Development Status and Main Application Progress of the Kinetica-1 Solid Launch Vehicle

2022-07-15YANGHaoliangLIXinyuSHIXiaoningZHANGYanruiZHUYongquanLIANJie

YANG Haoliang,LI Xinyu,SHI Xiaoning,ZHANG Yanrui,ZHU Yongquan,LIAN Jie

Beijing CAS Aerospace Exploration Technology Co.Ltd.,Beijing 100176

Abstract: The Kinetica-1 rocket is designed for small-and medium-sized spacecraft launch missions to sun-synchronous orbit and low Earth orbit.The maiden flight was performed on July 27,2022.The Kinetica-1 rocket is characterized by competitive payload capability and cost,robust orbital insertion accuracy,high reliability,availability at short notice and logistical versatility.12 new core technologies have been achieved during the development of the rocket.It is of great significance in promoting the innovation of China’s solid carrier rocket technology and science exploration.

Key words: science exploration,solid launch vehicle,new development mode

1 INTRODUCTION

The Kinetica-1 rocket is the first four-stage solid rocket jointly developed by the Institute of Mechanics of the Chinese Academy of Sciences and Beijing CAS Aerospace Exploration Technology Co.Ltd (CAS Space).The rocket was designed for small-and medium-sized spacecraft launch missions to sun-synchronous orbit (SSO) and low Earth orbit (LEO),including single-satellite,multi-satellite,plus for rapid constellation deployment and replacement tasks.The advanced,innovative and economical new solid rocket is of great significance in promoting the innovation of China’s launch vehicle technology and development mode.

The launch pad No.130,a proprietary one for Kinetica-1,was set up at the Jiuquan Satellite Launch Center (JSLC),and was equipped with a mobile environmental support device which has the characteristics of rapid response,flexible use,efficient launch,batch storage,and roll backup.

At 12:12 Beijing time on July 27,2022,the Kinetica-1 rocket successfully launched 6 satellites into a 500-kilometer SSO from the JSLC.The payload of the first flight was 1068.63 kg,and the total weight of all satellites was 899 kg.During the flight,the solid motors used in all stages,the servo tracking instructions,the separations between stages as well as fairing of the satellite and rocket were all normal.

Six satellites were delivered into their designated orbits accurately,and complete telemetry data such as overload,vibration,shock and noise were obtained.This first flight mission was a complete success.

The deviation of the semi-major axis,eccentricity and orbital inclination of satellite A separation was 545 m,0.000001 and 0.001° respectively.The semi-major axis deviation of satellites B,C,D,E and F was 2 km,the eccentricity deviation was 0.0002,and the orbital inclination deviation was 0.008°.

The consumption of terminal velocity adjustment and attitude control propellant was within the design envelope,and the margin was large.The attitude angle velocity before the separation of satellite A was less than 0.5˚/s (2.0˚/s was required in the satellite-rocket interface control document),and the attitude angle velocity before the separation of other satellites was less than 0.6˚/s (2.5˚/s was required in the satellite-rocket interface control document).

2 TECHNICAL ANALYSIS

The Kinetica-1 rocket is a four-stage solid-propellant launch vehicle.It was developed to significantly reduce payload cost per mass in anticipation of the booming commercial space economy.It features outstanding advantages,including competitive payload capability and cost,robust orbital insertion accuracy,high reliability,availability at short notice and logistical versatility.It was designed mainly for delivering small-and medium-sized spacecrafts to SSO and LEO,supporting launch missions of single satellite,multiple satellites,and rapid constellation deployment and replacement,and can be flexibly adapted to various launch missions.

The four-stage solid tandem rocket is 29.668 m high with a core diameter of 2.65 m,and a take-off mass of about 134.9 t,a take-off thrust of 200 t,and can deliver payloads up to 1500 kg into 500 km SSO.The Kinetica-1 carrier rocket is shown in Figure 1.

Figure 1 Kinetica-1 carrier rocket

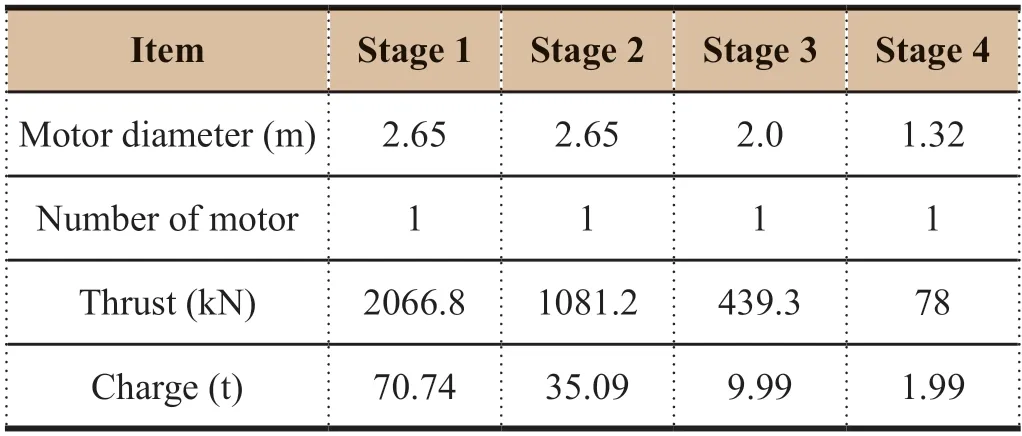

There are four solid propellant motors used on the Kinetica-1 launch vehicle.The first stage (takeoff thrust of 200 t) and the second stage (takeoff thrust of 100 t) motors fully inherit the mature technology of solid propellant motors in service,the third stage (takeoff thrust of 50 t) motor inherits the mature products,and the fourth stage (takeoff thrust of 10 t) motor is designed with mature technologies,using the materials,processes and methods widely used by the solid propellant motors in service.The configuration is shown in Table 1.

Table 1 The configuration of four solid propellant motors on Kinetica-1

The first stage has a “Gas generator+gas distribution valve”program to control rolling.

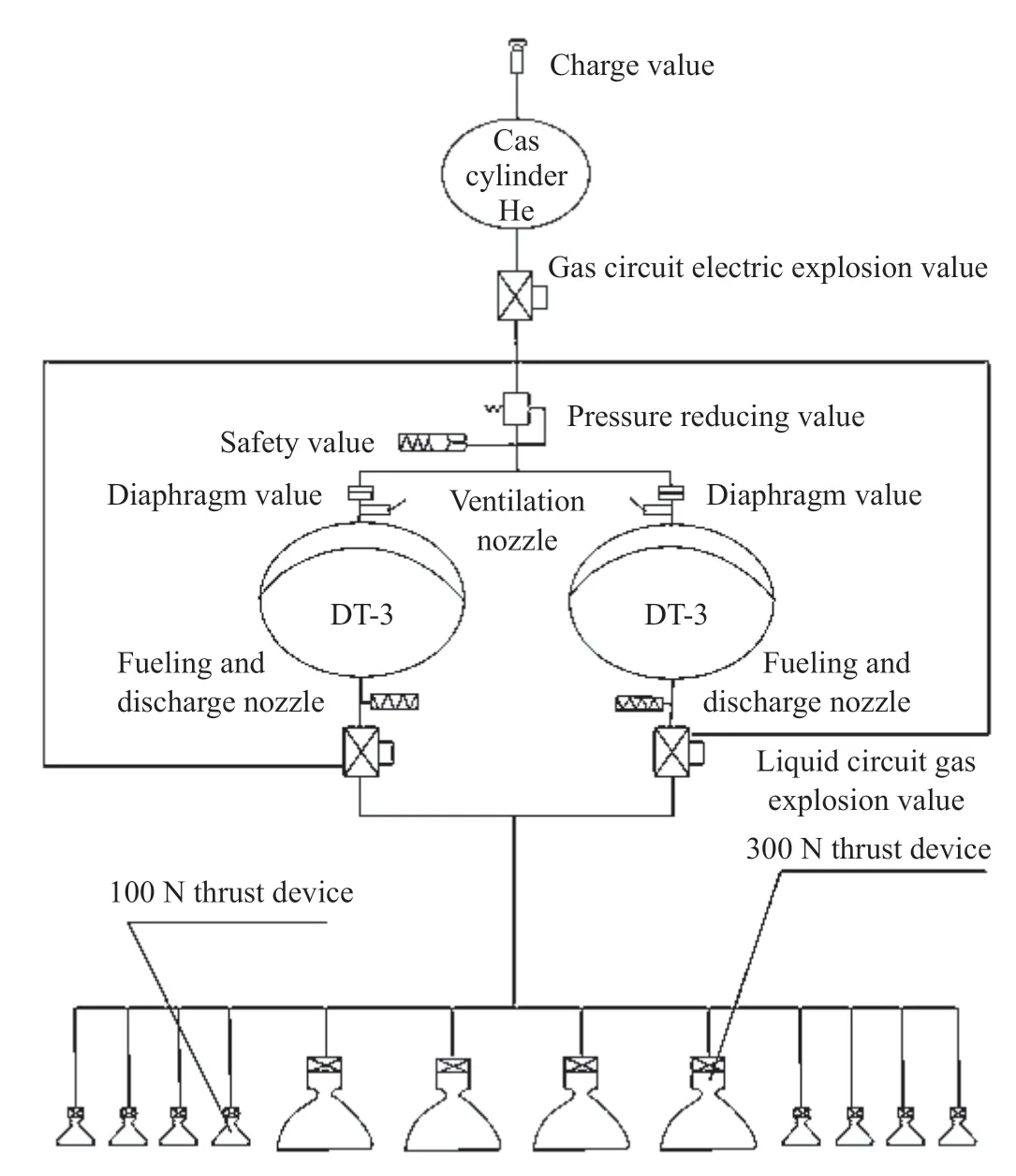

At the first stage,terminal velocity adjustment and attitude control system is applied,as shown in Figure 2.High-temperature and high-pressure gas flow is ejected from a left or right nozzle under the control of the distribution valve to control pitching,yawing and rolling to guarantee the accuracy of eccentricity.There are two thrust specifications: four 300 N motors and eight 100 N motors.The propellant tanks comprise two 40-L rubber-plastic composite semi-film tanks with a fueling capacity of about 83 kg.The gas cylinder is a 10-L titanium alloy cylinder.

Figure 2 Terminal velocity adjustment and attitude control system

Figure 3 The structural section of Kinetica-1

Figure 4 Measurement and control integration architecture avionics system

The structural section of Kinetica-1 is composed of 11 segments.For the fairing,the end is made of laminated glass fiber reinforced plastic,and the tapered column section is made of carbon panel-aramid paper honeycomb sandwich structure.A semihard shell structure with skin stringers is widely used in the first stage section,the third and fourth inter-stage section,the second and third inter-stage section,the second stage tail section,the first and second stage inter-stage section and the first stage tail section.Aluminum alloy castings are used for the third stage tail section and the first and second stages of the separation rings.

The navigation and guidance system of Kinetica-1 is composed of a composite navigation and guidance scheme using a“laser strap-down inertial measurement assembly+satellite navigation receiver+navigation satellite antenna feeder system+flight control assembly”.It determines the initial reference by means of“self-alignment+optical aiming” and uses “inertial/satellite integrated navigation+Kalman filtering”.

The first and second stages track the standard program angle and apply the transverse/normal guidance.The front section of the third stage tracks the standard program angle,and the rear section adopts an energy matching closed-circuit guidance.The fourth stage adopts the multi-constraint closed-circuit guidance method.

The attitude control system is a three-channel all-digital control scheme of pitch,yaw,and roll equipped with a “strap-down inertial measurement assembly+rate gyro+flight control assembly+data bus+actuator”.The flight control assembly completes the acquisition,processing,synthesis,correction,distribution,transformation and amplitude limiting of signals,and sends control commands through the bus.According to the control commands,the actuator controls the flexible nozzle and the terminal velocity adjustment and attitude control motor to realize the attitude control of pitching,yawing and rolling channels.

The avionics system of Kinetica-1 adopts a hybrid bus system and takes inputs from the inertial measurement assembly,rate gyro and various sensors to collect all kinds of physical parameters during the rocket flight.The key single control equipment adopts an integrated electronic equipment conforming to the 6U VPX standard,which includes the flight control assembly,intelligent measurement and control assembly,second stage integrated assembly,and data acquisition and processing assembly,so as to give full play to functions such as GNC calculation,integrated navigation calculation,timing control,and measurement parameter acquisition.The equipment applies“elector-mechanical servo mechanism+motor nozzle+attitude control nozzle” to realize the thrust vector and roll channel control of the whole rocket.The primary power supply of the whole rocket is provided by lithium-ion batteries and thermal batteries to realize the hierarchical and unified power supply and distribution.

The launch site equipment of Kinetica-1 includes a transfer vehicle,vertical transfer support vehicle of fairing assembly,fixed tower,measurement and control vehicle,launch pad,hoisting equipment.The assembly support equipment includes parking and docking equipment,spreader,gas distribution station.

The flight control function of the whole rocket adopts the 1553B bus standard,and realizes redundancy through A and B channels to ensure the reliability of the function.The communications channel between rocket and ground adopts an Ethernet dual network redundancy design,and the switch also adopts a dual redundancy design.Each device contains two switching modules,which are physically isolated to ensure the reliability of data interaction between rocket and ground.The CPU module adopts a triple redundancy architecture,and the module is composed of three computers with completely symmetrical design,and the interactive information among the three machines is shared and voted on to ensure the reliability of computer operation and control.The timing output module directly receives three hard-wired commands from the CPU module,and after being isolated by optocoupler,it drives a MOS transistor,and adopts a 2-out-of-3 voting design,which increases the reliability of the control circuit.

The guidance system is improved to deal with the fault condition when a motor fault affects the orbital insertion.The computers on the rocket can calculate the target orbit of the mission according to the real-time flight state,and match the orbital elements according to the real-time energy capacity,which further improves the flight safety of the guidance system and effectively ensures the reliability of the mission under fault conditions.

3 TECHNOLOGICAL INNOVATION

Kinetica-1 has completed 12 new core technologies,such as the high-tonnage solid rocket,three horizontals and one vertical mode.

Kinetica-1 is a large solid-propellant rocket,which uses a 70-ton motor for the first stage where its take-off thrust can reach 200 tons.It represents the development progress of China’s high-tonnage solid rocket program.It provides key inputs for the subsequent development of China’s solid rockets.

The three horizontals and one vertical refers to horizontal assembly,horizontal test,horizontal state transition and vertical launching of the rocket.These procedures can significantly reduce the rocket preparation time,and reduce launch time to an hour for the critical mission.It can also reduce the absolute dependence on the launch site so considerably improves the launch efficiency.These innovative technologies have laid a foundation for China’s further development of both liquid and solid rockets.The brief introduction of the 12 new technologies are as follows.

• Overall Optimization Design

From an overall perspective of rocket design,the concept of overall design and optimization replaces the independent design of stand alone systems.The carrying coefficient of Kinetica-1 can arrive at 1.12%.

• First Horizontal Modal Test of Large-tonnage Rocket in China

For the modal test,Kinetica-1 uses charged solid propellant motors with multiple air-springs being used to support the entire rocket,which greatly shortens the test cycle,reduces warranty conditions instead of traditional vertical test,and reduces the development costs.

• The Largest Integrated Solid Motor in China

The first stage of Kinetica-1 uses the largest integrated solid motor in China,which overcame the key technologies of large column structure design,design and manufacture of a large flow ablation-resistant flexible nozzle and joint,high-performance composite manufacturing.These innovations help the motor thrust increased to 200 tons.

• First Measurement and Control Integration Architecture Avionics System in China

With the design idea of function integration,board circuit integration,product generalization,each circuit board was connected through a custom communications protocol.This achieved hardware versatility and software customization.

• First Data-driven Ground Test and Launch Control System in China

The ground test and launch control system of Kinetica-1 was divided into the front end and the back end.They communicated with each other through a switch backbone network.

Software and rocket data are independent,and the data is used to drive processes.The development process of the rocket and the control interface were driven by custom data.The number of equipment on board and on the ground was greatly reduced.The digital system of the rocket defines its capabilities through software.

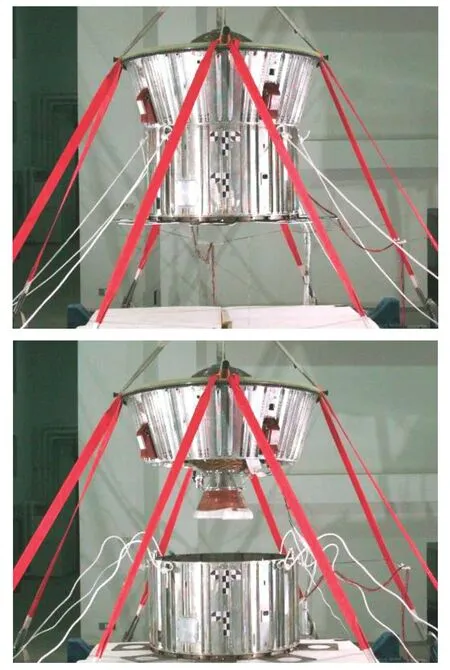

• First Non-pyrotechnic Separation Technology for Rocket Inter-stage Separation in China

The rocket adopted non-pyrotechnic separation technology for the rocket inter-stage separation,as shown in Figure 5.A pneumatic separation device is used instead of the traditional pyrotechnic scheme for flight separation.The pneumatic separation system is mainly used for inter-stage separation,using high-pressure gas as the separation energy source.It is applied to the separation of solid launch vehicles through a combination of mature technology and innovative technology.The mature technology includes the application of compressed gas mechanism,thermodynamics and kinetic energy transformation.The innovative technology includes efficient utilization of high-pressure gases,working sequences and redundant sealing mechanism.

Figure 5 Non-pyrotechnics separation technology for rocket inter-stage separation

Figure 7 Launching of the Kinetica-1

The mechanism conducts measures on ground more than 1000 times,while the pyrotechnic can only uses once.The system simplifies the structure,eliminate or minimize failures,and is committed to greatly improving the safety and reliability of launch vehicles while significantly reducing costs.

• First Solid-liquid Fusion Rocket Structure in China

A solid propellant motor with a skin-truss structure,which is commonly used in a liquid rocket,was adopted for Kinetica-1.A unified design approach was performed for all sections to reduce the types of components.Each structure section uses the same connecting format.The unified design of manufacture tooling frames was used to achieve the goal of low cost but with rapid manufacturing.

• China’s First Three 5-ms Cycle Redundant CPUs Software for Rocket Flight Control

The carrier rocket applies 3 redundant CPUs,where the control calculation cycle can be within 5 ms.Through optimization and precise analysis,it effectively improves the high precision and reliability of rocket flight.

• China’s First Layered Architecture System

Different from the traditional models,Kinetica-1 applied a layered architecture system for rocket flight control.The control software is clearly divided into three layers: functional layer,communications layer and driving layer.It can reduce the difficulty of implementing more complex and intelligent control functions in the future.

• First Multi-functional Assembled Mobile Environmental Support Plant in China

The plant undertakes missions including modal test environment assurance,launch area environment assurance and longterm environment assurance of the launch pad,thus saving funds for ground support equipment.

• Large Transfer and Hoisting Equipment for Rockets

Key new technologies have been achieved including design and process realization of vertical synchronous loading of multiple cylinders,which make the vertical test of the 135-ton rocket successfully conducted.

• Thermal-launch Solid Rocket Technology in China

To meet challenges,simulation of the gas flow field,design of a thermal protection scheme for the launch equipment and selection of protective materials were performed.It breaks through the thermal launch technology of large tonnage solid rockets and reduces the launch cost.

4 CONCLUSION

The solid launch vehicle is simple and reliable,which does not need to recharge the propellant before launching,and can be stored for a long time.At the same time,the solid rocket can respond quickly,be flexible and be convenient to use,has a low dependence on the launch site,and can be launched from land,sea and even in the air.

The first mission of the Kinetica-1 rocket was a complete success.It is used for launching small-and medium-sized satellites,it has enriched the spectrum of China’s solid rockets.It is of great significance to promote the reform and innovation of China’s carrier technology and promote the development of national space science.

杂志排行

Aerospace China的其它文章

- Kinetica-1 Carrier Rocket is Preparing for Launch

- CASC Released Blue Book of China Aerospace Science and Technology Activities in 2022

- Design and Application of Cloud Test Platform for Launch Vehicle Electrical System Based on Data-Driven Approach

- Psychological Issues in Simulated Space Missions: What We Learn From Chinese Crew

- Research on Key Technologies for Reusable Liquid Rocket Engines

- Development Status and Prospects of Solid Rocket Motor Technology for Large Launch Vehicles