纤维素基轻质多孔材料的研究进展

2022-07-27宗益峰王如意杨毓洁刘杨赵辉

宗益峰,王如意,杨毓洁,刘杨,b,赵辉,b

纤维素基轻质多孔材料的研究进展

宗益峰a,王如意a,杨毓洁a,刘杨a,b,赵辉a,b

(广西大学 a.轻工与食品工程学院 b.广西清洁化制浆造纸与污染控制重点实验室,南宁 530004)

纤维素基轻质多孔材料具有质轻、孔隙率高、成本低等优点,被广泛应用于吸附、催化、隔热等领域,但易燃、耐水性差等缺点限制了它的应用范围。通过复合改性可以改善上述缺点,并赋予其新的特性,因此需要充分了解功能化改性方法和复合轻质多孔材料的广泛应用。通过追踪国内外纤维素基轻质多孔材料的功能化改性研究和应用进展,概述纤维素基轻质多孔材料的基本性质和性能,重点分析纤维素基复合轻质多孔材料的功能化改性方法和应用,详细介绍纤维素基复合轻质多孔材料在众多领域的应用。将有机或无机材料与纤维素进行复合制成轻质多孔材料,可以实现阻燃、吸附、电磁屏蔽、导电、疏水、抗菌等功能,拓宽了纤维素基轻质多孔材料在包装、医用、电池等领域的应用范围。

纤维素;复合材料;功能化

纤维素基轻质多孔材料于1971年由Weatherwax等[1]首次制备完成,此后便很少有人关注。直到30年后的2001年,Tan等[2]以醋酸纤维素和乙酸丁酸纤维素为原料,以二异氰酸酯为交联剂,得到了具有高冲击强度的纤维素基轻质多孔材料。2004年,Jin等[3]首次使用非衍生性溶剂,将纤维素在硫氰酸钙水溶液中溶解和再生来制备纤维素多孔材料,随后,各种非衍生性溶剂体系被开发出来,包括NaOH水溶液体系[4]、N,N−二甲基乙酰胺/氯化锂(DMAc/LICI)体系[5]、碱/尿素或硫脲/水体系[6]、胺氧化物体系[7]、离子液体体系[8]等。2006年,从植物源或细菌纤维素(BC)中分离的纳米纤维素也被用来制备纤维素多孔材料[9]。纤维素基轻质多孔材料是一类密度低(<100 mg/cm3)、孔隙率高(>50%)、比表面积大、孔结构从纳米到微米的固体材料[10],在传统的多孔材料特性[11](低密度、高比表面积、高孔隙率及孔径分布小等)基础上增加了纤维素的生物性优势[12](可生物降解性和生物相容性),以及高的力学强度等优异性能,并带有丰富的羟基基团。

纤维素基轻质多孔材料的制备主要分为2步,首先将纤维素通过溶剂分散并凝胶化得到水凝胶,然后通过干燥去除溶剂成型。在凝胶过程中,纤维素的溶胶−凝胶转变通过物理或化学交联形成三维纤维网络[13]。这里最主要的问题是如何保持制备过程中形成的微观结构[14],可通过添加表面活性剂、稳泡剂等来解决[15]。纤维素基轻质多孔材料的孔结构还取决于干燥工艺的选择。超临界干燥可有效避免3D多孔结构的坍塌[16],但存在干燥周期长、产量低、成本高等缺点。相对而言,冷冻干燥使冰晶直接升华,更加安全且相对经济。目前也有研究采用冰模板定向冷冻干燥的方法来制备具有各向异性多孔结构和力学性能的纤维素泡沫/气凝胶[17]。在冷冻干燥过程的冷冻和升华阶段,大冰晶会导致纳米纤维的聚集,使纤维素多孔材料的比表面积显著降低,可以通过将溶剂改为叔丁醇来改善[18]。除了上述2种主要的干燥方法外,烘箱干燥方法因其成本低、工艺简单而被认为是最有前景的方法。在干燥过程中存在溶剂表面张力引起的黏附性,固体基质的毛细作用会导致内部网络结构崩塌[19]等问题的出现。目前也有研究致力于改善这些问题,从而降低制备材料的成本[20]。

纤维素基轻质多孔材料在应用过程中存在易燃、耐水性差、不易回收、可重复使用性能差等问题,可以通过化学或物理改性等方法来改善这些问题,并赋予其新的功能,从而应用于吸附[21]、抗菌[22]、疏水[23]、电磁屏蔽[24]、阻燃[25]等领域,这也是目前的研究热点。开发环境友好、成本低、可回收,以及具有特殊性能的纤维素基复合多孔材料将成为未来的主流研究方向。文中将围绕纤维素基轻质多孔材料的改性方法、结构特点、性能及应用等方面,着重阐述纤维素基复合轻质多孔材料在吸附、医用、电磁屏蔽、阻燃等领域的研究现状,为纤维素基复合轻质多孔材料研究提供一定的理论参考。

1 纤维素基轻质多孔材料的复合改性

纤维素基复合轻质多孔材料是以纤维素为基体,以有机或无机材料为功能体或增强体,通过复合制成的性能优良的新型功能材料[26]。功能体或增强体与纤维素的复合改性方法有很多,按与纤维素复合的材料种类分类,可分为有机材料复合、纳米碳材料复合、金属纳米粒子复合、氧化物复合、矿物复合等。

1.1 有机材料复合

与纤维素基轻质多孔材料复合的有机材料大多为高分子聚合物,如壳聚糖[27]、甲壳素[28]、共价有机骨架COF(Covalent Organic Framework)粉末材料[29]、单宁、海藻酸钠等。也有如甲醇[30]等非高分子聚合物的有机材料,用甲醇将纤维素进行再生,制成纤维素−甲醇凝胶,通过超临界干燥方法,可以制备出比表面积大、密度低(0.058 g/cm3)和孔隙率高(96%)的纳米孔径(<2 nm)气凝胶。

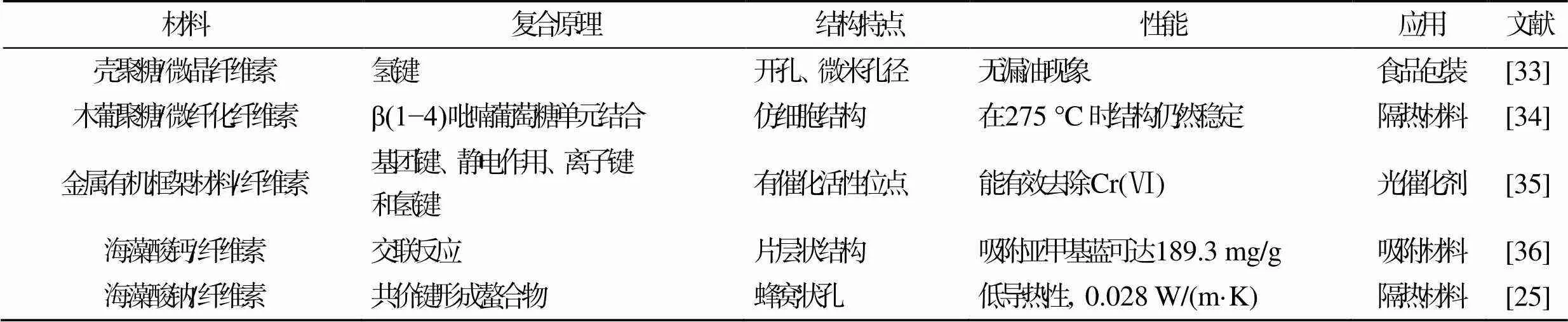

壳聚糖的化学结构与纤维素十分相似,其分子链上存在大量氨基和羟基,能与纤维素上丰富的羟基形成氢键[31]。Zhang等[32]制备了一种壳聚糖−纤维素包裹磁性碳泡沫吸附剂,将纤维素与壳聚糖混合后,壳聚糖水凝胶球的表面孔隙率增加,材料的微观结构得到改善。这些变化将促进重金属溶液渗透到聚合物网络结构中,从而提高金属离子的吸附性能和吸附速率。这里总结了部分有机材料与纤维素的复合原理,复合后的结构特点、性能和应用见表1。

表1 几种有机材料与纤维素的复合原理及应用

Tab.1 Principle and application of the compounding of several organic materials and cellulose

MOF/纤维素复合光催化材料在酸性环境中还原六价铬通过式(1)—(2)实现,其中过量的H+有利于将Cr(Ⅵ)还原为Cr(Ⅲ)[37]。在碱性环境中,Cr(Ⅵ)的存在形式是CrO42–,相应的Cr(Ⅵ)还原通过式(3)完成。

NH2-MIL-101(Fe)+→(h++e−) (1)

Cr2O72−+14H++6e−→(2Cr3++7H2O) (2)

CrO42−+4H2O+3e−→(Cr(OH)3+5OH−) (3)

共价有机骨架(COF)材料是一种结晶的、高度多孔的二维或三维聚合物,具有可调的拓扑结构和功能[38]。已经开发了COF材料的许多用途,包括催化剂载体[39]、超灵敏传感器[40]等。COF材料通常以粉末状存在,很难直接形成结晶多孔材料[41]。粉末本身不易均匀掺杂和进一步加工,且难以回收,所以将COF与纤维素复合,以对COF材料赋形,拓宽其应用领域。郭从宝[41]将NFC(Nano Fibrillated Cellulose)、CNC(Cellulose Nanocrystals)和COF材料相结合,制备了COF−CMC(Carboxymethyl Cellulose)/CNC复合气凝胶。将CNC和CMC进行功能化改性和化学交联,制备的气凝胶具有分层结构,并显示出良好的力学性能、热稳定性、机械稳定性和柔韧性。

1.2 纳米碳材料复合

纳米碳具有优异的导电性和导热性[42],由于聚集性的问题[43],它们很难单独应用。纤维素可以对各种纳米碳材料起到稳定的作用,还可以作为纳米碳材料优异的载体。碳纳米管与纳米纤维素之间具有良好的亲和力,可以制成性能优异的复合材料[44]。目前研究较多的就是碳纳米管和氧化石墨烯。

碳纳米管(CNT)的质量较轻,具有良好的导电性、导热性,出色的力学性能和高柔韧性,但CNT在水中不能均匀分散,这是急需解决的问题。Mougel等[45]将纤维素纳米晶体(CNCs)和碳纳米管(CNT)分散在水中制成三维大孔导电泡沫。由于CNCs的化学结构和其表面带有负电荷的影响,CNCs在水性介质中具有出色的胶体稳定性,从而具有静电稳定性,可以起到稳定CNT的作用。氧化石墨烯(GO)是一种单层石墨氧化物,力学性能较好,刚度强,比表面积大,具有优异的导电性和较高的电催化活性。由于纤维素基多孔材料具有较高的比表面积和孔隙率,所以具备一定的吸附能力。如果将纤维素基多孔材料与氧化石墨烯复合,就可以制备出吸附能力更强且具有导电性能的纤维素基复合材料[46]。

1.3 金属纳米粒子复合

金属纳米粒子具有独特的光学性质[47]、电学性质和良好的催化效果,在许多领域引起了人们的广泛关注。纤维素−纳米粒子复合多孔材料主要由Au、Ag、Cu[48]、Pb[49]等与纤维素复合而成,其中研究得最多的是金纳米离子和银纳米粒子。

最简单的金属纳米粒子与纤维素复合的方法就是物理沉积,一般通过静电作用来实现[50]。Zhou等[51]以MFC气凝胶为模板,通过简单的浸涂方法合成了MFC/PPy/Ag混合气凝胶。作为一种成本低、高效且环保的工艺,可实现纳米颗粒在纤维素气凝胶中的精细分散。所制备的混合气凝胶表现出增强的抗菌、导电和压力响应特性。

与物理负载相比,原位化学沉积更有利于实现纳米粒子在纳米纤维素上的均匀分布。纳米纤维素的表面电荷密度是影响贵金属离子静电吸附的一个关键因素,对纳米纤维素的形状、形貌和悬浮稳定性有着重要影响[52-53]。例如,部分脱硫处理的NCC比未脱硫的NCC能更好地稳定AgNPs(Ag Nanoparticles)。AgNPs的尺寸分布随着脱硫程度的增加而显著改善[54]。此外,通常需要还原剂来诱导纳米纤维素上金属前体的成核和控制纳米纤维素上金属纳米颗粒的形态,如硼氢化物[55]、抗坏血酸[56]、多巴胺(PDA)[57]等。

1.4 氧化物复合

与纤维素基复合的氧化物一般为ZnO、TiO2、SiO2、Fe3O4等。氧化物和纳米纤维素的复合材料通常通过溶胶−凝胶[58]、自组装[59]、原子层沉积[60]和原位合成[61]制备。氧化物的晶体结构、大小、形状和分布在很大程度上取决于纳米纤维素的形貌和表面官能团[62]。这里总结了部分氧化物与纤维素复合的制备方法,以及制备后的结构特点、性能及应用,见表2。

表2 几种氧化物与纤维素的复合方法及应用

Tab.2 Several composite methods and applications of oxides and cellulose

Fe3O4纳米粒子是传统的磁性材料,是一种双复介质,存在密度大、频带窄等缺点[67]。纤维素具有质轻、强度高、比面积大等优点,因此将这2种材料结合起来能够取长补短,使制成的复合材料具备2种材料的优点。He等[68]利用Pickering乳液技术结合冷冻干燥技术制备了纳米原纤维(CNF)/CNT/聚乳酸(PLA)/Fe3O4泡沫。复合材料具有质轻、隔热性能好、电磁波吸收性能好等优点。得益于纳米Fe3O4颗粒、碳纳米管的特性以及有机−无机组分组装产生的新型界面极化之间的协同效应,复合材料的最佳回波损耗为−65.14 dB。

TiO2是另一种被广泛研究的负载在纳米纤维素上的金属氧化物材料。Lu等[69]利用超临界干燥制备了TiO2/纤维素复合气凝胶。纤维素基质中的多孔结构和羟基通过静电和氢键相互作用,增强了二氧化钛的稳定性。二氧化钛/纤维素复合气凝胶在紫外光照射下表现出良好的光催化活性。这项研究为便携式和柔性光催化剂的开发提供了一种途径。

1.5 天然矿物复合

由于纤维素−氧化物基复合材料引入了金属氧化物,可能会产生二次污染,而矿物质材料无污染[70]且来源丰富、成本低,因此不会出现上述的问题。矿物质纤维素基复合吸附材料主要由沸石[71]、蒙脱土[72]、硅藻土[73]、坡缕石[74]等与多种纤维素复合而成。

蒙脱土(MMT)是一种天然粘土矿物质,具有层状结构和离子交换性能[75],是一种被广泛研究的吸附材料。如果只是单纯以MMT为原料进行吸附,则吸附后存在难以回收等问题。将纤维素与蒙脱土进行复合制成轻质多孔材料,不仅会提高材料的吸附性能,而且吸附后可以回收。PAN等[76]以超细碳酸钙为造孔剂,通过一种新的方法制备了胺化纤维素/蒙脱土介孔复合微珠(AceMt),作为绿色吸附剂,可用于染料的去除。在乙酸溶液中,经过5次吸附−解吸循环,复合材料的吸附容量也保持相对稳定。

羟基磷灰石(HAP)是脊椎动物体内骨骼和牙齿的主要无机成分,具有生物相容性高、无毒和易燃等优点。利用HAP和纤维素可以制备具有绝缘、阻燃、生物相容性良好的材料。Guo等[77]使用丙基三甲氧基硅烷和聚乙烯亚胺将HAP与CNF进行交联,采用冷冻干燥法制备CNF/HAP复合泡沫。复合泡沫具有热导率较低和阻燃性能良好等优点,在垂直燃烧测试中拥有自熄能力和非常低的峰值热释放率,具有良好的热稳定性。复合泡沫表现出优异的防火性能,可以用作绝缘和阻燃建筑材料。

2 功能化应用

将纤维素与有机或无机材料复合后可以赋予其特定的功能性,极大地拓展了材料的应用领域。相较于未功能化纤维素基轻质多孔材料,功能化纤维素基轻质多孔材料在电磁屏蔽、吸附、抗菌、阻燃隔热等领域有较大的应用前景,见图1。

图1 纤维素复合轻质多孔材料的应用领域

2.1 电磁屏蔽材料

电子产品的大量使用会造成严重的电磁效应,会对人体的健康造成严重的影响,并且还会引起信息泄露及干扰其他电子设备的正常运行[78]。电磁屏蔽材料可以减轻或者消除上述不良影响,但传统的电磁屏蔽材料存在质量大、屏蔽机理单一、二次污染严重、生产过程烦琐等缺点[79]。纤维素基电磁屏蔽材料具有轻质灵活、保温隔音、绿色无污染、循环可再生等优点,正成为目前研究的热点。

Zeng等[80]将CNF用来构建具有定向仿生细胞壁的过渡金属碳化物和氮化物(Mxene)气凝胶,采取了一种仿生的微结构设计方法(见图2),由珍珠状细胞壁的CNF“砂浆”黏结的MXene“砖”具备机械强度高、导电性好和界面极化的特性,从而使MXene/ CNF气凝胶具有超高的电磁屏蔽性能。在密度仅为8.0、1.5 mg/cm3的情况下,气凝胶的屏蔽效能(SE)分别达到74.6 dB和35.5 dB,跻身于目前研发的其他电磁屏蔽材料的第一梯队。

图2 MXene/CNF仿生细胞壁结构和定向冷冻干燥示意图[80]

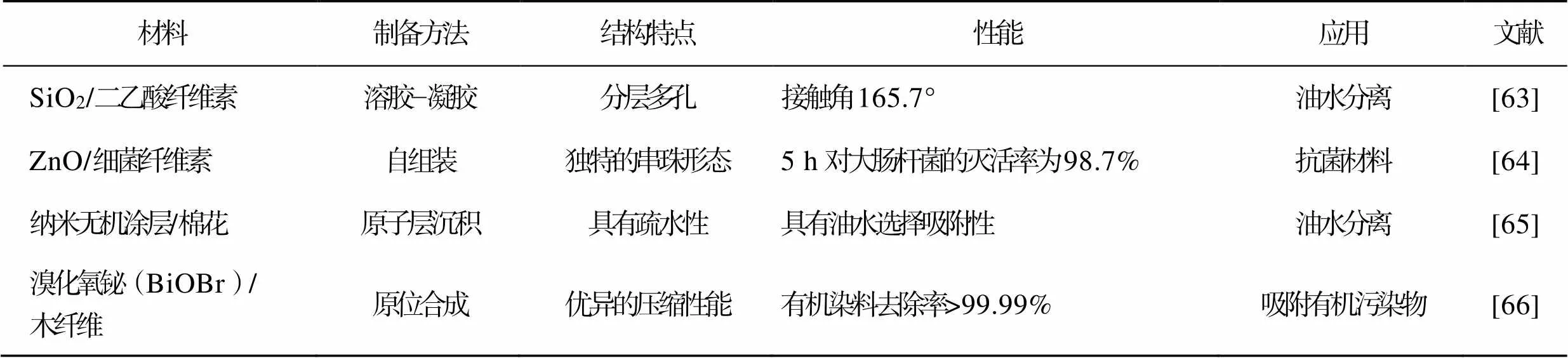

Zeng等[81]制备了超轻、高柔性的生物聚合物气凝胶,它由纤维素纳米纤维和银纳米线形成的仿生细胞微结构组成,通过冷冻干燥方法成型。结合原位压缩产生的屏蔽变换和建筑单元的控制,优化的层状多孔生物高聚物气凝胶具有非常好的电磁屏蔽效果,电磁屏蔽的原理见图3。在密度为6.2 mg/cm3时,X波段屏蔽效能为70.5 dB,电磁屏蔽性能优异。

图3 CNF/Ag气凝胶层状多孔结构实现电磁屏蔽效果的机制[81]

介绍的2种电磁屏蔽材料采取了不同的结构设计思路,并且材料都具有轻巧灵活、电磁屏蔽性能良好等优点,对以后设计电磁屏蔽材料有一定借鉴意义。

2.2 吸附材料

随着石油工业和化学工业的发展,漏油和化学品泄漏正在成为人类面临的环境问题[82-83]。吸附是一种成本低且操作简单的方法[84]。低成本、轻质、可循环使用是作为优异吸附材料必备的性能条件[85]。纤维素质轻且强度高,利用纤维素与其他材料复合可以制备出质轻且吸附性能优异的复合材料。目前,纤维素基复合吸附材料的研究主要集中在设计特定的细胞微结构[86]和使用可弯曲但坚固的固体成分等方面[87]。

Mi等[88]以纤维素和石墨烯为原料,采用双向冷冻干燥方法,制备了高弹性、可压缩和各向异性的纤维素/石墨烯气凝胶(CGAs)。制备的复合材料超轻(密度为5.9 mg/cm3)且具有高比表面积(47.3 m2/g)。经过超疏水改性的纤维素/石墨烯气凝胶(MCGA)具有相当于其质量80~197倍的显著吸附能力,并且可以通过简单的机械挤压快速高效地回收吸收的油。

Wei等[89]将纳米纤维素与氧化铁(Fe3O4)纳米颗粒集成在一起,制备了一种磁性杂化气凝胶。制备的杂化气凝胶对Cu2+、Pb2+、Cr6+的吸附容量分别为0.4、1.25、2.2 mg/g,见图4,可以有效地吸附水中的重金属离子,实现磁性条件下的可控回收。

通过与不同的材料复合,赋予新材料对不同污染物的吸附性能,如吸附重金属离子、印染废水和石油等,这对处理环境污染问题具有重要的意义。

2.3 电极材料

Fe3O4是一种优秀的电池材料,可以作为锂离子电池的负极材料。由于Fe3O4的导电性较差,且在应用中体积会膨胀,因而限制了它在实际中的应用。Sun等[90]通过分解纤维素/酒石酸铁络合物体系,制备了Fe3O4@C复合材料。酒石酸铁络合物经冷冻干燥和高温炭化后,分解成Fe3O4,均匀沉积在纤维素衍生的多孔炭中。多孔炭具有良好的导电性,在电化学研究中发现它可以适应复合材料的体积变化。复合材料作为锂电池的负极在100 mA/g下的充电容量可以达到864.9 mA·h/g,初始充电容量较高。在1 000 mA/g下循环300次后,容量保持率为86.4%。该方法为制备性能优良的Fe3O4@C复合材料提供了一种新的途径,并有望在未来的锂离子电池中得到实际应用。

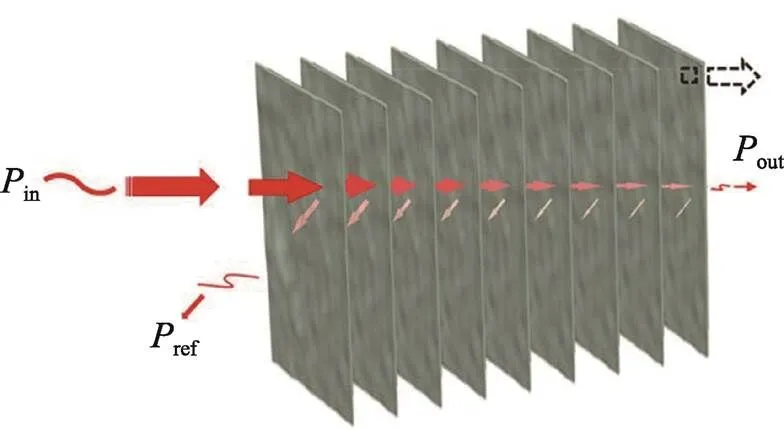

Zheng等[91]制备了一种以纤维素纳米纤维(CNF)/氧化石墨烯(RGO)/碳纳米管(CNT)杂化气凝胶为电极(见图5),以H2SO4/聚乙烯醇(PVA)凝胶为电解质的新型高柔性全固态超级电容器。首先将氧化石墨纳米片(GONS)与碳纳米管(CNT)均匀混合。由于GONS是水溶性的,含有大量的氧原子,因而极易与CNT形成均匀的溶液。再加入纤维素纳米纤维CNF形成均匀的溶液,通过预冻和冷冻干燥方法制成CNF/RGO/CNT气凝胶,并通过热还原形成最终的超级电容器电极材料。得益于气凝胶电极的多孔结构和CNF优异的电解质吸收性能,所制备的柔性超级电容器具有较高的比电容(216 mF/cm2)和优异的循环稳定性(在1000次充放电循环后仍保持99.5%以上的比电容)。CNF/RGO/CNT气凝胶电极具有优良的电化学性能、成本低、易于大规模生产、环境友好等特点,在柔性储能装置的开发中具有广阔的应用前景。

目前,电池性能制约了手机、汽车行业的发展,提高电池的容量和抗衰减性能显得至关重要。抗衰减性能的提高可以有效地延长电池的使用时间、节约成本。电池容量的提高可以减轻人们对石油等不可再生资源的依赖,使电动汽车的使用体验逐渐媲美燃油车,推动了人类在可持续能源领域的高质量发展。

2.4 疏水材料

由于存在大量的羟基,纤维素基轻质多孔材料具有较强的亲水性[92],这会导致材料的耐水性差、强度降低,并且影响油水分离性能[93]。为了提高纤维素基轻质多孔材料的耐水性能,可通过提高粗糙度(微米或纳米级的粗糙度)和引入低表面能物质来实现[94]。目前,常用的纤维素基轻质多孔材料的疏水化工艺包括化学气相沉积、原子层沉积、冷等离子体处理[95]、溶胶−凝胶[96]、酯化[97]和氟化等,主要以TiO2、SiO2、烷氧基硅烷、氯硅烷、烷基烯酮二聚体[98]、三氯甲基硅烷、全氟十二烷基三氯硅烷[99]、硬脂酰氯和棕榈酰氯[100]等为疏水改性原料。

图4 纳米纤维素−Fe3O4混合气凝胶的吸附效率[89]

图5 CNF/RGO/CNT气凝胶电极的制造过程[91]

在最新的研究中,研究人员发现使用木质素也可制备疏水纤维素基轻质多孔材料。Ferreira等[101]通过碱处理从木质纤维素中提取木质素,然后再将木质素沉积到木质纤维素中,通过烘箱干燥制备疏水纤维素泡沫。泡沫的接触角为117°±8°,最高测量值为127°(见图6),呈现出较好的疏水性。泡沫的疏水性主要归因于木质纤维素中残留木质素、再沉积木质素、纤维和泡沫表面粗糙度等的共同作用。从图6可以看出,再沉积的木质素增加了纤维表面的粗糙度,提高了泡沫的疏水性能。制备所用烘箱也具有成本低、操作简单等优点,为大规模的工业化生产提供了良好的借鉴意义。

图6 柠檬酸交联木质纤维素泡沫的接触角和表面特性[101]

2.5 抗菌材料

羟基磷灰石(HAP)与天然骨组织有着相似的结构和化学成分[102-103],将它植入骨缺损的部分无不良反应,但其自身强度低,难以起到支撑作用[104]。纤维素具有强度高的特点,可为HAP提供支撑作用,再与其他材料一起复合可以得到结构稳定、抗菌性能好、生物相容性好的复合支架[105]。Khan等[106]以细菌纤维素(BC)和−葡聚糖为原料,采用自由基聚合将−HAP和GO接枝到聚合物网络中,并通过冷冻干燥技术制备了应用于骨组织工程的纳米复合支架。复合支架对于革兰氏阴性菌和革兰氏阳性菌具有良好的抗菌性能,并且显示出较强的生物化学亲和力,以及细胞黏附、增殖和生物相容性,这对于应用抗菌性能的骨组织支架具有深远的意义。

作为天然抗菌剂,精油(Eos)既有抗菌作用,又有抗氧化作用,因此被广泛用于抗菌材料。Zhang等[107]采用了一种简单而环保的方法,用CNF和百里香精油(EO)制备出纳米纤维−百里香精油泡沫(CNF−EO),通过酶解预处理和TEMPO氧化预处理可以制备碳纳米纤维。将酶解纤维素纳米纤维(EHCN)和氧化纤维素纳米纤维(TOCN)浸泡在EO纳米乳液中,然后进行冷冻干燥,就可以制备出CNF−EO复合材料。在食品保鲜方面,采用CNF−EO泡沫保鲜的牛肉在风味、色泽等感官上均发挥出较好的效果,与同期不加精油的对照组相比,采用TOCN−EO泡沫保鲜牛肉的货架期延长了5 d,见图7。这种CNF−EO泡沫体系的制备方法对新鲜食品的保鲜具有重要意义。

研发具有抗菌性能的环境友好型材料,可以应用到食品保鲜和医用材料等领域,优异的抗菌性能可延长食品的保质期,用作医用材料可以降低患者被感染的风险。

图7 EHCN−EO和TOCN−EO的抗菌性能对比[107]

2.6 隔热、阻燃材料

纤维素气凝胶具有密度低、隔热性能好、导热性低等特点,被广泛应用于建筑的隔热保温材料。由于该材料易燃,因而限制了它在部分场景下的应用。由此,赋予纤维素气凝胶优异的阻燃性能,可以极大程度地拓展此材料的应用领域。

Wang等[108]将四甲氧基硅烷(TMOS)和磷腈缩合,合成了含有环三磷腈桥连基团的介孔有机二氧化硅(PMOPZ),然后将它掺入CNF悬浮液中,通过冷冻浇铸法制备了PMOPZ/CNF复合泡沫材料。相较于传统的CNF泡沫,复合泡沫在水平(图8a)和垂直(图8b)方向的燃烧结果都表明它具有优异的阻燃和自熄灭性能,极氧指数高达31%。SiO2的加入使复合泡沫塑料的放热率(PHRR)和总放热率(THR)分别降低了52.0%和61.3%,其优异的阻燃性能满足安全和节能的需要。

He等[109]受到硼酸盐在植物中的交联作用的启发,通过硼酸盐交联,制备出力学性能和阻燃性能均优异的轻质、高孔隙率纸浆泡沫。与易燃原浆泡沫相比,低导热系数(约0.045 W·m−1·K−1)的含硼纸浆泡沫具有更好的阻燃性能和良好的自熄灭性能。当硼的质量分数为3.45%时,制得的纸浆泡沫完全不燃,为制备具有优良阻燃和隔热性能的高强度、多孔纸浆泡沫提供了一条经济有效、简单易行的路线。

图8 PMOPZ/CNF泡沫在水平和垂直方向燃烧测试前后的照片[108]

赋予轻质多孔材料阻燃的性能可以将它作为建筑物或家用电器中的热绝缘体,提高材料的耐用性,降低材料的使用成本,从而降低社会的能耗需求。

3 结语

纤维素是一种纵横比高、比表面积大、力学性能优异,具有生物相容性和生物降解性的生物友好型材料。纤维素与有机或无机材料复合制备的轻质多孔材料可以实现阻燃、吸附、电磁屏蔽、导电、抗菌等功能,极大地拓展了其应用领域。随着研究的深入,未来会出现越来越多性能更加优异的纤维素基复合多孔材料,但是纤维素基复合多孔材料在成本控制、大规模生产、回收利用等方面还面临挑战。此外,还应认真考虑更环保、更绿色的合成方法,以满足可持续发展的要求。研发绿色、环保、可再生的材料是大势所趋,在碳中和的背景下显得尤为重要,所以纤维素基复合轻质多孔材料的开发、制备及其推广应用仍将是未来研究的重点。

[1] WEATHERWAX R C, CAULFIELD D F. Cellulose Aerogels: An Improved Method for Preparing a Highly Expanded form of Dry Cellulose[J]. Tappi, 1971, 54(6): 985-986.

[2] TAN C, FUNG B M, NEWMAN J K, et al. Organic Aerogels with Very High Impact Strength[J]. Advanced Materials, 2001, 13(9): 644-646.

[3] JIN Hao, NISHIYAMA Y, WADA M, et al. Nanofibrillar Cellulose Aerogels[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 240(1/2/3): 63-67.

[4] GAVILLON R, BUDTOVA T. Aerocellulose: New Highly Porous Cellulose Prepared from Cellulose-NaOH Aqueous Solutions[J]. Biomacromolecules, 2008, 9(1): 269-277.

[5] GAREMARK J, YANG Xuan, SHENG Xia, et al. Top-down Approach Making Anisotropic Cellulose Aerogels as Universal Substrates for Multifunctionalization[J]. ACS Nano, 2020, 14(6): 7111-7120.

[6] LI Qian, WU Ping-jian, ZHOU Jin-ping, et al. Structure and Solution Properties of Cyanoethyl Celluloses Synthesized in LiOH/Urea Aqueous Solution[J]. Cellulose, 2012, 19(1): 161-169.

[7] SESCOUSSE R, GAVILLON R, BUDTOVA T. Aerocellulose from Cellulose-Ionic Liquid Solutions: Preparation, Properties and Comparison with Cellulose-NaOH and Cellulose-NMMO Routes[J]. Carbohydrate Polymers, 2011, 83(4): 1766-1774.

[8] LOPES J M, MUSTAPA A N, PANTIĆ M, et al. Preparation of Cellulose Aerogels from Ionic Liquid Solutions for Supercritical Impregnation of Phytol[J]. The Journal of Supercritical Fluids, 2017, 130: 17-22.

[9] MAEDA H, NAKAJIMA M, HAGIWARA T, et al. Preparation and Properties of Bacterial Cellulose Aerogel[J]. Kobunshi Ronbunshu, 2006, 63(2): 135-137.

[10] SUN Yan, CHU You-lu, WU Wei-bing, et al. Nanocellulose-Based Lightweight Porous Materials: A Review[J]. Carbohydrate Polymers, 2021, 255: 117489.

[11] ZU Guo-qing, SHEN Jun, ZOU Li-ping, et al. Nanocellulose-Derived Highly Porous Carbon Aerogels for Supercapacitors[J]. Carbon, 2016, 99: 203-211.

[12] ZHAO Da-wei, ZHU Ying, CHENG Wan-ke, et al. Cellulose-Based Flexible Functional Materials for Emerging Intelligent Electronics[J]. Advanced Materials (Deerfield Beach, Fla), 2021, 33(28): e2000619.

[13] BISSON A, RIGACCI A, LECOMTE D, et al. Drying of Silica Gels to Obtain Aerogels: Phenomenology and Basic Techniques[J]. Drying Technology, 2003, 21(4): 593-628.

[14] SMIRNOVA I, GURIKOV P. Aerogel Production: Current Status, Research Directions, and Future Opportunities[J]. The Journal of Supercritical Fluids, 2018, 134: 228-233.

[15] BUREIKO A, TRYBALA A, KOVALCHUK N, et al. Current Applications of Foams Formed from Mixed Surfactant-Polymer Solutions[J]. Advances in Colloid and Interface Science, 2015, 222: 670-677.

[16] KOBAYASHI Y, SAITO T, ISOGAI A. Aerogels with 3D Ordered Nanofiber Skeletons of Liquid-Crystalline Nanocellulose Derivatives as Tough and Transparent Insulators[J]. Angewandte Chemie (International Ed in English), 2014, 53(39): 10394-10397.

[17] CHEN Yi-ming, ZHOU Li-jie, CHEN Lian, et al. Anisotropic Nanocellulose Aerogels with Ordered Structures Fabricated by Directional Freeze-Drying for Fast Liquid Transport[J]. Cellulose, 2019, 26(11): 6653-6667.

[18] JIANG Feng, HSIEH Y L. Assembling and Redispersibility of Rice Straw Nanocellulose: Effect of Tert-Butanol[J]. ACS Applied Materials & Interfaces, 2014, 6(22): 20075-20084.

[19] TEJADO A, CHEN W C, ALAM M N, et al. Superhydrophobic Foam-Like Cellulose Made of Hydrophobized Cellulose Fibres[J]. Cellulose, 2014, 21(3): 1735-1743.

[20] PARK S Y, GOO S, SHIN H, et al. Structural Properties of Cellulose Nanofibril Foam Depending on Wet Foaming Conditions in Pickering Stabilization[J]. Cellulose, 2021, 28(16): 10291-10304.

[21] NASSER ABDELHAMID H, MATHEW A P. Cellulose-Zeolitic Imidazolate Frameworks (CelloZIFs) for Multifunctional Environmental Remediation: Adsorption and Catalytic Degradation[J]. Chemical Engineering Journal, 2021, 426: 131733.

[22] WANG Yan-sen, ZHAO Yi-fan, QIAO Long-xue, et al. Cellulose Fibers-Reinforced Self-Expanding Porous Composite with Multiple Hemostatic Efficacy and Shape Adaptability for Uncontrollable Massive Hemorrhage Treatment[J]. Bioactive Materials, 2021, 6(7): 2089-2104.

[23] ZHAO Yi-fan, ZHONG Kai, LIU Wei, et al. Preparation and Oil Adsorption Properties of Hydrophobic Microcrystalline Cellulose Aerogel[J]. Cellulose, 2020, 27(13): 7663-7675.

[24] CHEN Jun-qing, ZHU Zhao-dong, ZHANG Hui, et al. Wood-Derived Nanostructured Hybrid for Efficient Flame Retarding and Electromagnetic Shielding[J]. Materials & Design, 2021, 204: 109695.

[25] JIANG Shuai, ZHANG Mei-ling, LI Meng-meng, et al. Cellulose-Based Composite Thermal-Insulating Foams Toward Eco-Friendly, Flexible and Flame-Retardant[J]. Carbohydrate Polymers, 2021, 273: 118544.

[26] 吕少一, 傅峰, 王思群, 等. 纳米纤维素基导电复合材料研究进展[J]. 林业科学, 2015, 51(10): 117-125.

LYU Shao-yi, FU Feng, WANG Si-qun, et al. Advances in Nanocellulose-Based Electroconductive Composites[J]. Scientia Silvae Sinicae, 2015, 51(10): 117-125.

[27] KIM U J, KIMURA S, WADA M. Highly Enhanced Adsorption of Congo Red Onto Dialdehyde Cellulose-Crosslinked Cellulose-Chitosan Foam[J]. Carbohydrate Polymers, 2019, 214: 294-302.

[28] 赵川川. 基于纤维素与甲壳素的多相催化剂的开发及其催化性能研究[D]. 保定: 河北大学, 2021: 5-9.

ZHAO Chuan-chuan. Development of Heterogeneous Catalysts Based on Cellulose and Chitin and Their Catalytic Performance Research[D]. Baoding: Hebei University, 2021: 5-9.

[29] HIVECHI A, BAHRAMI S H, SIEGEL R A. Drug Release and Biodegradability of Electrospun Cellulose Nanocrystal Reinforced Polycaprolactone[J]. Materials Science and Engineering: C, 2019, 94: 929-937.

[30] TSIOPTSIAS C, STEFOPOULOS A, KOKKINOMALIS I, et al. Development of Micro- and Nano-Porous Composite Materials by Processing Cellulose with Ionic Liquids and Supercritical CO2[J]. Green Chemistry, 2008, 10(9): 965.

[31] XIE Hai-bo, ZHANG Suo-bo, LI Sheng-hai. Chitin and Chitosan Dissolved in Ionic Liquids as Reversible Sorbents of CO2[J]. Green Chemistry, 2006, 8(7): 630.

[32] ZHANG Zhe-xin, LI Hui-dong, LI Jing, et al. A Novel Adsorbent of Core-Shell Construction of Chitosan-Cellulose Magnetic Carbon Foam: Synthesis, Characterization and Application to Remove Copper in Wastewater[J]. Chemical Physics Letters, 2019, 731: 136573.

[33] AHSAN H M, PEI Ying, LUO Xiao-gang, et al. Novel Stable Pickering Emulsion Based Solid Foams Efficiently Stabilized by Microcrystalline Cellulose/Chitosan Complex Particles[J]. Food Hydrocolloids, 2020, 108: 106044.

[34] SEHAQUI H, SALAJKOVÁ M, ZHOU Qi, et al. Mechanical Performance Tailoring of Tough Ultra-High Porosity Foams Prepared from Cellulose I Nanofiber Suspensions[J]. Soft Matter, 2010, 6(8): 1824.

[35] LIU Ju, HAO Dan-dan, SUN Hui-wen, et al. Integration of MIL-101-NH2into Cellulosic Foams for Efficient Cr(Ⅵ) Reduction under Visible Light[J]. Industrial & Engineering Chemistry Research, 2021, 60(33): 12220-12227.

[36] 张文良. 海藻酸盐/羧甲基纤维素复合材料的制备及吸附性能研究[D]. 青岛: 青岛大学, 2019: 57-59.

ZHANG Wen-liang. Preparation and Adsorption Properties of Alginate/Carboxymethyl Cellulose Composites[D]. Qingdao: Qingdao University, 2019: 57-59.

[37] WANG Shan-li, CHEN C C, TZOU Y M, et al. A Mechanism Study of Light-Induced Cr(VI) Reduction in an Acidic Solution[J]. Journal of Hazardous Materials, 2009, 164(1): 223-228.

[38] PACHFULE P, ACHARJYA A, ROESER J, et al. Diacetylene Functionalized Covalent Organic Framework (COF) for Photocatalytic Hydrogen Generation[J]. Journal of the American Chemical Society, 2018, 140(4): 1423-1427.

[39] ZHANG Jian-qiang, PENG Yong-sheng, LENG Wen-guang, et al. Nitrogen Ligands in Two-Dimensional Covalent Organic Frameworks for Metal Catalysis[J]. Chinese Journal of Catalysis, 2016, 37(4): 468-475.

[40] JHULKI S, EVANS A M, HAO Xue-li, et al. Humidity Sensing through Reversible Isomerization of a Covalent Organic Framework[J]. Journal of the American Chemical Society, 2020, 142(2): 783-791.

[41] 郭从宝. 纳米纤维素/共价有机骨架复合材料的制备表征及其用于二氯苯降解的催化性能研究[D]. 广州: 华南理工大学, 2019: 1-2.

GUO Cong-bao. Preparation, Characterization and Catalytic Performance for O-Dichlorobenzene Degradation of Nanocellulose/Covalent Organic Framework(COF) Composites[D]. Guangzhou: South China University of Technology, 2019: 1-2.

[42] GUO Si-hua, ZHENG Run, JIANG Jin-tian, et al. Enhanced Thermal Conductivity and Retained Electrical Insulation of Heat Spreader by Incorporating Alumina-Deposited Graphene Filler in Nano-Fibrillated Cellulose[J]. Composites Part B: Engineering, 2019, 178: 107489.

[43] LEE J K Y, CHEN Nuan, PENG Sheng-jie, et al. Polymer-Based Composites by Electrospinning: Preparation & Functionalization with Nanocarbons[J]. Progress in Polymer Science, 2018, 86: 40-84.

[44] FAIZ NORRRAHIM M N, MOHD KASIM N A, KNIGHT V F, et al. Nanocellulose: A Bioadsorbent for Chemical Contaminant Remediation[J]. RSC Advances, 2021, 11(13): 7347-7368.

[45] MOUGEL J B, BERTONCINI P, CATHALA B, et al. Macroporous Hybrid Pickering Foams Based on Carbon Nanotubes and Cellulose Nanocrystals[J]. Journal of Colloid and Interface Science, 2019, 544: 78-87.

[46] YOUSEFI N, WONG K K W, HOSSEINIDOUST Z, et al. Hierarchically Porous, Ultra-Strong Reduced Graphene Oxide-Cellulose Nanocrystal Sponges for Exceptional Adsorption of Water Contaminants[J]. Nanoscale, 2018, 10(15): 7171-7184.

[47] KHAN I, SAEED K, KHAN I. Nanoparticles: Properties, Applications and Toxicities[J]. Arabian Journal of Chemistry, 2019, 12(7): 908-931.

[48] DACRORY S, ABOU-YOUSEF H, KAMEL S, et al. Development of Biodegradable Semiconducting Foam Based on Micro-Fibrillated Cellulose/Cu-NPs[J]. International Journal of Biological Macromolecules, 2019, 132: 351-359.

[49] VIPIN A K, FUGETSU B, SAKATA I, et al. Cellulose Nanofiber Backboned Prussian Blue Nanoparticles as Powerful Adsorbents for the Selective Elimination of Radioactive Cesium[J]. Scientific Reports, 2016, 6: 37009.

[50] DONG Li-li, YAN Gui-hua, REN Su-xia, et al. Platinum Nanoparticle Decorated Poly(diallyldimethylammonium chloride)/Cellulose Nanocrystal Nanohybrid for Electrochemical Sensing of Dopamine[J]. Journal of Biobased Materials and Bioenergy, 2018, 12(6): 519-524.

[51] ZHOU Su-kun, WANG Meng, CHEN Xiong, et al. Facile Template Synthesis of Microfibrillated Cellulose/Polypyrrole/Silver Nanoparticles Hybrid Aerogels with Electrical Conductive and Pressure Responsive Properties[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(12): 3346-3354.

[52] ZHANG Qing, ZHANG Lei, WU Wei-bing, et al. Methods and Applications of Nanocellulose Loaded with Inorganic Nanomaterials: A Review[J]. Carbohydrate Polymers, 2020, 229: 115454.

[53] WU Xi, YAN Wen, ZHOU Ya-lan, et al. Thermal, Morphological, and Mechanical Characteristics of Sustainable Tannin Bio-Based Foams Reinforced with Wood Cellulosic Fibers[J]. Industrial Crops and Products, 2020, 158: 113029.

[54] LOKANATHAN A R, UDDIN K M A, ROJAS O J, et al. Cellulose Nanocrystal-Mediated Synthesis of Silver Nanoparticles: Role of Sulfate Groups in Nucleation Phenomena[J]. Biomacromolecules, 2014, 15(1): 373-379.

[55] XIONG Chuan-yin, DANG Wei-hua, NIE Shuang-xi, et al. Fabrication of High Value Cellulose nanofibers@Ni Foam by Non Carbonization: Various Application Developed during the Preparation[J]. Cellulose, 2021, 28(3): 1455-1468.

[56] LI Shu-ming, JIA Ning, ZHU Jie-fang, et al. Rapid Microwave-Assisted Preparation and Characterization of Cellulose-Silver Nanocomposites[J]. Carbohydrate Polymers, 2011, 83(2): 422-429.

[57] BAIG N, KAMMAKAKAM I. Removal of Oily Contaminants from Water by Using the Hydrophobic Ag Nanoparticles Incorporated Dopamine Modified Cellulose Foam[J]. Polymers, 2021, 13(18): 3163.

[58] NELSON K, DENG Yu-lin. The Shape Dependence of Core–Shell and Hollow Titania Nanoparticles on Coating Thickness during Layer-by-Layer and Sol–Gel Synthesis[J]. Nanotechnology, 2006, 17(13): 3219-3225.

[59] ZHAO Si-wei, ZHENG Ming, ZOU Xiao-hang, et al. Self-Assembly of Hierarchically Structured Cellulose@ZnO Composite in Solid–Liquid Homogeneous Phase: Synthesis, DFT Calculations, and Enhanced Antibacterial Activities[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(8): 6585-6596.

[60] GEBAUER D, OLIYNYK V, SALAJKOVA M, et al. A Transparent Hybrid of Nanocrystalline Cellulose and Amorphous Calcium Carbonate Nanoparticles[J]. Nanoscale, 2011, 3(9): 3563.

[61] ZHAN Hui, PENG Na, LEI Xiao-juan, et al. UV-Induced Self-Cleanable TiO2/Nanocellulose Membrane for Selective Separation of Oil/Water Emulsion[J]. Carbohydrate Polymers, 2018, 201: 464-470.

[62] OUN A A, SHANKAR S, RHIM J W. Multifunctional Nanocellulose/Metal and Metal Oxide Nanoparticle Hybrid Nanomaterials[J]. Critical Reviews in Food Science and Nutrition, 2020, 60(3): 435-460.

[63] PIRZADA T, ASHRAFI Z, XIE Wen-yi, et al. Cellulose Silica Hybrid Nanofiber Aerogels: From Sol–Gel Electrospun Nanofibers to Multifunctional Aerogels[J]. Advanced Functional Materials, 2020, 30(5): 1907359.

[64] WANG Pei-pei, ZHAO Jun, XUAN Rui-fei, et al. Flexible and Monolithic Zinc Oxide Bionanocomposite Foams by a Bacterial Cellulose Mediated Approach for Antibacterial Applications[J]. Dalton Transactions, 2014, 43(18): 6762-6768.

[65] SHORT A E, PAMIDI S V, BLOOMBERG Z E, et al. Atomic Layer Deposition (ALD) of Subnanometer Inorganic Layers on Natural Cotton to Enhance Oil Sorption Performance in Marine Environments[J]. Journal of Materials Research, 2019, 34(4): 563-570.

[66] XU Peng, YANG Jin, CHEN Yu, et al. Wood-Derived Fiber/BiOBr/AgBr Sponges by in Situ Synthesis for Separation of Emulsions and Degradation of Dyes[J]. Materials & Design, 2019, 183: 108179.

[67] 李群, 冯云, 邹杨, 等. 纳米纤维素-无机复合材料研究进展[J]. 天津造纸, 2018, 40(3): 14-18.

LI Qun, FENG Yun, ZOU Yang, et al. Research Progress of Nano-Cellulose-Inorganic Composite Materials[J]. Tianjin Paper Making, 2018, 40(3): 14-18.

[68] HE Ying-ying, LI Shuai, ZHOU Li, et al. Cellulose Nanofibrils-Based Hybrid Foam Generated from Pickering Emulsion Toward High-Performance Microwave Absorption[J]. Carbohydrate Polymers, 2021, 255: 117333.

[69] LU Yun, SUN Qing-feng, LI Jian, et al. Fabrication, Characterization and Photocatalytic Activity of TiO2/Cellulose Composite Aerogel[J]. Key Engineering Materials, 2014, 609/610: 542-546.

[70] 赵晓光, 欧阳静, 张毅, 等. 矿物基摩擦材料的研究进展[J]. 材料导报, 2019, 33(11): 1860-1868.

ZHAO Xiao-guang, OUYANG Jing, ZHANG Yi, et al. Research Progress in Mineral-Based Friction Materials[J]. Materials Reports, 2019, 33(11): 1860-1868.

[71] MA Shan-shan, ZHANG Mei-yun, NIE Jing-yi, et al. Lightweight and Porous Cellulose-Based Foams with High Loadings of Zeolitic Imidazolate Frameworks-8 for Adsorption Applications[J]. Carbohydrate Polymers, 2019, 208: 328-335.

[72] 赵亚红, 薛振华, 王喜明, 等. 羧甲基纤维素/蒙脱土纳米复合材料对刚果红染料的吸附及解吸性能[J]. 化工学报, 2012, 63(8): 2655-2660.

ZHAO Ya-hong, XUE Zhen-hua, WANG Xi-ming, et al. Adsorption and Desorption Properties for Congo Red Dye of Carboxymethylcellulose/Montmorillonite Nanocomposites[J]. CIESC Journal, 2012, 63(8): 2655-2660.

[73] LEE C Y, LEE Su-jin, HA J H, et al. The Effects of Kaolin Addition on the Properties of Reticulated Porous Diatomite-Kaolin Composites[J]. Journal of Korean Powder Metallurgy Institute, 2020, 27(4): 325-332.

[74] 杨发翠, 孙士淇, 常玥, 等. 羧甲基纤维素钠/坡缕石(CMC/PGS)复合材料的制备及其对Pb(Ⅱ)的吸附[J]. 硅酸盐通报, 2016, 35(1): 25-29.

YANG Fa-cui, SUN Shi-qi, CHANG Yue, et al. Preparation of Carboxymethyl Cellulose/Palygorskite (CMC/ PGS) and Adsorption Property for PB(Ⅱ)[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(1): 25-29.

[75] 赵宝宝. 纤维素基水凝胶的制备及其对亚甲基蓝染料和重金属离子的吸附研究[D]. 烟台: 烟台大学, 2021: 35-42.

ZHAO Bao-bao. Preparation of Cellulose Based Hydrogels and Study on Adsorption of Methylene Blue Dye and Heavy Metal Ions[D]. Yantai: Yantai University, 2021: 35-42.

[76] PAN Yuan-feng, XIE Hua-lei, LIU Hai-yan, et al. Novel Cellulose/Montmorillonite Mesoporous Composite Beads for Dye Removal in Single and Binary Systems[J]. Bioresource Technology, 2019, 286: 121366.

[77] GUO Wen-wen, WANG Xin, ZHANG Ping, et al. Nano- Fibrillated Cellulose-Hydroxyapatite Based Composite Foams with Excellent Fire Resistance[J]. Carbohydrate Polymers, 2018, 195: 71-78.

[78] 王丽, 王哲, 宁国艳, 等. 木基导电电磁屏蔽材料的研究进展[J]. 材料导报, 2018, 32(13): 2320-2328.

WANG Li, WANG Zhe, NING Guo-yan, et al. Research Progress of Electromagnetic Shielding Wood-Based Conductive Materials[J]. Materials Review, 2018, 32(13): 2320-2328.

[79] YAO Yuan-yuan, JIN Shao-hua, ZOU Hao-ming, et al. Polymer-Based Lightweight Materials for Electromagnetic Interference Shielding: A Review[J]. Journal of Materials Science, 2021, 56(11): 6549-6580.

[80] ZENG Zhi-hui, WANG Chang-xian, SIQUEIRA G, et al. Nanocellulose-MXene Biomimetic Aerogels with Orientation-Tunable Electromagnetic Interference Shielding Performance[J]. Advanced Science, 2020, 7(15): 2000979.

[81] ZENG Zhi-hui, WU Ting-ting, HAN Da-xin, et al. Ultralight, Flexible, and Biomimetic Nanocellulose/ Silver Nanowire Aerogels for Electromagnetic Interference Shielding[J]. ACS Nano, 2020, 14(3): 2927-2938.

[82] BULLOCK R J, PERKINS R A, AGGARWAL S. In-Situ Burning with Chemical Herders for Arctic Oil Spill Response: Meta-Analysis and Review[J]. Science of the Total Environment, 2019, 675: 705-716.

[83] LIU Hua, CAO Chang-yan, WEI Fang-fang, et al. Flexible Macroporous Carbon Nanofiber Film with High Oil Adsorption Capacity[J]. Journal of Materials Chemistry A, 2014, 2(10): 3557.

[84] HUANG Xiao-dan, SUN Bing, SU Da-wei, et al. Soft-Template Synthesis of 3D Porous Graphene Foams with Tunable Architectures for Lithium–O2Batteries and Oil Adsorption Applications[J]. J Mater Chem A, 2014, 2(21): 7973-7979.

[85] MEZA L R, DAS S, GREER J R. Strong, Lightweight, and Recoverable Three-Dimensional Ceramic Nanolattices [J]. Science, 2014, 345(6202): 1322-1326.

[86] WU Ying-peng, YI Ning-bo, HUANG Lu, et al. Three-Dimensionally Bonded Spongy Graphene Material with Super Compressive Elasticity and Near-Zero Poisson's Ratio[J]. Nature Communications, 2015, 6: 6141.

[87] BI Hui, CHEN I W, LIN Tian-quan, et al. A New Tubular Graphene Form of a Tetrahedrally Connected Cellular Structure[J]. Advanced Materials (Deerfield Beach, Fla), 2015, 27(39): 5943-5949.

[88] MI Hao-yang, JING Xin, POLITOWICZ A L, et al. Highly Compressible Ultra-Light Anisotropic Cellulose/Graphene Aerogel Fabricated by Bidirectional Freeze Drying for Selective Oil Absorption[J]. Carbon, 2018, 132: 199-209.

[89] WEI Jie, YANG Zhi-xing, SUN Yun, et al. Nanocellulose-Based Magnetic Hybrid Aerogel for Adsorption of Heavy Metal Ions from Water[J]. Journal of Materials Science, 2019, 54(8): 6709-6718.

[90] SUN Cheng-min, ZHENG Xiang, SUN Tian, et al. Synthesis of Fe3O4@C Composites Using Cellulose and Ferric Tartrate Complex as Precursor and Their Application as Anode for High Performance Lithium-Ion Batteries[J]. International Journal of Electrochemical Science, 2021: ArticleID: 210538.

[91] ZHENG Qi-feng, CAI Zhi-yong, MA Zhen-qiang, et al. Cellulose Nanofibril/Reduced Graphene Oxide/Carbon Nanotube Hybrid Aerogels for Highly Flexible and All-Solid-State Supercapacitors[J]. ACS Applied Materials & Interfaces, 2015, 7(5): 3263-3271.

[92] CHEN Cai-hong, LI Chao, YU De-you, et al. A Facile Method to Prepare Superhydrophobic Nanocellulose- Based Aerogel with High Thermal Insulation Performance via a Two-Step Impregnation Process[J]. Cellulose, 2022, 29(1): 245-257.

[93] YANG Bin, ZHANG Mei-yun, LU Zhao-qing, et al. Comparative Study of Aramid Nanofiber (ANF) and Cellulose Nanofiber (CNF)[J]. Carbohydrate Polymers, 2019, 208: 372-381.

[94] LIU Hong-zhi, GENG Bi-yao, CHEN Yu-fei, et al. Review on the Aerogel-Type Oil Sorbents Derived from Nanocellulose[J]. ACS Sustainable Chemistry & Engineering, 2017, 5(1): 49-66.

[95] SHI Jian-jun, LU Ling-bin, GUO Wan-tao, et al. An Environment-Friendly Thermal Insulation Material from Cellulose and Plasma Modification[J]. Journal of Applied Polymer Science, 2013, 130(5): 3652-3658.

[96] SAI Hua-zheng, XING Li, XIANG Jun-hui, et al. Flexible Aerogels with Interpenetrating Network Structure of Bacterial Cellulose–Silica Composite from Sodium Silicate Precursor via Freeze Drying Process[J]. RSC Advances, 2014, 4(57): 30453.

[97] GRANSTRÖM M, NÉE PÄÄKKÖ M K, JIN Hua, et al. Highly Water Repellent Aerogels Based on Cellulose Stearoyl Esters[J]. Polymer Chemistry, 2011, 2(8): 1789.

[98] RUSSLER A, WIELAND M, BACHER M, et al. AKD-Modification of Bacterial Cellulose Aerogels in Supercritical CO2[J]. Cellulose, 2012, 19(4): 1337-1349.

[99] AULIN C, NETRVAL J, WÅGBERG L, et al. Aerogels from Nanofibrillated Cellulose with Tunable Oleophobicity [J]. Soft Matter, 2010, 6(14): 3298.

[100]FUMAGALLI M, OUHAB D, BOISSEAU S M, et al. Versatile Gas-Phase Reactions for Surface to Bulk Esterification of Cellulose Microfibrils Aerogels[J]. Biomacromolecules, 2013, 14(9): 3246-3255.

[101]FERREIRA E S, CRANSTON E D, REZENDE C A. Naturally Hydrophobic Foams from Lignocellulosic Fibers Prepared by Oven-Drying[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(22): 8267-8278.

[102]PRABAKARAN S, RAJAN M, LV Chang-wei, et al. Lanthanides-Substituted Hydroxyapatite/ Aloe Vera Composite Coated Titanium Plate for Bone Tissue Regeneration[J]. International Journal of Nanomedicine, 2020, 15: 8261-8279.

[103]VENKATESAN J, KIM S K. Chitosan Composites for Bone Tissue Engineering—an Overview[J]. Marine Drugs, 2010, 8(8): 2252-2266.

[104]YU Han-ping, ZHU Ying-jie, XIONG Zhi-chao, et al. Bioinspired Fiberboard-and-Mortar Structural Nanocomposite Based on Ultralong Hydroxyapatite Nanowires with High Mechanical Performance[J]. Chemical Engineering Journal, 2020, 399: 125666.

[105]刘云利, 陕绍云, 支云飞, 等. 功能化纳米纤维素气凝胶应用研究[J]. 现代化工, 2020, 40(5): 36-41.

LIU Yun-li, SHAN Shao-yun, ZHI Yun-fei, et al. Research in Application of Functionalized Nanocellulose Aerogels[J]. Modern Chemical Industry, 2020, 40(5): 36-41.

[106]KHAN M U A, HAIDER S, HAIDER A, et al. Development of Porous, Antibacterial and Biocompatible GO/n-HAp/Bacterial Cellulose/β-Glucan Biocomposite Scaffold for Bone Tissue Engineering[J]. Arabian Journal of Chemistry, 2021, 14(2): 102924.

[107]ZHANG Zheng-jian, WANG Xiao-juan, GAO Meng, et al. Sustained Release of an Essential Oil by a Hybrid Cellulose Nanofiber Foam System[J]. Cellulose, 2020, 27(5): 2709-2721.

[108]WANG Dong, FENG Xia-ming, ZHANG Li-ping, et al. Cyclotriphosphazene-Bridged Periodic Mesoporous Organosilica-Integrated Cellulose Nanofiber Anisotropic Foam with Highly Flame-Retardant and Thermally Insulating Properties[J]. Chemical Engineering Journal, 2019, 375: 121933.

[109]HE Si-han, LIU Chao, CHI Xue-wen, et al. Bio-Inspired Lightweight Pulp Foams with Improved Mechanical Property and Flame Retardancy via Borate Cross-Linking[J]. Chemical Engineering Journal, 2019, 371: 34-42.

Research Progress of Cellulose-based Lightweight Porous Materials

ZONG Yi-fenga, WANG Ru-yia, YANG Yu-jiea, LIU Yanga,b, ZHAO Huia,b

(a. College of Light Industry and Food Engineering b. Guangxi Key Laboratory of Clean Pulp and Paper and Pollution Control, Guangxi University, Nanning 530004, China)

Cellulose-based lightweight porous material has the advantages of light weight, high porosity, and low cost. So they are widely used in adsorption, catalysis, heat insulation and other fields. However, problems such as flammability and poor water resistance limit its scope of application. Compound modification can improve the above shortcomings and give it new characteristics. Therefore, it is necessary to fully understand the functional modification method and the wide application of lightweight porous composite materials. In this paper, by tracking the research and application progress of functional modification of cellulose-based lightweight porous materials at home and abroad, the basic properties and performance of cellulose-based lightweight porous materials are summarized, and the functions of cellulose-based composite lightweight porous materials are analyzed. Chemical modification methods and applications, the opportunities and challenges of cellulose-based composite lightweight porous materials in many fields are introduced in detail. The organic or inorganic materials are combined with cellulose to make lightweight porous materials. These materials can achieve flame retardant, absorption, electromagnetic shielding, electrical conductivity, hydrophobic, antibacterial and other functions, which can broaden the application range of cellulose-based lightweight porous materials in packaging, medical, battery and other fields.

cellulose; compound material; functionalization

TS71+1;TB484

A

1001-3563(2022)13-0066-13

10.19554/j.cnki.1001-3563.2022.13.009

2021‒10‒26

国家自然科学基金(22068004,21534007);广西自然科学基金(2020GXNSFAA159027,2020GXNSFBA159023)

宗益峰(1997—),男,本科,主攻纤维素轻质多孔材料。

刘杨(1979—),女,博士,广西大学副教授,主要研究方向为木质纤维素基功能型先进材料。

责任编辑:彭颋