Quality enhancement and microbial reduction of mung bean (Vigna radiata)sprouts by non-thermal plasma pretreatment of seeds

2022-05-05DongjieCUI崔东洁XiaoxiaHU胡小霞YueYIN阴悦YupanZHU朱育攀JieZHUANG庄杰XiaojieWANG王小洁RuonanMA马若男andZhenJIAO焦浈

Dongjie CUI (崔东洁), Xiaoxia HU (胡小霞), Yue YIN (阴悦),Yupan ZHU (朱育攀), Jie ZHUANG (庄杰), Xiaojie WANG (王小洁),Ruonan MA (马若男),∗and Zhen JIAO (焦浈),∗

1 Henan Key Laboratory of Ion-Beam Bioengineering, School of Agricultural Sciences, Zhengzhou University, Zhengzhou 450052, People’s Republic of China

2 Suzhou Institute of Biomedical Engineering and Technology, Chinese Academy of Sciences, Suzhou 215163, People’s Republic of China

3 School of Life Sciences and Basic Medicine, Xinxiang University, Xinxiang 453003, People’s Republic of China

Abstract Mung bean(Vigna radiata)sprouts are widely consumed worldwide due to their high nutritional value.However, the low yield and microbial contamination of mung bean sprouts seriously reduces their economic value.This study investigates the effects of non-thermal plasma on the quality and microbial reduction of mung bean sprouts by pretreatment of seeds in water for different times (0, 1, 3 and 6 min).The quality results showed that short-time plasma treatment(1 and 3 min)promoted seed germination and seedling growth, whereas long-time plasma treatment (6 min)had inhibitory effects.Plasma also had a similar dose effects on the total flavonoid and phenolic contents of mung bean sprouts.The microbiological results showed that plasma treatment achieved a reduction of native microorganisms ranging from 0.54 to 7.09 log for fungi and 0.29 to 6.80 log for bacteria at 96 h incubation.Meanwhile,plasma treatment could also efficiently inactivate artificially inoculated Salmonella typhimurium (1.83-6.22 log)and yeast (0.53-3.19 log)on mung bean seeds.The results of seed coat permeability tests and scanning electron microscopy showed that plasma could damage the seed coat structure,consequently increasing the electrical conductivity of mung bean seeds.The physicochemical analysis of plasma-treated water showed that plasma generated various long- and short-lived active species [nitric oxide radicals (NO·), hydroxyl radicals (·OH), singlet oxygen (1O2),hydrogen peroxide (H2O2), nitrate (NO3-), and nitrite (NO2-)] in water, thus the oxidizability,acidity and conductivity of plasma-treated water were all increased in a treatment timedependent manner.The result for mimicked chemical mixtures confirmed the synergistic effect of activity of H2O2,NO3-andNO2-on bacterial inactivation and plant growth promotion.Taken together, these results imply that plasma pretreatment of mung bean seeds in water with moderate oxidizability and acidity is an effective method to improve the yield of mung bean sprouts and reduce microbial contamination.

Keywords:non-thermal plasma,mung bean sprout,quality,microbial reduction,reactive oxygen and nitrogen species

1.Introduction

Seed sprouts have long been used in the diet as health foods;they are not only a good source of basic nutrients but also have important phytochemicals with disease prevention and health-promoting properties[1].Among legumes,mung bean(Vigna radiata)sprouts are a popular part of the diet in many Asian countries (especially China, India, Bangladesh and Pakistan)[2].They are rich in protein,dietary fiber,minerals,vitamins and bioactive compounds (such as polyphenols,polysaccharides and peptides)[3, 4].Moreover, mung beans are also a relatively drought-tolerant and low-input crop with a short growth cycle (70 days or so)in agricultural production, making them popular for cultivation worldwide [2].

Nevertheless,many factors can lead to a considerable loss of production, nutrition and economic value of mung bean sprouts[5].Until now, various conventional methods (such as genetic engineering, physical intervention and chemical addition)have been used to increase the production of mung bean sprouts[6-8].However, the limitations of these methods, including gene transfer, high economic costs, a complex production process,environmental threats and human and animal health hazards,should be noted.Recently, non-thermal plasma has emerged as an innovative,eco-friendly,economical and effective approach to improve seed germination,seedling growth and yield of various crops [9, 10].Non-thermal plasma is a neutral ionized gas containing electrons, ions, UV photons, electric fields and reactive oxygen and nitrogen species(RONS)[such as hydrogen peroxide(H2O2), hydroxyl radicals (·OH), singlet oxygen (1O2), superoxide anions (·O2-), ozone (O3)and nitric oxide radicals (NO·)][11].These complex constituents in non-thermal plasma can etch the seed coat, increasing the seed coat permeability to oxygen,water and other nutritive species, consequently improving seed germination and seedling growth [12].In particular, RONS at low concentration can also act as bioactive signaling molecules to regulate plant growth and development [13].

Additionally, although mung bean sprouts are widely consumed due to their good health benefits and low calorific value, it should be acknowledged that mung bean sprouts, as the main edible sprout type, have been identified as a major cause of foodborne disease outbreaks.The primary source of microbial contamination on sprouts is mainly derived from the seeds rather than the sprouting process [14].Hence, disinfection of seeds before the cultivation of sprouts is the most effective measure to control microbial contamination during sprout growth.Numerous studies have reported that nonthermal plasma exhibits excellent antimicrobial activity against a wide range of pathogenic bacteria and fungi on seeds or plants, almost without producing any harmful byproducts[15].Non-thermal plasma not only directly damages the cell wall/membrane of microorganisms but also induces oxidative stress in microbial cells [16].Given that non-thermal plasma exhibits an outstanding stimulatory effect on plant growth and antimicrobial properties, it is considered as a promising technology for pretreatment of mung bean seeds to improve the yield and microbial safety of mung bean sprouts.

Although many studies have shown the effectiveness of non-thermal plasma in seed decontamination and promotion of seed germination and seedling growth by directly treating the seed surface, non-thermal plasma could generate a certain amount of heat and the plasma treatment is not uniform when encountering the irregular seed surface [17].Inspired by the study of Park et al [13], who reported that non-thermal plasma produced large amounts of RONS in water and their distribution in the aqueous solution was very homogeneous, allowing uniform treatment of seeds with irregular shapes, we decided to investigate the effects of plasma on the quality and microbial reduction of mung bean sprouts by pretreatment of mung bean seeds for different times in water.Firstly,the quality parameters of mung bean sprouts (seed germination, sprout fresh weight,sprout length, total flavonoid and total phenolic contents)were measured.Secondly, the reduction of native and artificially inoculated microorganisms in mung beans during germination by plasma treatment was measured.Thirdly, seed conductivity and scanning electron microscopy(SEM)were used to evaluate the effects of plasma on the seed coat structure.Fourthly, to explore the major agents in non-thermal plasma responsible for these effects when treating the seeds in water,the major RONS in gas plasma and plasma-treated water were measured by optical emission spectroscopy (OES), electron spin resonance(ESR)and UV spectrophotometry, respectively.Lastly, the oxidation-reduction potential (ORP), conductivity, pH, temperature and nitrate/nitrite (NO2-/NO3-)concentration were also measured to realize the physicochemical properties of plasmatreated water.Furthermore, in order to determine the main role of some components in the plasma treatment process, chemical simulation experiments were also performed.

2.Materials and methods

2.1.Mung bean seeds

The mung bean(Vigna radiata)seeds used in this study were purchased from a local supermarket in Zhengzhou, Henan.Uniform mung bean seeds based on shape and size were selected for the experiment and kept in a refrigerator at 4 °C until use.Before each experiment, seeds were allowed to equilibrate to room temperature for about 2 h.

2.2.Plasma device and plasma treatment

As shown in figure 1, a single electrode non-thermal atmospheric pressure plasma jet driven by an alternating current power supply was used to treat the mung bean seeds in water.The non-thermal plasma jet consists of a quartz tube,a 1 mΩ resistor and an outer copper foil that surrounds the quartz tube.The outer copper foil, serving as a single electrode, is connected to a 10 kHz sinusoidal high-voltage source with an 18 kV peak-to-peak voltage.The quartz tube has outer and inner diameters of 10 and 7 mm, respectively.Due to the difficulty of stable excitation of cold plasma jets at atmospheric pressure in air and the high cost of pure rare gases[18], premixed argon, oxygen and nitrogen (88% Ar, 2% O2and 10%N2per volume,referred to as Ar/O2/N2)were used as the working gas and with a flow rate of 5 l min−1.The plasma is generated inside the quartz tube near the powered outer electrode and then propagates to generate a continuous plasma jet outside the quartz tube in the surrounding atmospheric pressure air.The mean gas temperature of the nonthermal plasma is 40.3 °C.

For non-thermal plasma treatment of mung bean seeds in water, 20 uniform mung bean seeds were randomly selected and then placed in a sterile 50 ml plastic centrifuge tube containing 10 ml of sterile deionized water treated with the plasma for 0, 1, 3 and 6 min, respectively.The seeds treated by plasma for 0 min served as controls.The distance between the end of the plasma nozzle and the liquid level was fixed at 2 cm.After plasma treatment, 20 seeds were immediately collected from the water and randomly divided into two groups.One group with 10 seeds was used for the subsequent seed germination and sprout length analysis.Another group with 10 seeds was used for the following seed electroconductivity assay.

2.3.Evaluation of seed germination rate, sprout length and fresh weight

For measurement of the seed germination rate, the plasmatreated mung bean seeds were spread on a sterile 90 mm diameter Petri dish covered with two layers of sterile moistened gauze and then placed in an incubator at a temperature of 25 °C ± 2 °C and 85% ± 5% relative humidity for germination.Every 6 h, 5 ml of sterile deionized water was added to each Petri dish to maintain sufficient moisture for seed germination.The mung beans with a ruptured seed coat due to a protruding sprout were considered as germinated seeds[19].The seed germination rate was calculated based on the total number of germinated seed divided by the total number of seeds for each treatment using the following formula:germination rate(%) = N0/N × 100,where N is the total number of germinated seeds and N0is the total number of seeds.The germination rate of each treatment was recorded at 0, 6, 12 and 18 h.Ten seeds were germinated for each treatment, and seed germination was performed in triplicate.

The sprout length of plasma-treated mung beans was recorded at 48 h during seed germination and growth.The total length of mung bean sprouts, including the length of sprouts and the length of radicles, was measured with a vernier caliper.The measurement of sprout length was performed three times with 30 mung bean sprouts per treatment.Fresh weights of plasma-treated mung beans were counted at 48 h during seed germination and growth, respectively.The measurement of fresh weight was conducted with 20 seedlings per replicate,and all the experiments were conducted three times.

2.4.Determination of bioactive compounds in the sprouts of mung beans

2.4.1.Extraction of mung bean sprout samples.The sprout extracts were prepared according to the method described in[20,21].Briefly,the freeze-dried sprout samples(1.0 g)were extracted with 10 ml of extraction solvent (acetone/water/acetic acid, 70:29.5:0.5 v/v/v)at room temperature and the mixture was continuously shaken at 200 rpm on an oscillator for 3 h.The extract was centrifuged at 6800g for 15 min at ambient temperature, the supernatant was collected and the residues were re-extracted twice with 5 ml of fresh extracting solvent.All extracts were stored at 4 °C until analysis.

2.4.2.Determination of total phenolic content and total flavonoid content.After plasma treatment, the total phenolic content of mung bean sprouts was determined by a Folin-Ciocalteu assay using gallic acid (GA)as the standard.The total phenolic content was calculated based on the standard curve of GA concentration and expressed as milligrams of GA equivalent (GAE)per gram dry weight of sprouts (mg GAE/g DW).Total flavonoid content was estimated by the aluminum chloride (AlCl3)colorimetric method and rutin was used as the standard for the calibration curve.The results were expressed as milligrams of rutin equivalent(RE)/g dry weight of sprouts(mg RE/g DW).The detailed experimental procedures for determining total phenolic content and total flavonoid content were described in previous work by Xiang et al [20].Each sample was analyzed in triplicate.

2.5.Colony count assay

2.5.1.Native microorganisms.The population of native microorganisms on mung beans after plasma treatment was measured to reflect the plasma inactivation efficiency.The mung bean seeds were treated by plasma as described in section 2.2, then the population of native bacteria and fungi on the surface of the seeds was verified by pour-plate count methodology using standard method agar.Twenty seeds(1.5 g)were rinsed in a 20 ml centrifuge tube with 15 ml of sterile deionized water.Subsequently, 100 μl of the rinsing solution from the mung bean germination dishes was spread uniformly on nutrient agar (NA)and rose Bengal medium(RBM)plates and then incubated at 37 °C and 28 °C to measure the population of bacteria and fungi, respectively.Microbial counts were expressed as the logarithms of colonyforming units per gram (log10CFU g-1).

2.5.2.Artificially inoculated microorganisms.Mung bean seeds were sterilized with disinfectant (75% ethanol:30%hydrogen peroxide, 4:1)for 2 min then dried off naturally to inactivate the natural microflora on the outer skins before inoculation.For each experimental group, 12 sterile tubes were prepared in groups of three tubes.Each tube contained 20 seeds and was spiked with 10 ml of Salmonella typhimurium suspension adjusted to 107−108CFU ml-1[14].All the seeds in the tubes were stored with the bacterial suspension for 30 min in order to enable bacterial adhesion.The samples were then taken out of the tubes and held at room temperature for 10 min to dry.After an attachment period, the samples were treated by plasma as described in section 2.2, and then the plasma inactivation efficiency was determined by serial dilution and a CFU count on NA.All plates were incubated at 37 °C for 24 h.

The yeast inoculation procedure was based on the above method with some modifications as follows: (1)each tube contained 20 seeds and was spiked with 10 ml of yeast suspension adjusted to 106−107CFU ml-1; (2)the plasma inactivation efficiency was determined by serial dilution and CFU count on yeast extract peptone adenine dextrose(YPAD)medium [17]; (3)all plates were incubated at 30 °C for 48 h.

2.6.Measurement of seed electroconductivity

Ten plasma-treated mung bean seeds were washed with sterile deionized water and immersed in 25 ml of sterile deionized water to allow ions to leach through the seed membrane into the water.The electrical conductivity of the solutions was determined as seed electroconductivity, which can reflect the ions leached through the seed membrane.The seed electrical conductivity was detected by an electrical conductivity meter(Mettler-Toledo, Switzerland)at 0, 24, 48 and 72 h.The measurement of seed electroconductivity was repeated three times for each treatment.

2.7.Observation of seed coat morphology

SEM was used to characterize the seed coat morphology.After plasma treatment,the mung bean seeds were fixed with 2.5% glutaraldehyde at 4 °C overnight.The samples were then dried completely under ethanol dehydration(20%,40%,60%,80%,100%;15 min each time)and then the surface was sputter-coated with gold and observed by SEM (JSM-6700F,JEOL, Japan)[22].

2.8.Detection of major excited reactive species in plasma by OES

To identify the major excited reactive species generated by Ar/O2/N2plasma in air, OES was employed in the 200-900 nm range with an AvaSpec-2048-8 Fiber Optic Spectrometer (Avantes, USA).One end of the fiber optic cable was used to acquire the light signals at a distance approximately 5 mm away from the exit nozzle of plasma device.The dispersed emission spectra were recorded by a 2048 pixel charge-coupled device detector array.

2.9.Measurement of RONS in water treated by plasma

NO·,·OH and1O2,as important RONS in the water treated by plasma, were measured immediately after plasma treatment by ESR spin-trapping spectroscopy, which is a magnetic resonance technique based on the interaction of unpaired electron spins with an external magnetic field[23].Due to the short lifetime of NO· (around 5 s), ·OH (around 10−9s)and1O2(around 10−6s), the spin trapping reagents of 5,5-dimethyl-1-pyrroline N-oxide (DMPO), 2,2,6,6-tetramethylpiperidine (TEMP)as well as diethyldithiocarbamate(DETC)and Fe2+were used to trap ·OH,1O2and NO·,respectively.Either 2 μl DMPO (0.8 M)or 20 μl TEMP(≥99%)was added to 1 ml of filtered double-distilled water and mixed thoroughly before being treated by plasma for 30 s to detect ·OH and1O2, respectively.A mixture of 0.5 ml DETC and 0.5 ml Fe2+was treated by plasma for 30 s to detect NO·.Each final product was imbibed by a capillary and measured in the resonator cavity of an ESR spectrometer (E-500, Bruker, Germany)operated at room temperature.

The concentration of H2O2was detected by a H2O2assay kit (Beyotime, China)according to the manufacturer’s instructions [24].The optical absorbance at 560 nm was measured by a fluorescence microplate reader (Varioskan Lux, Thermo, USA).

2.10.Analysis of the physicochemical properties of water treated by plasma

After plasma treatment of 10 ml of sterile deionized water without mung bean seeds for 0, 1, 3 and 6 min, the ORP,pH and temperature of the water were immediately measured with a pH and redox multimeter (Mettler-Toledo, Switzerland).The electrical conductivity of the water was detected by an electrical conductivity meter (Mettler-Toledo, Switzerland).The measurements for each treatment were repeated in three replicate experiments with two samples per experiment.

2.11.Detection of NO3- and NO2- in water treated by plasma

Ten milliliters of sterile deionized water was treated by plasma for 0, 0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5 and 6 min,respectively.After plasma treatment,10 ml of plasmatreated water was immediately transferred into a centrifuge tube for the measurement ofNO3-andNO2-concentrations by spectrophotometry.The time for the transfer was controlled to within 5 s.For the measurement ofNO3-concentration,200 μl of 1 mol l−1hydrochloric acid and 20 μl of 0.8% sulfamic acid were added to 10 ml of plasma-treated water, then determined by ultraviolet absorption spectrometry(NanoDrop 8000, Thermo Scientific, USA)at a single wavelength of 220 nm.For the measurement ofNO2-concentration, sulfanilamide and N-(1-naphthyl)-ethylenediamine hydrochloride were used as the diazotizing reagent and coupling reagent,respectively.Two hundred microliters of 10 g l−1sulfanilamide was added to 10 ml of plasma-treated water and incubated at room temperature for 2 min; subsequently 200 μl of 1 g l−1N-(1-naphthyl)-ethylenediamine hydrochloride was added for 20 min at room temperature.After incubation,NO2-levels were measured at 540 nm.The measurement ofNO3-andNO2-for each treatment was conducted on three replicates with two samples per replicate.

2.12.Chemical mixture simulation and nitrate fertilizer effect

The analytical reagents sodium nitrite, sodium nitrate and 30% H2O2were applied to the prepared mimicked solutions,and then the pH was adjusted back with HCl [25].The composition of the simulated solution was close to that of the solution treated with plasma for 3 min.The effects of chemical mixture on plant growth promotion and bacterial inactivation of mung beans were evaluated as described in sections 2.2 and 2.5.2, respectively.

Calcium nitrate(Ca(NO3)2)was used to evaluate the role of nitrate as a fertilizer during the growth of mung beans.Chemical solutions containing an equivalent concentration range (0-200 mg l−1)ofNO3-to that in plasma-treated water were separately prepared, and applied to react with mung bean seeds.Whole seedlings were collected after 48 h cultivation for fresh weight measurement.The length of sprouts was measured using Image J software with the Segmentation Line tool after setting scales.Each sample was analyzed in triplicate.

2.13.Statistical analysis

All data were obtained from three replicate experiments with a completely randomized design.Values from all experiments were expressed as mean ± standard deviation (SD).Statistical analysis was performed using SPSS statistical package 17.0 (SPSS Inc., USA).An analysis of variance was conducted to compare the effects of different treatments on the seed electroconductivity of mung beans, and significant differences between mean values were identified by Duncan’s multiple range test with a confidence level at p ≤ 0.05.Moreover, the paired-sample t-test was applied to compare the values of seed germination rate, sprout length, physicochemical properties of water (ORP, electrical conductivity,pH and temperature)as well asNO3-andNO2-levels between plasma-treated and control groups.Significant differences are expressed as*p < 0.05,**p < 0.01 and***p < 0.001.

3.Results and discussion

3.1.Effects of non-thermal plasma on seed germination and sprout growth of mung beans

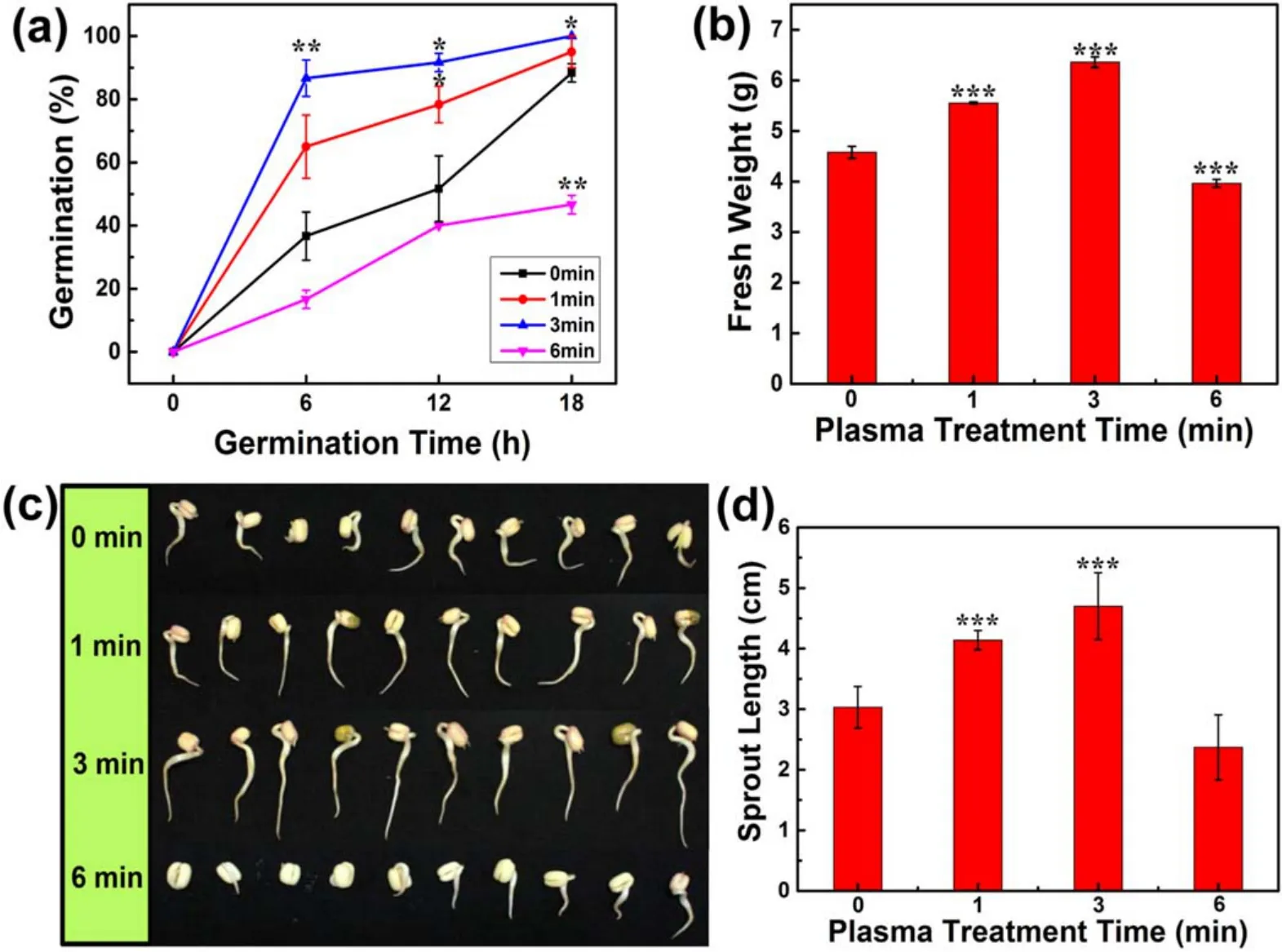

To investigate the effects of non-thermal plasma pretreatment of mung bean seeds on the yield of mung bean sprouts, the seed germination,sprout fresh weight and sprout length were measured.As shown in figure 2(a), the germination rate of mung bean seeds was significantly increased with the extension of plasma treatment time to 3 min over the whole germination process.For 3 min plasma treatment, the seed germination rate reached 86.67% at 6 h, then increased to 100% at 18 h, indicating that short-time plasma treatment (1 and 3 min)could enhance mung bean seed germination.However, when the plasma treatment time rose to 6 min, the seed germination rate was significantly lower than that of controls for the whole germination process.At 18 h, the seed germination rate for 6 min plasma-treated seeds was 46.67%,while control seeds achieved a germination rate of 88.33%,indicating that long-time plasma treatment (6 min)exhibited marked inhibitory effects on mung bean seed germination.These results reveal that non-thermal plasma has a dosedependent effect on the germination of mung bean seeds.

In figure 2(b),the fresh weight of mung bean sprouts was increased with plasma treatment time for the first 3 min, then decreased at 6 min.The 1 and 3 min plasma treatments resulted in a distinct increase of 21.3% and 38.9%, respectively, in fresh weight compared with controls (p < 0.001).For the 6 min plasma treatment, the fresh weight was significantly lower than that of the controls (p < 0.001).As shown in figure 2(d),the sprout length of mung beans showed a similar trend to that of fresh weight.The values of sprout length peaked at 3 min plasma treatment and then decreased with longer plasma treatment times.Compared with controls,the 1 and 3 min plasma treatments led to a distinct increase of 36.6% and 56.7%, respectively, in sprout length, while a decrease of 26.7% was observed after the 6 min plasma treatment.Photograph of mung bean sprouts after non-thermal plasma treatment are shown in figure 2(c), and it can be seen that 1 and 3 min plasma treatments have an obvious stimulating effect on the growth of mung bean sprouts while 6 min plasma treatment inhibits sprout growth.Taken together,non-thermal plasma also has a dose-dependent effect on the growth of mung bean sprouts and the maximum stimulatory effect was achieved with 3 min plasma treatment,similar to the results for seed germination.

These results demonstrate that non-thermal plasma pretreatment of mung bean seeds can enhance the yield of mung bean sprouts via improvement of seed germination,sprout fresh weight and sprout length.Similar results have also been observed in other plants.For example, Živković et al demonstrated that short-time(4-6 min)plasma-treated Paulownia tomentosa seeds had a germination rate of 75%,while untreated seeds only had a germination rate of 30%[9].Yin et al found that a significant improvement was observed in tomato germination percentage in a pot experiment after plasma treatment.The sprouting rate for the plasma-treated seeds was 32.75%, whereas that of controls was only 4.75%on the 11th day.Germination time was more than 1 day earlier than in controls, and the plasma treatment increased tomato yield by 20.7% [26].Kitazaki et al reported that non-thermal plasma treatment could improve the growth of radish sprouts[27].Mitra et al reported that seed germination of Cicer arietinum was increased with plasma treatment times up to 3 min, while longer plasma treatment inhibited seed germination [28].Jiang et al investigated the effect of different powers of non-thermal helium plasma on seed germination, seedling growth and yield of wheats.Their results showed that 80 W plasma treatment significantly increased the seed germination potential (6.0%), germination rate (6.7%), plant height (21.8%), root length (11.0%)and fresh weight(7.0%)of wheat seedlings [29].Stolárik et al reported that non-thermal plasma increased the germination percentage of pea (Pisum sativum L.)seeds as well as the growth parameters (root length, shoot length and dry weight)of seedlings in a treatment time-dependent manner [30].Guo et al claimed that the germination potential, germination rate, germination index and vigor index of wheat seeds as well as seedlings length and weight were all improved after plasma treatment at appropriate energy levels [12].In our previous study, non-thermal plasma also exhibited a dose effect on seed germination and early seedling growth of Arabidopsis, ranging from stimulation (≤3 min)to inhibition(≥5 min)depending on the plasma treatment time[31].In addition, plasma also had a dose effect in the medical field.A low dose stimulated the redox signal of cells,thereby improved antioxidant capacity, while a high dose led to accumulation of harmful cellular effects and cell apoptosis/necrosis [32].

3.2.Effect of non-thermal plasma on total flavonoid and phenolic content of mung bean sprouts

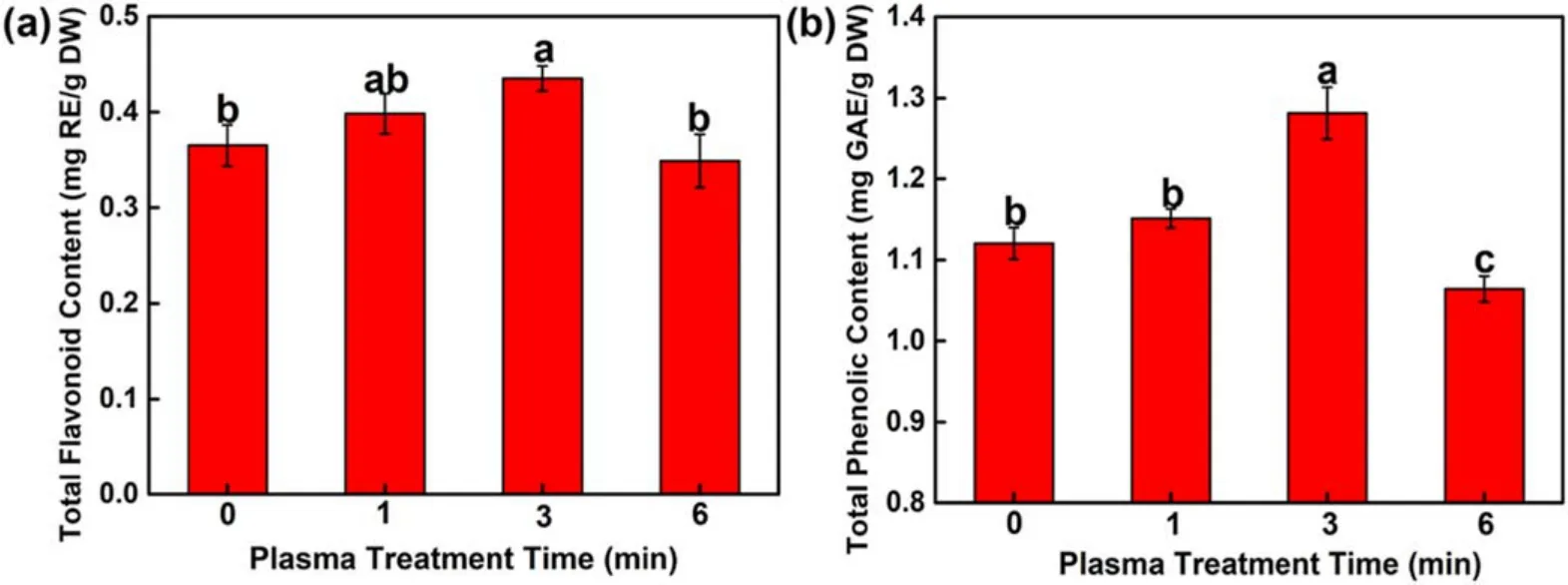

Flavonoids and phenolics,as the main bioactive compounds in the seeds and sprouts of mung beans,have been demonstrated to have potent anticancer activity [33-37].The total flavonoid and phenolic content of mung bean sprouts after 0,1,3 and 6 min plasma treatment are presented in figure 3.As shown in figure 3(a), the total flavonoid content reached a peak after 3 min plasma treatment at a concentration of 0.44 mg RE/g DW, subsequently reduced to 0.35 mg RE/g DW after 6 min treatment.In figure 3(b),total phenolic content of mung bean sprouts showed a similar tendency to that of flavonoid content, with a dramatic increase during the first 3 min plasma treatment, up to 1.28 mg GAE/g DW, then a significantly decrease.These results are in good agreement with the previous findings [38], in which PAW treatment caused a rise first and then a fall in the total flavonoid and phenolic contents of mung bean sprouts(p > 0.05).

3.3.Antimicrobial effect of non-thermal plasma against native and artificially inoculated microorganisms on mung bean seeds

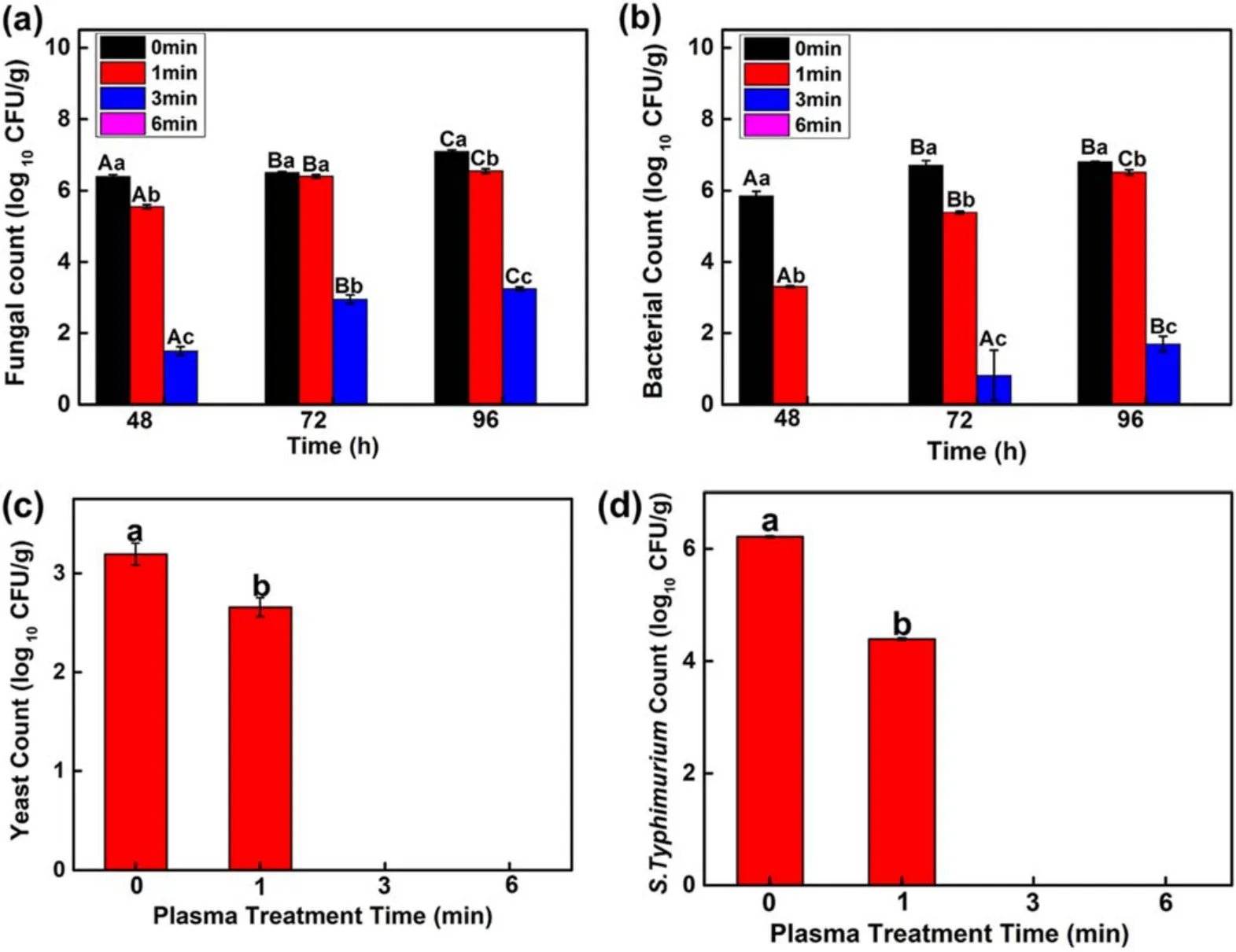

Given that contaminated seed is one of the main reasons for the majority of reported sprout-associated foodborne disease outbreaks [39], the mung bean seeds were pretreated by non-thermal plasma and the native fungal and bacterial population of the mung beans during the sprouting process was measured.As shown in figures 4(a)and(b),the fungal and bacterial counts of the untreated mung beans (control)was significantly increased from 6.39 to 7.09 log CFU g-1and 5.85 to 6.80 log CFU g-1with incubation time ranging from 48 to 96 h (p ≤ 0.05),respectively,indicating that the mung bean seeds used for sprout production were initially contaminated by fungi and bacteria.Non-thermal plasma treatment caused a remarkable reduction in the fungal and bacterial count of mung beans during the sprouting process in a treatment time-dependent manner(p ≤ 0.05).At 96 h incubation,1,3 and 6 min plasma treatment achieved 0.54, 3.84 and 7.09 log CFU g-1reduction for fungi and 0.29, 5.11 and 6.80 log CFU g-1reduction for bacteria,respectively.These results indicate that non-thermal plasma treatment could effectively inactivate the native microorganisms attached to the mung bean seeds (the inactivation efficiency for microorganisms with 6 min plasma treatment reached 100%),accordingly controlling microbial contamination during the growth of the mung bean sprouts.

The inactivation efficacy of plasma treatment against the artificially inoculated yeast and S.typhimurium on mung bean seeds is shown in figures 4(c)and (d).The populations of yeast and S.typhimurium on the mung bean seeds were reduced by 0.53 and 1.83 log CFU g-1, respectively, after 1 min plasma treatment.The inactivation efficiency of artificially inoculated yeast and S.typhimurium reached 100%after 3 min plasma treatment, indicating that non-thermal plasma is effective at reducing the populations of yeast and S.typhimurium inoculated on mung bean seeds.

Seed decontamination by non-thermal plasma has also been found by other groups.For example, Selcuk et al reported that plasma treatment significantly reduced the initial contamination level of fungus on seeds while maintaining the germination quality of the seeds[40].Mitra et al reported that 1- and 2-log reductions of the natural microbiota attached to the surface of Cicer arietinum seeds was observed after non-thermal plasma treatment for 2 and 5 min,respectively[35].Butscher et al reported that plasma treatment resulted in a maximum reduction of 3.4 log for Escherichia coli on cress seeds and highlighted that the inactivation efficiency of non-thermal plasma against the microorganisms on seeds was mainly influenced by the type of microbial contamination,substrate surface properties and moisture content of the seeds, as well as variations in the power input of the plasma device [41].Štěpánová et al found no surviving Cladosporium cucumerinum spores on cucumber seeds after plasma treatment, while plasma resulted in a 50%to 80%reduction of Didymella licopersici spores on pepper seeds[42].Therefore,non-thermal plasma may be established as an efficient method to reduce microbial contamination on seeds and ensure food safety.

Moreover, based on the results for mung bean sprout yield (figure 2)and seed decontamination (figure 4), it is worth noting that although 6 min plasma treatment exhibited the best antimicrobial effects against native and artificially inoculated fungi and bacteria on mung bean seeds, it caused obviously negative effects on the seed germination and sprout growth.On the contrary, 3 min plasma treatment not only enhanced the yield of mung bean sprouts but also reduced the microbial contamination during the sprouting process, so can be used as the optimal non-thermal plasma treatment time in practical application by trading off between the yield and microbial quality of mung bean sprouts.

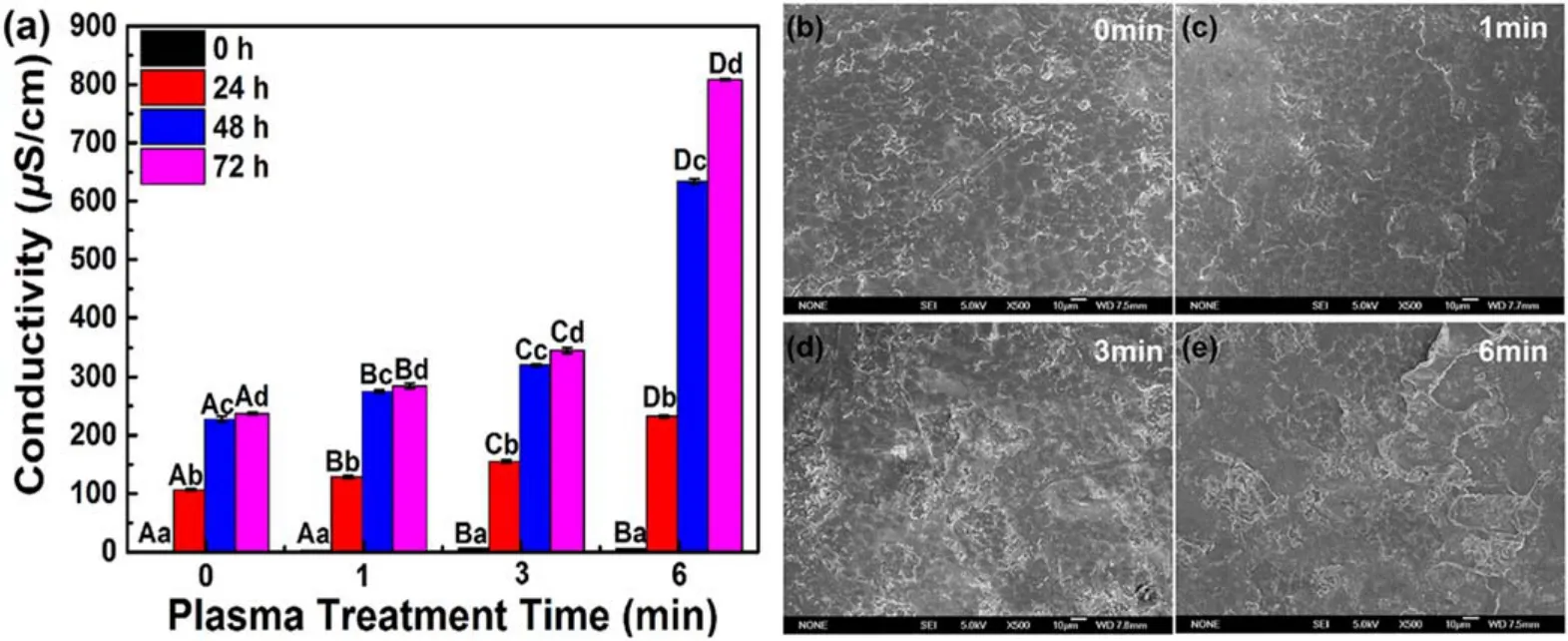

3.4.Effect of non-thermal plasma on the seed coat structure of mung bean seeds

It is generally accepted that non-thermal plasma can etch the seed husk, thus the electrical conductivity was measured to assess the extent of damage to the seed surface by non-thermal plasma.In figure 5(a), the electrical conductivity of the plasma-treated mung beans was higher than that of the control mung bean seeds at all storage times, and longer plasma treatment times led to a higher electrical conductivity(p ≤ 0.05).For all plasma treatment times, the electrical conductivity of mung bean seeds was significantly increased with increase in storage time(p ≤ 0.05),especially for 6 min plasma treatment.The electrical conductivity of control mung bean seeds was 2,106,228 and 237 μS cm−1at 0,24,48 and 72 h, respectively, while the electrical conductivity of mung bean seeds after 6 min plasma treatment was increased to 5,232,634 and 808 μS cm−1at 0,24,48 and 72 h,respectively.These results indicate that the plasma treatment can damage the seed surface and increase the permeability of the mung bean seed coat, which may be responsible for the effects of plasma on the seed germination and sprout growth of mung beans.

SEM was further used to verify the changes in seed coat morphology.Figures 5(b)-(e)represent the morphological alteration of mung bean seeds after plasma treatment.The degree of seed coat destruction is dependent on plasma treatment time.As shown in figure 5(c),there were only slight deformations and some wrinkles emerging on the seed surface after 1 min plasma treatment.However, the epidermis was obviously deformed and shrunken in the seeds treated for 3 min (figure 5(d)).In figure 5(e), the epidermis underwent severe physical destruction and epidermal debris was observed when the plasma treatment time was extended to 6 min.Similar results were reported in our previous research[31], in which the etching effects of dielectric-barrier discharge plasma on the seed surface were dose dependent,ranging from slight shrinkage to a detached epidermis.

Figure 1.(a)Photograph and (b)schematic diagram of mung bean seeds in water treated by non-thermal plasma.

Figure 2.Seed germination and sprout growth of mung bean seeds after 0,1, 3 and 6 min plasma treatment: (a)seed germination, (b)fresh weight,(c)photograph of mung bean sprout,(d)sprout length.Values are means ± SD.Significant differences between control and treated seeds are expressed as *p < 0.05, **p < 0.01 and ***p < 0.001.

Figure 3.The bioactive compound content of mung bean sprouts after 0, 1, 3 and 6 min plasma treatment: (a)total flavonoid and (b)total phenolic.Values are means ± SD.Different letters a-c indicate significant differences between treatments according to the least significant difference test (p < 0.05).

Figure 4.The microbial population of native (a)fungi and (b)bacteria on mung beans after 0, 1, 3 and 6 min plasma treatment during the growth of mung bean sprouts.The microbial population of artificially inoculated(c)yeast and(d)S.typhimurium on mung bean seeds after 0,1, 3 and 6 min plasma treatment.Values are means ± SD.Bars labeled with different small letters a-c indicate significant differences between different plasma treatments at the same incubation time (p ≤ 0.05).Bars labeled with different capital letters A-C indicate significant differences between different incubation times within the same plasma treatment (p ≤ 0.05).

Figure 5.Status of the epidermis of mung bean seeds after 0,1,3 and 6 min plasma treatment.(a)The conductivity of the mung bean seeds for different storage times.SEM images of the surface of (b)0, (c)1, (d)3 and (e)6 min plasma-treated mung bean seeds.Values are means ± SD.Bars labeled with different capital letters A-D indicate significant differences between different plasma treatments for the same storage time (p ≤ 0.05).Bars labeled with different small letters a-d indicate significant differences between different storage times for the same plasma treatment time (p ≤ 0.05).

Figure 6.Spectral detection of the main active substances produced by Ar/O2/N2 plasma discharge.

The seed coat permeability is directly related to the nutrient supply to the embryo.Mitra et al reported that a moderate modification of the seed surface by non-thermal plasma can increase the permeability of the seed coat and facilitate the entry of some macronutrients into the seeds,consequently stimulating seed germination and growth,while a severely damaged seed coat resulted in an excessive increase in seed coat permeability, which had a detrimental effect on seed germination and growth [35].Zhou et al also demonstrated that air plasma could increase the electrolyte leakage rate and metabolic activity of mung bean seeds,which led to an improvement in seed germination and sprout growth [43].Thus, it can be concluded that the stimulating effect of short-time (≤3 min)plasma pretreatment on seed germination and sprout growth of mung beans is attributable to the moderate increase in seed coat permeability.

3.5.OES detection of excited reactive species in non-thermal plasma

A fraction of the energy input to the plasma discharge results in excitement of several chemical species to higher energy states [44].OES was used to investigate the main excited active species generated by the Ar/O2/N2plasma, ranging from 200 to 900 nm.As shown in figure 6,the mixed working gas of Ar/O2/N2was excited by the high-voltage power supply to produce nitric oxide (NO), N2, Ar, and atomic oxygen (O).The emission spectrum was dominated by Ar emission lines since Ar is the major component in the working gas.Many emission lines associated with Ar at 696.5,706.7,714.7,727.3,738.4,750.4,751.5,763.5,772.4,794.8, 800.6, 801.5, 810.4, 811.5 and 826.5 nm were observed at high intensities.N2second positive system (C−B)emissions at 315,316,337.1,353.6,357.7,375.5,380.5,399.8,405.9,420.0 and 427.0 nm as well as NO emissions at 214.7, 226.1, 236.1, 246.9, 259.0 and 295.2 nm were also observed in the spectra.Meanwhile,weak O emissions at 777 and 844 nm were detected.The OES results indicate that excited NO, N2, Ar and O are generated in Ar/O2/N2gas plasma.

3.6.NO·, ·OH, 1O2 and H2O2 generated in water after nonthermal plasma treatment

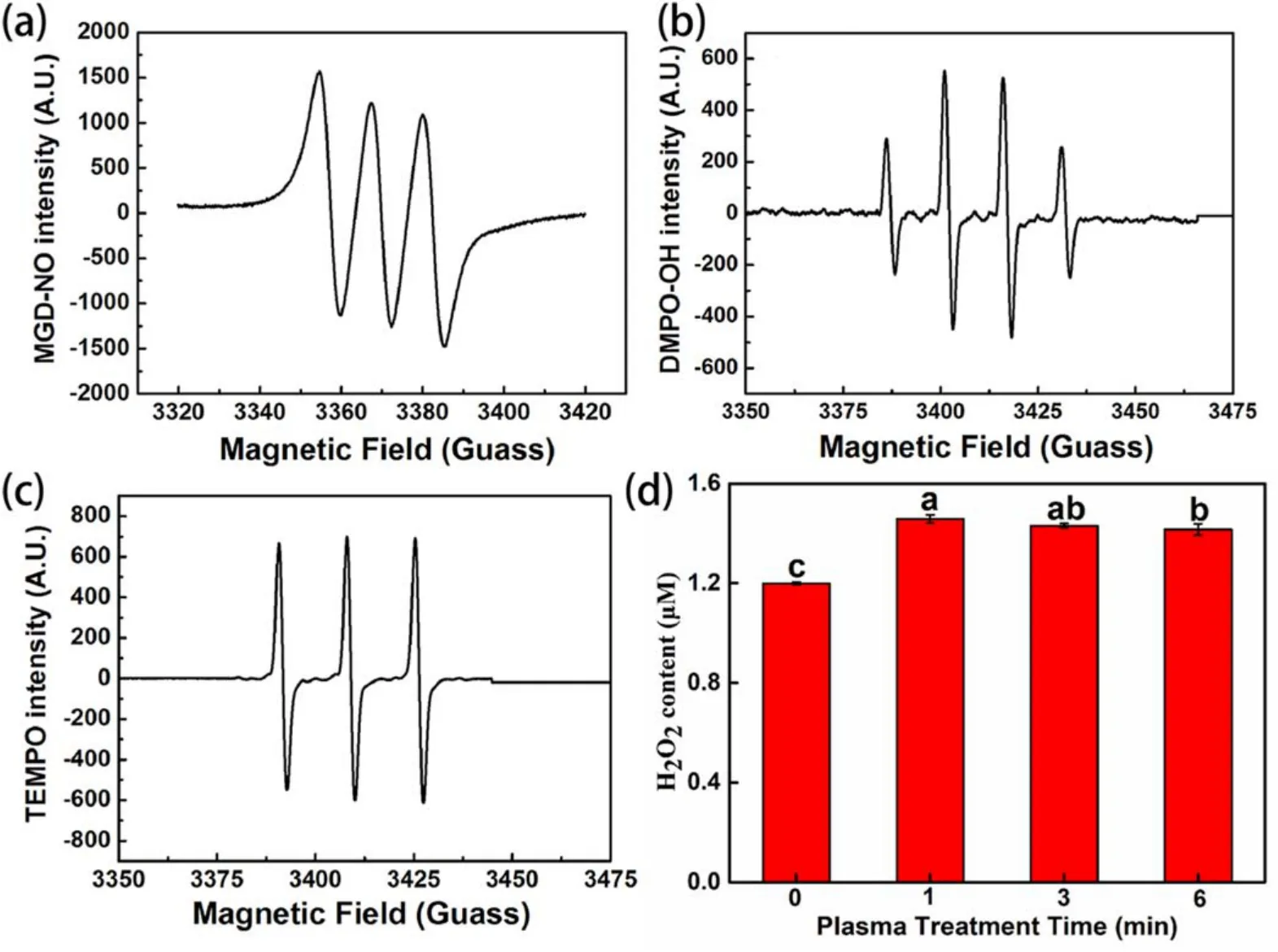

Next, ESR was used to measure the short-lived RONS in the plasma-treated water.(DETC)2-Fe2+-NO signals were detected in the plasma-treated water (figure 7(a)), indicating that NO· radicals are generated in water after plasma treatment.In figure 7(b), the spin-trap adduct DMPO-OH was produced by the spin trapping reaction between DMPO and·OH, showing a quartet pattern in the ESR spectrum with a peak ratio of 1:2:2:1, indicating that ·OH radicals are generated in water after plasma treatment.In figure 7(c), TEMP was used to spin-trap1O2.The spin-trap adduct TEMPO was characterized by a triplet quartet in the ESR spectrum with a peak intensity ratio of 1:1:1, indicating that1O2is generated in water after plasma treatment.Similar results were also reported by Wu et al,who found that·OH, ·O2-and1O2were generated in non-thermal He/O2(2%)plasma-treated water by ESR [45].

Figure 7(d)shows the concentration of H2O2in water after plasma treatment for different times.The H2O2concentration was first significantly increased to the maximum value after 1 min plasma treatment, then gradually decreased with longer plasma treatment times.Although H2O2is a relatively stable and long-lived active substance, it is susceptible to photolysis in light, especially ultraviolet (UV)[46,47].The plasma generates an intense beam of light when discharging, which is sufficient to cause the photolysis of H2O2, consequently resulting in a slight reduction of H2O2concentration after 3 and 6 min plasma treatments.

Figure 7.ESR spin-trapping spectra of (a)(DETC)2-Fe2+-NO (spin adduct of NO), (b)DMPO-OH (spin adduct of ·OH)and (c)TEMPO(spin adduct of 1O2)after Ar/O2/N2 plasma treatment.(d)H2O2 concentration in water after plasma treatment for 0,1,3 and 6 min.Values are means ± SD.Different letters a-c indicate significant differences between treatments according to the least significant differencetest (p < 0.05).

Figure 8.The variation of (a)ORP, (b)conductivity, (c)pH and (d)temperature in water after plasma treatment for 0, 1, 3 and 6 min.The significant difference between control and treatment is expressed as *p < 0.05, **p < 0.01 and ***p < 0.001.

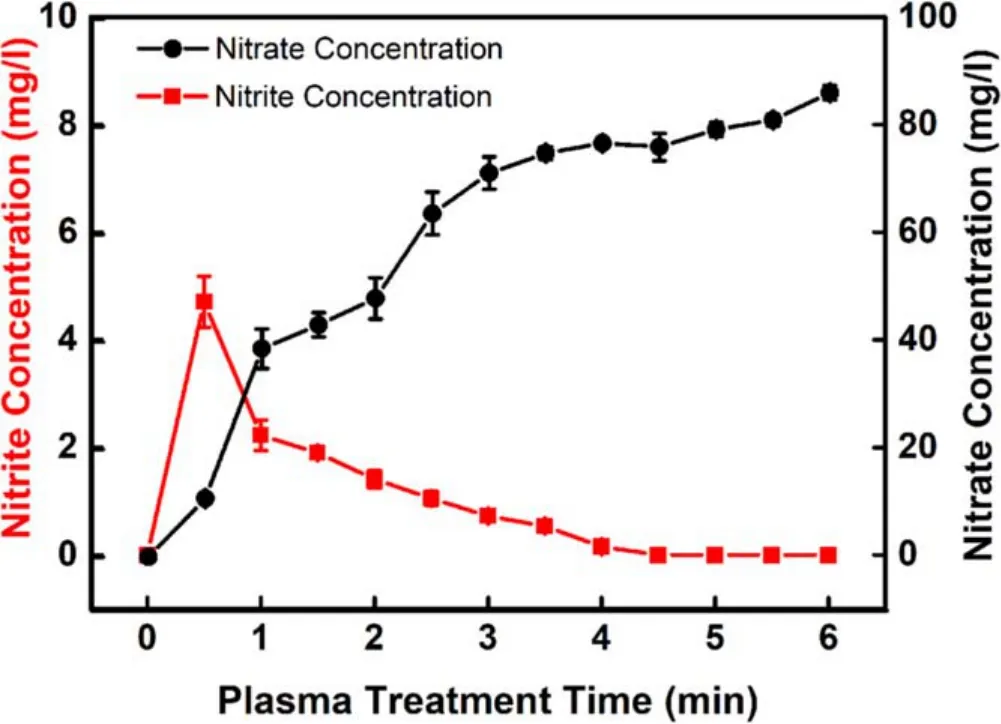

Figure 9.The concentration ofNO2-/NO3- in water after 0, 0.5, 1,1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5 and 6 min plasma treatments,respectively.Significant differences between control and treatment groups are expressed as *p < 0.05, **p < 0.01 and ***p < 0.001.

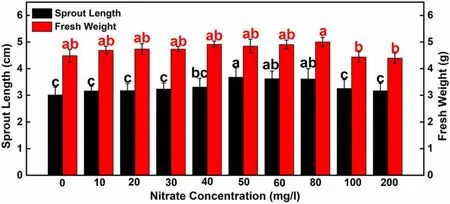

Figure 10.Effect of different nitrate concentrations on fresh weight and root length of mung bean sprouts.Values are means ± SD.Different letters a-c indicate significant differences between treatments according to the least significant difference test (p < 0.05).

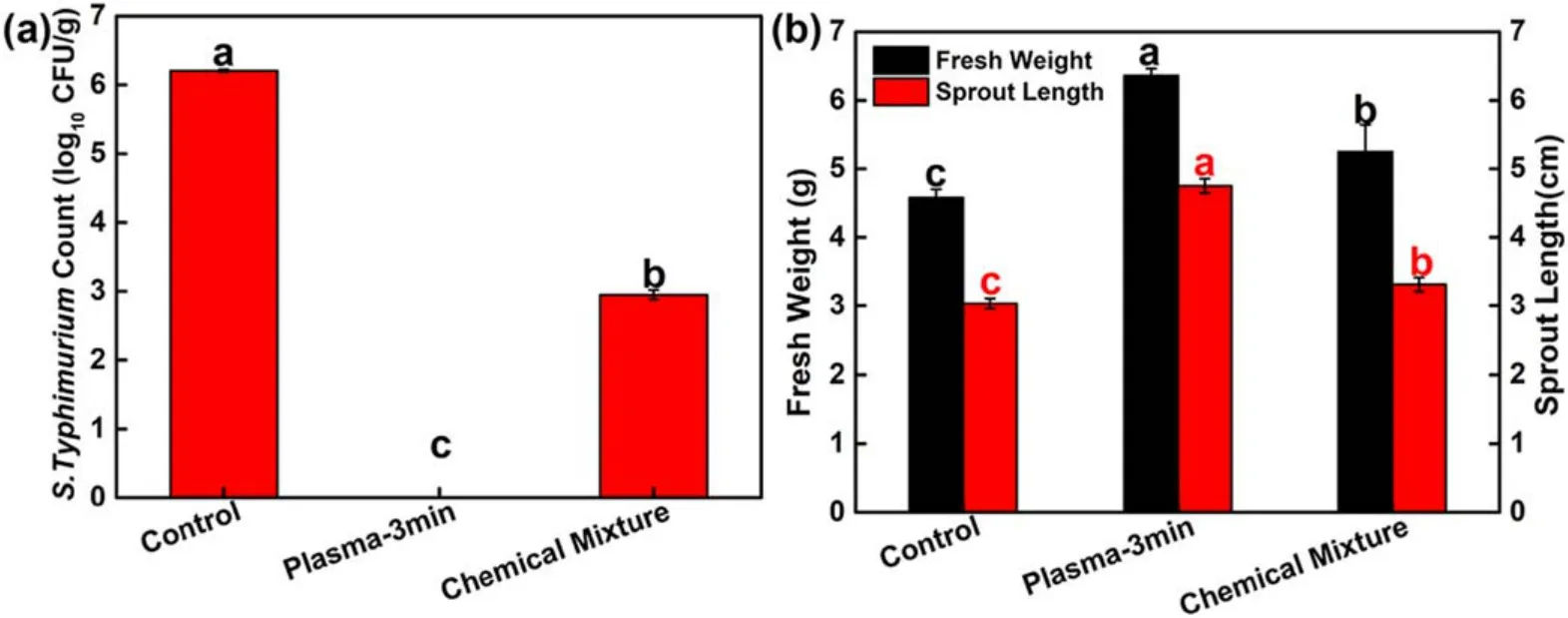

Figure 11.Comparison of the efficiency of 3 min plasma treatment and the mimicked chemical mixture on(a)bacterial inactivation against S.typhimurium and(b)growth promotion of mung bean sprouts.Values are means ± SD.Different letters a-c indicate significant differences between treatments according to the least significant difference test (p < 0.05).

Among the various constituents in plasma, RONS are well accepted by researchers as the major agents for plasmainduced biological effects [48].On the one hand, RONS are well-known signaling molecules that play important roles in regulating plant growth and development [49].On the other hand, RONS can lead to the accumulation of intracellular reactive oxygen species, causing a drop in the membrane potential and a breach in membrane integrity, and eventually cell death [50].Thus, the results of OES and ESR indicate that abundant excited N2molecules and ions,O and NO exist in the Ar/O2/N2plasma, which can transfer into the water and react with each other to form various kinds of RONS in water.Theses RONS play important roles in enhancing the sprout yield of mung beans and the microbial decontamination of mung bean seeds.

3.7.Physicochemical properties of water treated by nonthermal plasma

Given that ESR can only confirm the existence of some shortlived RONS,the overall level of RONS in water after plasma treatment was evaluated by measuring the ORP of plasmatreated water.As shown in figure 8(a), water without plasma treatment had an ORP of 235 mV,while the ORP of 1,3 and 6 min plasma-treated water was significantly increased to 345,420 and 475 mV, respectively.These results indicate that the plasma-generated RONS can accumulate in water and the concentrations of these RONS in water increase with plasma treatment time,which is in good agreement with our previous works [16, 51].There are numerous studies reporting that RONS can not only regulate plant growth and development as secondary messengers but also inactivate microorganisms as oxidizing disinfectants[51-53].Therefore,the increased ORP is responsible for the biological effects induced by the plasma.

To determine whether some active ions exist in water after plasma treatment, the electrical conductivity of water was measured.In figure 8(b), the electrical conductivity of water after plasma treatment for 0, 1, 3 and 6 min was 5, 21,72 and 157 μS cm−1, respectively, an almost linear increase over the plasma treatment time.These result are consistent with our previous studies [16, 24], demonstrating that many active ions were generated in the plasma-treated water,which may be various RONS or other reactive species.

Besides ORP and conductivity, pH also plays an important role in the biological effects of plasma-treated liquids, which can act as a catalyst for post-discharge reactions and promote the biological effects of RONS,particularly antimicrobial properties[54,55].As shown in figure 8(c),the pH was significantly decreased from 7.0 to 3.3 after plasma treatment for 6 min, demonstrating that Ar/O2/N2plasma treatment can result in acidification of the water.Zhou et al reported that the acidification of plasma-activated water contributed to the chapping of the waxy layer in the seed coat of mung beans, which in turn promoted the ability of the treated seeds to absorb water and nutrients, accordingly accelerating the seed germination and sprout growth of mung beans [42].

A thermometer was used to measure the overall temperature of the plasma-treated water after different times.As shown in figure 8(d), although the water temperature after plasma treatment for 1,3 and 6 min was increased to 20.8°C,25.2 °C and 29.1 °C, respectively, the temperature of the plasma-treated water was below 30°C in all cases,that is not sufficiently high to affect seed germination and cause microbial inactivation due to pure thermal effects [16, 56].Taken together, the plasma-treated water has high ORP,high electrical conductivity and low pH, which endows it with antimicrobial activity and the capacity to regulate seed germination and seedling growth.In addition, it is important to note that these physicochemical properties are strongly timedependent and it is essential to select an appropriate treatment time for practical applications.

3.8.NO3- and NO2- concentrations in water treated by nonthermal plasma

Concentrations ofNO3-andNO2-in plasma-treated water were measured to clarify the effect of plasma treatment on sprout growth of mung beans because nitrous nitrogen typically works as a fertilizer in plant cultivation [57].As shown in figure 9, the concentrations ofNO3-andNO2-in plasmatreated water exhibited different change trends over the plasma treatment time.The concentration ofNO3-was increased from 0 to 86.33 mg l−1with plasma treatment times ranging from 0 to 6 min,while the concentration ofNO2-first increased to a maximum value (4.71 mg l−1)at 0.5 min and then decreased to almost 0 mg l−1at 4.5 min.Similar results were also reported in [13, 50], where it was found that the NO3-content was gradually enriched in water with increasing plasma treatment time.Given thatNO2-is unstable in highly oxidizing solutions,and is easily to oxidize to formNO3-in a liquid over the plasma treatment time [58], theNO2-concentration in the plasma-treated water finally dropped to 0 mg l−1after a initial rise.The decrease inNO2-concentration and increase inNO3-concentration suggest the existence ofNO2-decomposition processes andNO3-synthetic processes, probably through the reaction (1)[25].In addition, it has also been reported that ONOOH, an unstable isomer of HNO3, can be formed through reaction (2)whenNO2-and H2O2are present in a solution with a pH of 3.3 [59], which also accelerated the consumption ofNO2-

Furthermore,to evaluate the contribution of nitric acid to the promotion of plant growth of mung beans after plasma treatment, different concentrations of Ca(NO3)2were employed to treat the mung bean seeds and the fresh weight and sprout length of mung bean sprouts were measured.Ca(NO3)2, a common nitrate nitrogen fertilizer, has a wide range of applications in agricultural production [60, 61].The concentration of Ca(NO3)2was set based on theNO3-concentration in water after plasma treatment (figure 9).The effects of differentNO3-concentrations on fresh weight and sprout length of mung bean sprouts are shown in figure 10.Only the 80 mg l−1case showed a significant growth-promoting effect on fresh weight compared with the control.With respect to shoot length, the 50, 60, 80 mg l−1cases showed significant growth-promoting effects.Thus,NO3-as a nitrogen fertilizer contributes to the plasma-induced growthpromoting effects to some extent.However, the growth-promoting effect ofNO3-alone was inferior to that of plasma treatment of seeds in water (figure 2), indicating that besides NO-3,there are also other agents in plasma that contribute to the promotion of mung bean plant growth.

3.9.Comparison of plasma and mimicked chemical mixtures on plant growth promotion and bacterial inactivation

In order to gain more insight into the synergistic effect of NO-2,NO-3,H2O2and strong acids on bacterial inactivation and plant growth promotion, chemical solutions containing equivalent concentrations ofNO-2,NO-3,H2O2and pH to those in 3 min plasma-treated water were prepared.As shown in figure 11(a), S.typhimurium was applied to evaluate the inactivation efficiency between the chemical mixture and 3 min plasma treatment.The simulated chemical solution resulted in a 3-log reduction of S.typhimurium, which was lower than for 3 min plasma treatment.Figure 11(b)evaluates the effect of the chemical mixture and 3 min plasma treatment on the growth promotion of mung bean sprouts in terms of fresh weight and sprout length.The results show that both the chemical mixture and 3 min plasma treatment could promote the growth of mung bean sprouts.Compared with control seedlings, chemical mixture and 3 min plasma treatment led to a distinct increase of 9.37%and 56.77%in sprout length as well as 14.7% and 38.86% in fresh weight (p < 0.05),respectively.The results demonstrate that althoughNO-2,NO-3,H2O2and strong acids play important roles in plasmainduced biological effects, there is a certain difference between the mimicked chemical mixture and direct plasma treatment.

4.Conclusions

In summary,this study demonstrates that non-thermal plasma pretreatment of mung bean seeds in water has the potential to improve the yield and microbial quality of mung bean sprouts.Short-time(1 and 3 min)plasma treatments could not only enhance seed germination and sprout fresh weight and length of mung beans,but also effectively reduced the natural microbial population of mung beans during the sprouting process.Although the long-time (6 min)plasma treatment exhibited the highest microbial inactivation, it markedly inhibited seed germination and sprout growth of mung beans.Plasma generates various RONS in water, leading to the oxidation and acidification of water and an increase in seed coat permeability, consequently resulting in enhancement of sprout growth and seed decontamination.Therefore, nonthermal plasma could be attractive for use in industrial production of mung bean sprouts.

Acknowledgments

This work was supported by National Natural Science Foundation of China (Nos.11605159 and 11405147), Chinese Postdoctoral Science Foundation (No.2017M612412),the Foundation of Key Technology Research Project of Henan Province (No.182102311115), Key Discipline Construction Project of Zhengzhou University (No.32410257)and Youth Innovation Project of Key Discipline of Zhengzhou University (No.XKZDQN202002), Natural Science Foundation of Henan Province (No.202300410013).

杂志排行

Plasma Science and Technology的其它文章

- Quantitative analysis and time-resolved characterization of simulated tokamak exhaust gas by laser-induced breakdown spectroscopy

- Influence of plasma-induced reflected wave variations on microwave transmission characterization of supersonic plasma excited in shock tube

- In situ quantification of NO synthesis in a warm air glow discharge by WMS-based Mid-IR QCL absorption spectroscopy

- Effects of the electric field at the edge of a substrate to deposit a Ø100 mm uniform diamond film in a 2.45 GHz MPCVD system

- Realizing high efficiency and large-area sterilization by a rotating plasma jet device

- Study of post-arc residual plasma dissipation process of vacuum circuit breakers based on a 2D particle-in-cell model