Microstructures and mechanical properties of titanium-reinforced magnesium matrix composites: Review and perspective

2022-10-24HongYangXianhuaChenGuangshengHuangJiangfengSongJiaSheJunTanKaihongZhengYimingJinBinJiangFushengPan

Hong Yang ,Xianhua Chen,* ,Guangsheng Huang ,Jiangfeng Song ,Jia She ,Jun Tan ,Kaihong Zheng,Yiming Jin,Bin Jiang,Fusheng Pan,*

aNational Engineering Research Center for Magnesium Alloys,Chongqing University,Chongqing 400044,China

bCollege of Materials Science and Engineering,Chongqing University,Chongqing 400044,China

c Institute of New Materials,Guangdong Academy of Sciences,Guangzhou 510650,China

d Southwest Technology and Engineering Research Institute,Chongqing 400039,China

Abstract Currently,many gratifying signs of progress have been made in magnesium (Mg) matrix composites (MMCs) by virtue of their high mechanical properties both at room and elevated temperatures.Although the commonly used reinforcements in MMCs are ceramic particles,they often provide improved yield and ultimate stresses by a significant loss in ductility.Therefore,hard metallic phases were introduced as alternative candidates for the manufacturing of MMCs,especially titanium (Ti).It has a high melting point,high Young’s modulus,high plasticity,low level of mutual solubility with Mg matrix,and closer thermal expansion coefficient to that of Mg metal than that of ceramic particles.It is highly preferable to provide both high ultimate stress and ductility in Mg matrix.However,many critical challenges for the fabrication of Ti-reinforced MMCs remain,such as Ti’s homogeneity,low recovery rate,and the optimization of interfacial bonding strength between Mg and Ti,etc.Meanwhile,different fabrication methods have various effects on the microstructures,mechanical properties,and the interfacial strength of Ti-reinforced MMCs.Hence,this review placed emphasis on the microstructural characteristics and mechanical properties of Ti-reinforced MMCs fabricated by different techniques.The influencing factors that govern the strengthening mechanisms were systematically compared and discussed.Future research trends,key issues,and prospects were also proposed to develop Ti-reinforced MMCs.

Keywords: Magnesium matrix composites;Ti;Microstructures;Mechanical properties;Fabrication techniques.

1.Introduction

As the lightest metal structural materials,magnesium (Mg)alloys have excellent application prospects in automotive transportation,aerospace,and electronic products,which have led to their rapid development owing to the growing concern on energy saving and CO2emission reduction [1–3].Nevertheless,the broader implementation of Mg alloys was severely restricted because of their limited properties,such as relatively low ductility,low elastic modulus,poor creep and corrosion resistance [4–9].To resolve these limitations,alloying elements or the introduction of reinforcements were utilized to improve the mechanical properties of Mg alloys [10–17].In particular,extensive investigations have been devoted to manufacturing the Mg matrix composites (MMCs) [18–22].

A consensus has been achieved in the previous research that the mechanical properties of MMCs,both at room and elevated temperatures,can be significantly enhanced by the incorporation of reinforcements via distinct fabrication methods [23–28].Various reinforcements have been successfully adopted in MMCs,such as ceramic particles,fibers,and whiskers.Among them,the commonly used reinforcements are SiC,Al2O3,AlN,TiB2,Y2O3etc.[23,29–38].However,they often provide improved yield and ultimate stresses at the expense of ductility due to the significant rigidity difference between the Mg matrix and the reinforcements.To achieve a better balance of high strength and ductility,hard metallic particles were introduced as alternative candidates to enhance the Mg matrix,such as nickel (Ni),copper (Cu),molybdenum (Mo) and titanium (Ti) etc [39–49].They usually show high melting points,high Young’s modulus,high plasticity,low level of mutual solubility with the matrix,and closer thermal expansion coefficients to Mg metal than those of ceramic particles [50–52].Notably,among the hard-metallic elements,Cu and Ni are inclined to form intermetallic compounds with Mg,such as Mg2Cu [53] and Mg2Ni [54],which prevents them from being used as hard metal particles to strengthen the Mg matrix.Mo has no interfacial reaction with Mg matrix [40],but its wettability with Mg and its grain refinement effect have not been widely reported.Ti shows a potential coherent lattice relationship with Mg.It has a neglected ultimate solid solubility in Mg alloys,and it is more deformable than ceramic particles,which is of the ideal choice for the preparation of metal-reinforced MMCs.

To date,considerable efforts have been devoted to introducing metallic Ti in Mg alloys to achieve both high strength and ductility.It is reported that many factors affect the mechanical properties of Ti-reinforced MMCs,including grain size,intermetallic phase,uniformity of Ti,and the interfacial bonding strength between Ti and Mg,etc.,while some of these factors might be dominant under distinct fabrication methods.Hence,in this review,the advantages and challenges of Ti were firstly introduced as a background.Then the microstructural characteristics and mechanical properties of Ti-reinforced MMCs were elaborately collected and discussed based on different manufacturing techniques.Particular focus was on correlating their microstructural evolution with strengthening mechanisms and mechanical properties in Ti reinforced-Mg alloys.Research trends,key issues,and prospects were also proposed for the future development of Ti-reinforced MMCs.

2.Advantages and challenges of Ti

2.1.Advantages of Ti

2.1.1.Grain refinement strengthening of Ti

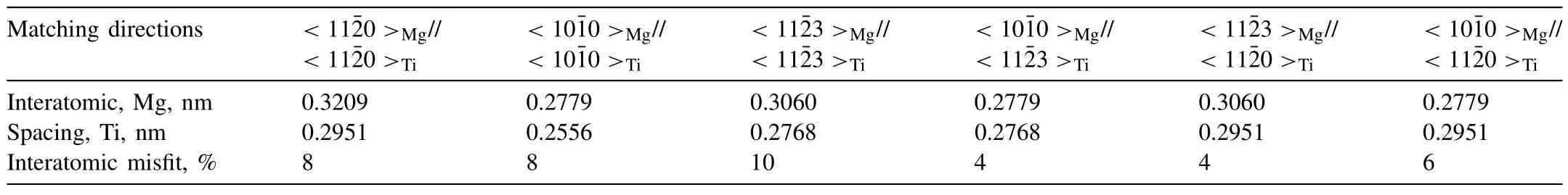

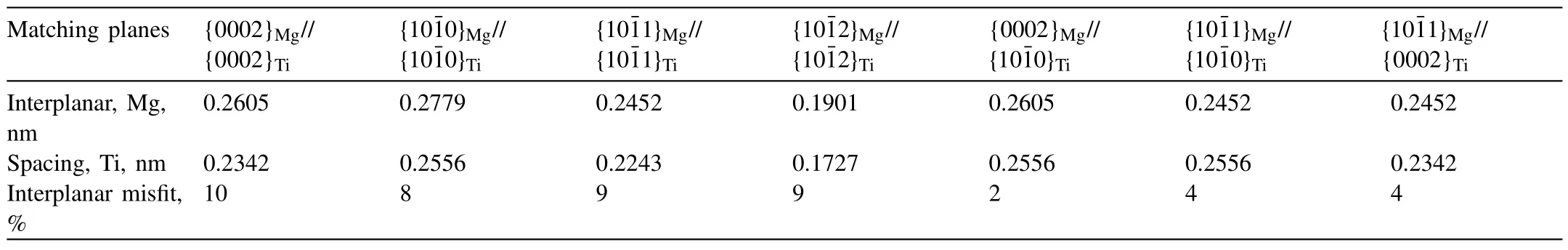

To evaluate whether a metal element can act as an effective grain refiner for a metal matrix,Zhang et al.[55–58] developed an edge-to-edge matching (E2EM) model to calculate their potential crystallographic match.They proposed that when the crystallographic mismatch between the possible nucleant phase and the matrix was below 10%,the nucleant phase was considered as an effective grain refiner for the matrix.Based on this model,Ti and Mg’s interatomic spacing misfits along with possible matching directions,and the interplanar spacing misfits between possible matching planes are calculated in Tables 1 and 2,respectively [59].They revealed that all their misfits are equal to or less than 10%,especially for<100>Mg//<113>Tidirections and {0002}Mg//{100}Tiplanes with low values of 4% and 2%,respectively.It indicates that Ti has a potential grain refinement effect in Mg alloys,which might create a significant grain refinement strengthening according to Hall-Petch equation [51,60–65].A “growth restriction factor” (GRF,Q-value) was commonly utilized to evaluate the ability of solute to refine grains in Mg alloys [66].St John et al.[67] theoretically calculated that the Q-value of Ti is 59500.This value is more than three orders of magnitude higher than Zr (38.29),which is the commonly used grain refiner in Mg alloys.The Q-value of other metallic elements,such as Cu and Ni,are 5.28 and 6.13,respectively.However,Mo’s Q-value was not yet reported.

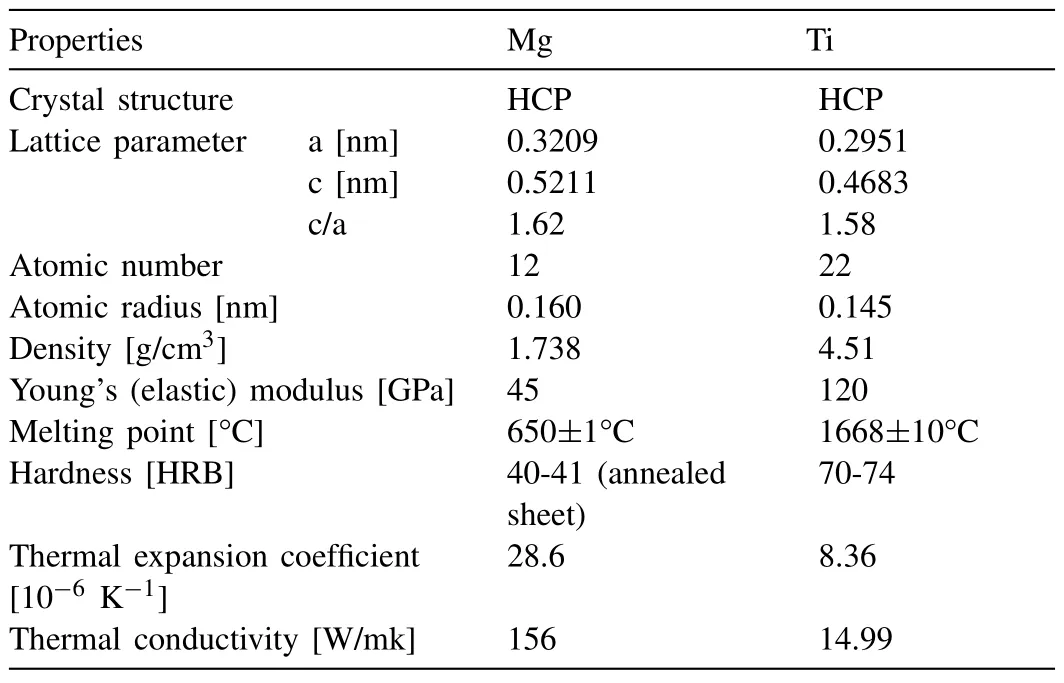

2.1.2.Orowan strengthening of Ti

Ti usually exists as a divorced particle in the Mg matrix due to its highly marginal ultimate solid solubility in Mg (0.12 at.% at 927 K [68]).It also shows much higher Young’s modulus,melting point,and hardness than Mg (Table 3),indicating that Ti is strong enough to resist the dislocation penetration during deformation and to empower Orowan strengthening in the Mg matrix [31,69–73].Zhang and Chen[74] pointed out that the size of particles significantly influenced the Orowan strengthening in MMCs.For the MMCs with 5 μm or larger particles,Orowan strengthening was not a dominant factor influencing the properties.On the contrary,uniform distribution of nano-sized particles (<100 nm)is beneficial to creating Orowan strengthening in Mg matrix nanocomposites(MMNCs),even with a small volume fraction below 1%.Zhang and Chen [75] claimed that the critical size of nanoparticles for creating the Orowan strengthening is 5.44 times the Burgers vector or atomic diameter of the matrix in Ti/Y2O3MMNCs and Al2O3/Mg composites.However,the extremely tiny Ti particles are inclined to cause particle agglomeration in the matrix,further deteriorating their Orowan strengthening effect.Hence,in the design of Ti-reinforced MMCs,it is essential to consider both the size and dispersion morphology of Ti particles in the Mg matrix to maximize their Orowan strengthening effect.

Table 1 The interatomic spacing misfits along with possible matching directions between Ti and Mg matrix [59].

Table 2 Interplanar spacing misfit between possible matching planes of Ti and Mg matrix [59].

Table 3 Physical and mechanical properties of Mg and Ti [25,76–80].

2.1.3.Load transfer effect of Ti

In particle-reinforced MMCs,effective load transfer occurs when a good interfacial bonding is achieved between the particles and matrix,in which reinforcements take up part of the external stresses instead of the matrix [30,70,81–85].Based on the modified shear-lag model [86,87],the effective load transfer effect in MMCs is mainly affected by the size and content of Ti reinforcements.However,without a strong interfacial bonding strength,it is difficult to create load transfer strengthening even with appropriate particle size and content.It was proposed that a high interfacial bonding strength and effective load transfer effect in MMCs can be achieved due to the excellent wettability between Ti and Mg.Kondoh et al.[51] evaluated the wettability of Ti by molten pure Mg using the sessile drop method to manufacture Ti-reinforced MMCs.They found the equilibrium contact angle was 31° between molten pure Mg droplets on the Ti substrate,which was apparently smaller than using TiC and SiC as the substrates.Therefore,the wettability between Mg and Ti was much better than the commonly used ceramic reinforcements in MMCs theoretically.Furthermore,as the Ti particle size decreases,the interfacial bonding between Ti and Mg matrix becomes stronger due to the reduced surface defects on the particles.

Besides,no chemical reactions occur at the interface of Mg/Ti,which is also beneficial to increasing the strength of the Mg matrix by an effective load transfer from Mg to Ti without sacrificing plasticity [30,70,81–88].Yu et al.[89] calculated the increment of YS from load transfer strengthening in extruded Ti/AZ31 alloy [90],which is estimated to be approximately 5.4 MPa from 15 at.% Ti particles.In Table 3,Young’s modulus of Ti(120 GPa)is approximately 2.67 times than that of Mg (45 GPa),allowing Ti to be strong reinforcements in the Mg matrix to withstand the applied stress.In particular,Young’s modulus of Ti is significantly smaller than that of commonly used ceramic particles (such as SiC:401 GPa [91]),which signifies that Ti is more deformable than ceramic particles.This ensures better plasticity and wear properties than those matrices reinforced with ceramic particles.

Moreover,the c/a ratio of Ti is 1.58,indicating that Ti’s basal plane is less packed than that of Mg (1.62) and comparable to its prismatic and pyramidal planes.Hence,the prismatic and pyramidal planes of Ti are more easily to be activated than that of Mg and it shows better ductility than Mg[92].Ti can also decrease the axial ratio (c/a) of Mg alloys,making it further deformable to transfer the externally applied load from the matrix to itself [93,94].

2.1.4.EM and CTE strengthening of Ti

Table 3 displays that Ti’s elastic modulus (EM) is nearly three times that of Mg,while its coefficient of thermal expansion (CTE) is nearly one-third that of the latter [95].Their mismatch of EM and CTE could create a high density of geometrically necessary dislocation in the vicinity of their interface,which accordingly yields a higher level of internal stress [96–99].Furthermore,the dislocation density generated from the mismatch of EM [100] and CTE [101] could significantly contribute to the yield strength,thus improving the mechanical properties of Ti-reinforced MMCs.

2.2.Challenges for the fabrication of Ti-reinforced MMCs

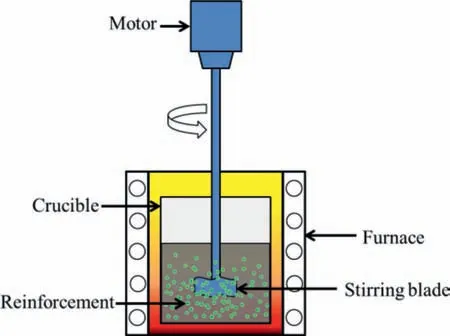

Fig.1.Schematic diagram of stirring casting machine.

Although Ti was considered as an excellent candidate for the fabrication of MMCs,one crucial challenge of introducing the metallic Ti into the liquid Mg matrix remains.The density discrepancy between Mg and Ti is relatively more significant than between Mg and ceramic reinforcements (such as SiC)(Table 3).By using the conventional casting method,such as stir casting,metallic Ti tends to quickly settle down to the bottom of the crucible,which severely limits the recovery rate and grain refinement of Ti in Mg alloys.The segregation ability of solute Ti in the Mg matrix also remains contradictory due to the scarce information of the liquidus and solidus lines in the Mg-Ti phase diagram [102].The next challenge is to effectively enhance the interfacial bonding strength of Ti/Mg with improved wettability and reduced impurities,especially for Ti-reinforced MMCs prepared by powder metallurgy.The 3rdchallenge is how to effectively optimize the microstructural characteristics of intermetallics in Mg alloys by Ti particles,including morphology,size,distribution,etc.A fundamental understanding between Ti and the formation of intermetallic phase needs to be further clarified.Lastly,the effect of Ti on the corrosion behavior of Mg alloys is of key practical implications,as it is essential to acquire appropriate mechanical properties both before and after Mg degradation.Although galvanic corrosion might be generated due to their potential difference,the addition of Ti particles are not bound to reduce the corrosion resistance of Mg alloys [103].Candan et al.[104] reported that AZ91 with addition of Ti showed apparently high corrosion resistance under the same cooling condition.Cheng and co-authors [105] claimed that Ti particles can promote uniform corrosion of Mg matrix and acquire better corrosion resistance by changing the shape of LPSO (long-period stacking order) phase.Although revealing the corrosion mechanism of Ti on Mg alloys is well worth investigating,it is not the focus of this review and therefore this part will not be analyzed in detail here.

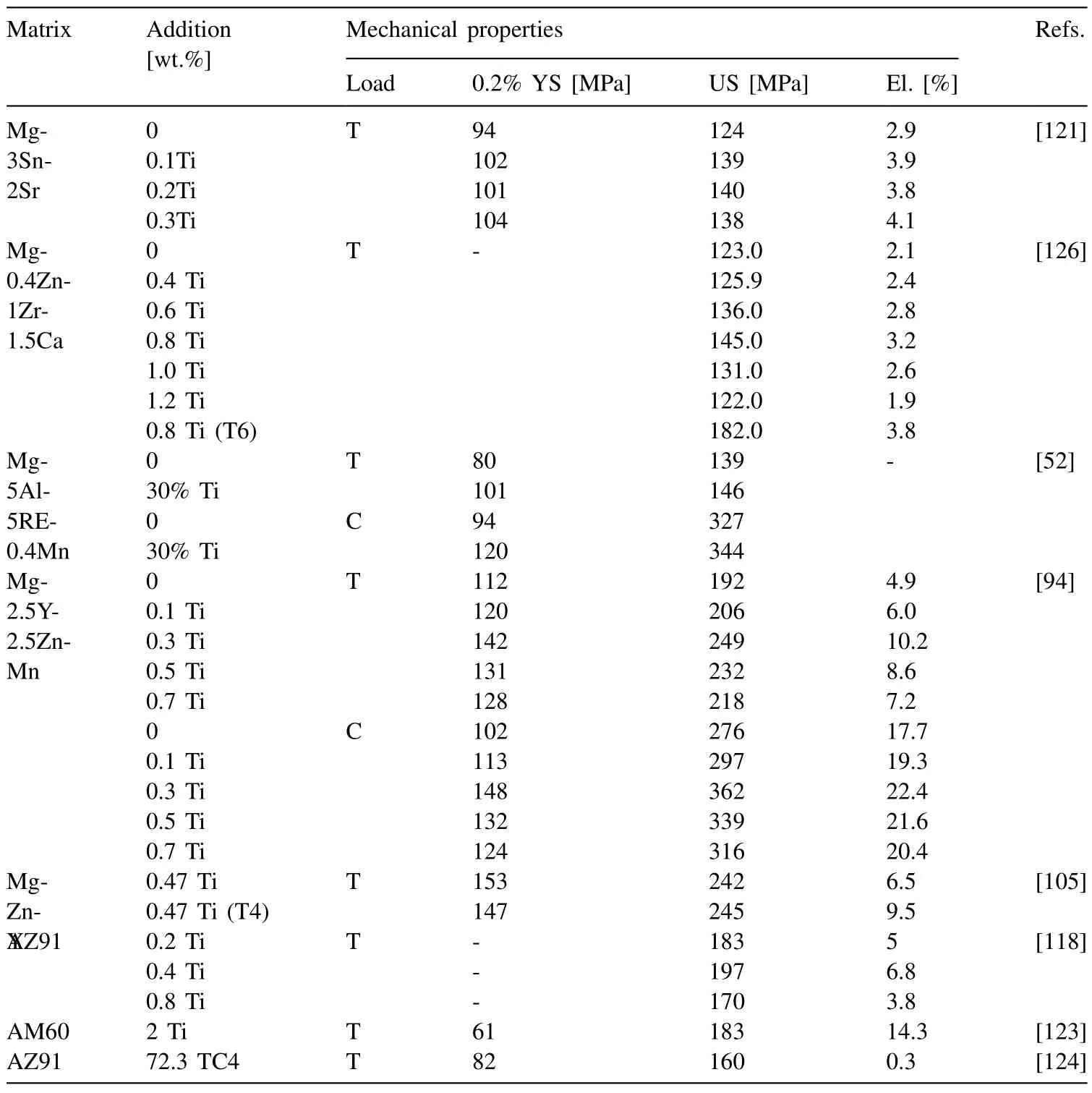

Table 4 Mechanical properties of Ti particles reinforced Mg-based composites prepared by stirring casting (T: tensile,C: compressive).

In the following sections,the microstructures and mechanical properties of Ti-reinforced MMCs are classified and discussed according to different fabrication methods based on recent literature.The microstructural characteristics such as grain size,intermetallic phase,precipitation behavior,and interfacial bonding of Ti/Mg,which significantly affect the mechanical properties and strengthening mechanisms,are underlined.

3.Microstructures and mechanical properties of Ti-reinforced MMCs

3.1.Ti-reinforced MMCs prepared by stir casting

3.1.1.Stir casting

Stir casting method was initiated by S.Ray in 1968 to fabricate ceramic particles reinforced materials [106] (Fig.1),which shows high production efficiency,simplicity and flexibility.Especially for its manufacturing cost,it is only approximate one-third to one-tenth compared to other methods of preparing MMCs [107].Four main factors affect the stirring effect during casting,including stirring temperature,stirring speed,stirring time,and types of stirrers [72,108–115].

Based on recent literature,for stir cast Ti-reinforced MMCs,the amount of Ti in Mg is significantly limited due to its settlement in the bottom of the crucible.Hence,its recovery rate,addition amount,dispersion morphology,and grain refinement effect are of paramount importance to influence the mechanical properties of stir cast Ti-reinforced MMCs.Meanwhile,influences of Ti on the intermetallic phase,precipitation behavior and interfacial reaction at Mg-Ti interface are also highlighted in these literatures.

3.1.2.Microstructures and mechanical properties

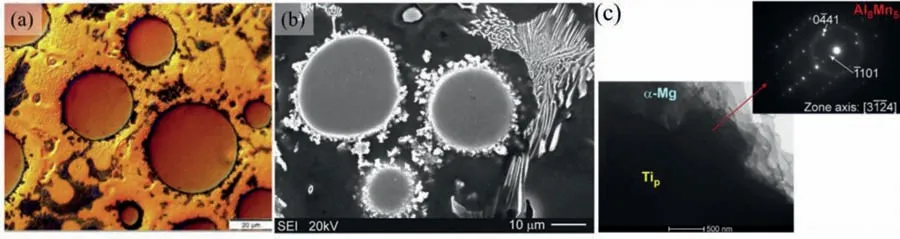

When preparing Ti-reinforced Mg alloys by stir casting,Ti can be introduced in two forms: Al-Ti master alloys and Ti particles.Since Mg and Ti are almost insoluble [116],it is difficult to produce Mg-Ti master alloys.Nagasivamuni and Ravi[117]selected Al-12.5Ti(wt.%)as a master alloy to prepare Mg-3Al-Ti and Mg-9Al-Ti composites.They observed that Al-12.5Ti contains plentiful polygonal shaped Al3Ti particles (Fig.2(a)).Ai and Quan [118] utilized Al-6Ti master alloy to fabricate AZ91-xTi (x=0.2,0.4,0.8 wt.%) composites.They found that when Al-Ti master alloys were added to Mg alloys,the original Al3Ti contained in the master alloy was still present in the matrix as particles,rather than pure Ti (Fig.2(b)).However,it is widely acknowledged that Al3Ti particles are much brittle,they are prone to cause stress concentration and initiate cracks under applied stresses [119].Moreover,Al-Ti master alloys contain Al element,it is only suitable for being added to the Al containing-Mg matrix.

Hence,great efforts have been conducted to add Ti particles in Mg alloys.Following a literature review,a significant portion of the work was focused on Mg alloys with less than 1% Ti content [105,120],because Ti particles are inclined to settle down to the bottom of the crucible during melting and thus decreasing their recovery rates.For example,Yang and co-authors [121] added 0.1,0.2 and 0.3 wt.% Ti particles in Mg-3Sn-2Sr alloys.They detected the actual contents of Ti particles to be 0.05,0.11 and 0.20 %,and their recovery rates are 50%,55% and 67%,respectively.Wang et al.[122] reported an even much lower recovery rates of Ti in AZ31 alloy.The nominal contents of Ti were 0.01,0.03 and 0.05 % (wt.%),while their actual contents were only 0.002,0.003 and 0.007 %,respectively,whose recovery rates were calculated to be low values between 10% and 20%.

Fig.2.(a) OM of Al-12.5Ti master alloy [117],(b) as-cast microstructures of AZ91-0.8Ti [118].

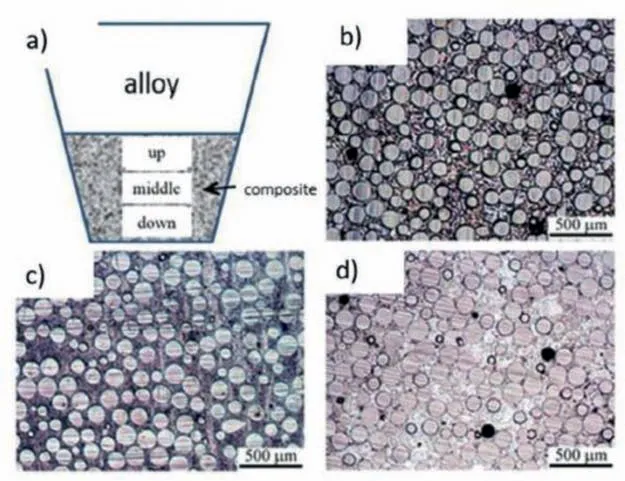

In order to improve the recovery rate of Ti and increase its addition amount in Mg alloys,plenty of investigations have been deliberated to optimize the preparation parameters of Ti-reinforced MMCs through stir casting.Pu Dongmei et al.[123] investigated the influence of stirring speed on the microstructures and mechanical properties of AM60 alloys.They stated that stirring speed of 600 rpm at semisolid temperature was beneficial for achieving the maximum UTS and elongation of 2% Ti/AM60 composites (Table 4).At the stirring speed of 600 rpm,relatively larger amount of Ti particles can be stirred into the matrix without apparent settlement,while higher stirring speed caused porosities by solidification shrinkage and gas entrapment.Nevertheless,their content of Ti is still low (2%),which keeps inspiring researchers to develop other ways for fabrication of Tireinforced MMCs.Zhang and co-workers [124] reported a novel liquid settling method via stirring casting to manufacture AZ91 based MMCs with extremely high-volume fraction of TC4 (Ti6Al4V,dp=100 μm,50 vol.%,72.3 wt.%).They took advantage of the density difference between TC4 particles and Mg melt and gave TC4 particles appropriate settling time to obtain dense distribution with high content (Fig.3).Although this stirring method is simple and efficient to introduce high volume content of TC4 particles,it results in uneven distribution of TC4 particles and waste of the upper ingot(Fig.3(b–d)).Meanwhile,its mechanical properties are not competitive compared to conventional AZ91 alloys (Table 4).Wang et al.[46] fabricated 10 vol.% TC4/AZ91 (dp=15 μm)composites following a semi-solid stirring method.The only difference was that they did not use water cooling for solidification,but pressure cooling (100 MPa) in steel mould to avoid particle sedimentation.Using such method,they obtained homogeneous and dense composites with high volume fractions of TC4.

Fig.3.(a) Different sampling position of 20 vol.% TC4/AZ91 composite and (b-d) optical micrographs of upside,middle and downside positions,respectively[124].

Although high recovery rate and high content of Ti particles can be successfully achieved using above stir casting methods,little attention has been paid to the grain refinement effect of Ti particles in these MMCs.Currently,the research on grain refinement of Ti particles is still mainly focused on Mg alloys with lower Ti additions.Theoretically,Ti can play a critical role in grain refinement of Mg alloys.Nevertheless,its grain refinement effect remains controversial in the practical experiments.Some experts proposed that careful controlling Ti content below 0.1 wt.% led to apparent grain refinement,whereas the excess of Ti caused grain coarsening in the stir cast Mg alloys.For instance,Choi and Kim [125] reported that 0.02 wt.% Ti slightly decreased the grain size of AZ61 alloy from 271 μm to 247 μm.Wang’s work [122] revealed that 0.03 wt.% Ti particles led to significant grain refinement in AZ31 alloy (150 μm),while an excess of Ti resulted in a noticeable grain coarsening (600 μm).

In contrast,Yang et al.[121] added trace additions of Ti,from 0.1 to 0.3 wt.% in 0.1 wt.% steps,to Mg-3Sn-2Sr matrix.The additions of 0.1–0.3 wt.% Ti do not have an apparent effect on the grain size,as well as the tensile properties(Table 4).Chen and co-authors [126] increased the content of Ti up to 1 wt.% in Mg-0.4Zn-1Zr-1.5Ca (wt.%) alloy.They claimed that Ti contents below 0.8 wt.% decreased the grain size of Mg alloys,while 1 wt.% Ti addition increased it significantly.Grain coarsening was also reported in 2%Ti/AM60 composites [123],the grain size of AM60 increases significantly from 217 μm to 606 μm with the addition 2% Ti.

These above authors held different views on Ti’s grain refinement effect in Mg alloys.Chen et al.[126] suggested that the grain coarsening effect of excessive addition of Ti resulted from its local segregation,which decreased the number of nucleation particles and led to grain growth.Mg-0.4Zn-1Zr-1.5Ca with 0.8% Ti shows the optimum UTS (145 MPa)and an elongation of 3.2%,which increased by approximately 17.9% and 52.3% compared to that of Ti-free alloy,respectively (Table 4).Yang and co-workers [121] proposed that Ti suppressed the primary SrMgSn phase and promoted the formation of the eutectic SrMgSn phase rather than causing grain refinement.Such result was attributed to the Ti enrichment on the grain boundaries,which inhibited Sn atom diffusion and induced constitutional undercooling ahead of the solid-liquid interface.Pu Dongmei et al.[123] stated the grain coarsening of 2% Ti/AM60 composites resulted from the loss of grain refiner Al and Mn in AM60 matrix,which is rooted in the interfacial reaction between Ti,Al and Mn.

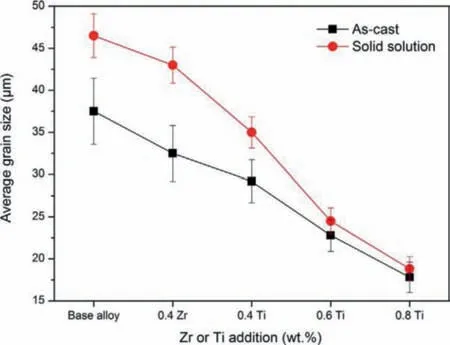

In addition to affecting the grain size of Mg alloys during solidification,Ti particles can also pin the grain boundaries and hinder grain growth at elevated temperatures.Cheng et al.[120] fabricated Mg-10Gd-3Y-1.6Zn with 0.4,0.6 and 0.8 wt.% Ti in an electromagnetic induction furnace followed by T6 heat treatment.Fig.4 shows that an apparent grain growth was observed in the base alloy,while Mg alloy with 0.8 Ti exhibited excellent grain stability after solid solution.They proposed that Ti segregated at the solid-liquid interface,which hindered the grain growth and promoted the constitutional supercooling during solidification.

Fig.4.The average grain size of as-cast and solid solution Mg-Gd-Y-Zn alloy with 0.4Zr,0.4Ti.0.6Ti,and 0.8Ti [120].

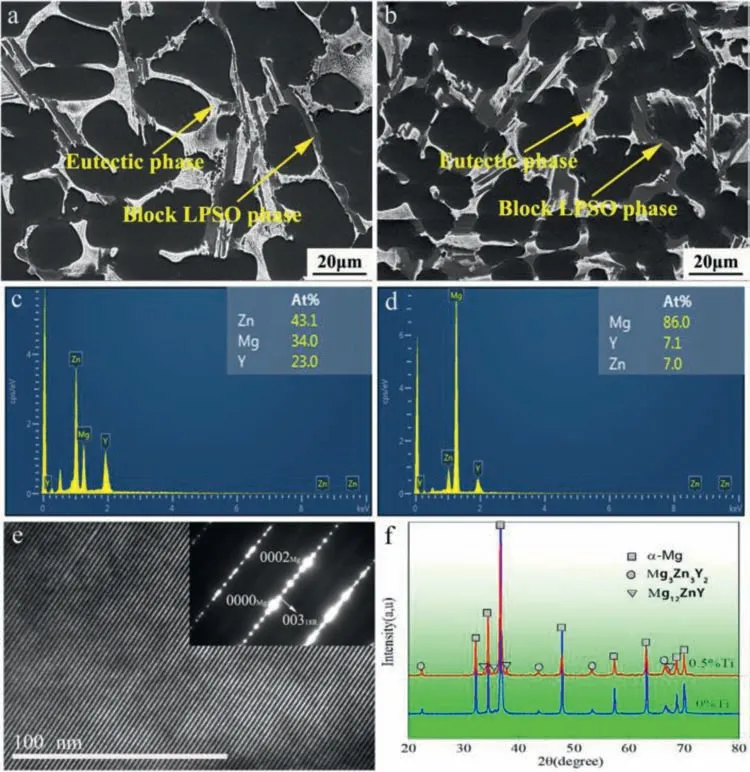

Ti also influences the formation of intermetallic phases in Mg alloys.Hao and co-authors [94] conducted an in-depth study on the interactions between Ti and long-period stacking ordered (LPSO) structure in Mg-Zn-Y-Mn alloy.In Fig.5(a,b),the quantity of block LPSO phase (18R-LPSO) increased while that of eutectic phase (W-phase,Mg3Zn3Y2) decreased.The authors proposed that Ti hindered the migration of Zn and Y atoms,thus suppressing the formation of Zn and Y concentration area and promoting the LPSO phase formation.Besides,0.3 at.% Ti caused the finest grain size in Mg-Zn-Y-Mn alloy,which presents the highest ultimate tensile and compressive properties (Table 4).Nevertheless,Wu et al.[127] used another Mg-Y-Ni-Ti matrix.They reported that Ti addition barely influenced the formation and type of the LPSO phase,but their size was apparently refined.They found Ti mainly concentrated along the grain boundaries,which played an essential role in restricting the grain growth of Mg-Y-Ni-Ti alloy,thereby decreasing the grain size.The optimum content of Ti in Mg-Y-Ni-Ti MMCs was 0.2 at.%,which is quite similar to that in Hao’s work.

Ti particles could also involve the interfacial reactions in Mg alloys,which affect the strength of interfacial bonding and thus the mechanical properties of MMCs.For instance,although Ti does not react with Mg,it can easily segregate and/or react with Al,the commonly used alloying element in Mg alloys.Fig.6(a,b) reveals the microstructures of Mg-5Al-5RE-0.5Mn (AME505) alloy with the addition of 30 wt.%Ti particles via gravity casting [52].Plentiful fine particles with blocky morphology surrounded the spherical Ti particles,identified as Al2RE phase using TEM characterization.These Al2RE particles tightly attached to Ti particles without visible pores or cracks,which could result in Orowan strengthening and load transfer strengthening.Table 4 presents that the addition of 30 wt.% Ti particles notably increased the tensile and compressive yield stresses by approximately 26.2% and 27.6%,respectively.Such improvement resulted from the introduction of Ti particles,which created a higher density of dislocations due to the significant differences of CTE and Young’s modulus between Mg and Ti.Braszczy´nska-Malik et al.[128] also revealed that some particles were formed at the interface of Ti and AM50 matrix.TEM characterization confirmed that these particles were Al8Mn5compound(Fig.6).It is claimed that during solidification Ti particles could act as privileged sites for heterogeneous nucleation of Al8Mn5compound based on solidification curve using Scheil model.Zhang and co-authors [124] reported that an Al2Ti interfacial product was formed at the interface of TC4 and AZ91 alloy.The severe interfacial reaction weakened the load transfer effect and CTE mismatch strengthening of TC4 particles,However,the interfacial product Al2Ti phase can be preferentially formed due to its lowest formation energy,which was strongly embedded into the matrix and can notably increase the mechanical properties of AZ91 alloy by second phase strengthening.

3.2.Ti-reinforced MMCs prepared by powder metallurgy

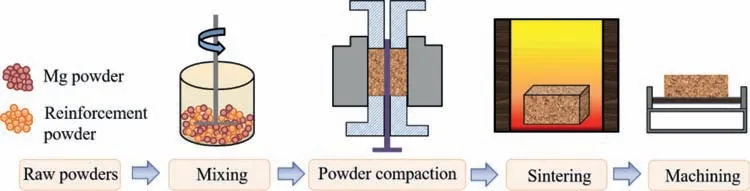

3.2.1.Powder metallurgy

Powder metallurgy (PM) is one of the most versatile methods for fabricating particle-reinforced MMCs,especially for high-quality near-net-shape components [129–134].It generally contains five primary stages: raw powder production,powder mixing,compaction,sintering,and post-machining for specific precision (Fig.7).To achieve a better homogeneity of the powders,the pre-blending process was employed for mixing,such as the ball milling (BM).Careful selections of milling time,milling speed,and the weight ratio of ball to powder ensure a better manipulation of mixed powder structure.

Unlike stir casting operated at temperatures above the melting point,the sintering temperature of PM is lower than the melting point of Mg alloys.Therefore,the possibility of interfacial reaction between Ti particles and Mg matrix is significantly reduced.Meanwhile,Ti particles in the stir-cast MMCs are not easily dispersed uniformly,while the distribution of Ti particles in PM-cast MMCs can be relatively homogeneous.Nonetheless,as the Ti-reinforced MMCs prepared by PM are mechanically compacted,the interfacial wetting behavior of Ti particles and Mg matrix,as well as the interfacial strength,are crucial to the mechanical properties.So far,extensive investigations have been devoted to developing Ti-reinforced MMCs with high strength by PM.Much attentions were paid on the optimization of Ti content or tailoring the wettability between Ti/Mg interface.

3.2.2.Microstructural characteristics and mechanical properties

Initially,researchers selected pure Mg as the matrix to fabricate Ti reinforced Mg composite by PM.Pérez and coworkers [135] fabricated Mg-10 vol.% Ti via powder metallurgical route followed by hot extrusion.Although the extruded Mg-10 vol.% Ti shows a relatively large grain size(~40 μm) compared to pure Mg powders,its strength was comparable to that with finer grain sizes in ceramic particles reinforced pure Mg composites(160 MPa),accompanied with higher ductility.Load transfer from Ti particles was defined as the primary mechanism contributing to improving mechanical properties.Hwang and Nishimura [136] also reported that Ti(325 mesh) addition was beneficial for enhancing the ductility in pure Mg.An excellent ductility with compressive strain above 60%was achieved in Ti reinforced Mg composites(Table 5).However,its reason was not revealed in their work.

Fig.5.SEM images of as-cast (a) Mg94Zn2.5Y2.5Mn1 and (b) Mg93.5Zn2.5Y2.5Mn1Ti0.5,EDS analysis of (c) eutectic phase and (d) block LPSO phase,€TEM micrograph and selected area electron diffraction (SAED) pattern of block LPSO phase,(f) XRD patterns of Mg94Zn2.5Y2.5Mn1 with different Ti contents[94].

Fig.6.(a) The optical microstructure and (b) SEM images of Mg-5Al-5RE-0.5Mn (AME505)-TiP composite,(c) TEM characterization of Ti and AM50 interface [52,128].

Fig.7.Schematic illustration of the PM process.

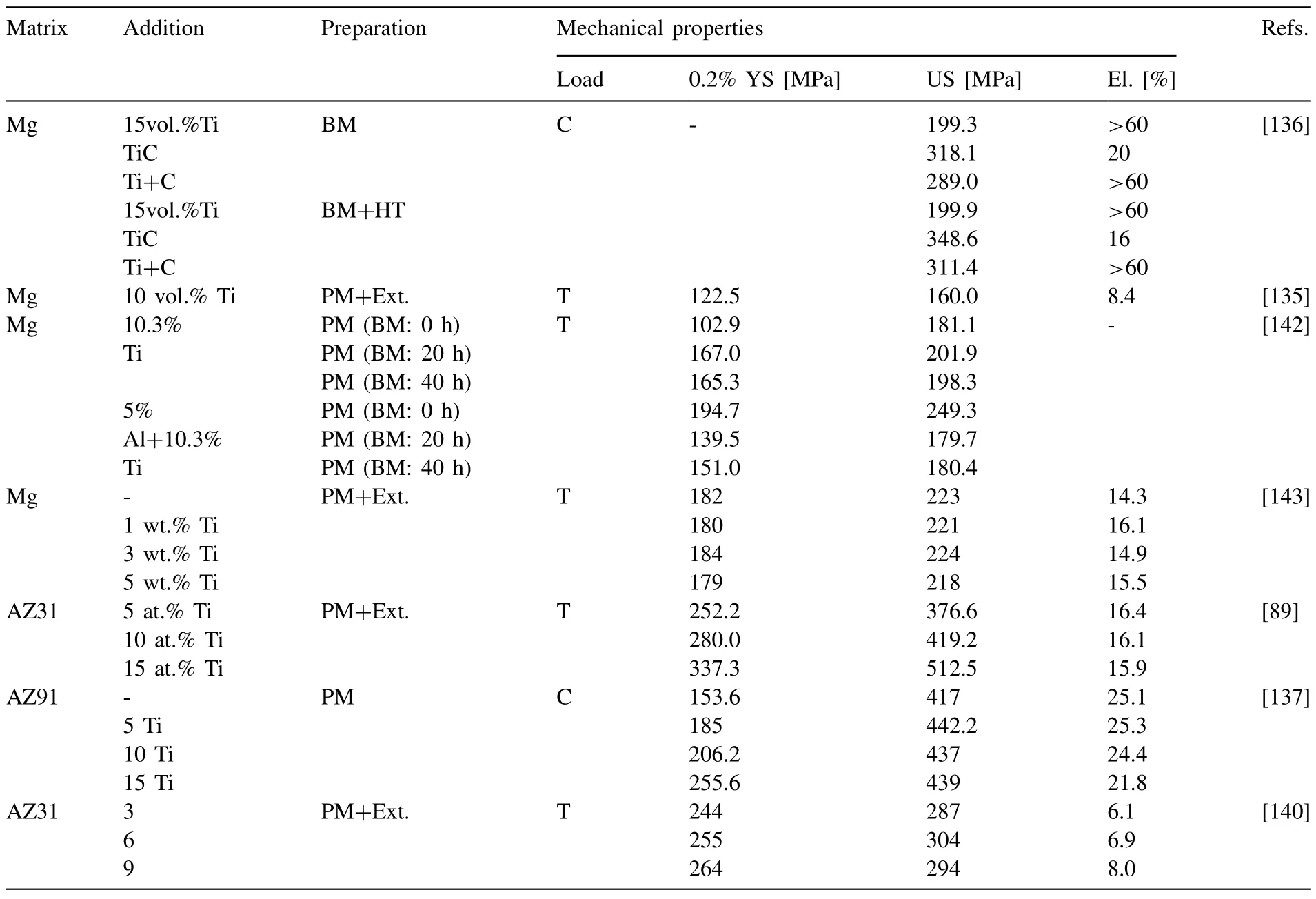

Table 5 Mechanical properties of Ti particles reinforced Mg-based composites prepared through powder metallurgy (T: tensile,C: compressive,HT: heat treatment).

On the basis of pure Mg,the optimum Ti content in AZ31 alloys was revealed by Yu et al.[89],where an in-depth research on the strengthening mechanisms was explored.With increasing the Ti contents from 5 at.% to 15 at.%,the YS and UTS of Ti/AZ31 composites increased apparently from~252 to~337 MPa and~376 to~512 MPa,respectively(Table 5).Ti particles were dispersed homogeneously with no visible clusters in extruded AZ31-15 at.% Ti composite (Fig.8(a)).Some large Ti particles with about 2 μm were visible in the HAADF image,while most Ti particles have much smaller sizes less than 500 nm (yellow ellipse in Fig.8(a)).The authors quantitatively concluded that grain boundary strengthening is mainly responsible for about 70% of the total improvement of mechanical strength.Wu et al.[137] further optimized the content of Ti (dp<37 μm) in AZ91 alloys by spark plasma sintering (SPS) [137].Table 5 reveals that the compressive yield stress (CYS) and ultimate compressive stress(UCS) are simultaneously improved by adding 20 wt.% Ti particles compared to that without Ti,especially the CYS.By analyzing the work-hardening curves,the values of work hardening capacity (Hc) decreased with the increasing content of Ti particles.The authors claimed that Ti has more slip systems than Mg at room temperatures,which reduced stress concentration and the Hcvalues.

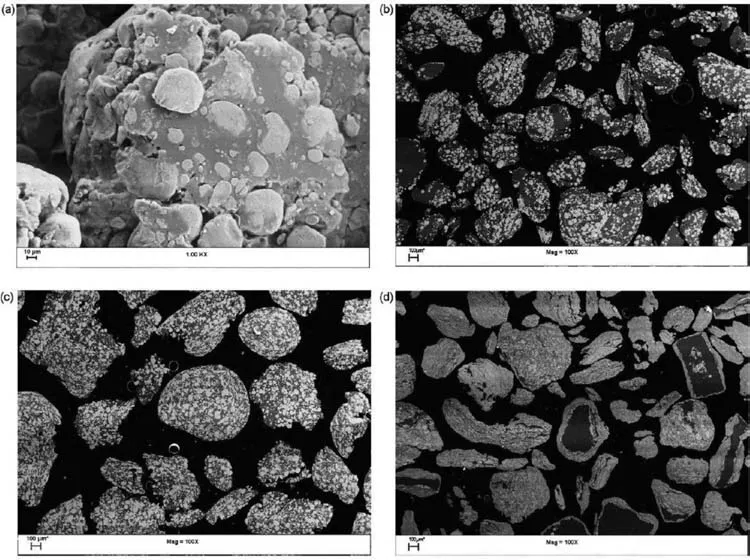

In addition to the optimization of Ti content,the wettability at the Ti and Mg matrix interface is vital to influence the mechanical properties of Ti-reinforced MMCs prepared by PM.The production methods of raw Ti particles were considered as an essential step towards increased wettability and strong interfacial strength of Ti/Mg.Umeda et al.[138] reported that atomized Mg powders with Ti particles(dp=29.8 μm) showed a better wettability at the Mg-Ti interface than elemental mixture of Mg and Ti particulates,which caused effective load transfer strengthening from the matrix to Ti particles.Besides,pre-treatment via ball milling (BM)influences the wettability and morphology of mixed Mg and Ti powders.Phasha et al.[139] found that when Mg and Ti particles were milled at 200 rpm for 8 h,the smaller hard Ti particles (<45 μm) were glued entirely on the surface of coarse Mg particles (>300 μm) (Fig.9(a,b)).With prolonged milling time to 32 h,a layered structure of Mg/Ti powder was produced with an elongated shape along the deformation axis(Fig.9(d)).They proposed that the yield of BM decreased dramatically when the milling time was above 24 h,which was ascribed to the increase of total area that the process control agent did not cover.BM process can also partially change the crystal structure of pure Ti from hcp to fcc,while Mg has no phase transformation under the same milling time (25 h)[92].BM effectively increased the solid solubility of Mg in Ti and transformed its crystal structure from hcp to fcc for Ti75Mg25and Ti50Mg50composites,which are rooted in the accumulation of stacking faults during the severe deformation process [92].

Fig.8.(a) the HAADF image and (b-f) the corresponding EDS mapping of extruded AZ31+15 at.% Ti composite [89].

Fig.9.SEM micrographs of Mg and Ti particles milled for (a) 8 h and (b) lower magnification of (a),Mg and Ti particles milled for (c) 16 h and (d) 32 h at 200 rpm [139].

Fig.10.Optical microstructures of (a) pure Mg-3%Ti composite,(b) as extruded Mg-3%Ti composite [138].

The effect of Ti particles on the grain size of Mg alloys is also controversial.Wu et al.[137]discovered that the addition of 5,10 and 15 wt.% Ti have no significant influence on the grain size of AZ91 alloys.Umeda et al.[138] also revealed that the grain sizes of Mg+1%Ti and Mg+3%Ti composites were 13.54 and 13.46 μm,respectively,which indicate that Ti has no apparent impact on the grain size of Mg matrix.Nonetheless,Ye and co-authors[140]utilized Ti particles with an average diameter of 10 μm to fabricate Ti/AZ31 composites via PM.They found that 3,6 and 9 wt.% slightly refined the grain size of AZ31 alloy from 5.2 μm to 4.6,3.4 and 2.5 μm,respectively.Particle stimulated nucleation of recrystallization during extrusion was the essential cause for its grain refinement.Like stir casting,the grain size of Ti-reinforced MMCs at elevated temperatures was also influenced by the addition of Ti particles due to its relatively high thermal stability (Table 3).Yu et al.[141] manufactured nanocrystalline Ti/AZ61 composite by mechanical milling followed by annealing in a temperature range of 573-723 K.They reported that the submicron original Ti particulates could hinder the grain boundary sliding during annealing,which was beneficial for the improvement of thermal stability.On the contrary,the grain size of nanocrystalline Ti-free AZ61 increased prominently from~68 nm to~309 nm under the same annealing process.

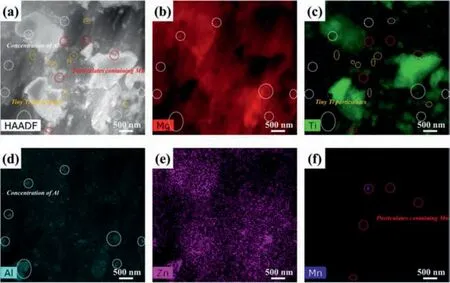

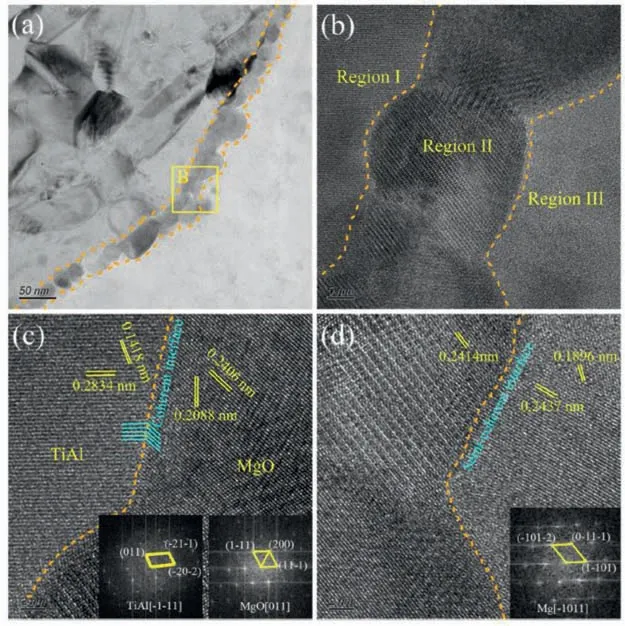

The effect of Ti particles on the Mg-Ti interface is also diverse.Umeda et al.[138]revealed that Ti addition affected the solidification behavior of grains at the interface of Mg and Ti.The dendrite arm spacing (DAS) at different distances from the interface of Ti and Mg matrix was distinct in Mg-3%Ti composite (Fig.10(a)).The DAS was coarser in the distal region of the interface (area B),while it was much refined in the proximal region (area A).The authors explained the cooling rate of Ti particles was slower than that of the Mg matrix,thereby causing a coarse DAS.Ye et al.[140] characterized that Ti particles had a diffusion layer of Al element at its periphery while the edges of Ti particles were rich in oxygen elements (Fig.11).TEM and HRTEM images show that several nano-sized interfacial products were formed along the surface of Ti,which were confirmed as AlTi and MgO particles.Such products greatly improved the interfacial bonding and the strength of MMCs.

3.3.Ti-reinforced MMCs prepared by spray deposition technique

3.3.1.Spray deposition technique

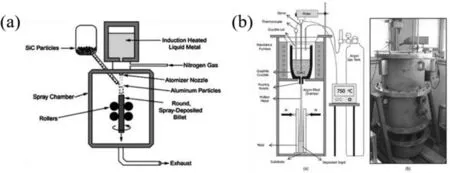

The spray deposition method is an efficient way to produce near-net-shaped components,developed based on PM technology.The droplet stream can be stemmed from a molten bath or the continuous feeding of cold metal into an area with rapid heat injection (thermal spray process) [144–147] (Fig.12(a)).The disintegrated melt deposition (DMD) technique was further developed to combine the merits of traditional casting and spray deposition methods at the National University of Singapore (NUS) in 1994 (Fig.12(b)).It requires higher superheat temperatures and lower impinging gas jet velocity to produce bulk or composite,which is one of the most economical ways to fabricate Al-and Mg-based materials [25,148–153].

Like PM technique,the particle distribution of MMCs prepared by spray deposition is relatively uniform.The difference is that the material is deposited in an inert gas atmosphere,its interfacial reaction,impurity and oxygen content are relatively lower than that prepared by PM.To date,the manufacturing of Ti particle-reinforced MMCs by spray deposition has been mainly reported by the NUS.Many meaningful attempts have been made to optimize the strength of the Ti/Mg interface in Ti reinforced Mg composites,such as hybridization with reinforcements,pre-treatment by BM and chemical wetting through interfacial reactions etc.

3.3.2.Microstructural characteristics and mechanical properties

According to available literatures,the spray deposition technique that was used is mainly DMD technique in Tireinforced Mg composites.Hence,for clearer interpretation,DMD was utilized in the following description.Like PM,the introduction of Ti particles has little effect on the grain size of Mg matrix prepared by DMD.Sankaranarayanan et al.[154] revealed that the addition of 5.6 wt.% Ti (dp<140 μm)only slightly decreased the grain size of Mg from 21±3 to 15±4 μm,whose refinement effect was lower than that of 3%Al in Mg.Hence,most investigations of Ti particle-reinforced Mg prepared by DMD have focused on the optimization of Mg-Ti interfacial strength.

Fig.11.(a) TEM and (b-d) HRTEM images of the interface of Mg and Ti in 9Ti/AZ31 composite.

Fig.12.Schematic illustration of (a) spray deposition method for the fabrication of composites [144] and (b) the used DMD setup in National University of Singapore [25].

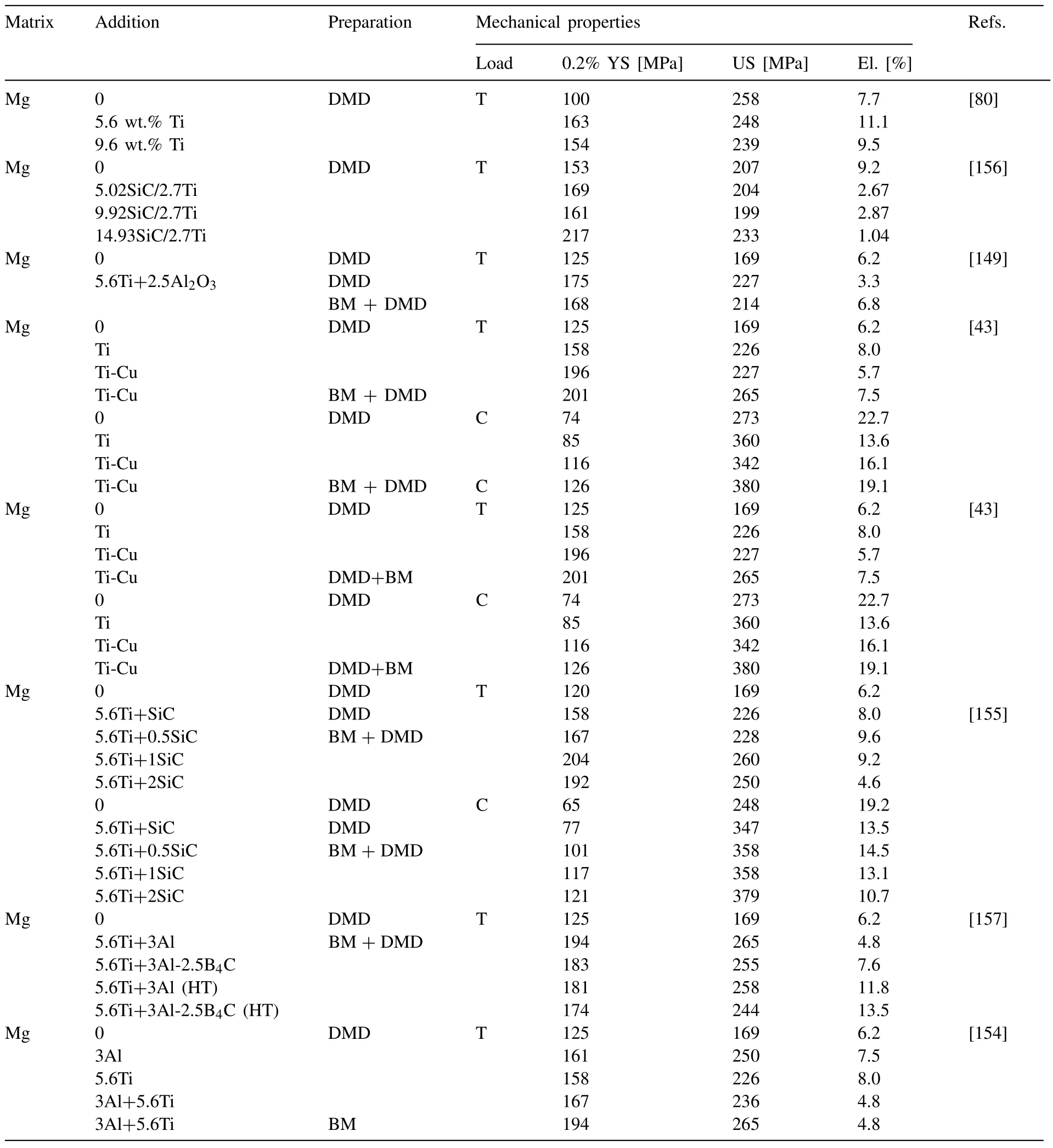

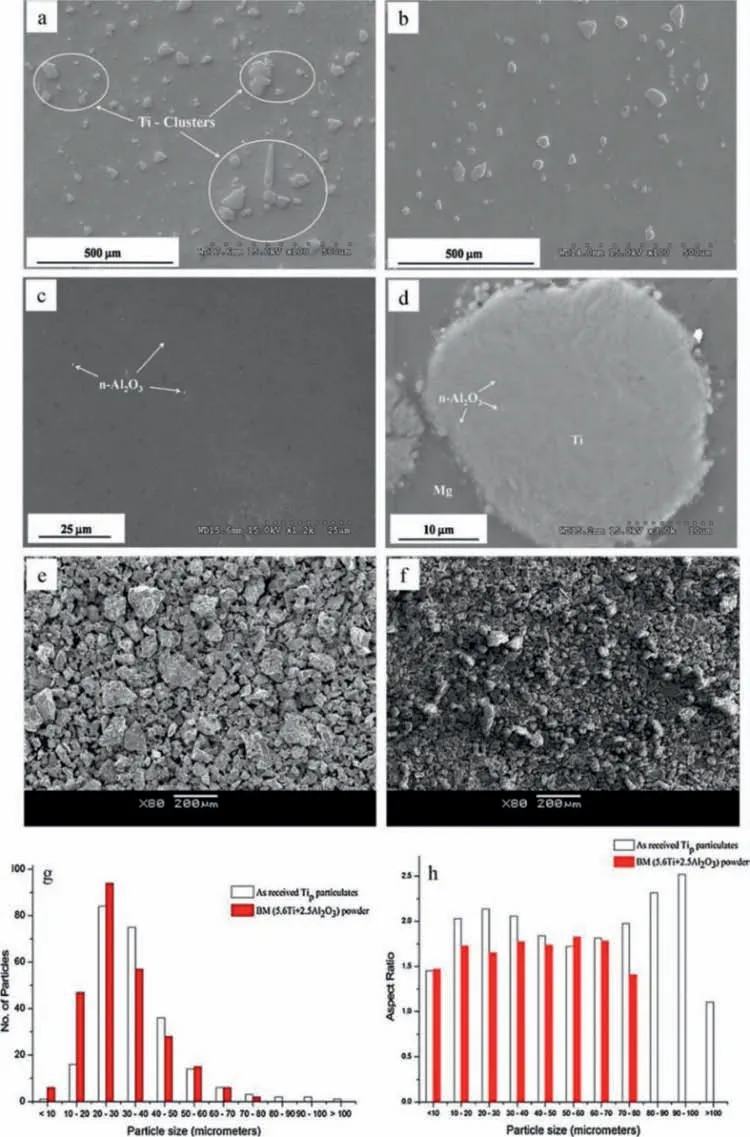

The commonly used way to improve the interfacial strength of Mg and Ti is to enhance their interfacial wettability by alloying,hybridization with ceramic particles or pre-treatment of BM.Initially,in 2002,Hassan and Gupta[80] synthesized pure 5.6 wt.% Ti particles reinforced Mg alloys via DMD followed by hot extrusion.Table 6 indicates that the addition of 5.6 wt.% Ti particles can prominently improve the YS and ductility of Mg alloys by~63%and~44%,accompanied by slightly decreased UTS.They suggested that a good wetting behavior of Ti and Mg was achieved using DMD.Based on the above work [80],Sankaranarayanan et al.[154] alloyed Al with Ti to fabricate Mg,Mg-5.6Ti,Mg-3Al,Mg-5.6Ti-3Al,and Mg-(5.6Ti-3Al)BMcomposites using DMD.They proposed that Mg-(3Al+5.6Ti)BMhas refined grains and lower CTE,which substantially improved its tensile properties.Same authors [149] found that BM treatment on the Ti/Al2O3particles could further enhance the wettability of the Ti and Mg matrix.They manufactured hybrid particles of 5.6%Ti+2.5%Al2O3(nm) with and without BM to reinforce Mg alloy by DMD.The SEM micrographs indicate that a more uniform distribution of mixed particles was achieved in Mg+(5.6Ti+2.5Al2O3)BMthan that without BM (Fig.13(a,b)).After BM,the shape of 5.6%Ti+2.5%Al2O3particles changed from sharp-edged to blunted corners and rounded edges with a lower aspect ratio(Fig.13(e–h)).Table 6 reveals that Mg+(5.6Ti+2.5Al2O3)composite shows significantly higher YS and UTS than Mg+(5.6Ti+2.5Al2O3)BMat a slight expense of ductility.

Another way is creating an appropriate interfacial reaction at Ti/Mg interface to optimize their wettability and thus increasing the interface strength.Sankaranarayanan andco-workers [155] utilized DMD to produce other hybrid particulates with Ti (dp<140 μm) and SiC (dp=~50 nm).Mg-(5.6Ti+1.0SiC) composite shows the optimum tensile and compressive properties among all composites (Table 6).They reported that (Ti,Si)C phases were formed at the Mg/Ti interface in Mg-(5.6Ti+1.0SiC),which contributed to strengthening the particle-matrix interface.Nevertheless,no chemical bonding was formed in Mg-5.6Ti,whose wettability between Mg and Ti becomes the only interfacial bonding.Load transfer strengthening,Orowan strengthening of nanoparticles and EM and CTE strengthening of Ti were speculated to be the strengthening mechanisms governing their mechanical properties.Other researchers also validated that the wettability between metal/Mg can be increased via chemical reaction [43].Two different metallic elements,Ti(dp<140 μm) and Cu (dp=~50 nm),which have negligible and limited solubilities in Mg alloys,were systematically compared.The essential difference between Mg-Ti and Mg-Cu alloys is that the former has no interfacial products at the Mg-Ti interface,and the latter formed Mg2Cu eutectic phase at the interface of Mg-Cu.In Mg-Ti alloy,the effective interfacial bonding only naturally came from the excellent wettability between Mg and Ti.At the same time,the Mg2Cu eutectic phase chemically facilitated the wettability between Mg and Cu.Therefore,although the additions of Ti and Cu both enhanced the mechanical properties of Mg alloys,the Cu particles improved their strength more significantly(Table 6).The authors concluded that CTE mismatch of Mg and Ti,grain refinement and load carrying capacity of Ti were the primary strengthening mechanisms

Table 6 Mechanical properties of Ti particles reinforced Mg-based composites prepared by the spray deposition method(T:tensile,C:compressive).

Fig.13.SEM micrographs of (a) Mg+(5.6Ti+2.5Al2O3) composite and (b) Mg+(5.6Ti+2.5Al2O3)BM,(c) the existence of nano-sized Al2O3 in Mg+(5.6Ti+2.5Al2O3) composite,(d) nano-sized Al2O3 particles in Mg+(5.6Ti+2.5Al2O3)BM,(e) as received Ti particles,(f) ball milled 5.6Ti+2.5Al2O3 particulates,the distribution graphs of (g) particle size vs particle amount and (f) particle size vs aspect ratio of particles [149].

3.4.Ti-reinforced MMCs prepared by other techniques

3.4.1.Ti-reinforced MMCs prepared by physical vapor deposition

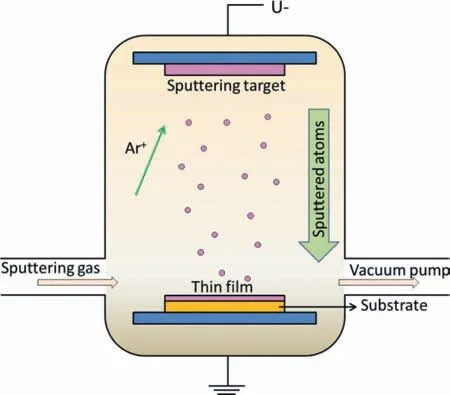

Fig.14.Schematic description of PVD process.

Physical vapor deposition (PVD) describes a process in which the materials transfer from a condensed solid to a vapor phase and then deposit onto the substrate surface in a vacuum(Fig.14).Using PVD,the thickness of sputtered layers can be controlled in a range of angstroms to millimeters [158–160].The common types of PVC include sputtering,ion-plating,magnetron sputtering,and electron beam sputtering.It has a wide application in turning,milling,drills,taps,welding tools,and other tool surfaces [160].

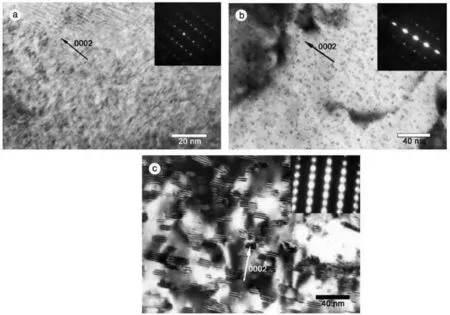

For Ti-reinforced MMCs fabricated by PVD,the parameters of heat treatment influenced the precipitation behavior of Ti-reinforced MMCs.Garcés et al.[161] investigated the precipitate evolution in Mg-12 wt.%Ti composites.They were treated at isothermal temperatures of 300 °C and 350 °C.Fig.15 reveals that the size of the precipitates is~2–3 nm for the sample annealed at 300°C for 32 h,which are entirely coherent with the Mg matrix (Fig.15(a)).As the annealing time proceeds to 470 h,the precipitates coarsened significantly and lost their coherency with the matrix (Fig.15(c)).

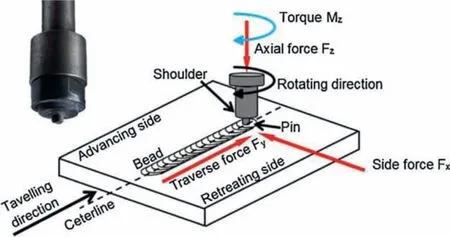

3.4.2.Ti-reinforced MMCs prepared by friction stir processing

Friction stir processing (FSP) has been widely considered as an efficient method to incorporate particulates into Mg alloys (Fig.16),such as Ti [162],SiC [163],TiC [164],ZrO2[165],and Al2O3[166].It shares the same principles as friction stir welding (FSW).Nevertheless,unlike the purpose of joining specimens,FSP is utilized to disperse the particulates homogeneously in the metallic matrix with no severe interfacial reaction [167–172].

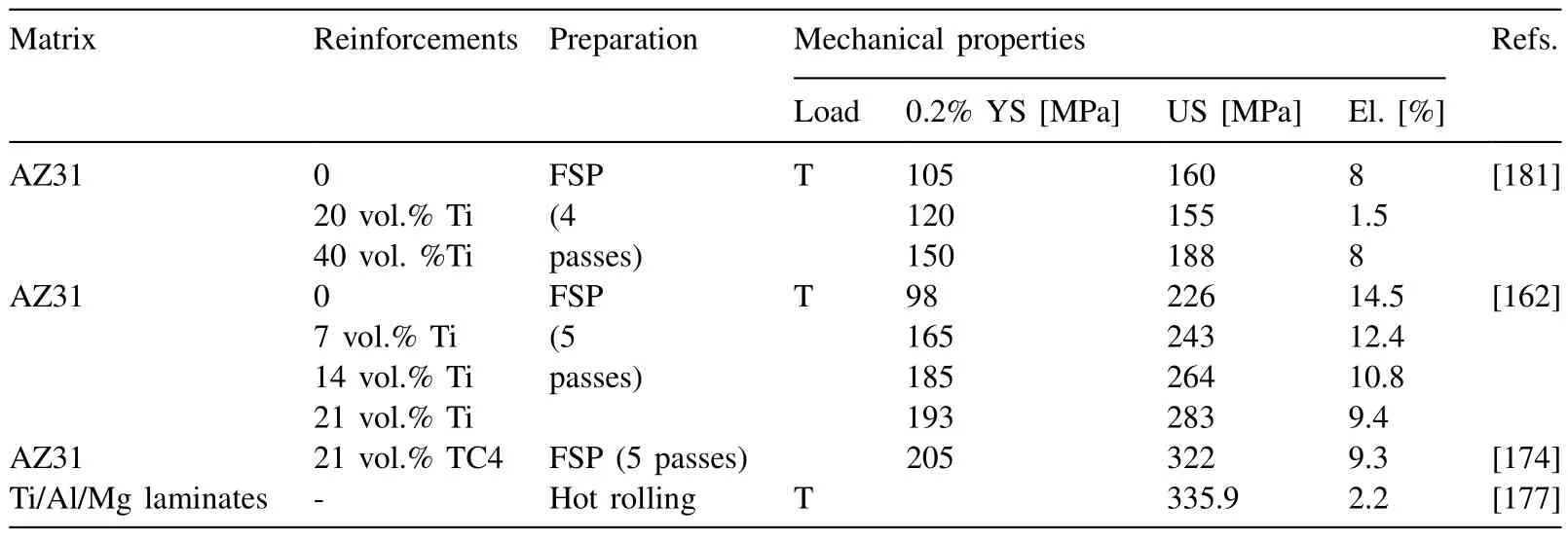

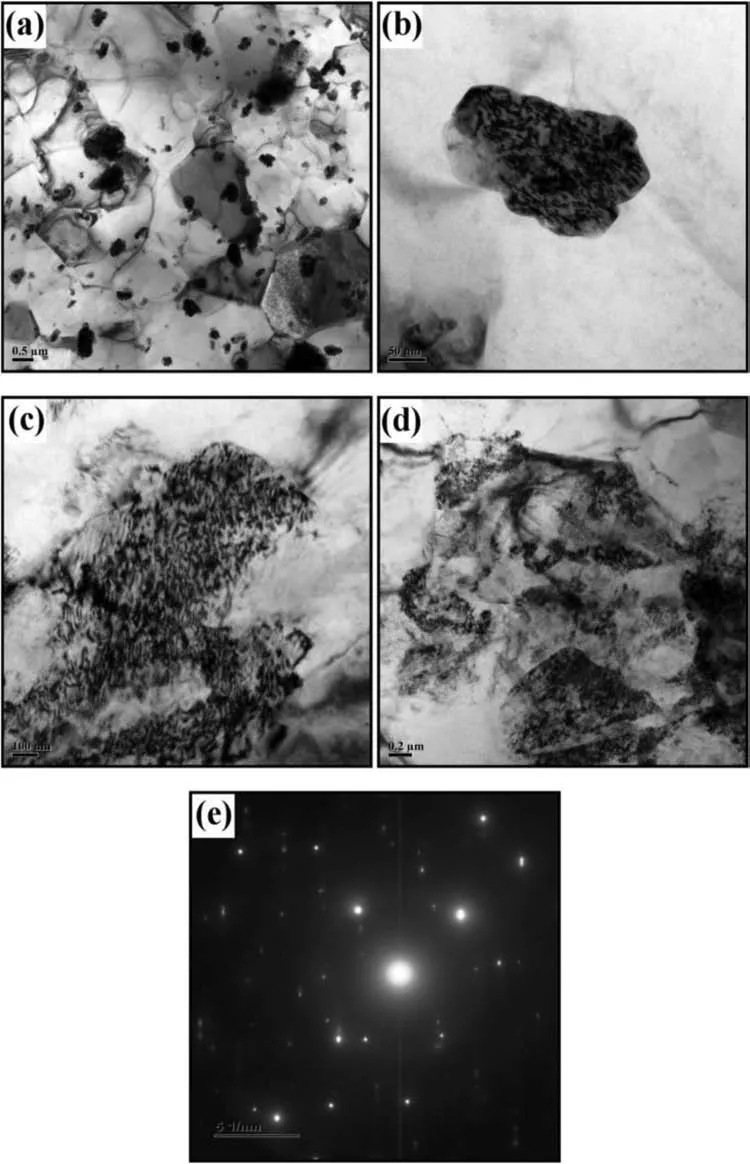

The crucial challenge of Ti-reinforced MMCs fabricated by FSP is the dispersion of Ti particles and the interfacial bonding of Ti and Mg,which can be tailored by changing the processing parameters.The interface with no visible gap or impurity has the potential to serve as a strong adhesion to contribute to the mechanical properties of Tireinforced MMCs.Dinaharan et al.[162] successfully fabricated Ti particles-reinforced AZ31 by changing the processing parameters via FSP,including traverse speed,number of passes,and volume percent of Ti particles.They found that the clustered and sintered zones were promoted due to decreased frictional heat and mechanical stirring with increased traverse speed and number of passes.TEM micrographs reveal that AZ31+2vol.%Ti composite consists of various refined grains with relatively uniform particles (Fig.17(a)).A clear Mg/Ti interface with no visible gap or impurity was observed in Fig.17(b),indicating a strong interfacial bonding between Ti particles and the matrix.A high density of dislocations was notably found in the vicinity of Ti particles,which contributes to the heavy plastic deformation of the composites (Fig.17(c,d).The mechanical properties indicate that 14 vol.%Ti/AZ31 composites produced at a traverse speed of 30 mm/min and 5 passes achieved the best tensile strength and ductility (Table 7).Dinaharan et al.[174] further added Ti-6Al-4V(TC4)particles in AZ31 alloy via FSP.They found 21 vol.% TC4 particles have even stronger strengthening effect than Ti particles in enhancing the mechanical properties of AZ31 (Table 7).The values of YS and UTS both increased from 98 MPa and 226 MPa to 205 MPa and 322 MPa,respectively.TC4 particles were observed bonding well with the matrix and they were in favor of promoting dynamic recrystallization during extrusion process.Hence,effective pinning effect and grain refinement strengthening participated in improving the mechanical properties of AZ31 alloy.

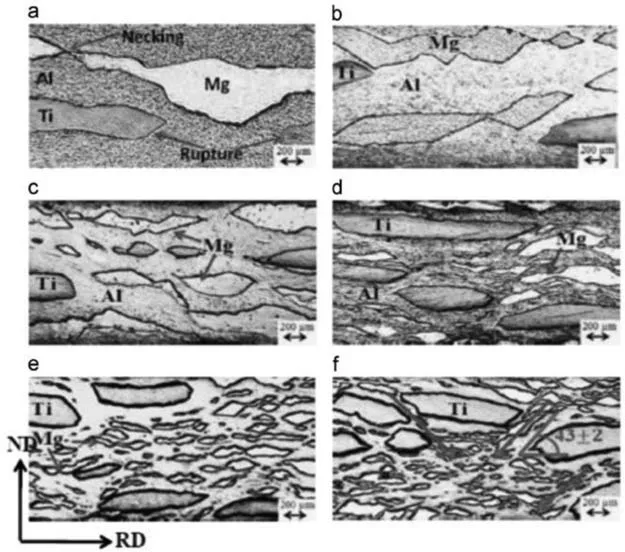

3.4.3.Ti-reinforced MMCs prepared by accumulative roll bonding

Accumulative roll bonding (ARB) is acknowledged as a cost-effective severe plastic deformation(SPD)technology for the production of metal materials with ultrafine grains [175–177].It is a process that involves multi-stage rolling a stack of similar and/or dissimilar sheets.The metal sheets are firstly surface treated before stacking,and then they are rolled to a severe reduction ratio,cut into two halves,stacked again,and repeatedly rolled (Fig.18).Numerous parameters,including material types,surface characteristics,rolling parameters(rolling reduction,rolling temperature,rolling speed,rolling friction,number of layers,post-heat treatment),significantly influence the bonding quality and practical properties [178–180].

As different metal sheets show distinct Young’s modulus and stiffness,they exhibit different deformation behavior during ARB process.Softer metal sheets are inclined to fracture or break severely,while harder metal sheets may simply be stretched.The effect of such bimodal microstructural features on the mechanical properties of laminated composite needs to be revealed and optimized in Ti/Mg laminates.Motevalli and Eghbali [177] fabricated tri-metal Mg/Ti/Al laminated composite via ARB at 150 °C for up to 5 passes.It is found that Ti and Mg layers fractured and necked earlier than Al laminate (Fig.19).By increasing the cycle number of ARB,Ti and Mg layers were further broken into smaller particulates distributing uniformly in the Al matrix.After 4-cycle ARB,the distribution of metal particles was optimized,thus achieving an optimum tensile strength of 335.9 MPa in this composite (Table 7).

Table 7 Mechanical properties of Ti reinforced Mg-based composites prepared by other preparation methods (T: tensile,C:compressive).

Fig.15.Transmission electron micrographs (TEM) of Mg-12%Ti after isothermal treatment (a) at 300 °C for 32 h,(b) at 350 °C for 30 min,and (c) at 350°C for 470 h [161].

Fig.16.Schematic diagram of FSP technique and the used pin tool [173].

Fig.17.(a-d) TEM characterizations of 2vol.%Ti/AZ31B MMCs and SAED pattern of Ti particle [162].

4.Comparisons and discussions

4.1.Effects on mechanical properties

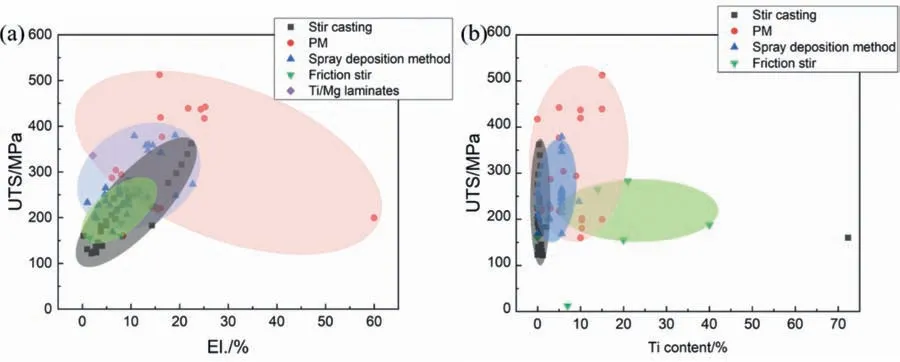

In this review,various fabrication methods of Ti-reinforced Mg composites were elaborately collected and discussed concerning their microstructures and mechanical properties.Following an in-depth literature review,the distribution maps of UTS versus elongation,UTS versus Ti content in MMCs were summarized in Fig.20,respectively.

Fig.18.Schematic description of accumulative roll bonding.

Fig.19.Optical microstructures of tri-metal Al/Mg/Ti laminated composite (a) 0 cycle,(b) 1 cycles,(c) 2 cycles,(d) 3 cycles,(e) 4 cycles and (f) 5 cycles[177].

Apparently,the mechanical properties of Ti-reinforced Mg composites prepared by different fabrication methods vary greatly.In general,Ti-reinforced Mg composites prepared via PM show relatively higher UTS and elongations than those prepared by other methods (Fig.20(a)).Their mechanical properties are significantly influenced by the Ti content(Fig.20(b)).In contrast,for the Ti-reinforced MMCs prepared by stir casting and DMD (spray deposition method),although most of their mechanical properties are improved to varying degrees by tailoring their casting parameters,they are still lower than that fabricated by PM process.

Meanwhile,the amount of Ti that can be added in Mg matrix by different fabrication methods also varies notably(Fig.20(b)).For PM-prepared MMCs,Ti contents can be varied in a wide range of 0-15 %.For stir casting,although a novel liquid settling method allows the addition of large volume fraction of Ti particles (72.3 wt.%),the corresponding MMCs with such high content of Ti did not exhibit excellent mechanical properties (Fig.20(b)).According to available literature,in most cases,the addition of Ti particles in Mg alloys is generally not higher than 2% by stir casting.Similarly,the content of Ti particles did not exceed 6% in spray deposited composites,which limits their further enhancement of mechanical properties in Ti/Mg composites (Fig.20(b)).Ti reinforced Mg composites processed by FSP and/or Ti/Mg laminates exhibit similar mechanical properties as stir cast ones.Nevertheless,it is worth noting that although FSP could even incorporate 40 vol.% Ti in Mg matrix,it shows a limited enhancement on the mechanical properties of the MMCs,which is not as significant as that prepared by PM (Fig.20(b)).

Fig.20.Distribution maps of (a) UTS and elongation and the corresponding (b) UTS and Ti content in Ti containing Mg alloys at room temperature (data are acquired from Tables 4–7).

4.2.Effects on microstructures

For stir-cast Ti-reinforced Mg composites,Ti particles mainly affect the microstructures of Mg alloy from both direct and indirect aspects.The direct influence includes the interfacial reaction between Ti and the constituent elements in Mg alloy.Various types of interfacial products can be formed between Ti and alloying elements.For example,Al2RE in Mg-5RE-5RE-0.5Mn [52],Al2Ti particles in AZ91 [124],TiMn and AlTi3in AM60 [123].These interfacial products were usually formed on the edge of Ti particle,sometimes accompanied by the diffusion of element in Ti particles.The effect of these interfacial products on the mechanical properties of MMCs depends on their characteristics,including their crystallographic relationship with Ti,wettability,brittleness,hardness,shape,size and distribution,etc.The indirect impact includes the influence on the grain size,the formation of intermetallic phases and hinderance of grain growth.Currently.the grain refinement effect of Ti particles on Mg alloys is still controversial.However,in the previously available literature,the addition of Ti particles is relatively low.Perhaps the effect of Ti particles on grain refinement can be more obvious if their amount and recovery ray can be increased.The addition of Ti particles could alter the formation of the intermetallic phase in Mg alloys.For instance,suppressing SrMgSn phase,promoting the formation of SrMgSn[121],changing the quantity of LPSO phase [94],refining the size of LPSO phase [127].Since Ti is thermally stable at high temperatures,it also hinders grain growth under heat treatment and high temperature stress.

For PM prepared Ti-reinforced Mg composites,scholars have explored plentiful ways to improve their mechanical properties,starting with pure Mg matrix and focusing on the matrix of AZ series.The effect of Ti particles on the grain size and interfacial strength of MMCs has been focused,while available literatures do not mention any effect on the intermetalic phases.Similar to stir casting,the effect of Ti particles on the grain size of Mg alloys is also debatable.The difference is that the grain size of PM prepared MMCs is usually much smaller (around several tens of microns),hence the grain refinement effect of Ti particles is not as obvious as that of stir-cast composites.Unlike stir casting,PM allows incorporating a larger volume fraction of Ti in Mg alloys.To create strengthening effect,it is especially important to form strong and stable interfical bonding between Mg and Ti.Therefore,optimizing interfacial wettability of Mg-Ti and regulating their interfacial products were regarded as key research direction to develop Mg-Ti interface strength.In the last decades,researchers focused on the following two aspects to optimize the interfacial wettability.One is investigating the effect of different production methods of raw powders on interfacial wettability.Another way is pre-treatment of ball milling on Mg and Ti powders.Due to the lower preparation temperature of PM,it has a lower degree of interfacial reaction than stir casting.Limited by literature coverage,only AlTi and MgO particles were reported around the edge of Ti particles [140],while MgO was not characterized in stir cast MMCs.

For spray deposited Ti particle-reinforced Mg composites(DMD),not much research had been conducted until now.Its selection of matrix only focused on pure Mg.Compared to stir cast Ti particle-reinforced MMCs,the effect of Ti particles on the grain refinement of Mg matrix has been little studied.Specifically,the research direction of spray deposited Ti particle-reinforced Mg composites is very similar to that of PM prepared MMCs.More attention has been paid to improving the strength of Mg-Ti interface by optimizing interfacial wettability and introducing favorable interfacial products.For instance,alloying Al element,BM treatment of Ti/Al2O3particles,and forming interfacial product of (Ti,Si)C phases.These methods were all proven to be a feasible way for enhancing its interface strength.

For other fabrication techniques,the relevant literature is not particularly well reported.Related research is still in the exploration stage of experimental parameters,which is of paramount importance towards increasing the mechanical properties.For example,for Ti-reinforced MMCs fabricated by FSP,the study focused on how to reduce interfacial gap or impurity through optimizing processing parameter.For Tireinforced MMCs fabricated by ARB,the cycle number was explored to break Ti sheets into small particulates with uniformity,thus leading to coordinated deformation and excellent strength.

4.3.Strengthening mechanism

Although metallic Ti can increase the mechanical properties of Mg alloys via four main mechanisms (Section 2.1),the dominant strengthening mechanism might vary using different fabrication methods.For stir casting,the content of Ti is strongly limited,which made its load transfer,Orowan strengthening or EM and CTE strengthening less effective.Thus,Ti particles appear to be overriding for grain refinement strengthening.For other techniques,such as PM,DMD and PVD,the influence of Ti particles on the grain sized is less significant.Ti particles are either mechanically compacted or physically deposited,the interfacial strength of Ti and Mg matrix becomes crucial in determining the mechanical properties of Ti-reinforced MMCs.It is validated that strong interfacial bonding can cause effective load transfer,EM and CTE strengthening during deformation.For Orowan strengthening,it is mainly related to the size of Ti particles.PM,DMD and PVD are more suitable for adding nano-sized Ti particles with relatively uniform distribution.Hence,load transfer,EM and CTE strengthening and Orowan strengthening can be the dominant mechanisms for PM,DMD and PVD-prepared MMCs.For FSP and ARB-prepared Ti reinforced Mg composites,the improvement of mechanical properties is firmly related to the morphology and amount of Ti.Therefore,load transfer,EM and CTE strengthening might be the dominant mechanisms for enhancing their properties.

5.Conclusion and remarks

To sum up,Ti-reinforced MMCs can be successfully fabricated via plentiful methods,such as stir casting,powder metallurgy,spray deposition techniques (DMD),physical vapor deposition,friction stir processing,and accumulative roll bonding,etc.Based on the above description,it is well acknowledged that the factors affecting the mechanical properties and microstructures of Ti reinforced Mg composites vary under distinct casting methods.Hence,they also have different challenges and future development directions.

The critical challenges that stir cast Ti-reinforced Mg composite encountered focus mainly on the following four aspects.The first one is the limitation of Ti content and its recovery rate in the Mg matrix,which restricts its further enhancement of mechanical properties.On the one hand,the process of stirring casting should be optimized experimentally.Reliable casting parameters are highly required.On the other hand,the effect of stirring speed,time and temperature on the settling speed and viscosity of Ti particles in Mg melt should be theoretically simulated and calculated,which could better guide the operation of casting process.Once the recovery rate and amount of Ti particles have been improved,the second important aspect is to improve the homogeneity of the Ti particles.Novel stirring device with high dispersion efficiency needs to be developed.Since the effect of Ti on the grain size of Mg alloys is still far from consensus,the next important research area is to reveal the mechanism underlying the grain refinement of Ti.Lastly,due to the high temperature during stir casting,severe interfacial reactions tend to be occurred.Therefore,it is worthwhile to systematically explore how to form interfacial products that favorable to interfacial strength and how to optimize the morphology of interfacial products.

Compared with stir casting,the grain size of Ti reinforced MMCs via PM is much smaller and the particle dispersion is relatively more homogeneous.However,the MMCs fabricated via PM are mechanically compacted,this trait makes the strength of their interface and the distribution of particles especially critical.In terms of interfacial optimization,current research is still in the trial-and-error stage.Future emphasis should be paid on the design of interface reaction.For example,it can be an efficient way to predict the reaction products and design interfacial phase between Ti and Mg matrix based on thermodynamic and kinetic calculations.The interfacial phase that has better wettability and higher strength can also be simulated according to alloy composition and reaction conditions.Aggregation of high content Ti particle is still one of the major barriers disabling improvement of mechanical properties,which is the bottlenecks needing to be broken through.Optimizing the PM parameters and hybridization of Ti/ceramic particles can be a potential way to gain better distribution of Ti particles in the future.

At present,the used matrix in Ti-reinforced MMCs by DMD is relatively single,mainly using pure Mg.However,the mechanical properties of pure Mg are not excellent enough to meet service requirement.Choosing a matrix with better mechanical properties to add Ti particle needs to be studied,such as commercial AZ series and AM series.Meanwhile,although some chemical reactions were revealed at the interface of Mg and Ti,no detailed description on the thermodynamic formation mechanism has been proposed so far.Moreover,the Mg-Ti interfaces of MMCs fabricated by these three methods(stir casting,PM and spray deposition) both have interfacial reactions.Efforts need to be made toward distinguishing the difference between their chemical reactions at Mg-Ti interfaces,such as reaction intensity and type of reaction products,which plays an essential role in tuning the microstructures and mechanical properties.

The literature about other ways,such as PVD,FSP and Ti/Mg laminates,is relatively rare.Since related research is still in its beginning stage,desiderative attempts are needed to exploit the appropriate processing processes and parameters on microstructural characteristics and their mechanical properties.

In summary,this review specifically aims to provide an overview on the lesser noticed but very important Tireinforced Mg composites,with the hope to inspire more attention and research efforts for the achievement of Tireinforced MMCs that combine both excellent strength and ductility.

Declaration of Competing Interest

We declare that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors acknowledge National Natural Science Foundation of China (52101123,52171103).The authors also gratefully thank Guangdong Major Project of Basic and Applied Basic Research (2020B0301030006) for the support.

杂志排行

Journal of Magnesium and Alloys的其它文章

- Effects of deformation twins on microstructure evolution,mechanical properties and corrosion behaviors in magnesium alloys -A review

- A review of effective strides in amelioration of the biocompatibility of PEO coatings on Mg alloys

- The mechanisms of grain growth of Mg alloys: A review

- A new nano-scale surface marking technique for the deformation analysis of Mg-based alloys

- Additive friction stir deposition of AZ31B magnesium alloy

- Nonisothermal dissolution kinetics on Mg17Al12 intermetallic in Mg-Al alloys