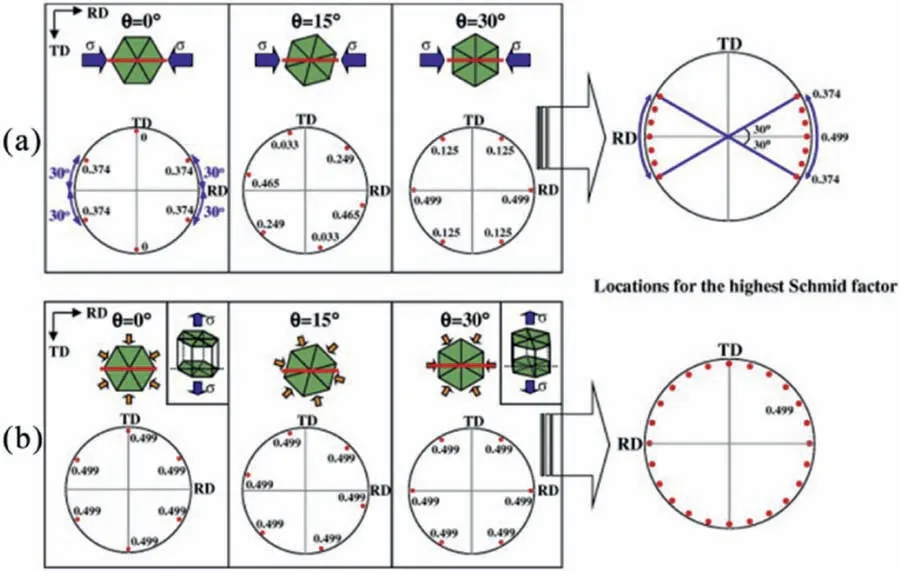

The selection of twin variants commonly conforms to the Schmid law,and the variant with larger SF in the crystal is activated to coordinate the deformation.Hong et al.[72]studied in detail the mechanism of activating twin variants under different strain paths.As shown in Fig.5,the activated {10-12} TTWs conform to the Schmid law regardless of contraction along RD and stretching along ND [72].However,researchers also found that the selection of some twin variants does not follow the Schmid law,which is mainly affected by local strain coordination.For example,Guan et al.[73] studied the selection of TTW variants mediated by basal slip in WE43 alloy,and found that the activated twin variants with low SF are related to strong basal slip or twinning activity in adjacent grains.Therefore,the selection mechanism of twin variants can be divided into two categories: most twin variants with high SF are controlled by macroscopic deformation;some twin variants with low SF are regulated by local strain.For the latter,basal slip,prismatic slip and tension twinning systems can all contribute to low SF twin variants [74].

As we all know,the Schmid law is a simple function of crystal orientation under uniaxial loading,and is not fully applicable to the current plastic deformation with complex multiaxial stress states [75].Aiming at the prediction of twin variants under complex stress conditions,Chen et al.[76]proposed an effective Schmid factor (ESF) as an alternative parameter for the SF based on uniaxial stress.In addition,the SF cannot forecast the tendency of twin variants nucleation at GB during Mg alloy deformation.Xin et al.[77] first proposed composite Schmid factor (CSF) to predict the variants of common-boundary twins in Mg alloys.

3.Influencing factors of twins

The deformation twins with good development prospects are affected by many factors,such as deformation temperature,grain size,initial grain orientation,strain parameters(strain rate,strain and strain path),precipitates and alloying elements [68].

3.1.Deformation temperature

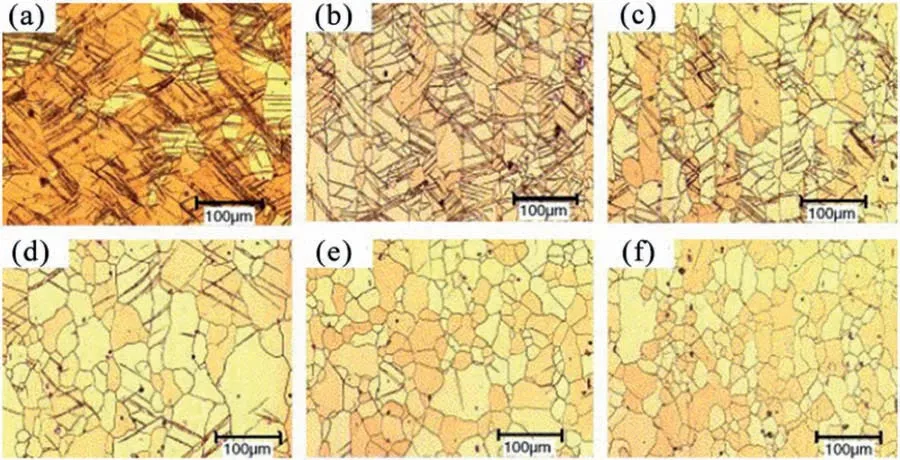

Deformation temperature,as a very important influencing factor,indirectly affects twinning activity by affecting dislocation slip activity.As we all know,Mg alloy with HCP structure has less available slip system at RT,so twins are needed to coordinate the deformation.Studies have shown that the CRSS of dislocation slip decreases with increasing temperature,but the CRSS of twins is very insensitive to temperature [78].Therefore,more twins will be activated during plastic deformation at a relatively low temperature[79,80].As shown in Fig.6,the number of twins in the grains decreases as the temperature increases,and the twinning phenomenon is rarely seen in AM30 Mg alloy above 200 °C [81].ˇCapek et al.[82] quantitatively analyzed the dependence of nucleation and growth of {10-12} TTW on deformation temperature by acoustic emission and neutron diffraction techniques.The results showed that the number of {10-12} TTWs decreased by nearly two orders of magnitude when the temperature was increased from 25 to 300 °C.Although the number of {10-12} TTWs was similar at 100–200 °C,the increase in temperature inhibited their growth [82].It has been demonstrated that

Fig.5.SF analysis on {10-12} twinning system: (a) RD (contraction perpendicular to the c-axis),(b) ND (tension parallel to the c-axis) [72].

Fig.6.Optical micrographs showing the effect of deformation temperature on microstructural evolution: (a) 25 °C,(b) 100 °C,(c) 150 °C,(d) 175 °C,(e)200 °C and (f) 250 °C [81].

3.2.Grain size

Fig.7.EBSD maps of samples with different angles after dynamic plastic deformation (DPD): (a) 0°,(b) 30°,(c) 60°,and (d) 90° Red,purple and blue lines indicate {10-12} TB,60° boundary and {10-11}-{10-12} TB,respectively.TD and LD represent the transverse direction and the loading direction,respectively[99].

It is well known that grain size has an important effect on twinning behavior in Mg alloys [85].In general,the twin nucleation rate decreases with decreasing grain size,which is attributed to the sensitivity of twin nucleation stress to grain size [86].Compared with coarse grains,fine grain structure not only has shorter dislocation slip travel,but more importantly,fine grain structure can be coordinated deformation through intragranular non-basal slip and grain boundary sliding,and the stress concentration at GB is not easy to reach the condition of twin nucleation [87,88].In addition,this grain effect also varies with twin type,and grain refinement has a more significant effect on the suppression of CTWs than TTWs [89].When the grains are reduced to micron and submicron scales,CTWs are suppressed during compression along the c-axis,and pyramidal slip dominates the plastic deformation [90–92].In contrast,TTWs remain the dominant deformation mechanism at the micron scale until it is replaced by dislocation slip when the grain size decreases to the submicron scale [93,94].This indicates that twins in Mg alloys,especially CTWs,is more sensitive to grain size than dislocation slip,and the same phenomenon also exists in Ti alloys [86].

3.3.Initial grain orientation

The effect of the original grain orientation on twinning behavior is similar to the effect on slip,and its essence is to control the activation of twinning by SF,and twins preferentially appear in parent grains with relatively large SF values.Barnett et al.[95] investigated the role of grain orientation in twinning behavior at low strain and found that both twin aspect ratio and twin density varied with grain orientation,with the latter in particular being more sensitive to orientation.The twin density of grains with SF of 0.45–0.5 was 10 times higher than that of grains with SF of 0.15–0.2,and the twin aspect ratio was also 40% higher [95].However,not all nucleation and growth of twins follow the Schmid law,which is also widely reported [96,97].This phenomenon is mainly attributed to the strain regulation of surrounding grains,the nucleation of TTWs is positively affected by shearing and

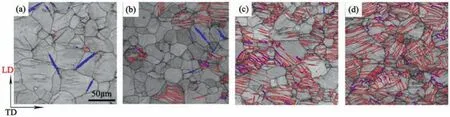

{10-12} twins are activated by compression perpendicular to the c-axis of HCP lattice or tension parallel to the c-axis,so different loading directions will result in different numbers and types of twins in the grains.It can be seen from Fig.7 that as the angle between the loading direction and the c-axis increases,more {10-12} TTWs appear in AZ31 alloy [99].When the c-axis of the grain is in a compressed state,both CTWs and non-basal slips may be activated.However,many studies have shown that CTWs are only found in a small area close to the fracture surface under certain stress state [100,101].Therefore,it is generally believed that

3.4.Strain parameters

The different strain parameters will lead to different twinning characteristics of the Mg alloy [103].For example,changes in strain rate,strain and strain history will all have certain effects on the type,volume fraction and morphology of twins.

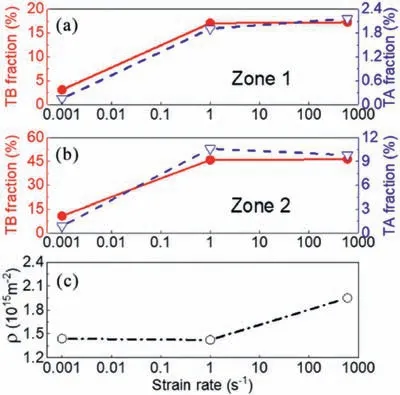

Fig.8.Evolutions of TB fraction (solid line) and twin area (TA) fraction(dashed line) in (a) Zone 1 and (b) Zone 2 and (c) average dislocation density (ρ) with strain rate at 0.02 strain [106].

Due to the athermal nature of basal slip and twinning,the strain rate has little effect on their CRSS,but has a larger effect on non-basal slips [104].Meanwhile,the response of dislocation slip to plastic deformation requires a certain time,while twinning is generated by the shearing of atoms,and its nucleation and growth have no time limit [100].Therefore,the plastic deformation mechanisms of Mg alloys at different strain rates will be different.In general,the yield stress increases significantly with the strain rate,which provides more driving force for the activation of twinning.In quasi-static and high strain rate tests of AZ31 alloy,it was shown that the dependence of yield stress on strain rate was anisotropic,while twin density increased with strain rate in all directions [105].The same conclusion was also obtained by Dudamell[100]and Jiang et al.[81].However,there is a limit to the increase in twin density with strain rate.As shown in Fig.8,the evolution of deformation twins and dislocations in the ATZ311 Mg alloy under different strains was quantitatively investigated.It is found that the twins density increases significantly as the strain rate increased from 0.001 to 1 s-1and reached a saturation state at 1 s-1,while the dislocation density required a larger strain rate (600 s-1) to increase significantly [106].The tensile deformation microstructures of Mg-Al-Ca-Mn alloy sheets under various strain rates (0–500 s-1) also showed the most obvious twin structures when the strain rate was 1 s-1[107].Similar to the phase transition process,the saturation of the twin density means that the nucleation sites of twins reach a maximum at a specific strain rate.Surprisingly,the Mg-10Gd-3Y-0.5Zr alloy had a lower twin fraction at RT and high-speed strain [108].This is because RE and fine precipitation phases inhibit the twinning behavior.

It is well known that slip and twinning are the mechanisms of plastic deformation of Mg alloys.Among them,basal slip and {10-12} TTWs are easily activated due to their low CRSS.Hong et al.[72] studied the twinning behavior of rolled AZ31 alloy under different strains and found that the twin volume fraction was positively correlated with strain.The deformation mechanism at strains below 3% was dominated by slip,while twinning was the main deformation mechanism in the 3–9% strain range.Chen et al.[109] obtained similar conclusions on the contribution of TTWs to plastic strain in the low-stress stage of AZ31 alloy.As shown in Fig.9,the contribution of twins to plastic strain is relatively small in the early stage of plastic deformation (<1%).When the plastic strain exceeds 1%,the twin volume fraction increases greatly,and the contribution of twins to plastic strain reaches 91.3% [109].In addition,the CRSS of {10-11}-{10-12} DTWs is much higher than that of TTWs,about 76–153 MPa [110].With the further increase of strain,CTWs and {10-11}-{10-12} DTWs also appeared one after another.For example,Barnett et al.[111] studied the microstructure and texture evolution of cold rolled Mg-0.2Ce alloy and found that when the strain reached 10%,not only {10-11} CTWs were observed in grains,but {10-11}-{10-12} DTWs were also formed in CTWs.Meanwhile,the CRSS of pyramidal slip was overcome due to twins changing the grain orientation and the shear stress in the c-axis direction increases with strain.Therefore,the deformation mechanism of Mg alloy in the later stage of deformation is mainly

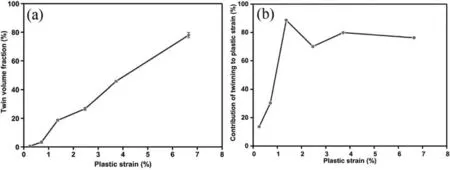

The strain path has an evident effect on the twinning behavior and is intrinsically dependent on whether there is a positive strain along the c-axis for TTWs (The rule also applies to CTWs.).Controlled by the Schmid law,AZ31 and AM30 alloy tubes exhibited different twinning behaviors under different strain paths.{10-12} TTWs were the dominant twinning mechanism in uniaxial compression and ring hoop tension experiments,while {10-11} CTWs and {10-11}-{10-12} DTWs dominated in uniaxial tensile experiments [112].In addition,{10-12}-{10-12} DTWs nucleate and grow in primary TTWs due to the strain path change,which control significantly different textures.Most of the {10-12}-{10-12}DTWs obey the Schmid law,while a small amount of low SF {10-12}-{10-12} DTWs are affected by the strain coordination of the surrounding grains [62,63].Wan et al.[113] investigated the effect of different strain paths on the twinning behavior of extruded Mg-Zr alloys byin-situEBSD.As shown in Fig.10,it is found that under the same cumulative deformation,multiple deformations can obtain more and finer twins than direct compression.And with the increase of total deformation,Mg-Zr alloy has higher twin density and twin aspect ratio [113].The dislocation density in the alloy increases with the complex strain path,which is beneficial to provide more sites for twin nucleation.Meanwhile,various defects existing in the grains hinder twin growth through the interaction of dislocations and TB [114].Therefore,the dislocation density has a very important effect on the twinning behavior of Mg alloys under different strain paths.

3.5.Precipitates

Fig.9.(a) Evolution of twin volume fraction as a function of plastic strain,(b) contribution of {10–12} TTWs to plastic strain at the low stress stage [109].

Fig.10.(a1–d1) Optical microstructure of pre-strained samples under different loading conditions,(a2-d2) optical microstructure of the re-compressed samples[113].

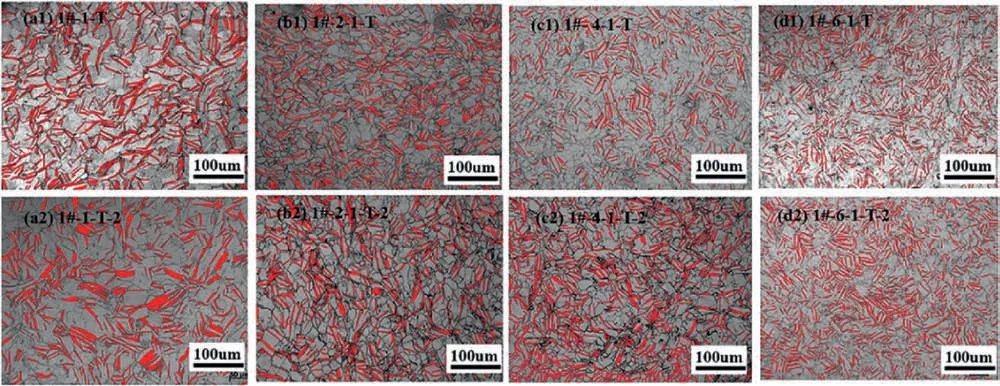

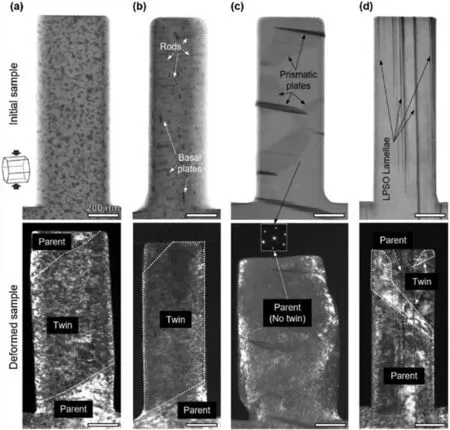

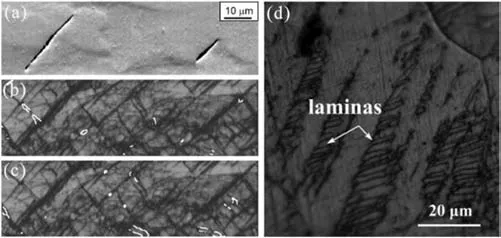

Precipitation strengthening,which prevents the movement of dislocation slip and twin,is an effective strengthening mechanism for many Mg alloys [115].As an important deformation mechanism in Mg alloys,TTWs and CTWs are the most common types of twins [51].Extensive studies have shown that twins in Mg alloys are affected by the precipitate morphology,and different types of twins also behave differently [55,116].When studying the effect of c-axis rod precipitate morphology on the twins of Mg-6.5Zn alloy,Wang et al.[55] found that {10-11} CTWs would be suppressed by precipitates,while {10-12} TTWs showed the opposite situation.The reason for this difference may be a lower twin surface energy and a larger twin dislocation Burgers vector in CTWs [55].Han et al.[84] also found that twin nucleation and growth in pure Mg and Mg-0.5Ca alloy exhibited different trends.{10-12} TTWs were inhibited and {10-11} CTWs were promoted,which was related to the abundant presence of Mg2Ca phase and its effect on the microstructure.The above studies only indirectly judge the influence of precipitates on twins through the twin volume fraction,and lack intuitive evidence.Recently,Li et al.[117] directly explored the effect of the MgZn2phase on twinning behavior by a new highthroughput methodology,and showed that the MgZn2phase reduces the CRSS of TTWs nucleation compared with solid solution.Meanwhile,the CRSS of twin nucleation is smaller than that of twin growth,which is due to the strong pinning effect of MgZn2phase on the migration of TB.The inhibition of twin growth by the precipitates comes from the additional back-stress created by the embedding of unsheared precipitates in the twins [118].During their interaction,the precipitates rotate due to plastic deformation,rather than being sheared and twinned,and the rotation angle is affected by the precipitate thickness[119].In addition,Liu et al.[120]directly observed the effect of different precipitate morphologies(particles,rods and a small number of nanoscale plates,platenetwork and LPSO lamellae) on the twinning behavior byin situmicroscopy.As shown in Fig.11,compared with the others,the pillar containing plate-network precipitates shows no twins during plastic deformation,and dislocation slip dominates.Therefore,this experiment shows that the plate-network precipitates have the best inhibition effect on twinning.This structure can divide the Mg matrix into many tiny regions,the nucleation stress of twins increases sharply with grain refinement,and dislocations are less sensitive,so dislocation slip becomes the main mechanism of plastic deformation[86].Therefore,the rational selection of the precipitate morphology can limit the twinning activity to a certain extent,so that the non-basal slips that originally does not play a role are activated,which can provide ideas for the design of new high-strength Mg alloys.

Fig.11. In-situ TEM observation of the deformation behavior of Mg alloys with different precipitate morphology.Top row,bright field Scanning Transmission Electron Microscope (STEM) images showing initial samples.Bottom row,dark field TEM images showing deformed samples.In (a) ZK60 pillar with particles,(b) Mg-6Zn pillar with rods and a small number of nanoscale plates,almost the entire pillar is twinned.In (c) WE54 pillar with plate-network or in (d) GWZ931 pillar with LPSO lamellae,twin is significantly suppressed.Compressive loading was along the pillar axial orientation,which is parallel to the plane (basal) of Mg.The observation (electron beam) direction is parallel to the basal plane in (a),(b),(d),and is parallel to the c-axis in (c).All scale bars,200 nm [120].

3.6.Alloying elements

Alloying elements are also one of the important factors affecting twinning behavior.For example,Zhang et al.[121] proved by first-principles calculations that Sn addition can reduce the ratio of unstable stacking fault energy(SFE)/intrinsic SFE,thereby improving the twin nucleation ability.At the same time,adding 1 w.% Sn makes the twin structure of Mg-Gd-Y-Zr alloy finer.Zhang et al.[122] studied the effect of adding Zn element on the deformation behavior of Mg-Gd-Nd-Zr alloy under high temperature uniaxial compression.The results showed that Zn addition led to a large number of {10-12} twin nucleation,which may be related to the decrease of SFE caused by Gd/Nd-Zn compound.Therefore,it is widely believed that the twin nucleation ability depends on the SFE.As shown in Eq.(1),largerΛratiomeans stronger twin nucleation ability [122,123].

where Yus(I2),Yis(I2),Yus(T2) and Yis(T2) represent the unstable SFE,intrinsic SFE,unstable twin-like SFE and intrinsic twin-like SFE in {0001}<1-100>slip system,respectively(unit: mJ/m2).Furthermore,in the deformation behavior of Mg-Zn-Zr-(Ca) alloys,Ca was found to promote twin nucleation by reducing the CRSS of TTWs [124].For RE,it is generally found to promote non-basal slips and suppress twinning [125,126].Compared with pure Mg,Y addition activated prismatic and pyramidal slips,but significantly reduced the twin volume fraction [127].Yang et al.[128] also found that Gd addition reduced the SF of twins.In other words,assuming that the CRSS of twins remained unchanged,a higher stress was required to activate the twinning behavior in Mg-Gd alloy.Moreover,an interesting phenomenon to note is that solute atoms of different sizes periodically segregate on different TBs,which is driven by the minimization of the total energy and elastic strain energy in the system.At the same time,the ordered segregation of solute atoms will have a strong pinning effect on TB,which is beneficial for improving the strength of the material [129].

4.The effect of twins on microstructure

The effect of twins on the microstructure is mainly reflected in three aspects: First,different types of twins can achieve specific reorientation of grains,thereby changing the crystal structure;secondly,twins can induce recrystallization during plastic deformation,thereby refining the grains;finally,TB can promote the precipitation and uniform distribution of precipitates to a certain extent [130].

4.1.Grain reorientation

Twins are considered to be an important means to optimize the microstructure due to their unique crystal lattice orientation and the characteristics of promoting recrystallization nucleation.Mg alloys usually produce strong texture due to insufficient activatable slip system during conventional processing (rolling,extrusion or forging),resulting in poor RT formability and tensile-compression yield asymmetry,which severely limits their application in various fields [131,132].A large number of studies have proven that adding alloying elements,especially low-concentration RE,can significantly weaken the texture strength and improve the formability and strength of Mg alloys.This is because RE addition promotes non-basal slips by reducing the energy of I1stacking fault.At the same time,RE has a large solid solubility in Mg alloys,and the solid solubility decreases significantly with the decrease of temperature.Therefore,RE alloying can significantly improve the mechanical properties of Mg alloys by enhancing non-basal slips,solid solution strengthening and age hardening [133–136].For example,the addition of Ce in Mg-Zn alloy results in a weaker non-basal texture,and a reorientation of approximately 45° occurs in the texture[137].However,RE addition increases the cost of the material,so more easily obtained twins are introduced into the Mg alloy to control the preferred orientation of grains,thereby eliminating the strong anisotropy of the alloy.It is reported that compression along TD (or RD) can generate {10-12}twins and lead to the formation of c-axis//TD (or RD) twin textures in rolled Mg alloy sheets [37,138].As shown in Fig.12a and b,the rolled AZ31 alloy is compressed along the TD direction to introduce TTWs,which weaken the strong basal texture of the alloy and lead to a c-axis// TD texture component.After another 3% compression along the RD direction,it is found that there are c-axis//RD,c-axis//TD and c-axis// ND texture components in AZ31 alloy.Therefore,it can be seen that multi-directional loading can produce more dispersed texture components,which will greatly reduce the basal texture strength of Mg alloy during plastic deformation and achieve the purpose of improving yield asymmetry.

4.2.Grain refinement

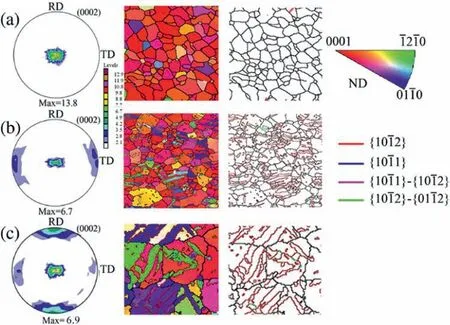

In addition to directly affecting the orientation transformation of the parent grains,twinning also controls the microstructure by influencing the recrystallization during the plastic deformation process.As is known to all,the common types of twins in Mg alloys are {10-12} TTWs,{10-11}CTWs and {10-11}-{10-12} DTWs.However,not all twins promote the nucleation of recrystallization.A large number of studies have shown that {10-11} CTWs and {10-11}-{10-12}DTWs rather than {10-12} TTWs are usually used as nucleation sites for static recrystallization (SRX) and DRX [139–141].For example,Liu et al.[141] observed the microstructure of the Mg-1Zn alloy annealed for 5 min and annealed for 24 h by EBSD and found that both {10-11} CTWs and{10-11}-{10-12} DTWs were basically transformed into SRX(as shown in Fig.13a and b).This is because the preferential occurrence of basal slip and dislocation accumulation leads to their high strain energy,which provides the driving force for SRX during the subsequent annealing treatment.However,the number of TTWs after annealing for 24 h was significantly less than that of annealing for 5 min(as shown in Fig.13c and d),indicating that the TTWs were de-twinned rather than recrystallized during the annealing process.It is confirmed that{10-12} twins induced by uniaxial compression are prone to move due to their wider core width and lower burgers vector magnitude of the twinning dislocation[142].However,a large number of {10-12} TB generated by MDIF are pinned due to the interaction of surrounding dislocations,and dislocation slip can accumulate efficiently,therefore,SRX nucleation and growth are promoted during the annealing process [143].

It is generally believed that the DRX behavior is related to {10-11} and {10-11}-{10-12} twins [144,145].Peng et al.[146] found that a complete DRX was formed in the {10-11}twin region.Chen et al.[139]also demonstrated that favorable nucleation sites for DRX were {10-11} and {10-11}-{10-12}TBs.This is because of their thin thickness and higher CRSS compared to TTWs.The limitation of crystal slip (reduction of the mean dislocation free path) and the resulting internal stress promote the formation of low angle grain boundary(LAGB) and favor DRX nucleation [147].In addition,Ma et al.[148] found that a certain proportion of DRX grains in high-temperature extruded AZ61 Mg alloy satisfied the {10-12}<10-1-1>twinning orientation relationship.It is believed that {10-12} TTWs have an important influence on DRX behavior during elevated temperature deformation,but the reasons for this are not clear [148].

In short,the recrystallization mechanism of different types of twins depends on the high local strain of twins or twin variants,or high dislocation entanglement.The strain energy stored in adjacent regions determines whether the recrystallization can penetrate TB.In addition,the mutual intersection of twin-twin and twin-LAGB within the same grain can also promote DXR [149].

4.3.Promote the precipitation and distribution of precipitates

Fig.12.(0002) Pole figures and Inverse pole figure (IPF) maps of various samples: (a) the as-received sample,(b) 3% compression along the TD and (c) 3%compression along the TD and then 3% compression along the RD [138].

Fig.13.EBSD of (a,b) 5 min and (c,d) 24 h annealed samples,(b,d) band contrast (BC) maps with highlighted special boundaries [141].

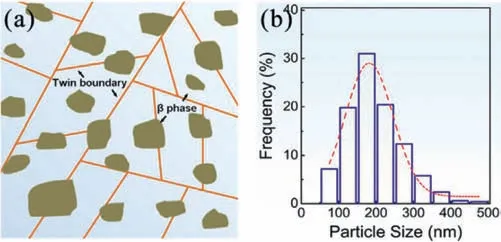

Due to the large internal stress,TB not only serves as a nucleation site for recrystallization and cracks,but also promotes the segregation of solute atoms,leading to the precipitation of precipitates [61,145,150,151].High-density TB can change the morphology and distribution of precipitates,which has a positive effect on the microstructure and performance optimization of the alloy.For example,the ultrafine crystal structure prepared by multi-directional compression is shown in Fig.14.After aging,a large number of nano-scale precipitates were found in the grain,which were evenly separated by TB.The dispersed fine precipitates and high density of ultrafine twins(UFT)made the YS of the alloy as high as 469 MPa[61].From a structural design point of view,Mg alloys with high-density twins have great development prospects due to their superior mechanical properties and corrosion resistance.

Fig.14.(a) Schematic diagram showing the microstructure of aged UFT-4,and (b) size distribution of the precipitates in aged UFT-4.Solid solutiontreated AZ80 with compression passe for 12 is designated as UFT-4 [61].

5.The effect of twins on mechanical properties

5.1.Twins strengthening and improved yield asymmetry

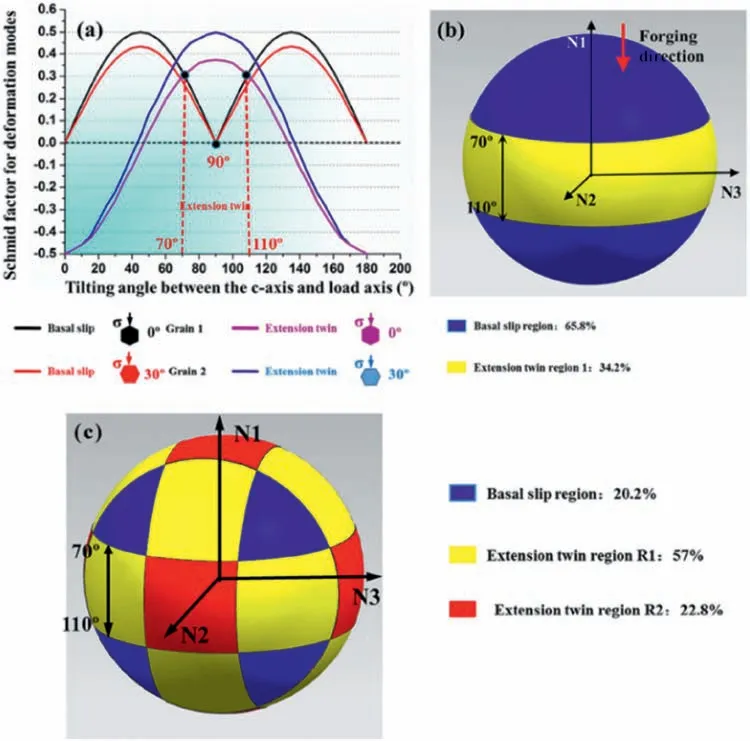

Fig.15.(a) SF distribution of basal slip and {10-12} TTWs for type grain 1 (θ=0°) and type grain 2 (θ=30°),(b) corresponding distribution of TTWs region 1 and basal slip region for solution-treated alloy with random texture during forging along the N1 direction,and (c) Orientation dependence of basal slip and TTWs activity in solution-treated Mg-Gd-Y alloy with random texture during MDIF in present work [42].

Among the numerous strengthening mechanisms,twin strengthening and fine-grain strengthening are considered to be two promising methods to improve the comprehensive mechanical properties of metal materials [4,152].According to the Hall-Petch formula,the smaller the grain size,the higher the YS of the alloy.If the grains of Mg alloys are refined to~1 μm,their YS can reach more than 300 MPa,far exceeding conventional steel Q235 and high-strength Al-Si alloys.The fine grains can increase the number of GB per unit volume,which can not only hinder the movement of dislocations to improve the strength,but also limit the propagation of cracks to improve the plasticity [153].Compared with fine-grain strengthening,extensive {10-12} TTWs divide the original grains into fine regions.At the same time,a large number of TBs are pinned by interacting with dislocations.Furthermore,the pinned TB favors the accumulation of dislocations and the formation of LAGB [143].In addition to grain refinement,twin reorientation reduces tension-compression yield asymmetry caused by strong base texture [154].It was reported that the introduction of {10-12} twins in the Mg-Gd-Y alloy through MDIF has achieved significant grain refinement and developed a high-strength (UTS=354 MPa) isotropic alloy.These changes come from the development of high-density{10-12} TTWs,and the three orthogonal loading directions make the regions where the high SF TTWs are activated superimpose each other.As shown in Fig.15,the estimated number fraction of {10-12} twins loaded in multiple directions totals 79.8% (yellow and red areas),which is much higher than the 34.2% {10-12} twins produced by unidirectional loading (N1) [42].The parent grains are divided by a large number of twins,and numerous micro-regions formed by LAGB undergo dynamic recovery and develop into fine DRX grains.All of these have made a great contribution to the high strength and isotropy of this alloy.

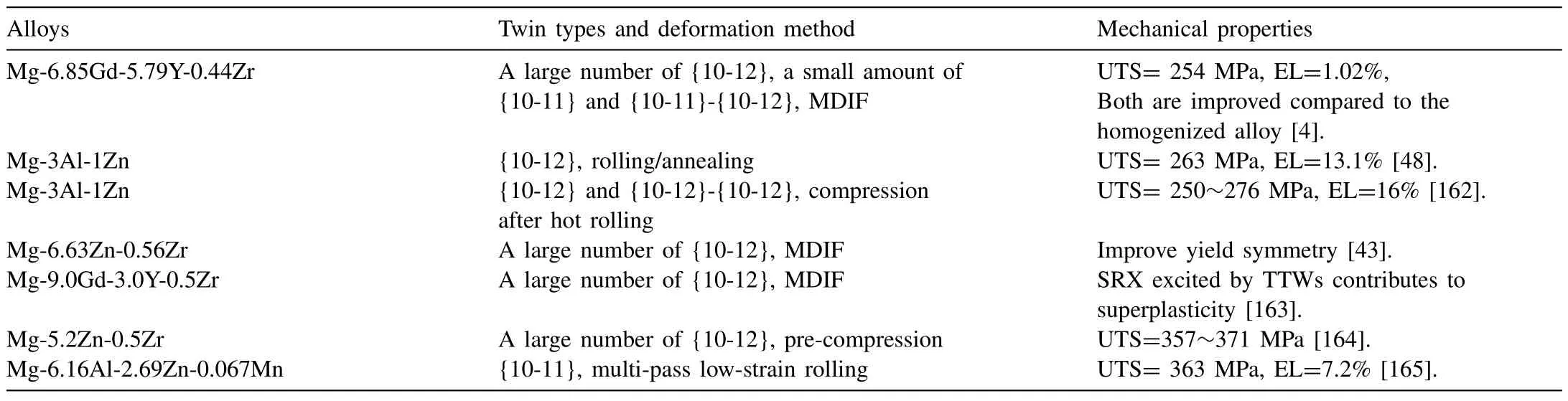

In addition,there are still many studies on the improvement of the mechanical properties of alloys by twinning,and some typical cases are listed in Table 2.Compared with the twin strengthening caused by unidirectional compression,the alloy processed by MDIF has a simultaneous increase in strength and plasticity.Unlike the former which directly causes brittle failure due to the high local stress of TTWs,the latter ductility should be caused by lower stress concentration and fine recrystallized structure.

Table 2 The strengthening effect of twins on different Mg alloys (UTS and EL).

Generally speaking,compression perpendicular to the caxis will generate {10-12} twins.Continuous loading in the same direction can cause the twins to coarsen,while they are removed by reverse loading and SRX under thermal effect[64,155,156].It was reported that the texture of the Mg alloy would return to the initial state after the detwinning was completed [157].This may lead to premature failure of materials strengthened by twinning and increase instability during alloy use.In fact,the coarsening and shrinkage of twins are related to the migration of TB under stress [19,158].There-fore,the active stress of detwinning can be increased by pinning the TB,thereby improving the stability of twins.It was reported that dislocations,solute atoms and precipitation can all contribute to the pinning of TB [116,159–161].In addition,the pre-compression and subsequent annealing treatment will cause the strengthening of the alloy,because an ordered segregation of solid solution elements is formed on the GB of TTWs,thereby producing a pinning effect on the TB [129].

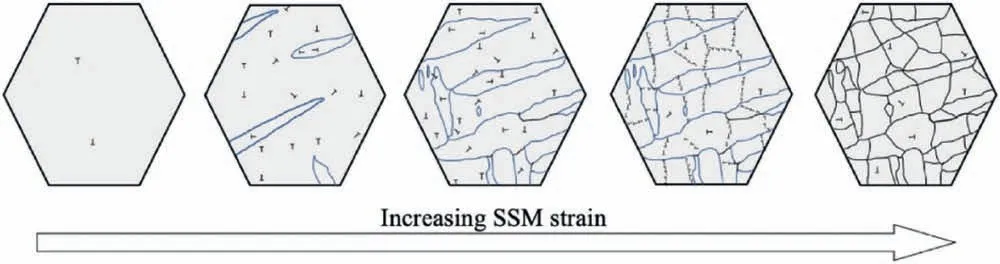

5.2.Effect of twins on ductility and formability

In general,{10-12}TTWs can improve the ductility of Mg alloys.This is because twinning can not only refine the grains and promote fine DRX,but also change the orientation of the surrounding grains and weaken the texture.Barnett et al.[166] demonstrated by tensile experiments and constitutive modeling that {10-12} TTWs can increase the EL of AZ31 alloys.However,some studies have reported negative effects of {10-12} TTWs on ductility.Although {10-12} TTWs do not act as crack nucleation sites,their TBs have the potential to serve as crack propagation paths [167].This is mainly because the TB of TTWs can accumulate more dislocations as obstacles to basal slip,and the cracks tend to propagate towards a high dislocation density.At present,through multidirectional,small-strain deformation processing methods such as MDIF and surface SPEX milling(SSM),a large number of{10-12} TTW variants can be activated as much as possible to simultaneously improve strength and plasticity [42,168].The main reasons for the improved performance are considered to be dislocation-twin interactions,the development of dislocation walls,and the microstructural evolution caused by cross-structural twins.As shown in Fig.16,high-frequency,multidirectional SSM activates different twin variants in the same grain,which grow until they touch each other.Both parallel and cross-structure twinning in the grains hinder slip.As the strain progresses,the hindered dislocations rearrange to form dislocation walls and grow into LAGB,which eventually evolve into ultrafine grain structures.Tensile test results show that this microstructure obtained by SSM doubles the strength and ductility compared to untreated pure Mg[168].Therefore,more twin variants are introduced at the grain level to form a crossed structure,which provides a reliable idea for improving the strength-ductility combination of Mg alloys.

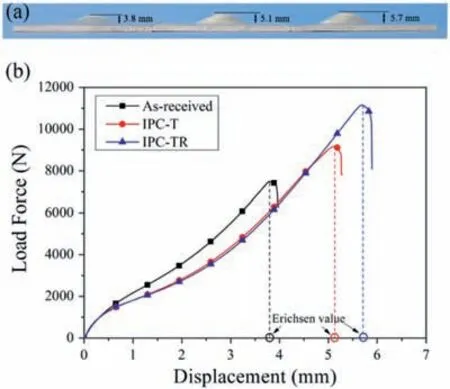

For rolled Mg alloys,the strong (0002) texture is not conducive to activating deformation modes that can accommodate strain along the thickness direction,thus severely limiting the stretch formability of Mg alloys [169].Some studies have shown that the basal texture strength can be reduced by pretwinning,thereby significantly improving the formability of Mg alloys at RT [33,170].As shown in Fig.17,the stretch formability of AZ31 alloy sheet can be improved by introducing TTWs,and the improvement of stretch formability is more obvious by multiple compressions in different directions.This is because the grain orientation of the pre-twin region is favorable for the formation of new TTWs in the subsequent plastic deformation,and the formation of new twins is adapted to the strain in the thickness direction of the AZ31 alloy sheet [44].However,Park et al.[169] reported a different situation where detwinning was a key factor in improving stretch formability at RT in the Erichsen test.In addition,twinning can promote DRX and SRX,and the recrystallized structure can weaken the original texture,which is beneficial to formability [171–173].It was found that TTWs activated by cold pre-forging provided a large number of nucleation sites for DRX during extrusion,and the increase of DRX volume fraction weakened the texture strength [174].Cheng et al.[175] also showed that the SRX behavior was induced by pre-crossed twinning and annealing treatment,and the significant weakening of the basal texture resulted in a 112.4%improvement in stretch formability.

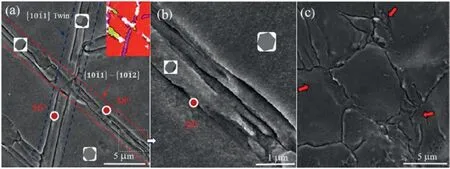

As mentioned earlier,{10-12} TTWs tend to nucleate in{10-11} CTWs as the deformation continues,thereby transforming into {10-11}-{10-12} DTWs.The current consensus is that {10-11}-{10-12} and {10-12}-{10-12} DTWs cause large local stress concentrations,which can easily lead to failure or fracture of Mg alloys [65,176].As shown in Fig.18,cracks and voids are found near these twins,which also confirmed the above view.Additionally,since the CRSS of other twin types are much larger than TTWs,they usually have a smaller volume fraction during the plastic deformation of Mg alloys.Therefore,the current improvements in the microstructure and mechanical properties of Mg alloys are mainly concentrated in {10-12} TTWs,while other twins are rarely used in Mg alloys.

Fig.16.Schematic of microstructural evolution during SSM.The boundaries in blue represent twin boundaries and the “T” symbols represent dislocations[168].(For interpretation of the references to color in this figure legend,the reader is referred to the web version of this article.).

Fig.17.Erichsen tests results: (a) typical profiles of deformed as-received sample,IPC-T sample (in-plane pre-compression sample along TD compression) and IPC-TR sample (in-plane pre-compression sample compressed along TD and then RD),and (b) typical load-displacement curves during Erichsen test [44].

Fig.18.Scanning electron microscopy (SEM) images of voids seen in alloy ZK60 strained to failure at RT.(a) secondary electron image showing voids,(b) EBSD-Kikuchi band contrast map showing {10-11} TB (56° <1-210>±7°),(c) EBSD-Kikuchi band contrast map showing {10-11}-{10-12} TB(38° <1-210> ±7°) and (d) {10-12}-{10-12} twins of the AZ31 sample surface near the fracture region [65,176].

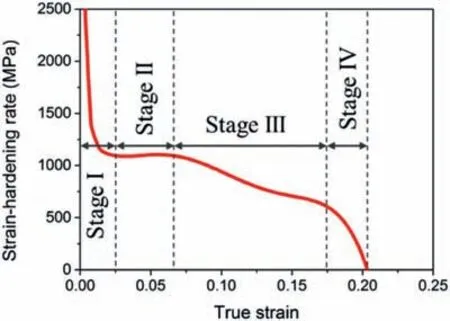

5.3.Relationship between twinning and strain hardening

Strain hardening effects are often studied for plastic deformation as a characterization of metallic materials.Good strain hardening ability indicates acceptable strength and ductility of the alloy [177].The conventional view is that strain hardening arises from the dynamic interaction of dislocations with barriers,such as GB,precipitates and solutes,etc.[178,179].The current study has demonstrated that twinning also has a strong influence on the strain hardening curve [180].Fig.19 shows the strain hardening rate versus the true strain curve of the Mg-Yb alloy.In general,the strain hardening rate of Mg alloys always decreases as the strain progresses [181].The strain hardening rate exhibits an abnormal increase in Stage II,which is mainly attributed to the onset of deformation twinning.The relationship between twinning and strain strengthening can be summarized as follows: (1) The activation of twins divides the grains and shortens the effective distance of dislocation slip,and promoting strain hardening through the Hall-Petch effect;(2) Twins change the orientation of the crystal lattice (hard or soft orientation);(3) The Basinski hardening mechanism states that a twin region in a slightly strained matrix should be harder than an adjacent non-twinned matrix of the same grain [177,179,180].

6.The effect of twins on corrosion properties

Poor corrosion resistance is another major problem that limits the development of Mg alloys [182–185].There are many factors that affect the corrosion rate of Mg alloys,including grain size,second phase size and distribution,crystal defects,and so on [186].This article mainly analyzes and discusses the effect of twins on the corrosion resistance of Mg alloys.

6.1.Corrosion mechanism

Before that,it is necessary to describe the corrosion mechanism of Mg alloy.Firstly,due to the low standard electrode potential (-2.37 V),Mg is very active and easily corroded,especially in moisture and aqueous solutions.As shown in Eqs.(2)–(4),Mg(OH)2corrosion products are formed on the surface of Mg,and H2is released at the same time.Although Mg(OH)2corrosion product has a certain protective effect,it is easily damaged by Cl ions,which is also an important factor in the rapid corrosion of biodegradable Mg alloys in physiological environments.Furthermore,the galvanic corrosion caused by the potential difference between the substrate and the second phase also has a significant impact on the corrosion resistance of the Mg alloy [187].

Fig.19.Strain hardening rate vs.true strain curve of the Mg-Yb alloy [179].

6.2.The relationship between twins and corrosion

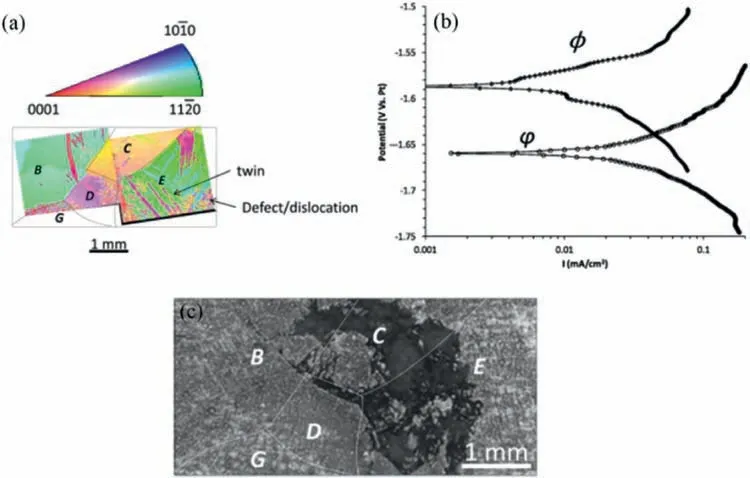

From an energy point of view,corrosion is more likely to occur near higher energy atoms.Generally speaking,the energy of the atoms in the twin region is higher than the energy of the atoms regularly arranged in the crystal [188].This means that twins are more likely to preferentially provide locations for corrosion.The experimental results of some researchers have also verified the above view.For example,Aung and Zhou [189] found that the corrosion resistance of the AZ31B alloy was significantly reduced due to the twins accelerated intra-granular corrosion.In another study [190],the grain size (9–14 mm) of AZ31 alloy after equal channel angular extrusion (ECAE) was similar to that of conventional extrusion,but the high density of dislocations and twins in the former led to an increase in corrosion rate.The main drawback of this experiment is that the influence of the morphology and distribution of the second phase on corrosion is not considered.To exclude other factors such as secondary phases and solute segregation,Song et al.[191] investigated the difference in corrosion resistance between different grains in pure Mg.The results (as shown in Fig.20) show that the basal plane has a higher corrosion potential,a lower corrosion current density,and a tendency to form thinner and higherresistance corrosion product films.Compared with other crystal planes,the basal plane exhibits the best corrosion resistance [191].In other words,defects in Mg alloys (such as twins) are considered to be the place where corrosion begins preferentially.

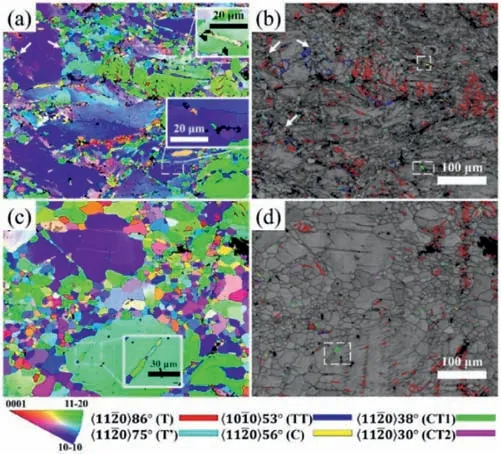

In addition,Sabbaghian et al.[192] investigated the relationship between twins and corrosion behavior in extruded biodegradable Mg-4Zn alloys and found that stress concentration at TB had a negative effect on corrosion resistance.A similar phenomenon was found by Wang et al.[193],the high KAM at TB indicated that the accumulation of dislocations led to stress concentration.At the same time,as shown in Fig.21,relatively severe corrosion occurred at the TB.Interestingly,the corrosion degree around {10-11}-{10-12} DTWs was more severe compared to {10-11} CTWs.These indicate that the high local stress generated at TB increases localized corrosion around the twins.

Fig.20.(a) EBSD grain distribution,(b) polarization curves measured from spots D and E of the surface of the Mg coupon immersed in 0.01 M NaCl solution and (c) optical microscopic image of the Mg coupon after 180 min immersion in the 0.01 M NaCl solution [191].

Fig.21.(a–c) SEM image of the surface morphology for Mg-2Zn-20% (20% hot rolling reduction) following 1 h immersion in simulated body fluid solution at 37 °C.Insert in (a) is the EBSD IPF map to reveal the twin types [193].

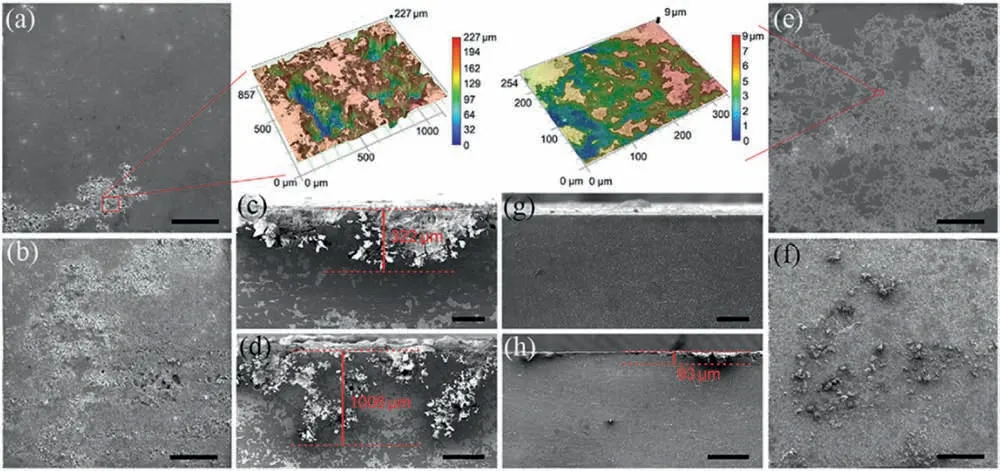

Fig.22.Corrosion morphology after exposure to 3 wt.% NaCl solution.AZ80-T6 after (a) 24 h and (b) 168 h,scale bar=2 mm in a and b;aged UFT-4 after (e) 24 h and (f) 168 h,scale bar=2 mm in (e) and (f).Cross-sectional views of AZ80-T6 after (c) 24 h and (d) 168 h,scale bar=200 μm in (c) and scale bar=500 μm in (d).Cross-sectional views of aged UFT-4 after (g) 24 h and (h) 168 h,scale bar=200 μm in (g) and scale bar=500 μm in (h)[61].

However,some studies have reported the opposite conclusion that twins are beneficial for corrosion resistance.For example,AZ31 alloy sheets were compressed at different strains to introduce different TTWs volume fractions,and the corrosion resistance properties of the alloys under various conditions were compared.The corrosion rate first decreased and then increased with the increase of the twin volume fraction,and the corrosion resistance of the AZ31 alloy at 6% strain was the best.Notably,the TB volume fraction reached a maximum at 6% strain,and the twins grew and swallowed each other under continuous loading,ultimately leading to a reduction in TB [194].As the surface energy of TB is lower than that of HAGB,TB with high density and uniformity is conducive to reducing the occurrence of localized corrosion and thus slowing down the corrosion rate [11].

In general,the corrosion resistance of Mg alloys increases with grain refinement [195,196].As mentioned earlier,MDIF is an effective method to obtain ultrafine grains and more twins.It can be seen from Fig.22 that compared with AZ80-T6,the AZ80 alloy prepared by MDIF is more uniformly corroded in NaCl solution for 24 h and 168 h,and the thickness of the corrosion product is significantly reduced [61].A large number of twins not only refine the grains,but also evenly separate the distribution of second phase during the hot working process.This makes Mg alloys have a lower tendency to galvanic corrosion,which greatly inhibits the occurrence of localized corrosion [197].The comprehensive mechanical properties and corrosion resistance are improved at the same time,which provides a valuable idea for the actual production of corrosion-resistant high-strength Mg alloys.

For Mg-RE alloys,the introduction of twins is beneficial to improve corrosion resistance.Excluding the effects of grain size,texture,and secondary relative corrosion,Zou et al.[198] found that the corrosion rate of Mg-Y alloy containing TTWs was relatively low.Liu et al.[46] also found that TTWs avoided further erosion by NaCl solution by promoting the formation of a dense surface film,which effectively improved the corrosion resistance of the Mg-7Gd-5Y-1Nd-0.5Zr alloy.The reason for this difference is believed to be that RE plays a positive role in the corrosion process.On the one hand,the twins with higher surface energy form micro-galvanic corrosion with Mg matrix,which accelerates the dissolution of Mg matrix.On the other hand,due to the high chemical activity of RE,this process promotes the formation of RE-rich oxide and hydroxide surface films in Mg alloys [199].Compared with non-Mg-RE alloys,the protective effect of surface film is dominant in Mg-RE alloys,so it is generally believed that the twins of Mg-RE alloys play a positive role in improving corrosion resistance [198].

7.Summary and overall outlook

Mg alloys have broad prospects for development in terms of energy saving and emission reduction due to their low density.However,its low strength and poor RT formability have severely restricted their wide application.At present,a large number of studies have shown that twinning has made outstanding contributions to regulating microstructure and improving mechanical properties and corrosion resistance.This article reviews the common types of twins in Mg alloys,the influencing factors of twins,and the improvements of twins on the structure and properties of the alloy.The most important conclusions are effectively summarized as follows:

(1) {10-12} TTWs,{10-11} CTWs,{10-11}-{10-12} and{10-12}-{10-12} DTWs are the common twin types of Mg alloys in plastic deformation process.Compared with the other three,{10-12}-{10-12} twins are less prone to appear under uniaxial stress.

(2) During plastic deformation,temperature,grain size,initial grain orientation,strain parameters,precipitates and alloying elements have significant effects on the twinning behavior in Mg alloys.By controlling the influencing factors,it is expected to achieve a satisfied twin structure,so as to hit the desired goals in terms of microstructure,mechanical properties and corrosion resistance.

(3) It is generally agreed that {10-11} CTWs,{10-11}-{10-12} DTWs can promote DRX,while for {10-12}TTWs,opinions are divergent.Ultimately,whether recrystallization can be stimulated depends on the local strain of twins and the strain energy stored by adjacent grains.Furthermore,the mutual intersection of a large number of twin-twin and twin-LAGB in the same grain can also form new grains.

(4) {10-11} CTWs,{10-11}-{10-12} and {10-12}-{10-12}DTWs are closely related to the formation of cracks and voids due to the large local stress concentration.Therefore,they are rarely introduced into Mg alloys to improve the structure and performance.Studies have shown that the migration of TB can release internal stress,but its migration is not conducive to the increase of strength,so it will be an interesting solution to coordinate the migration of TB.

(5) The specific effect of twins on the corrosion of Mg alloys is controversial.On the one hand,it forms a microgalvanic couple with the Mg matrix to accelerate corrosion;on the other hand,the twin region preferentially forms a uniform oxide layer.In other words,the twins of different Mg alloys are affected by distinct factors and play different roles in corrosion process.

Declaration of Competing Interest

The authors declare no conflicts of interest.

Acknowledgments

This research was financially supported by the National Key Research and Development Program of China (Grant No.2021YFB3701004),the National Natural Science Foundation of China (Grant Nos.51971054 and 52171055) and the Fundamental Research Funds for the Central Universities(N2009006 and N2107007).

杂志排行

Journal of Magnesium and Alloys的其它文章

- Microstructures and mechanical properties of titanium-reinforced magnesium matrix composites: Review and perspective

- A review of effective strides in amelioration of the biocompatibility of PEO coatings on Mg alloys

- The mechanisms of grain growth of Mg alloys: A review

- A new nano-scale surface marking technique for the deformation analysis of Mg-based alloys

- Additive friction stir deposition of AZ31B magnesium alloy

- Nonisothermal dissolution kinetics on Mg17Al12 intermetallic in Mg-Al alloys