Photoemission oscillation in epitaxially grown van der Waals β-In2Se3/WS2 heterobilayer bubbles*

2021-11-23JiyuDong董继宇KangLin林康CongpuMu牟从普ZhiyanJia贾智研JinXu徐瑾AnminNie聂安民BochongWang王博翀JianyongXiang向建勇FushengWen温福昇KunZhai翟昆TianyuXue薛天宇andZhongyuanLiu柳忠元

Jiyu Dong(董继宇) Kang Lin(林康) Congpu Mu(牟从普) Zhiyan Jia(贾智研) Jin Xu(徐瑾)Anmin Nie(聂安民) Bochong Wang(王博翀) Jianyong Xiang(向建勇) Fusheng Wen(温福昇)Kun Zhai(翟昆) Tianyu Xue(薛天宇) and Zhongyuan Liu(柳忠元)

1Center for High Pressure Science(CHiPS),State Key Laboratory of Metastable Materials Science&Technology,Yanshan University,Qinhuangdao 066004,China

2Key Laboratory of Microstructure Materials Physics of Hebei Province,School of Science,Yanshan University,Qinhuangdao 066004,China

Keywords: bubble,monolayer WS2,heterostructure,In2Se3

1. Introduction

The optical, mechanical, and electrical properties of two-dimensional (2D) layered materials can be readily tuned via chemical doping, defect, or thickness reducing.[1-5]2D transition-metal dichalcogenides(TMDCs)as one of the typical semiconductors possess novel physical properties for the potential application in a next generation photodetector,fieldeffect transistors, valleytronic devices.[6-8]The 2D van der Waals heterostructures consisted with stacking different 2D layered materials have novel properties beyond their individual counterparts, which provide opportunities in devices engineering.[9,10]For instance,the epitaxial grown multilayerβ-In2Se3on monolayer WS2have been shown to have the interlayers interaction effect constraining the phase transformation of adjacent few layersβ-In2Se3.[11]Ultrahigh photo responsivity and detectivity of photodetectors are gained because of an acceleration of electron-hole separation and charge transfer owing to constructing lateral MoS2and WS2heterostructures.[12]In addition,various lateral and vertical 2D materials heterostructures have been constructed and investigated in physics and materials field.[13-15]It has been demonstrated that heterostructures based on TMDCs can provide a platform for tailoring the devices properties.

Recently, bubbles of monolayer or few layers 2D materials are created via various method and investigated in physics, chemistry, and devices.[1,5,16,17]A biaxial strain in bubbles can cause the direct-to-indirect band gap transition of few-layer TMDCs.[18]Strain localization excitons states formed a doughnut-like pattern around the nanoscale bubbles of monolayer WSe2and MoS2at room temperature.[19,20]Moreover,optical properties and lattice vibrations of graphene and TMDCs are sensitive with strain in material. Photoluminescence (PL) and Raman spectra oscillations can be found across graphene, monolayer WS2, and few layer WSe2bubble profile due to light interference.[1,11,16]In addition, PL of monolayer WS2is sensitive with strain, electric filed, and temperature. Monolayer WS2has a potential application for photodetectors due to strong PL with narrower emission bandwidth. Although properties of single crystal monolayer WS2bubbles have been investigated, there have not been reported about heterostructure bubbles of a millimeter-scale continuous monolayer polycrystalline WS2and other 2D layer materials so far.

In this paper, verticalβ-In2Se3/monolayer WS2heterostructures were grown via a two-step chemical vapor deposition(CVD)and heterostructure bubbles on SiO2/Si substrate were created during the growth ofβ-In2Se3due to a hightemperature treatment.Characteristics ofβ-In2Se3/monolayer WS2heterostructure bubbles are investigated via optical and fluorescence(FL)images, Raman and PL spectra. The oscillatory behaviors are presented in mapping images of PL and Raman spectra of monolayerβ-In2Se3/monolayer WS2heterostructure bubbles due to the constructive and destructive interference. The mechanism for oscillatory behaviors of PL intensity, position, and width are elucidated via changing an exterior pressure of bubble. In addition,strain effect in PL position and width is also observed during the gradual decrease of exterior pressure of bubbles.

2. Experimental section

2.1. Thin film of millimeter-scale continuous monolayer WS222

Thin films of millimeter-scale continuous monolayer WS2were grown on p-type silicon wafer with 300 nm in thickness of SiO2CVD method in a two-zone home-made tube furnace. As schematically shown in Fig. S1, precursors of sulfur powder (Alfa Aesar, purity 99.999%) of 1.2 g and WO3powder of 2 g (Alfa Aesar, purity 99.99%) were placed in two separated Al2O3crucibles located downstream at the low and high temperature zones,respectively. During the growth,the low and high temperature zones were set at 180°C and 950°C,respectively,and the sulfur and WO3vapor were carried to SiO2/Si substrate via a highly pure Ar gas at a flow rate of 50 sccm. After a growth time of 50 minutes,thin films of millimeter-scale continuous monolayer WS2were successfully grown on SiO2/Si wafers.

2.2. In2Se3/monolayer WS2 heterostructure bubbles

Theβ-In2Se3/monolayer WS2heterostructure bubbles were created by using CVD method in a home-made threezone tube furnace. Precursors of Se pellets of 0.08 g(Alfa Aesar, purity 99.999%) and In2O3powder of 0.1 g (Alfa Aesar,purity 99.99%)were placed in two separated Al2O3crucibles located downstream along the tube. The as-grown millimeterscale continuous monolayer WS2films were served as 2D substrates and were downstream placed 5 cm away from the crucible of In2O3. During the growth,the temperatures were kept at 270, 640, and 620°C for Se, In2O3, and substrate, respectively, and Se and In2O3vapors were carried to the substrate via a 34 sccm mixed gas flow of H2and Ar. Similar to the previous reports that heat treatment of large area WS2or WSe2monolayers can help to create bubbles of monolayer,[11,16]In2Se3/monolayer WS2heterostructure bubbles with spherical cap were created during the growth of In2Se3on WS2monolayer at 620°C.

2.3. Characterizations

Optical and FL images were taken via a Leica microscope(DM4000M) equipped with FL accessory. PL and Raman spectra were collected in a confocal micro Raman microscope system(HR Evolution, JY Horriba, Japan)with an excitation of 532 nm and spot size of~1µm in diameter. PL characterizations of bubbles under different exterior pressures are collected via a confocal micro Raman microscope system with a home-made vacuum chamber with a high-throughput optical window under an excitation of 532 nm focused on the center of bubble.Atomic force microscopy(AFM)measurement was performed on MultiMode 8(Veeco Instruments Inc.,USA)in a tapping mode. Structure was elucidated via an aberrationcorrected scanning transmission electron microscopy (ACSTEM,FEI Themis Z STEM)operating at 300 kV.

3. Results and discussion

Figure 1(a)and figure S2 present the optical images and corresponding FL images of a typical as-grown thin film of monolayer WS2on SiO2/Si substrate. It is clear that substrate is dominantly covered by monolayer WS2that is continuous over millimeter-scale. The polycrystalline thin film of monolayer WS2has a typical grain size of~100 µm, and the FL is greatly enhanced in intensity at the grain boundaries owing to the abundant structural defects.[21]The determined thickness of WS2from AFM height profile shown in Fig. S3 is~0.79 nm, which is consistent with previous results.[22,23]The high quality thin film of monolayer WS2enables the growth of layeredβ-In2Se3crystals via CVD method.The optical images shown in Figs.1(b)and 1(c)indicate that monolayer WS2is coated by layer structuredβ-In2Se3crystals with different thicknesses andβ-In2Se3/monolayer WS2heterostructures are obtained. Compared to the particles in the voids of monolayer WS2thin film,the well-defined multilayerβ-In2Se3crystals on WS2is indicating a preferential growth of the layeredβ-In2Se3on 2D substrates. The high magnification optical image (Fig. 1(c)) also shows the absence of straight edge in morphology for the first and second layers ofβ-In2Se3(i.e., monolayer and bilayer In2Se3), which is consistent with the reported results.[11]Figure 1(d)shows the FL image of the monolayer WS2thin film after the growth of In2Se3. In comparison with the monolayer WS2, the FL is significantly suppressed in intensity at the junction area of In2Se3/WS2. In addition, high density of brighter spots are evidenced in FL image, and fringes can be observed in spots with large size and are attributed to bubbles formed in monolayer WS2during growth of In2Se3.[11]It is also evident that bubbles of monolayer WS2have stronger FL signal than those ofβ-In2Se3/WS2heterostructure. From the variation in AFM height profile(inset of Fig.1(e))scanned along direction marked by the green line in Fig.1(e), the thickness of monolayerβ-In2Se3is calculated to be~1.01 nm,being in a good agreement with previous report forβ-In2Se3.

Fig. 1. Optical, FL, AFM characterizations of monolayer WS2 before and after the growth of β-In2Se3: (a) optical image of millimeterscale continuous monolayer WS2 grown on SiO2/Si substrate, the inset is FL image of green wireframe marked in optical image, indicating that millimeter-scale WS2 is monolayer; (b) and (c) low- and high-magnification optical images of monolayer WS2 covered with β-In2Se3,indicating forming β-In2Se3/monolayer WS2 heterostructures; (d)FL image of β-In2Se3/monolayer WS2 heterostructure,indicating that FL is suppressed after covering β-In2Se3, which is corresponding to panel (c); (e) AFM image of β-In2Se3/monolayer WS2 heterostructure.The inset is the height profile from green wireframe, green dots come from AFM height profile, and green dashed line is linearly fitting the experiment dots according to the expression of h=−3.6+1.01n (h is height and n is a layer number of In2Se3), indicating a thickness of~1.01 nm for monolayer β-In2Se3.

Raman and PL measurements were carried out to characterize the as-grown WS2monolayer and In2Se3/WS2heterostructures transferred on TEM grid. Compared to the Raman spectra of monolayer WS2, extra Raman bands are evidenced at the positions marked by the cyan for theβ-In2Se3/WS2heterostructures,as shown in Fig.2(a).The peaks located at~110 cm−1and 206 cm−1are assigned to the A11gand A21gmodes ofβ-In2Se3crystal, respectively. According to previous work, Raman bands in intensity are very weak in intensity for the In2Se3monolayer and bilayer.[11,24]The WS2monolayer possesses two characteristic peaks located at 353 cm−1and 419 cm−1,that are the in-plane mode of A1and out-of-plane mode of E', respectively. No significant change occurs for the A1and E'in frequency as well as intensity upon covering a layer of In2Se3with a thickness from monolayer to few-layer.[11]When thickness of the atopβ-In2Se3increases up to 14 layers,the degenerated A1mode of monolayer WS2is observed to be split into two peaks due to the tensile strain preserved in thickerβ-In2Se3crystals grown at high temperatures.[11]It also indicates a strong coupling between monolayer WS2and multilayer In2Se3. Upon covering one layer ofβ-In2Se3atop, PL is significantly decreased (by a factor of~20)in intensity for monolayer WS2,as shown in Fig.1(d)and Fig.2(b),and is even completely quenched with a 14-layerβ-In2Se3crystal atop.As shown in Fig.2(c),conduction band minimum and the valence band maximum of monolayer WS2are higher than those ofβ-In2Se3,indicating a type-II alignment interface betweenβ-In2Se3and WS2.[25-27]Due to a type-II alignment,the photo-excited electron in monolayer WS2is injected from conduction band of WS2to conduction band ofβ-In2Se3and photo-excited holes will transfer from the valence band ofβ-In2Se3to the valence band of WS2due to a type-II alignment ofβ-In2Se3/monolayer WS2. Since the In2Se3possesses an indirect bandgap, the suppression of PL in monolayer WS2after covering one layer ofβ-In2Se3atop is due to the decrease of photo-excited electron-hole recombination rate. In addition, the quench of PL in monolayer WS2is predominantly attributed to that the photo-excited electron in monolayer WS2will transfer from monolayer WS2to thickβ-In2Se3.

Fig.2. (a)Raman and(b)PL characterizations of monolayer WS2 before and after covered with 1L and 14L β-In2Se3 on TEM grid. (c)Band alignment of monolayer β-In2Se3 and monolayer WS2. (d)SAED pattern and(e)atomic scale HAADF image of β-In2Se3/WS2 heterobilayer.

In order to check the crystal structure and the crystallographic orientation of WS2and In2Se3, AC-STEM measurements were carried out on the heterobilayer of monolayer In2Se3/monolayer WS2. Figure 2(d) presents a selected area electron diffraction(SAED)pattern of a typical heterobilayerβ-In2Se3/WS2. Two sets of diffraction patterns with sharp spots are evidenced owing to the high quality of WS2and In2Se3crystal. The interplanar spacing of WS2and In2Se3are 0.27 nm and 0.35 nm corresponding to the(100)lattice plane of 1H-WS2andβ-In2Se3, respectively, which are consistent with previous results.[11,28,29]From the SAED pattern of the heterobilayer, it is clear that the monolayerβ-In2Se3crystal is nearly epitaxially grown on monolayer WS2. Diffraction pattern of single crystal WS2is presented in SAED shown in Fig. 2(d) due to large grain size (~100 µm) in polycrystalline thin film of monolayer WS2(shown in Fig. 1(a) and Fig. S2). Figure 2(e) shows an atomic scale high angle annular dark field(HAADF)image of theβ-In2Se3/WS2heterobilayer. Compared to the monolayer WS2(the dark domain as pointed out by the arrow),well-defined Moir´e patterns can be observed in the domain of the heterobilayer owing to an interference of two sets mismatched lattices.

Fig. 3. (a) Optical and corresponding (b) FL images of monolayer WS2 covered by In2Se3, (c) optical and corresponding (d) FL images of the bubble of In2Se3/monolayer WS2 heterostructure,(e)AFM image of monolayer In2Se3/monolayer WS2 heterostructure bubble (corresponding to the green dashed rectangle in panel(c)),inset is the height profile corresponding to the white line in panel(e).

Large number bubbles of In2Se3/monolayer WS2heterostructures were also created besides the monolayer WS2bubbles during the growth ofβ-In2Se3, as shown by the optical image and corresponding FL image of the as-grownβ-In2Se3/monolayer WS2heterostructure in Figs.3(a)and 3(b),respectively. These bubbles have a widely distributed diameters range from few tens of micrometers down to the order of sub-micrometer or even smaller. Interference fringes with different color are clearly observed in bubbles with large diameter owing to the light interference, resembling a diffraction grating under the illumination of white light.β-In2Se3/WS2heterostructure bubbles can be formed with the topβ-In2Se3crystal varying from monolayer to more than 10 layers in thickness. The FL image clearly demonstrates an enhancement of FL in intensity upon the formation of bubbles of monolayer WS2as well as heterobilayerβ-In2Se3/WS2,though the FL intensity of the latter is much weaker. No evident FL is observed for the In2Se3/WS2heterostructure when layer number ofβ-In2Se3is more than 1 layer in thickness.The enhancement in FL signal of bubbles is attributed to strain and/or the reduction in dielectric screening effect from the substrate.[30-32]Figures 3(c) and 3(d) show a high magnification optical image and corresponding FL image of a bubble spanning over monolayer WS2, monolayer In2Se3/WS2, and multilayers In2Se3/WS2. Interference fringe rings are clearly presented in the contrast of optical and FL image owing to the interference of incident and reflected light at surface of the bubble, also signifying the suppression of FL of WS2in the heterostructure.

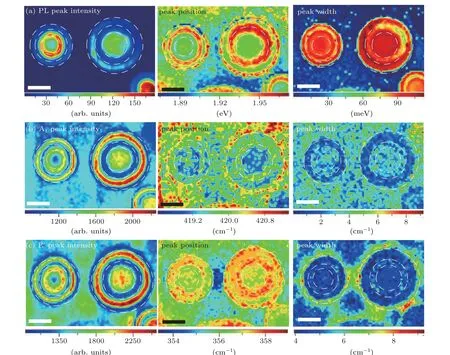

Fig. 4. PL and Ramana characterizations of In2Se3/WS2 heterobilayer bubbles. (a) PL, (b) Raman A1, and (c) Raman E' peaks mapping images of intensity(left),position(middle),and width(right)collected via using laser light of 532 nm. Scales bars are 10µm.

In order to check the morphology of bubble, AFM measurements were carried out on a bubble spanning over a monolayer WS2and a heterobilayerβ-In2Se3/WS2, as marked by the green dashed rectangle in Fig. 3(c). Figure 3(e) displays the AFM image and figure S4 presents a line profile across the top of bubble. The bubble demonstrates a well-defined spherical cap (with a lateral size of~4.6 µm and height of~164 nm). Inset in Fig. 3(e) is a height profile along the marked white line, a thickness~1.08 nm for the monolayer In2Se3atop the monolayer WS2is clearly demonstrated.

Raman and PL measurements were carried out to characterize bubbles of In2Se3/WS2heterobilayer because the FL signal is nearly completely suppressed for heterostructure bubbles with the layer number ofβ-In2Se3crystal more than one layer in thickness. Two heterobilayer bubbles with different lateral sizes were chosen for the characterization, as marked by the green dashed rectangle on the optical image and corresponding FL image in Fig.S5, where Newton’s rings and FL enhancement are clearly visible. Mapping images of peak intensity,position,and width for PL emission peak as well as for two characteristic Raman modes of the heterobilayer bubbles are presented in Fig.4.From the center to the edge of bubbles,rings with periodic variation in intensity are clearly presented in the mapping of PL peak and Raman peaks of the A1and E'modes(Figs.4(a)-4(c)),sharing a spatial period depending on the bubble size. These rings with oscillatory intensity can originate from the interference of the constructive and destructive light in which the optical path difference varies as the light moving from the center to the edge of a bubble. The mappings of PL emission as well as for two characteristic Raman modes also display an oscillatory behaviors of the shift in peak position and broadening in peak width, and are attributed to the localized oscillatory heating induced by the periodic enhancement and suppression of the incident laser in intensity over the surface of bubbles.[1,16]In comparison with the phenomenon in the pure monolayer WS2,[16]the oscillatory behavior in the PL emission and lattice vibrating is more profound in WS2for the In2Se3/WS2heterobilayer. This is attributed to lower thermal diffusivity in the In2Se3/WS2heterobilayer than of the monolayer WS2owing to the much lower thermal conductivity of monolayerβ-In2Se3(<4 W/m·K) than that of monolayer WS2(~60 W/m·K).[33,34]

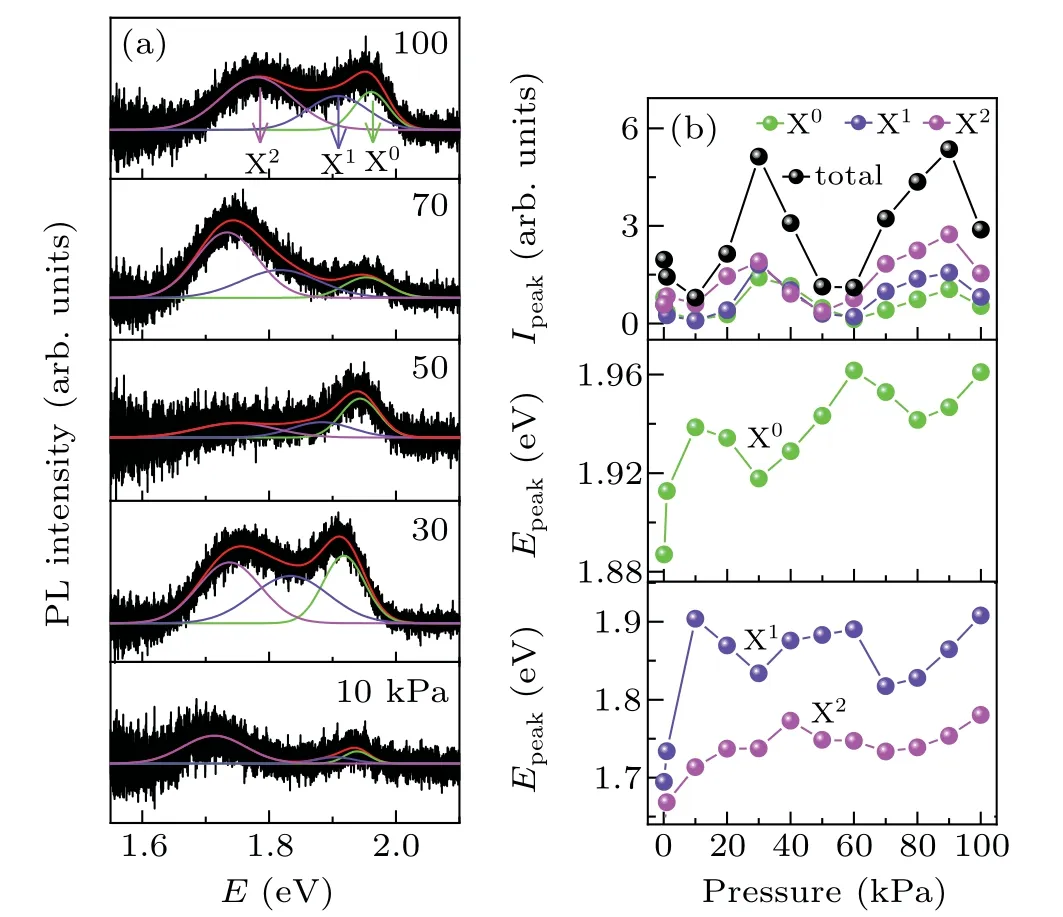

The interference phenomena at the surface of bubble depends on the optical path difference which is very sensitive to the bubble size(as shown in Fig.4)and the pressure balancing the interior and exterior gas of the bubble.[35]By placing the In2Se3/WS2heterobilayer bubble into a home-made vacuum chamber, it tends to be gradually inflated when the vacuum chamber is subjected to a slow purging with a pump. Meanwhile,a tensile strain owing to the inflation of the bubble can be precisely generated,[1]which was used to finely tune the properties of monolayer WS2via strain.[36]Figure 5 presents the PL collected at center position of theβ-In2Se3/WS2heterobilayer bubble subject to different exterior pressures. Typical PL spectra of the heterobilayer bubble at the exterior pressures of 100,70,50,30,and 10 kPa are shown in Fig.5(a),demonstrating a drastically modified emission characteristics of the monolayer WS2in the heterobilayer upon decreasing the exterior pressure. These spectra are deconvoluted by three Gaussian profiles(symbolized by X0,X1,and X2)and parameters of intensityIpeakand emission energyEpeakare summarized in Fig.5(b). An oscillatory behavior forIpeakandEpeakis clearly displayed, and superimposed on a nearly linear background forEpeakupon decreasing the exterior pressure of the heterobilayer bubble. The oscillation is resulted from the interference,while the persisting redshift ofEpeak(linear background)is attributed to the increase of tensile strain during the inflation of the heterobilayer bubble,which is consistent with previous results on the counter part of monolayer WS2.[32,36]

Fig.5. PL characterizations for In2Se3/WS2 heterobilayer bubble subjected to different exterior pressures with an excitation of 532 nm focused on the center of bubble. (a)PL spectra of the heterobilayer bubble at some typical exterior pressures of 10, 30, 50, 70, and 100 kPa. The spectra were deconvoluted by three Gaussian profiles (symbolized by X0, X1, and X2). (b)Deconvoluted PL peak intensity Ipeak and position Epeak as a function of the exterior pressure.

4. Conclusion

In conclusion,β-In2Se3crystals are grown on a millimeter-scale continuous monolayer WS2attached on SiO2/Si substrate via two-step CVD technique,preparing vertical van de Waals heterostructure. After the growth ofβ-In2Se3at elevated temperatures, high density of In2Se3/WS2heterostructure bubbles with monolayer to multilayerβ-In2Se3crystals atop is observed. Newton rings are significantly observed in optical images of heterostructure bubbles due to constructive and destructive interference.In Raman and PL mapping images ofβ-In2Se3/WS2heterobilayer bubbles,significant oscillatory behaviors of emission intensity and peak positions are observed due to optical interference effect. However, oscillatory behaviors of peak position are also observed and come from a local heating effect induced by laser beam.The oscillatory mechanism of PL is further verified by changing the exterior pressure of bubbles. In addition, redshifted in peak positions are observed due to strain effect during decreasing the exterior pressure of bubbles.

猜你喜欢

杂志排行

Chinese Physics B的其它文章

- Numerical investigation on threading dislocation bending with InAs/GaAs quantum dots*

- Connes distance of 2D harmonic oscillators in quantum phase space*

- Effect of external electric field on the terahertz transmission characteristics of electrolyte solutions*

- Classical-field description of Bose-Einstein condensation of parallel light in a nonlinear optical cavity*

- Dense coding capacity in correlated noisy channels with weak measurement*

- Probability density and oscillating period of magnetopolaron in parabolic quantum dot in the presence of Rashba effect and temperature*