Development of Standardization in Surfactant Industry

2022-03-29XueWei

Xue Wei

Sinolight Daily Chemical Inspection &Certification Co.,Ltd.,Taiyuan,China National Technical Committee for Standardization of Surfactants and Detergents,China

Yao Chenzhi

National Technical Committee for Standardization of Food Washing and Disinfection Products,China

Wang Wanxu

China Household Chemical Industry Association,China

Abstract Surfactants are the most essential active substances in detergents,and their standardization process has a significant impact on the development of the surfactant industry.The development history of the standardization of detergents has been introduced previously.Herein,from the perspective of standardization,the development history of various surfactant products has been reviewed and analyzed in detail.Moreover,the development history of the main raw materials for surfactant synthesis has also been introduced briefly.

Key words surfactant;standardization;development

The prosperity of the detergent industry is not only closely related to formulation technology,but also inseparable from the development of surfactants.Usually,detergent formulations are compounded by a variety of surfactants.The research and industrial production of surfactants are prerequisites for their widespread application in detergent formulations.Surfactants can generally be divided into anionic surfactants,cationic surfactants,nonionic surfactants and zwitterionic surfactants.The synthesis of surfactants often originates from main raw materials,such as fatty alcohols and tertiary amines,through ethoxylation,oxidation,quaternization and other processes.The progress of the surfactant industry is closely related to the development of these main raw materials.

Herein,the development of surfactants standardization is presented,which are the main raw material of detergents.The standardization process of several common surfactants is introduced in which typical products are the focus.In addition,the standardization process of the main raw materials for the preparation of surfactants is also briefly given.Through the process of surfactant standardization,we hope to effectively standardize the production process and product quality of surfactants and promote the sustainable and healthy development of the surfactant industry.

1 Anionic surfactants

Anionic surfactants are one of the most important types of surfactant products.At present,there are tens of national and industry standards corresponding to every anionic surfactant,as shown in Table 1.

It can be seen from Table 1 that among the 14 existing standards,there are 5 national standards and 9 light industry standards.

From the view of the anionic group type of anionic surfactants,all of the main surfactants,such as sulfate type,sulfonic acid type,phosphoric acid type,carboxylic acid type.have corresponding standards,and some types of anionic surfactants even have a couple of standards.The standard system has gradually evolved from prevailed surfactants with a large initial output to new,functional surfactants with limited production.These characteristics show that the current surfactant standard system is relatively comprehensive,and it would develop continuously in the direction of specialization,which is in good agreement with the development trend of the industry.The publication date when the standard was first formulated has a large time span.The earliest surfactant product standard is QB 523 “Industrial stearic acid”,which is often used in soaps;the second is GB/T 8447-1987 “Industrial alkylbenzene sulfonic acid” which is the most important active ingredient in early detergents;the latest one is QB/T 5480-2020“Sodium cocoyl isethionate”.From the perspective of publication time,anionic surfactant standards are being revised one after another within this time span,indicating that the standardization of anionic surfactants is advancing steadily and the scope of business is still expanding.The revision dates of current available standards are all in the 21st century,which can effectively reflect the characteristics and quality of the product.

Industrial linear alkylbenzene sulfonic acid is one of the longest used and most widely used anionic surfactants,and its standardization process is highly representative in this category of products.Table 2 lists the previous standard versions and the corresponding index changes of industrial linear alkylbenzene sulfonic acid.

Table 1.Available standards of anionic surfactants

Table 2.Development history of standards and indexes for industrial linear alkylbenzene sulfonic acid

It can be seen from Table 2 that the standard of alkylbenzene sulfonic acid has been revised twice,and the product indexes are generally set as 4 items:“alkylbenzene sulfonic acid(content)”,“free oil content”,“sulfuric acid content” and “coloration”.When the standard name was first revised,the“linear chain” was added in front of “alkylbenzene”to restrict the application of branch-chain products with relatively poor biodegradability in detergents.In the first revision,some index names were also revised.For example,“alkylbenzene sulfonic acid”was changed to “alkylbenzene sulfonic acid content”to make its directivity more definite and its meaning clearer.The index value “second-class products”for alkylbenzene sulfonic acid content was slightly lowered in the first revision,reflecting the difference between products of different grades.The product categories in the previous two editions are all three categories:“superior products”,“first-class products”,and “second-class product”.In the 2008 version,however,only two categories of “superior products”and “qualified products” are retained.This change is closely related to the improvement of production process.Besides,the index “coloration” is also related to process improvement.With the improvement of the production process,the index value of “superior products” has tightened.“Sulfuric acid content” and“free oil” remained unchanged.

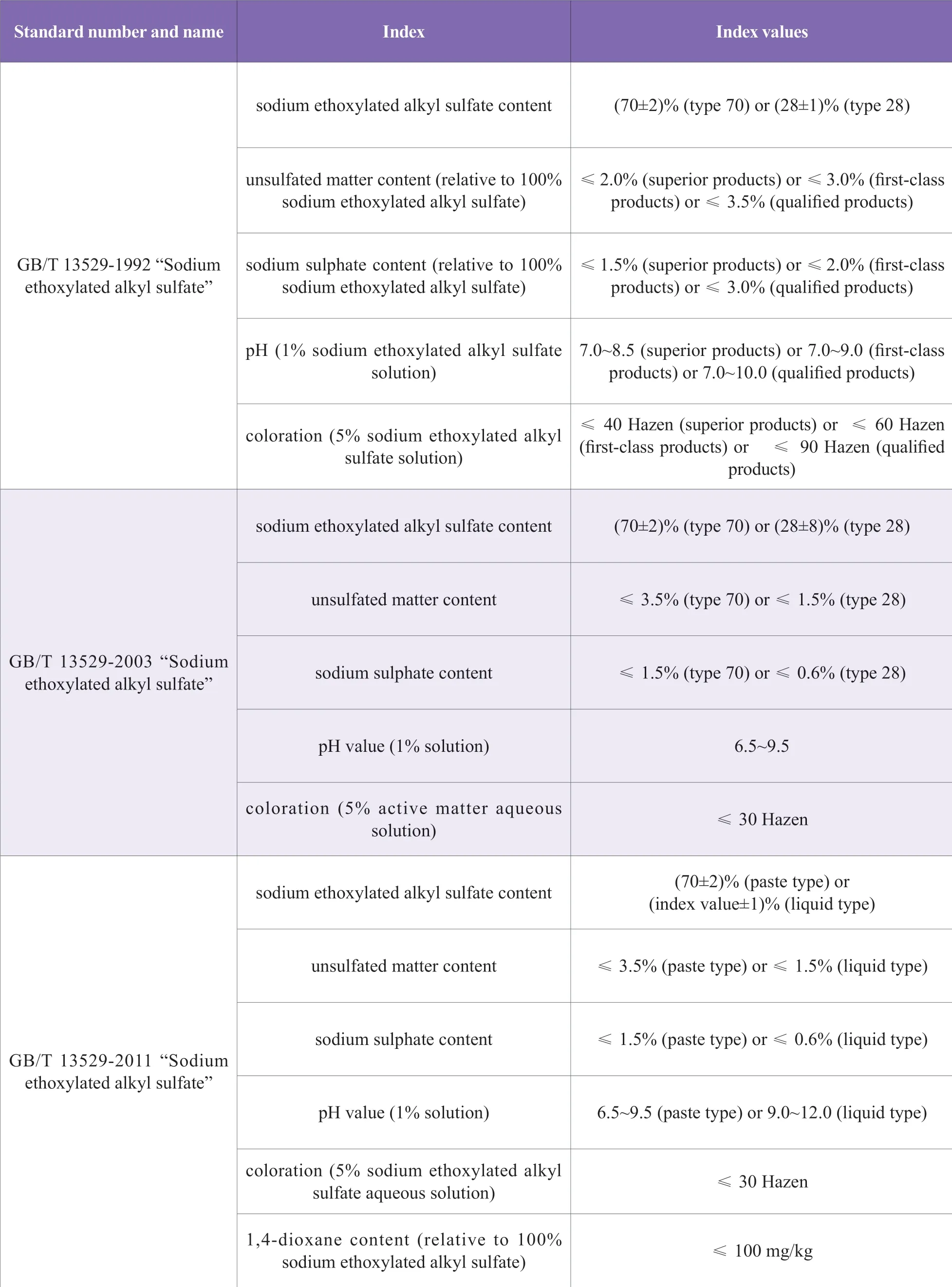

Currently,sodium ethoxylated alkyl sulfate is a widely used anionic surfactant in detergents,and its standardization process is also rather representative in this category.Table 3 lists all the versions of sodium ethoxylated alkyl sulfate standards and the corresponding index variations.

Table 3.Development history of standards and indexes for sodium ethoxylated alkyl sulfate

It can be seen from Table 3 that,similar to the standard for linear alkylbenzene sulfonic acid,the standard for ethoxylated sodium alkyl sulfate has also been revised twice,and the first revision time is slightly later.In all versions,the overall index setting remained stable.The 5 indexes in the 1992 version have been maintained to the 2011 version when the "1,4-dioxane content" was added according to the actual application situation.Product classifications maintain two categories.In the 1992 and 2003 versions,according to the content of active matter,the classification names are“type 70” and “type 28”,corresponding to higher and lower active matter contents respectively.In the version of 2011,the name changed to “paste type” and “liquid type” on the basis of the appearance state.There is a one-to-one correspondence between the “type 70” and“type 28” products in the 1992 and 2003 versions and the “paste type” and “liquid type” products in the 2011 version.The 1992 version of the standard subdivided them into three categories:superior products,first-class and qualified products,and separated them by indexes such as unsulfated matter content and sodium sulfate content.With the improvement of the process and the needs of market development,the classification of product categories was simplified in the 2003 version.The subdivision was deleted,and the index values of“unsulfated matter content”,“sodium sulfate content”,“pH value” and “coloration” are adjusted accordingly.Taking the “sodium sulfate content” as an example,this substance is formed by the excess sulfuric acid in the subsequent neutralization process,which is introduced in the sulfation process.When revised in the 2003 version,it was adjusted to “≤1.5%” for type 70 and “≤0.6%”for type 28,which is based on the active matter content.Based on 100% active matter,the allowable sodium sulfate content is formed for both of them.The index value is equivalent to the first-class products in the previous standard,however,the workload of the production enterprise is greatly simplified.

2 Cationic surfactants

As an important branch of surfactant products,cationic surfactants are mainly used in cleaning products as bactericides,softeners,antistatic agents,softeners,etc.The consumption is less than anionic surfactants.The relevant standards of existing cationic surfactant products are listed in Table 4.

Table 4.Available standards of cationic surfactants

It can be seen from Table 4 that there are only 5 relevant standards for cationic surfactant products,which are far less than the standards for anionic surfactant products.All of these standards are industry standards,and it is also different from the situation of anionic surfactants.Moreover,only QB/T 1915 has been revised once,and the rest of the standards have maintained theirs original state,which is far from the anionic surfactant standard.This phenomenon is highly related to the category,quantity and application status of cationic surfactants.Take the development of QB/T 1915 as an example,the changes including index are shown in Table 5.

Table 5.Development history of QB/T 1915 indexes

QB/T 1915 is the first cationic surfactant product standard.The index in that edition contained active matter content,pH value,free amine content,ash content,heavy metal content,and arsenic content.In the 2021 version,the indexes not only maintain all the original ones,but also add "methanol content".The index value of the active matter content has not been adjusted,and its determination method still is two-phase titration.However,both the titrant and indicator changed,from sodium tetraphenylborate and bromophenol blue to sodium lauryl sulfate and mixed acid indicator,respectively,and the end-point phenomenon of the test also changed accordingly.The combination of titrant and indicator in the previous version is only used in China,however,the combination in available edition,which is used worldwide,comes from national standard GB/T 5174.When QB/T 1915 was first formulated during the Cold War period,relations between international communities were tense,and some reagents needed to be imported.In order to avoid being constrained by other countries,a method that is not only equivalent to the GB/T 5174 but also using homemade reagents was obtained after many experiments,that is,“sodium tetraphenylborate + bromophenol blue”.At present,scientific exchanges between countries are extremely frequent,and reagents are no longer restricted by other countries.Therefore,the test method is adjusted to directly adopt GB/T 5174.According to the results of market research,the two index values "pH value"and "free amine content" are appropriately adjusted during the revision,so that they can better represent the actual situation of the current product.

3 Nonionic surfactants

Nonionic surfactants are a type of surfactants that are frequently used in detergents.They are usually used in combination with anionic surfactants.Table 6 lists the current non-ionic surfactant product standards.

Table 6.Available standards of nonionic surfactants

According to Table 6,there are 17 relevant standards for non-ionic surfactant products,including 3 national standards,4 light industry standards and 10 chemical industry standards.The first non-ionic surfactant product standard was GB/T 15046 “Fatty diethanolamine”,which was issued and implemented in 1994,slightly later than anionic surfactants.Although the number of non-ionic surfactant products and corresponding standards are significantly less than that of anionic surfactants,they are widely used due to their outstanding performance.Alkylpolyglycosides is a green non-ionic surfactant,which has been gradually used in detergents and other cleaning products in recent years.Table 7 lists the variations in the standards of alkylpolyglycosides.

Table 7.Development history of standards and indexes for alkylpolyglycosides

It can be seen from Table 7 that the product standard of alkylpolyglycosides was first formulated in 2004 and contains 8 indexes which were all retained in 2014 version.At the same time,in view of application field expansion for alkylpolyglycosides,indexes for cosmetics including heavy metals and the total plate count were added to the standard.In the 2004 version,the product category is divided into 3 categories according to the product level,namely:first-class products,second-class product,and third-class product.After the revision in 2014,the classification has 2 levels:the first level is divided into direct method and indirect method according to preparation methods;the second level is separated into first-class products,second-class products and qualified products(for industrial cleaning).According to the actual situation,the coloration in the revised version can reflect its quality more precisely.The coloration for first-class and second-class products is retained and deleted,respectively.The coloration of qualified-class products is distinguished according to preparation methods.In the previous version,the pH of the product is required to be 11.5~12.5.After revision,the pH value range becomes much wider to ≥7.0 so as to ensure product free from hydrolysis during storage.Due to the dissolve process of C12~14 is rather timeexhausting in aqueous solution,therefore,the solvent is adjusted to isopropanol-water mixed system to shorten time under the prerequisite for accuracy.The “inorganic salt content” is changed to,which makes the index name more consistent with the measurement process and dispels the doubts of customers.Based on the results of product survey,combined with the production process,“sulfated ash” value is reduced.The variation of free total fatty alcohol content,low carbon number alkylpolyglycosides,and viscosity is also based on the production process and product market survey results.

4 Amphoteric surfactants

Amphoteric surfactants are functional surfactants with relatively mild performance.They are used in many fields,such as emulsifiers,dispersants,antistatic agents,bactericides,wetting agents,thickeners,etc.Table 8 lists the current product standards of amphoteric surfactants.

Table 8.Available standards of amphoteric surfactants

It can be seen from Table 8 that there are 4 available product standards:a piece of national standard and 3 pieces of industry standards.QB/T 2118,implemented in 1995,is the earliest product standard for amphoteric surfactants.Among the above-mentioned standards,half of them have been revised.Imidazoline is one of the most common zwitterionic surfactants and its standard development history is shown in Table 9.

Table 9.Development history of standards and indexes for undecyl imidazolines

QB/T 2118 has been revised once since its implementation,as shown in Table 9,and the number of indexes has increased from 5 to 6.The products mainly include carboxymethyl and carboxyethyl type.Ⅰn the 1995 version,they are classified into superior,first-class and qualified-class product according to the total solid matter content.At the same time,the salt content,coloration and pH value are used to regulate the product quality further.Based on the actual application situation,the 2012 version retains the classification by functional group,cancels the subdivision according to the solid matter content and the indexes are adjusted accordingly.The solid matter content is adjusted to(index value ± 2)%,and the pH value and salt content are simplified and unified on the basis of the functional group type,so that the production enterprise can control the product quality more efficiently.The revision of coloration is mainly based on the improvement of the process and the results of product research.The foaming power is mainly related to the product structure whereas has a poor relation with quality,thus deleted.The addition of chloroacetic acid and unreacted amide can more accurately control the product quality and reduce the environmental hazard and human body irritation from residual substances yielding from production process.

5 Others

Surfactants are not prepared in a single step and intermediates are essential usually.For example,fatty alkyl dimethyl tertiary amines are important intermediates for the preparation of cationic surfactants and zwitterionic surfactants.Natural fatty alcohols are one of the very important raw materials for the synthesis of anionic and nonionic surfactants.The relevant standards of the main raw materials used in the synthesis of surfactants are shown in Table 10.

Table 10.Standards of the main raw materials for synthesis of surfactants

The main raw materials are tertiary amines,fatty alcohols,as shown in Table 10,including 8 product standards,4 national standards and 4 industry standards.Among them,the formulated date of the standard for industrial linear alkylbenzenes was the earliest and they have been revised many times;both tertiary amines and fatty alcohols were formulated in 1990s,and have undergone revisions to follow the development trend of the industry.Natural fatty alcohol is one of the typical representatives within these substances,and the standardization process is shown in Table 11.

Table 11.Development history of standards and indexes for natural fatty alcohols

In view of the numerous categories of natural fatty alcohols,the index setting is rather complicated.Table 11 does not list all the indexes in detail,but only present them in the form of outlines.In the 1996 version,as listed in Table 11,there are 8 categories according to the carbon chain length and purity.When revised in 2008,in order to meet the needs of consumers,C8 and C10 alcohols with low carbon chains were added,and they were included in the 2017 version too.Based on the previous classification,they are further divided into three categories:superior products,first-class products and qualified products.There are 8 indexes in 1996 version,such as melting point;and there are 10 indexes in 2008 version where water content and carbonyl value are the new added ones.Since products with short carbon chain lengths are easy to absorb water,the setting of water content is necessary to control product quality.Introducing carbonyl value from foreign counterparts aims to monitor the product quality,yielding proper indexes value on the basis of current situation.With the improvement of customer needs,the production process has been continuously improved,so the coloration,acid value,principal component content,saponification value and other indexes in the 2008 version have been tightened again.In 2017 version,indexes such as carbonyl value and determination methods were revised,and the limits for the content of harmful substances such as mercury,lead,and arsenic applicable to cosmetics were added.

6 Prospects

After decades of development,the surfactant industry expands continuously,and its standardization process has also attracted attention.In order that standards can better play a leading role in the development of surfactant industry in the future,the cooperation between surfactant research and production units and standards committee should be strengthen further.For example,information,such as national policy documents,the latest industry technology,cuttingedge products,and customer needs,could be exchanged.The aim to yield more representative surfactant product standards could be reached.Meanwhile,product quality can be normalized and consumers' rights and interests could be protected.

杂志排行

China Detergent & Cosmetics的其它文章

- “R&D Competitions” of New Prominent Beauty Makeups

- Makeup Mirror Becoming the New Blue Ocean of Beauty Industry

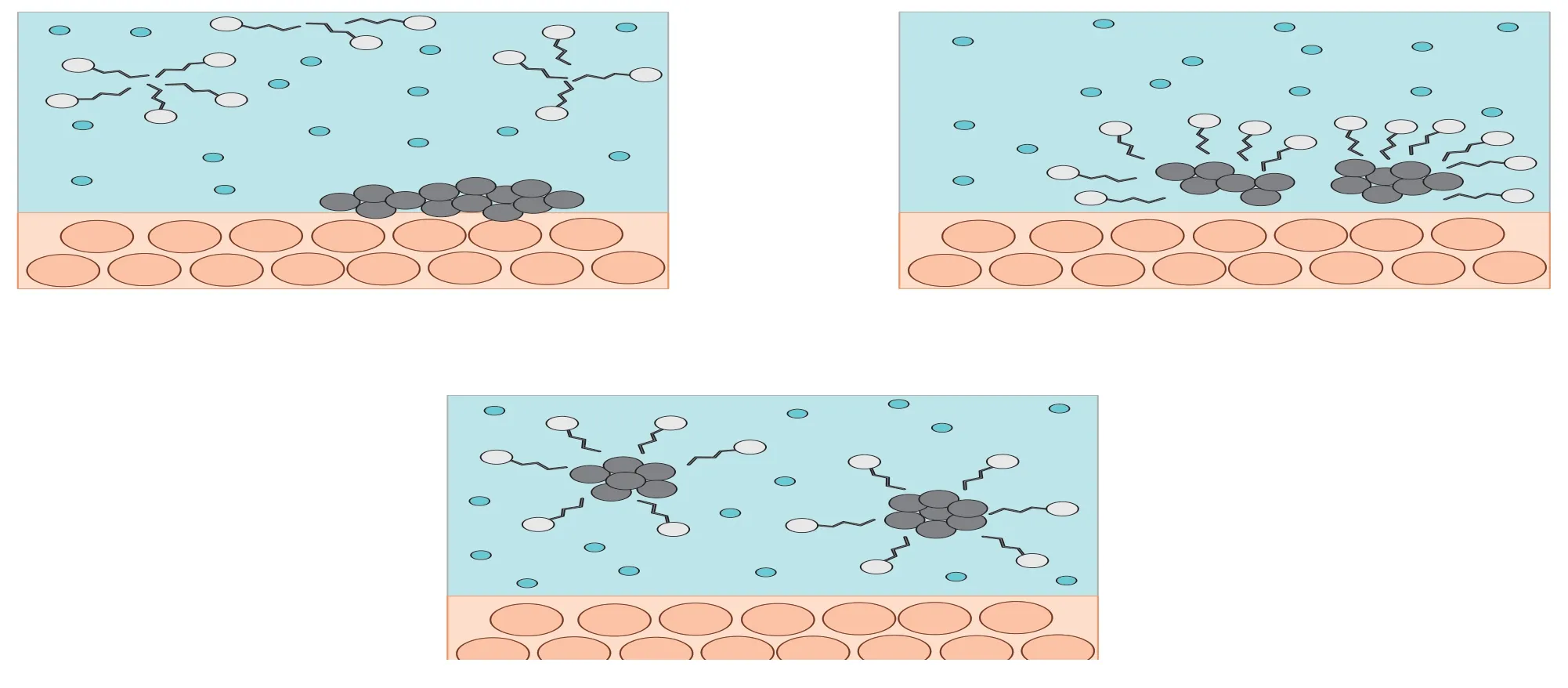

- A Method for Determination of Critical Micellar Concentration of Surfactant

- Application of Water-Based Polyurethane in Sunscreen Products

- Analysis and Comparison of Cleaning Power and Moisturizing Effect of Different Shower Gels

- Study on the Factors Affecting the Darkening of Liquid Foundations