A Triple Human-Digital Twin Architecture for Cyber-Physical Systems

2022-07-02DuansenShangguanLipingChenChangSuJianwanDingandChanLiu

Duansen Shangguan,Liping Chen,Chang Su,Jianwan Ding and Chan Liu

School of Mechanical Science and Engineering,Huazhong University of Science and Technology,Wuhan,430070,China

ABSTRACT With the development of information and communication technology and the advent of the Internet of Things(IoT)era,cyber-physical system(CPS)is becoming the trend of products or systems.The deep integration and real-time interaction between the physical world and the virtual world expand system functions.Although there are some CPS implementation guidelines,the virtual world is still relatively abstract compared to the concrete physical world that can be touched through the IoT.Besides that,human is a non-negligible CPS endogenous interactive intelligent component.In this paper,we propose a triple human-digital twin architecture,where the physical objects and the digital twins that are the projections of the physical entities establish the cornerstone of

KEYWORDS Cyber-physical systems;digital twin;human factors;systems architecture;collaboration

1 Introduction

In the last decades,the rapid advances in information and communication technology (ICT)have caused more and more physical objects to be interconnected through the network,where the physical objects have the embedded computing and communication capabilities so that they can recognize environmental events and supply environmental context services [1].And this smart,interconnected,and interoperable network is commonly referred to as machine-to-machine communications (M2M) or Internet of Things (IoT) [2,3].

Sensors and actuators that interact with the environment are widely used,where smart devices collect data (mostly from sensors) and use cloud computing or similar technologies to make comprehensive and timely decisions (act on actuators) [4].This phenomenon is depicted in the form of the cyber-physical system (CPS) [5].Here,the physical systems collect information data from the physical world and send them to the digital twin computing modules residing in the virtual world through communication technology.The digital twin computing modules process these data and return corresponding information such as findings,control commands,and system parameter configuration [6].And the digital twin is a complete and operational simulation of the physical system that represents all of its functionalities.

Since the National Science Foundation (NSF) first presented the concept of the CPS at the high confidence software and systems seminar in 2006 [7],academia and industry have shown tremendous interest in the field of CPS.In the Manufacturing area,machines are interconnected,and the CPS is used for real-time monitoring and production management [8].In the smart transportation area,this technology strengthens the connection among vehicles,roads,and drivers,sharing information on traffic intensity,congestion locations,and accidents to improve transportation efficiency [9].In the smart healthcare area,it can be used as the wireless sensor network for real-time remote monitoring of the patient’s physical condition [10].In the smart building field,the interaction between CPS and smart devices can reduce energy consumption and increase the protection,safety,and comfort of residents [11].In these applications,smart devices and sensors are the core to create more excellent system value.

The current researches related to the CPS mainly focus on the physical world,where most architectures give a detailed description of the construction and operation of the physical entities,such as heterogeneous systems integration,sensor network,and IoT.However,the idea of how to build a vivid and concrete virtual world is still an abstract concept.As a comprehensive digital representation of the physical system,the digital twin is a much more innovative and collaborative concept that can be used to simulate for various purposes.The most contribution to the CPS is that the digital twin realizes a two-way interaction between the physical and virtual worlds.On the one hand,changes in the behavior state of the physical entities can be dynamically reflected in the virtual model in real-time.On the other hand,the digital twin can collect the physical and virtual data by synchronized simulation for monitoring,control,intelligent analysis,and decisionmaking [12,13].Furthermore,humans,the most active and fundamental intelligent component of the CPS,play an increasingly significant role.Whereas there is no clear bridge to support the collaboration of the humans,the vivid physical world,and the unequivocal virtual world to make the distributed CPS a real-time,visible,controllable,and scalable value network along the product life cycle.

This paper presents a triple human-digital twin (THDT) architecture,where the physical objects and their accompanying digital twins collaborate with the humans in all the lifecycle phases.In previous research,we have established a hierarchical digital twin in the design phase that ensures the virtual world grows dynamically with the physical world [14].Moreover,the digital twin as a product data center throughout the life cycle can continue functioning in the subsequent stages.Here,with the human factors taken into consideration,a THDT architecture is established.The interaction,communication,and collaboration between the human and digital twin make the CPS an intelligent and flexible system that provides more real-time,efficient,intelligent,and personalized services.In this way,a digital twin is expected to be the center of the value chain and achieve a seamless synergy.

The remaining parts of the paper are organized as follows.The following section covers the related works.Section 3 introduces the hierarchical digital twin model.Section 4 presents the details of the THDT architecture.Section 5 showcases a case study of the power management digital companion platform for the lunar probe.Finally,Section 6 gives the conclusions and future work.

2 Related Works

CPS,a multi-dimensional complex system of integrated computing,network,and physical environment,implements the large-scale engineering systems’real-time monitoring,dynamic control,and information services with deep integration and collaboration of 3C (computation,communication,control) technologies [15].According to this definition,a typical CPS architecture consists of three levels: a physical layer at the bottom,an application layer at the top,and the cyber layer as a bridge connecting the two ends.Nowadays,most CPS architectures are the refinement and complement to these three levels.

With the advent of the IoT era,the new CPS-based automation architecture has taken shape.Lee et al.[16] proposed a unified 5C (connection,conversion,cyber,cognition,configure) architecture,which integrates different levels of the devices in the vertical direction of the industrial system,including sensors,parts,machines,plants,and enterprises.Each level performs a further analysis,generating helpful knowledge from the raw data and passing it up.Besides that,Jiang added 3C aspects (coalition,customer,and content) into the 5C architecture to further realize the horizontal integration of the value network [17].Both architectures provide a step-by-step guideline for the implementation of the CPS in manufacturing.However,these architectures mainly focus on the performance of the physical layer of the CPS,where the core of creating more excellent system value depends on the smart devices on the IoT.But due to the easily extended devices or systems and massive data,the virtual world is much more open.Therefore,it is challenging to construct virtual models matching the physical objects in design,manufacture quality,and operation.

In addition,most application layers are deployed to work in the social space.Pirvu et al.[18]proposed an anthropocentric cyber-physical reference architecture for smart factories (ACPS4SF)that embeds human subjective initiative into the smart industrial systems.Jiang et al.[19] proposed new social manufacturing (SocialM) paradigm,which can provide consumers with related services related to production and products.Zamfirescu et al.[20] proposed the anthropocentric cyber-physical system (ACPS) reference model to achieve the automated factory.Aheleroff et al.[21] proposed a digital twin reference model representing the digital twin as a service and highlighted the digital transformation in humans,processes,and technologies.These researches emphasize that human is a critical factor in achieving an intelligent manufacturing ecosystem.However,the abstract virtual world is hard to touch and control for different human task roles.What is essential is that the deep interaction and collaboration of the social space,physical space,and cyberspace will be possible if the virtual world is sufficiently specific.

Recently,the digital twin has emerged as the core technology for implementing the CPS.The digital twin is defined as an integrated multiphysics,multiscale,probabilistic simulation of the physical entities that use the best available physical models,updated sensor data,and historical data to mirror the status,behavior,and performance of its corresponding physical twin [22].The digital twin is thus touted as the ideal brushto draw the cyber layer.Tao et al.[23] proposed a new digital twin-based product design method,which enables the designers to understand the intrinsic principle of the physical entities and have the fingeron the pulse of the consumers.Leng et al.[24] proposed a novel digital twin-driven approach for rapid reconfiguration of automated manufacturing systems,which realizes rapid alteration of manufacturing system capacity and fast integration of multiple processes into existing systems.Liu et al.[25] proposed a digital twinbased manufacturing system design platform prototype,allowing the dynamic execution of a new manufacturing system to be verified in its early stage of deployment.Söderberg et al.[26] applied the digital twin in the individualized production process to guarantee the geometric quality of the final product.Alam et al.[27] proposed a digital twin architecture reference model for the cloudbased CPS,which implements intelligent control and decision-making with Bayesian networks and fuzzy logic-based rules.Leng et al.[28] proposed a digital twin-driven joint optimization approach to improve the utilization and efficiency of the large-scale automated high-rise warehouse productservice systems.However,these researches mainly focus on the description,implementation,and application of some phases of the product life cycle,such as design,production,operation,and control.Therefore,the digital twin lacks a unified presentation of the entire life cycle and cannot be the optimal bridge to support the interaction and collaboration of the virtual and physical worlds.

In previous research,we have established a hierarchically distributed framework of the digital twin to achieve dynamic growth with the physical entities [14].In this paper,further,we propose a THDT architecture,where the digital twins are the data center of the projection of the physical entities and open to different human roles from the perspective of the product life cycle.And the contact and collision between the physical objects,virtual objects,and humans are expected to create an entire value integration system.

3 Triple Human-Digital Twin Architecture

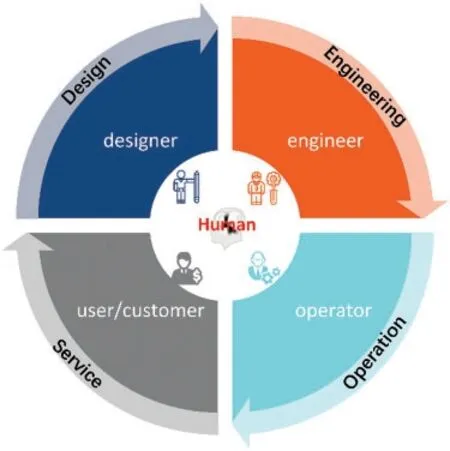

In large complex systems,humans (e.g.,designers,engineers,consumers) not only play a clear role in the product lifecycle but also are the composite factor in a highly automated system [18].The proposed THDT architecture is shown in Fig.1.Driven by the digital twin data,the humans interact and collaborate with the digital twins,which implement a service network together.Therefore,the architecture is mainly composed of the following five parts.

(1) Interconnected Physical Things in Physical World

In the physical world,physical things are various functional units (such as sensors,actuators,etc.) that make up physical objects.Functional units complete specific tasks through collaborations with each other.These collaborations are further enhanced with the ubiquitous IoT,and even many independent functional units are interconnected to perform particular goals as systems of systems [29].Physical individuals plan their response mechanisms based on control instructions and disturbance data.And they can also respond to requests from other individuals or request other individuals to respond.Thus,under the goal of global optimization,the individual behaviors are coordinated and optimized.In addition,compared to the traditional mechatronic systems,the real-time status,behavior,and performance of the physical entities can be perceived by the higher levels of the CPS.Accurate and reliable data can be obtained from various devices or systems through sensors or information systems.What needs to be added is that the interconnected physical individuals should be clearly described in a hierarchical manner.

Figure 1:A triple human-digital twin architecture for cyber-physical systems

(2) Virtual Companion of Physical Entities in Virtual World

The virtual things (i.e.,virtual models) in the virtual world are the full-element reconstruction and simulation of the physical objects’functions,behaviors,and states.

In the THDT architecture,each physical thing is automatically accompanied by a virtual thing in the virtual world.The virtual thing and the physical thing are one-to-one correspondence.Each physical or virtual thing is identified by a unique ID and the existence of its counterpart is known.Whenever the physical thing state changes in the physical world,the virtual models use the current best available physical model,the updated sensor data,and the historical data to mirror the state of the physical objects.The construction and update mechanisms of these models are all done in a hierarchical architecture.

(3) Humans in Social World

Different human roles,such as designers,engineers,consumers,users,maintainers,can participate in the product life cycle and collaborate with each other,as shown in Fig.2.The smart manufacturing system implemented in the form of the CPS requires different human roles to build various artificial societies,organizations,and systems to provide sufficient human resources support for analysis,evaluation,and decision [30].

Figure 2:Various human task roles in the product life cycle

It is worth noting that the activities of humans in the physical and virtual worlds,in turn,affect the function,behavior,and structure of the physical system.The ubiquity of the knowledge and the information caused by the ICT has completely changed the relationship between consumers and manufacturers.The social network information,the historical transaction data,and vast amounts of information from all aspects of the customer provide a wealth of materials for big data technology and facilitate the implementation of the mass-customized flexible production systems.In addition,due to the development of the IoT and cloud technologies,enterprises and manufacturers can achieve remote benchmark services at a low cost.

(4) Digital Twin Data

Digital twin data refers to all the data related to the humans,the virtual models,the physical objects,their intertwined services,and the derived data through data fusion of the above four parts.The data in the architecture consists mainly of five parts: The human behavior data(management data,customer reviews,market data,etc.),the physical entity data (process data,operation data,status data,capacity data,energy data,fault data,environ-mental data,etc.),the virtual model data (model parameters,simulation data,etc.),the service data (evaluation data,optimization data,prediction data,etc.) and the fusion data.The fusion data refers to the derivative data generated by the integration,statistics,correlation,clustering,evolution,regression,and generalization of the other four types of the existing data.

The ubiquitous digital twin data provides a full-featured,full-process,full-service data integration and sharing platform eliminating information silos.

(5) Digital Twin Data-driven Services

Digital twin data-driven services such as precise management,intelligent prediction,resilient control,and reliable operation and maintenance are provided by the pairwise interaction and collaboration of the physical things,the virtual things,and the humans.

The virtual things in the virtual world refine and improve their models based on the data from the physical world,and in turn,realize the real-time monitoring,control,and prediction of the physical things by collecting,counting,analyzing,and processing the digital twin data.And the virtual things and the physical things are peer-to-peer correspondence.Thus,in the light of the digital twin,the humans can get comprehensive information of the CPS,including any independent devices,sensors,and even the tiny internal components that are perceived by the soft sensors [31],which makes it possible to perform the subtle process adjustment and the local optimization possible.In addition,humans can force termination and modify system-specific functions according to the context (e.g.,designers can respond to consumer feedback and add system patches promptly).The interaction and collaboration among the physical things,the cyber things,and humans enhance the flexibility of the CPS.

In short,the most important enlightening significance of digital twins is that it realizes the two-way interaction between virtual and real.Humans can put everything that happens in the physical world back into the virtual world,including humans’subjective thoughts.The whole life tracking with loop feedback may be a perfect whole life cycle concept.In this way,the coordination of the physical and virtual worlds can be ensured throughout the entire life cycle.Various simulations,analysis,data accumulation,mining,and even the application of artificial intelligence based on virtual models can ensure its applicability with real physical systems.Then,the simulation technology of virtual models can be used to explore and predict the unknown world to find better methods and stimulate innovative thinking.The following is the specific description of the collaboration process among the physical objects,the virtual models,and the humans,making the CPS a smart and flexible system.

4 Key Enabling Techniques

The most challenging aspects of achieving THDT applications are the construction of multidomain integrated system models,the consolidation of twin data,and the implementation of integrated services derived from collaboration between humans and digital twins.This section describes these key enabling technologies.

4.1 Construction of Hierarchical Multi-Domain Integrated System Models

In previous research,we adopted a hierarchical and distributed framework to build a digital twin that dynamically grows with the product life cycle,as shown in Fig.3 [14].Compared with traditional modeling methods,the hierarchical structure of the system model achieves the consistency of the topological structure of the virtual models and the physical objects.This ensures a one-to-one correspondence between the virtual and real models in each level from the system to the components to the interface.And a unique correspondence between virtual and real things is formed.Here,the model framework is retained and extended.

Figure 3:A hierarchical digital twin model for cyber-physical system

As shown on the left of Fig.3,the physical entity is defined as a hierarchical structure to realize the level-by-level decomposition from the application scenario and system level to the component and interface level.Starting from the top-level design of CPS,the system model is represented as a lumped parameter model.The physical constitutive of systems in different fields are usually described by Ordinary Differential Equations (ODEs),and the constraints between system components are generally represented by Algebraic Equations.In object-oriented physical modeling,the characteristics of the physical system are reflected in the interaction of the component models,and the connection relationship represents the constraints between the component models.There is a coupling between the differential equations that express the system characteristics and the algebraic equations that connect and transform.The physical modeling of the components will naturally produce differential-algebraic equations (Differential-Algebraic Equations,DAEs) in a general form.Therefore,for CPS,its functional knowledge model can be represented by the multi-domain physics unified modeling language Modelica [32].Modelica can consistently describe the CPS’s energy flow,abstract the concepts of potential variables and flow variables in different fields,and realize a unified mathematical mapping representation of multi-domain models based on the generalized Kirchhoff’s law.

With the advancement of the life cycle,since many subsystems usually come from different departments or suppliers,the realization of the model usually involves personnel of different professions.At this time,humans familiar with the principles and composition of the respective subsystems merge the component models of different fields into the subsystem model in the vertical direction.Finally,through the horizontal integration of each sub-system,a parameterized and modular system-level comprehensive analysis model can be quickly constructed [33].

In the process of association and integration,the realization of the model should consider the correspondence between virtual and real architectures to ensure the unity of information and the intuitiveness of applications.And it must also consider better independence among different professional models to ensure better-distributed team collaboration.Therefore,in integrated development,several major factors such as model architecture,behavior,and interfaces must be considered comprehensively to implement the system model from bottom to top,as shown in Fig.4.

Figure 4:Model association integration process

4.2 Consolidation of Digital Twin Data

The digital twin data is a bridge between the virtual model and the physical entity.Twin data includes real-time physical data,model data,and data fusion between the two,which is continuously updated and optimized as real-time data is generated.The integration of twin data is to establish a two-way mapping relationship between virtual data and physical data.In the operating phase,the operating data from the physical entity is parsed and transmitted to the virtual model to complete simulation,verification,and dynamic adjustment.At the same time,virtual data is fed back to the physical world to respond to changes,improve operations and increase value.

However,due to the various types of data,different data formats,and the huge amount of data,twin data needs to be integrated as needed.As shown in Fig.5,the data consolidation process consists of four main processes:

(1) Data docking.The key to realizing data docking is to establish the mapping relationship between the physical device hardware driver interface and the device interface model.Use the unified modeling language Modelica to describe the device driver interface uniformly and directly associate and match the model interface with the device driver interface.Whenever the physical world changes,the sensor data will be transmitted directly to the model through the device driver interface and vice versa.

(2) Data preprocessing.Whether virtual data or physical data,due to the influence of various factors such as external interference,system error,or measurement error,digital twin data inevitably have defects such as time deviation,missing points or key points,single or patched outliers,and random noise.These flaws seriously affect the consistency verification results of the test data and may even lead to an incorrect evaluation of the credibility of the simulation system.To minimize the impact of various flaws,the digital twin data must be preprocessed before performing data-driven services.

(3) Data mapping.Establish the mapping relationship between the engineering parameters in the physical entity and the virtual model parameters.And a direct one-to-one connection is realized between the physical entity and the virtual model through data interaction.

(4) Fusion of virtual and real.During the virtual and real fusion operation,the virtual model and the physical entity are synchronized in parallel.Control instructions,mission events,and environmental boundaries are the common inputs of the digital twin.In the operation process,based on the virtual and real model data fusion solution operation technology,and the virtual model receives real physical data in real-time and updates the model state at each solution iteration step,which guarantees the consistency of the virtual model and the physical entity to the greatest extent.

Figure 5:Twin data consolidation process

4.3 Integrated Services from Collaboration among Physical Things,Virtual Things&Human

Compared with the current development methodology based on detailed engineering,the interrelationship among the different stages of the CPS’s life cycle will become more critical.The THDT architecture not only focuses on the integration between virtual things and physical things but also emphasizes the human factors in the life cycle.The abstract collaborative process between the physical things,virtual things,and humans can be visually represented by the interaction among the three worlds (i.e.,the expected world,the interpreted world,and the external world) [34].The interpreted world plays a crucial role in connecting the expected world to the external world.The expected world is the fantasy world that the imaginative actions of the designers or the design agents will produce.The external world is the world that is composed of various physical entities (equivalent to the physical world here).And the interpreted world is the world that is built up by the design agents based on subjective understanding and objective knowledge about the physical world (equivalent to the virtual world here).

Similarly,further than that,the relationship between the digital twin and various human roles that are not limited to the designers in the product life cycle can also be vividly illustrated in the interaction of the three worlds.The physical objects in the physical world are still in the external world.The difference is that the expected world is expected to expand from the designer to various human roles,with a particular focus on the designers and the users/consumers.Finally,the interpreted world is presented by the digital twin in the virtual world.The digital twin is a collection of all digital artifacts that describe the physical entities,including data information in existing information systems (such as PLM,PDM,ERP,SCADA,and service cloud,etc.) and models describing the behavior of the physical entities.On the one hand,the digital twin is a virtual representation of the human thought that reflects the design intent of the designer,the operational status of the operator,and the feedback from the user.On the other hand,the digital twin can monitor and control the real-time status of the physical entities.Naturally,the digital twin in the interpreted world is generated as a link between the expected world and the external world.

Fig.6 details the collaborative process among the three worlds.Here,to clearly describe the interaction process,the twin data serves as a separate module that provides a single data source for the humans,the virtual models,and the physical entities.

Figure 6:Collaboration between the humans,the virtual models,and the physical objects in their respective worlds throughout the life cycle

Firstly,in the expected world,the designers establish the system requirements based on the historical data and the physical knowledge from the past versions of the products (i.e.,Arrow 1 in Fig.6).Then,a series of demand,functional,and product models are used to repeatedly verify and validate the desired design requirements in the interpreted world (i.e.,Arrow 2 in Fig.6).In this process,the digital twin integrates the traditionally large and decentralized data (such as historical data,demand data,feedback data,etc.) into the hierarchical digital twin.In turn,the designers can obtain the improvement measures and methods of the product through a single data source (i.e.,Arrow 3 in Fig.6).At the end of the product design phase,various components need to be integrated into a complete system for testing.At this moment,as accurate mapping of previous versions of the product,the virtual models may be used for real-time interaction with the previous physical entities to comprehensively consider the environmental factors and the realtime factors,ensuring the correctness of the design and helping reduce the unnecessary physical testing.Therefore,for the designers,the digital twin is a smart tool to recognize,create,and modify physical products,providing the designers with new ideas,methods,and implementation approaches.

Secondly,after the design is completed,the virtual model in the interpretation space is projected onto the physical entity manufactured in the external world by the engineer.During the operation of the product,the operational status,behavior,and performance of the physical entities in the external world will be transmitted to the interpreted world to update the virtual models(i.e.,Arrow 4 in Fig.6) through the enabling technologies such as the IoTs,sensors networks,etc.With the context-aware data,the product status data,and the knowledge of the older product,the digital twin enables intelligent analysis and decision making and real-time control of the state and behavior of the product (i.e.,Arrow 5 in Fig.6).

The highlight of the collaboration between the humans and the digital twins occurs in the service phase,which is the most significant difference from the traditional methodologies.In the light of the intelligent view of the system provided by the digital twin,the human roles in different scenarios can access the models and results from other lifecycle phases,laying a foundation for a more flexible service plan.Specifically,the customer feedback and the product usage information in cyberspace can be obtained and delivered to the enterprises through the integrated network (i.e.,Arrow 6 in Fig.6).The enterprises can rely on this information for online updates of the products without re-engineering.As a result,the design process at the initial stage and the operation and maintenance process at the late stage are connected by the digital twin.From this perspective,the digital twin can close the cycle from the operation and service to the new products design or the version update.

Combined with the new generation of artificial intelligence (AI) technology,it is worth mentioning that the role of humans is enhanced.Humans can build intelligent information systems with cognitive and learning capacity by transferring part of the cognitive and learning manual work to computers.Applying the information system that continuously optimizes decision-making processes through machine learning using existing data,historical experience,and context can significantly improve system autonomy in practical engineering systems.Moreover,humans have cognitive and innovative thinking abilities that are not available in computers or AI,e.g.,the human brain can detect correlations between millions of multidimensional signals and abstract complex problems or things.Furthermore,in the light of the human-in-the-loop hybrid enhancement intelligence,the human-machine deep integration can improve the system’s capability to handle the complexity and uncertainty problems and heavily enhance the performance of the manufacturing system [35].

5 Case Study:Power Management Digital Companion for Lunar Probe

5.1 System Description

The power system of the lunar probe is a typical CPS,which is highly open to the external physical environment.The continuous interaction between the energy calculation management process and the physical operation process ensures the reliable,sustainable energy supply of the probe.However,in the current test phase and the future on-orbit operation phase,the Chang’e-5 lunar probe [36,37] lacks an effective digital intervention for the comprehensive grasp of the state of the power system,which makes the later control and optimization difficult.In this section,we present a case study of the power management digital companion platform to demonstrate how the collaboration between humans and the digital twins can drive the design,operation,and maintenance of the complex CPS.

Fig.7 shows the composition module and operation process of the power management digital companion platform for the Chang’e-5 lunar probe.The left side of the figure shows the participants in two critical phases of the lunar probe life cycle: Designers and operators.The middle of the figure is the virtual and real corresponding on-orbit lunar probe power system and virtual simulation model,which maintain a two-way interaction.On the right side of the figure are the digital twin data-driven serves,including condition monitoring,data interpretation,fault diagnosis,and maintenance decision-making.And in the light of the unified data center and information center,the designers and the operators can collaborate across different lifecycle phases to maximize the subjective initiative of the human roles,which reduces the development costs and time and improves the performance of the designed probe.

Figure 7:The power management digital companion process for lunar probe

5.2 System Implementation

5.2.1 Built the Digital Representation of the Power System

The lunar probe power system is a complex continuous-discrete hybrid multi-physics system,so it is evident that the implementation of its hierarchical digital twin architecture is a challenging task.Here,Modelica,an object-oriented multidomain unified modeling language,is used to describe the digital twin models rather than the heterogeneous model collaboration based on the high-level architecture (HLA),avoiding the interface compatibility problem caused by the integration of multiple software [38–40].Fortunately,the knowledge and experience of the previous lunar probes or similar systems have accumulated into a series of model libraries that can be relied upon to accelerate and simplify the development of the current one [33].This process also often occurs in the design process of other complex CPSs.

As shown in Fig.8,the lunar probe power system model is expressed in a unified form,supporting a multilevel and multi-granularity simulation.The system model library on the left covers the environmental models,solar array models,battery-pack models,power controller models,load models,and power distribution models.The right side is the digital artifact of the real power system described by the Modelica models.And the lunar probe power system model provides a hierarchical view from the system level and subsystem level to the component level and interface level corresponding to the physical things,which runs in a unified architecture and facilitates the inspection,verification,and optimization of the entire system in an overall view.In addition,in light of the extensive experimental and historical data,the iterative calibration and verification of the models enhance the fidelity of the digital models in terms of the behavioral characteristics and ensure the accurate mapping of the model and the real physical entity.

Figure 8:The unified-form,multidomain,multiview power system simulation model

Then,in the design and subsequent phases,based on the system simulation model,a series of simulation analyses on the function,performance,and reliability of the power system can be performed,such as the battery pack simulation,the power regulation,the distribution design simulation,the energy balance simulation,the power flow simulation,the failure mode simulation,and the primary power interface circuit simulation.The simulation results of the multi-physical unified model can accurately reflect and mirror the real state and behavior of the real lunar probe power system,which makes it possible to detect the function and performance of the system in the virtual environment and eventually replace the physical prototype.

5.2.2 Data Mapping to Facilitate Virtual-Real Synthesis

After the future launch,the lunar probe is measured and controlled by the ground station (the ground equipment for space communication on the earth).And the mission of the ground station is mainly to monitor,receive,process,and store the telemetry and remote control (TTC) data.Therefore,for the lunar probe power system,the data fusion between the virtual things and the physical things in the THDT architecture is to establish a two-way mapping relationship between the power system model data and the TTC data.

The power management digital companion platform can subscribe to the TTC data from the ground station via TCP/IP protocol.The received telemetry packets are unpacked and parsed according to the profile specification protocol.Then,the real physical data is processed into a series of flight events that the model can use.Then,the flight event is associated with the corresponding model parameters to generate a time series about the flight scene.In turn,the simulation process/result data generated by the real-time data-driven virtual model is stored in the agreed.xml format file.This format file generates the remote feedback information via the data processing analysis module (such as data interpretation and identification) to establish a negative feedback map.

Therefore,a mapping relationship between virtual model data and TTC data is established: a forward mapping relationship between telemetry data and model input data and a reverse mapping relationship between simulation result data and remote data.In this way,the digital twin can effectively integrate and fuse TTC data to achieve the purpose of virtual and real synthesis.

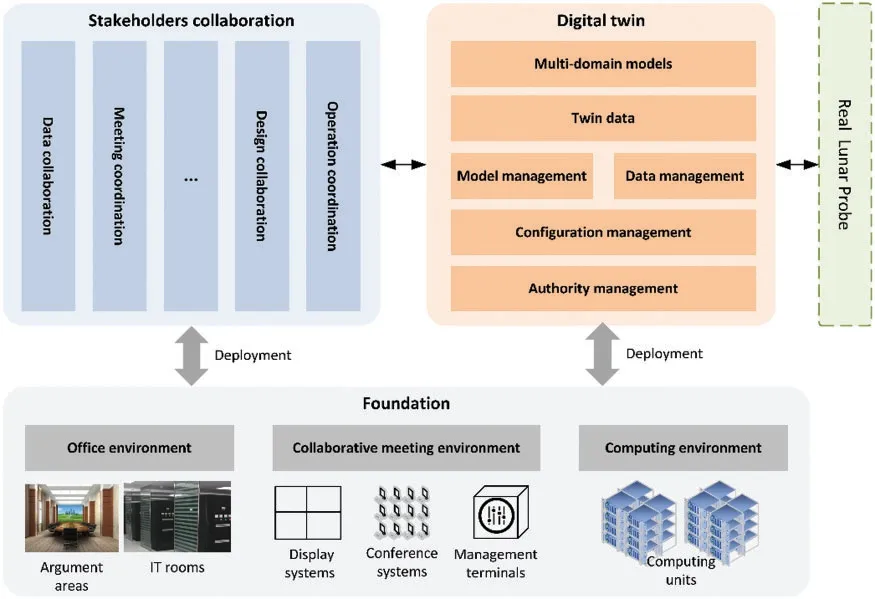

5.2.3 Stakeholder Collaborative Management Platform

Whether it is the design of the lunar probe or the operation and monitoring process,it is a considerable challenge,requiring engineers and experts from different fields.Digital twins provide these stakeholders who were not close in the past with a material foundation for collaboration.Concerning the THDT architecture,the multi-person collaborative management platform consists of a fundamental support environment,a stakeholder collaboration system,and a digital twin system,as shown in Fig.9.

Figure 9:Stakeholder collaborative management platform

The fundamental support environment provides hardware support,including office environment,collaborative meeting environment,and high-performance computing environment.

The stakeholder collaboration system is deployed and runs on each node station of the collaborative meeting environment to provide a software system for stakeholders to collaborate on meetings,data,design processes,and operation processes.Combined with the digital twin,it can meet the needs of application scenarios of the lunar probe power systems,such as design,scenario trade-offs,state monitoring,fault diagnosis,maintenance,etc.

The digital twin system is deployed on the fundamental support environment,and the virtual model interacts with the lunar probe power system in real-time.The computing environment supports high-performance computing for digital twins in different scenarios.

5.2.4 Digital Twin Data-Driven Services

When designing the lunar probe power system,the digital twin became a bridge for communication and collaboration between engineers and experts in different fields.On the collaborative management platform,experts can focus on their areas of expertise and conduct cross-domain collaboration and multi-system integration.Moreover,as the life cycle progresses,digital twins are gradually filled with more realistic models and related data and eventually become an essential link in the operation of physical entities.

During the operation of the lunar probe,the digital twin realizes the effective integration of the real-time dynamic information related to the time dimension and space dimension,promoting the integration of the virtual models and the physical system.Hence the power management digital companion platform can provide further online status monitoring,data interpretation,fault diagnose,and maintenance decision-making services.

The digital twin actually reflects the real operation of the power system through simulation and analysis,which is the foundation of the digital twin data-driven services.When the on-orbit lunar probe power system and the virtual model are running in parallel,control commands,mission events,and environmental boundaries are their common inputs.During operation,the virtual model accepts real physical data in real-time and updates the model state at each solution iteration step,so as to ensure the consistency of the virtual model and the physical entity to the greatest extent.Therefore,the digital twin can provide an intuitive and comprehensive view of the on-orbit lunar probe power system,as shown in Fig.10.This dramatically reduces the trivial work of testers and operators.Moreover,operators can easily and intuitively communicate with designers and manufacturing personnel based on the same digital twin.

Figure 10:The power management digital companion platform provides a more intuitive and comprehensive display about the power system of the on-orbit lunar probe

Data interpretation refers to the analysis,monitoring,and reasoning of the real-time physical data and simulation data,judging whether the operating state of the lunar probe power system meets the design expectations.As shown in Fig.11,based on the hierarchical dynamic companion model,the critical simulation parameters,such as bus voltage,bus current,wire voltage drop,device switch,device power consumption,etc.,can be compared with the on-orbit telemetry data in real-time to interpret the online telemetry data.The result of the abnormal interpretation is given a failure warning value and an eye-catching sign,which can assist the on-orbit staff in monitoring the operational status of the power system and providing a reasonable evaluation.In this modularized,automated,and visual way,the on-orbit operation management capability is effectively improved.

Figure 11:Real-time data comparison and online fault interpretation

When the interpretation result gives a fault warning,the power system fails.The feature parameters of the power system are compared with the corresponding model parameters to analyze the system state.Then,use data-driven intelligent algorithms,such as decision tree [33]and deep transfer learning [41],to determine the failure causes of system failures.

Another vital contribution of digital twins is collaborative decision-making maintenance.During the lunar probe design process,the possible failure modes are often fully considered,and corresponding maintenance measures are proposed.Two basic maintenance strategies are mainly used here: Regular maintenance and condition-based maintenance.Regular maintenance is to replace the wearing parts or switch the working mode of the power system according to the original flight plan.These plans can be described in the virtual model and reminded at the necessary point in time.Condition-based maintenance is when a failure occurs in actual operation,a set of maintenance measures can be selected from the maintenance plans.The effectiveness of the chosen measures can be verified on the digital twin before being executed.Based on the digital twins,different stakeholders can discuss and analyze based on the digital twin and improve their decision-making opinions on the collaborative management platform.

5.3 Discussion

Due to the complex mission requirements,variable operating environments,and closed R&D environments,the lunar probe is highly customized.Therefore,the design and operation phases at both ends of the lunar probe life cycle are significant and challenging.And,the space-ground environment taken into consideration,the operation and maintenance of the power system often rely on the logic and functions defined in the early design process.In this paper,the power management digital companion platform supports the development of the power system based on the digital twin method,which helps improve the rapidly closed loop of the development process and the ability to control the data source.The development pattern is changed:

(1) A change to model- and data-centric from the traditional tool-and text-centric.

(2) A change to models and flexible data-based processes from traditional serial processes.

(3) A change to all-digital,industrial intelligent aided design from traditional semi-digital design.

As a result,the power management digital companion platform becomes the model and data center for different human roles.On the one hand,the digital twin provides a consistent and shared functional integration model for designers in various fields,supporting group argument and group innovation.On the other hand,real-time monitoring enables operators to perform quantitative assessments of system status.

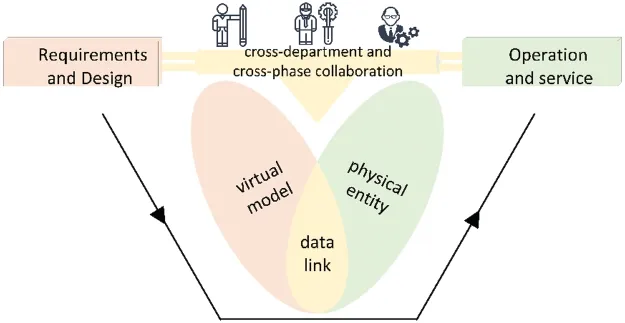

What’s more,the designers and operators can collaborate on the resources,technologies,and information across the lifecycle based on the unified digital companion platform (Fig.12).Everyone no longer only pays attention to their own work but can see a bigger picture.The goals of all teams can be linked together in a way that breaks the info vallum inside the split teams.The designers are able to face usage requirements in real-world scenarios,which include the operator habits that text or data cannot reflect.In this way,the passive demand response is translated into the proactive service response.In addition,the operators can provide a more comprehensive insight into the operating principle of the system with the help of the designers,so as to troubleshoot and deal with the faults when the faults occur.

Figure 12:Digital twin-driven collaboration across the departments and phases

The power management digital companion platform is a smart cross-department and crossphase collaboration environment for designers and operators.During the development of the Chang’e-5 lunar probe,the design and operation departments are organically integrated into a complete team to maximize the value of the digital twin.

However,there are still several issues to be addressed in future work:

(1) In consideration of the constantly updated and refined models over time,managing and scheduling the enormous model resources according to the application requirements requires further research.

(2) Given that the digital twin involves all the models and data along the product lifecycle,ensuring data security and protecting personal privacy needs future research.

(3) Human-machine collaborative intelligence.In the current THDT,we have clarified the critical role of humans.However,in the above applications,the role of humans is mainly played at the level of collaboration between humans and the communication of needs and models.The autonomy and intelligence of human beings as intelligent agents to promote digital twins require more in-depth research.

6 Conclusions

In the upcoming Internet of Things era,the cyber-physical system (CPS) is a smart system with the deep integration of the virtual and physical worlds,where the real-time interaction between the physical objects and the digital twins expands new capabilities.Digital twins are ultrarealistic digital artifacts that reflect the real-time state of physical entities and control them when necessary.This gives a transparent implementation approach to the virtual world,emphasizing the collaboration between physical objects and virtual models.Furthermore,once human factors are accounted for,information integration across the product value chain is possible.

This paper proposes a triple human-digital twin (THDT) architecture,where a hierarchical digital twin is the data center,service center,and value center for different human roles to recognize and change the physical world.The hierarchical distribution makes the physical objects and the virtual models match one to one,ensuring that digital twins can evolve with the dynamically growing CPS.The collaboration between these three (physical objects,virtual models,and humans) is vividly reflected through the al-ternate interactions among the expected world,the interpreted world,and the external world along the whole life cycle.It is worth noting that the digital twins provide humans with a visual perspective of the physical objects to support the interdisciplinary collaboration across the departments (even enterprises) and phases,which makes the comprehensive control of the CPS possible.Moreover,in light of the digital twin,the visual and quantitative tool for the unknown world,humans can continually inspire innovative thinking to optimize and update the design.Finally,the lunar probe’s power management digital companion platform succinctly demonstrates the practical application process and effects of the THDT architecture,which hopes to provide experience and lessons for other complex systems developments.

As part of ongoing and future work,we plan to study the scheduling of complex models and the security management of twin data.In addition,human-machine collaborative intelligence is also the core research content of the future.

Acknowledgement: Thanks for the support of the members of the complex system design team in Huazhong University of Science &Technology CAD Center.

Funding Statement: This research was funded by National Key R&D Program of China [Grant No.2018YFB1700905] and National Defense Basic Scientific Research Program of China [Grant No.JCKY2018203A001].

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

杂志排行

Computer Modeling In Engineering&Sciences的其它文章

- Analysis of Multi-AGVs Management System and Key Issues:A Review

- Assessment of the Solid Waste Disposal Method during COVID-19 Period Using the ELECTRE III Method in an Interval-Valued q-Rung Orthopair Fuzzy Approach

- Sentiment Analysis of Roman Urdu on E-Commerce Reviews Using Machine Learning

- Nonlinear Response of Tunnel Portal under Earthquake Waves with Different Vibration Directions

- A Method Based on Knowledge Distillation for Fish School Stress State Recognition in Intensive Aquaculture

- Detecting and Repairing Data-Flow Errors in WFD-net Systems