铝硅镀层22MnB5高强钢高温拉伸性能及本构模型

2021-09-23张双杰刘恺源王伟高颖朱庆齐

张双杰 刘恺源 王伟 高颖 朱庆齐

摘要:為了分析和表征热成形用的铝硅镀层22MnB5高强钢的热变形行为,采用Gleeble-3800热模拟试验机,在成形温度750~900 ℃、应变速率0.1~10 s-1试验条件下实施了铝硅镀层22MnB5高强钢的板材等温拉伸试验,采用双曲正弦型Arrhenius本构模型描述铝硅镀层22MnB5高强钢的高温流变行为,并考虑应变影响构建了模型。结果表明:1)铝硅镀层22MnB5高强钢的真应力随成形温度的升高而降低,随应变速率的增大而升高,在高温低应变速率条件下(900 ℃,0.1 s-1),峰值应力为134.24 MPa;在低温高应变速率条件下(750 ℃,10 s-1),峰值应力为381.25 MPa;2)本构模型预测值与等温拉伸试验值线性拟合的相关系数R2为0.978,表明构建的本构模型在整个应变范围具有良好的预测精度。研究成果能够准确表征铝硅镀层22MnB5高强钢的热变形行为,为其数值模拟提供材料模型数据支持,并为其热加工工艺研究提供了参考。

关键词:材料力学;铝硅镀层;22MnB5;高强钢;高温拉伸性能;本构模型

中图分类号:TG115;TG142文献标识码:ADOI: 10.7535/hbgykj.2021yx04001

Elevated temperature tensile properties and constitutive model of

Al-Si coated 22MnB5 high-strength steel

ZHANG Shuangjie1,2,3, LIU Kaiyuan1, WANG Wei1,2, GAO Ying1,2,4, ZHU Qingqi5

(1. School of Materials Science and Engineering, Hebei University of Science and Technology, Shijiazhuang,Hebei 050018, China; 2. Hebei Key Laboratory of Material Near-net Forming Technology, Shijiazhuang, Hebei 050018, China; 3. Hebei Engineering Technology Research Center of Precision Punching Process and Die, Cangzhou, Hebei 061500, China; 4. Hebei Industrial Technology Research Institute of Mechanical and Electrical Parts, Cangzhou, Hebei 061500, China; 5. Baoding Exquisite Auto Mould Technology Company Limited, Baoding, Hebei 071000, China.)

Abstract:In order to analyze and characterize the hot deformation behavior of Al-Si coated 22MnB5 high strength steel for hot forming, Gleeble-3800 thermal simulation machine was used to conduct isothermal tensile tests of Al-Si coated 22MnB5 high strength steel under the test conditions of forming temperature 750~900 ℃ and strain rate 0.1~10 s-1. The Arrhenius constitutive model with hyperbolic sinusoidal form was used to describe the elevated temperature rheological behavior of Al-Si coated 22MnB5 high strength steel. In addition, the model considering the influence of strain was constructed. The results indicate that:1) the true stress of Al-Si coated 22MnB5 high strength steel decreases with the increase of forming temperature and increases with the increase of strain rate. At high temperature and low strain rate (900 ℃, 0.1 s-1), the peak stress is 134.24 MPa. At low temperature and high strain rate (750 ℃, 10 s-1), the peak stress is 381.25 MPa; 2)the correlation coefficient R2 of the linear fitting between the predicted values of the constitutive model and the experimental values of isothermal tensile is 0.978, which indicates that the constructed constitutive model has good prediction accuracy in the whole strain range. The results can accurately characterize the thermal deformation behavior of Al-Si coated 22MnB5 high strength steel, provide material model data support for the numerical simulation and a reference for the further study of the hot processing technology of this kind of material.

Keywords:mechanics of materials; Al-Si coating; 22MnB5; high-strength steel; elevated temperature tensile properties; constitutive model

近年来,为满足汽车轻量化和安全性的双重要求,热成形高强度钢被广泛用于制造车身的结构件[1-2],如A/B柱、防撞梁和各纵梁等。国内外学者针对热成形高强钢的CCT曲线[3]、相变温度[4]、热成形性能[5-7]及成形极限[8]、热冲压数值模拟及工艺参数优化[9-13]等方面开展了一系列研究。

在22MnB5热成形高强钢的研究中,高温变形行为及高温本构模型是重要的研究内容,其在热成形的数值模拟、工艺制定及参数优化等方面具有基础性作用。许多学者针对无镀层的22MnB5高强钢开展了大量研究,肖碧媛[14]采用Gleeble-1500研究了22MnB5高强钢在成形温度500~900 ℃、应变速率0.01~1 s-1条件下的热变形行为,将结果用于热冲压工艺的有限元仿真分析,但并未构建22MnB5高强钢的本构模型。曹淑芬等[15]采用Gleeble-1500,研究了成形温度500~950 ℃、应变速率0.01~1 s-1条件下22MnB5高强钢的热变形行为,基于峰值应力,采用包含Zener-Hollomon因子的蠕变方程,建立了温度700~950 ℃、应变速率0.1~1 s-1变形条件下的本构方程。王祥等[16]采用单向热拉伸试验,研究了22MnB5高强钢在成形温度500~800 ℃、应变速率0.01~1.0 s-1条件下的热变形行为,基于井上胜郎模型和Norton-Hoff模型的改进模型建立了22MnB5高强钢的塑性本构方程。童坤等[17]采用Gleeble-1500D,研究了成形温度550~850 ℃、应变速率0.1~5 s-1条件下22MnB5(Nb&V)高强钢的高温流变力学行为,采用Johnson-Cook模型予以描述,将建立的本构模型应用于热冲压的数值模拟中。

目前,对于铝硅镀层22MnB5高强钢的研究集中在镀层性能[18-19]和焊接性能方面[20-21],鲜有其热变形行为和本构关系的研究。因此,本文以铝硅镀层22MnB5高强钢为研究对象,以其典型应用(汽车B柱的热成形)为研究背景,根据其实际热冲压成形工艺参数,分析其在成形温度750~900 ℃、应变速率0.1~10 s-1条件下的热变形行为。考虑到变形过程中的温度、应变速率和形变强化等影响因素,采用双曲正弦型Arrhenius本构模型描述其高温流变行为[22-26],并考虑应变影响构建了模型,以进一步提高模型预测精度,以期为铝硅镀层22MnB5高强钢热成形工艺的研究提供参考。第4期张双杰,等:铝硅镀层22MnB5高强钢高温拉伸性能及本构模型河北工业科技第38卷

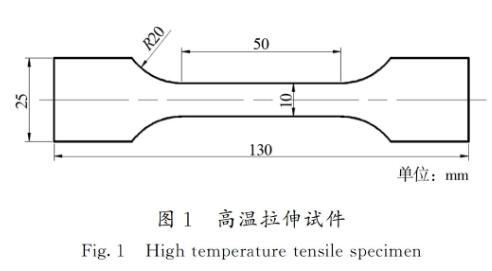

1试验材料及试验方案

试验材料为铝硅镀层22MnB5高强钢,板厚为1.4 mm,鍍层代码为AS60G60G,镀层质量71~74 g/m2,镀层厚度为20~33 μm。采用Gleeble-3800热模拟试验机进行高温条件下的等温拉伸试验,拉伸试件如图1所示,标距为50 mm。拉伸试验前,将热电偶焊接于试件表面,试件加热前,将试验舱抽真空并通入氩气,防止试件发生高温氧化。

根据汽车B柱的热冲压工艺参数,制定等温拉伸试验方案。首先以15 ℃/s将试件加热至930 ℃,保温180 s,使试件充分奥氏体化,再以40 ℃/s分别降温至拉伸温度750,800,850和900 ℃,保温5 s使试件温度均匀化,分别在0.1,1和10 s-1应变速率下进行等温拉伸试验[27]。另外,在实际汽车结构件的热成形中,为避免发生贝氏体转变,制件的冷却速率必须大于27 ℃/s,以确保热冲压件为全马氏体组织[3-4],因此拉伸试验结束后,试件以40 ℃/s冷却至室温。

2拉伸性能及应力-应变延伸

高温拉伸缩颈前的数据是有效且可靠的,因此需去除缩颈阶段的试验数据,得到铝硅镀层22MnB5高强钢在不同温度、不同应变速率下的真应力-应变曲线,如图2中的点实线所示。通过分析图2中的点实线发现,铝硅镀层22MnB5高强钢在高温拉伸过程中具有较宽的塑性变形区,并且在塑性区应力较低,其高温拉伸性能符合典型钢铁材料的高温变形行为,即相同应变速率时,随着温度的升高,真应力呈降低趋势;相同变形温度时,随着应变速率的升高,真应力呈上升趋势。在高温低应变速率条件下(900 ℃,0.1 s-1),峰值应力为134.24 MPa;在低温高应变速率条件下(750 ℃,10 s-1),峰值应力为381.25 MPa。抗拉强度亦具有相同的变化规律。

由于各试验方案发生缩颈时的应变不同,为充分利用缩颈前的试验数据,获得能够描述所有试验方案缩颈前应力-应变关系的本构模型,采用下述方法对试验所得的应力-应变曲线进行延伸[28]。

1)选择参照曲线观察试验数据曲线,拉伸温度为850 ℃、应变速率为10 s-1时的拉伸试件发生缩颈前应变量最大,因此以850 ℃,10 s-1的应力-应变曲线为参照,对其它试验曲线予以延伸。

2)确定延伸区间及平移距离以变形温度为750 ℃、应变速率为10 s-1时的应力-应变曲线为例,确定发生缩颈时的应变值ε1和应力值σ1,应力-应变曲线中ε≥ε1的部分即为延伸区间。通过线性插值法,确定参照曲线中应变为ε1处的应力值σ2,σ2-σ1即为平移距离。

3)平移延伸将参照曲线中ε≥ε1的部分复制并平移σ2-σ1的距离,取代750 ℃,10 s-1条件下真应力-应变曲线中产生缩颈后的部分,实现应力-应变曲线的延伸。

采用相同方法,将其它试验条件下的真应力-应变曲线进行延伸,如图2中虚线所示。

3铝硅镀层22MnB5高强钢本构模型

3.1Arrhenius本构模型

采用双曲正弦型Arrhenius本构模型描述铝硅镀层22MnB5高强钢的热变形行为,如式(1)所示。

ε·=A[sinh(ασ)]nexp(-QRT)。(1)

对式(1)进行Tayler级数展开,得到适用于不同应力条件下的本构关系,如式(2)—式(4)所示。

Z=f(σ)=A1σn1,ασ<0.8,(2)

Z=f(σ)=A2exp(βσ),ασ>1.2, (3)

Z=f(σ)=A[sinh(ασ)]n,for all σ 。 (4)

式(1)—式(4)中ε·為应变速率,s-1;σ为流变应力,MPa;R为气体常数,取8.314 J·mol-1·K-1;T为变形温度,℃;A,α,n,Q,A1,n1,A2和β均是与应变量有关的材料常数,α,β和n1之间满足式(5)。

α=β/n1 。(5)

将式(1)与式(3)联立,可得式(6)。

σ=ln ε·β-ln A2β+QβRT。 (6)

由式(6)可知,σ与ln ε·之间符合线性关系,斜率为1/β,取应变为0.2时各变形温度和应变速率的真应力值,绘制σ与ln ε·的线性拟合曲线,如图3所示,求得β的值为0.041 31。

将式(1)与式(2)联立,可得式(7)。

ln σ=ln ε·n1-ln A1n1+Qn1RT。 (7)

由式(7)可知,ln σ与ln ε·之间符合线性关系,斜率为1/n1。取应变为0.2时各变形温度和应变速率的真应力值,绘制ln σ与ln ε·的线性拟合曲线,如图4所示,求得n1的值为8.867 2。将β和n1的值代入式(5),求得α的值为4.659 1×10-3。

假定Q和T无关,对式(1)两侧分别取对数可得式(8)。

ln ε·=ln A+nln[sinh(ασ)]-QRT。 (8)

由式(8)可知,通过ln[sinh(ασ)]和ln ε·线性拟合曲线的斜率即可求得n值。采用应变为0.2时的真应力值,对ln[sinh(ασ)]和ln ε·进行线性拟合,如图5所示,求得n的值为6.667 4。

将式(8)变换后,可得式(9)。

ln[sinh(ασ)]=QnR×1T+ln ε·-ln An 。(9)

由式(9)可知,ln[sinh(ασ)]和1/T关系曲线的斜率为Q/nR,截距为(ln ε·-ln A)/n,即可求解变形激活能Q和材料常数A。假设斜率为k,截距为h,则应变能Q和材料参数A可以由式(10)和式(11)求得。

Q=knR,(10)

ln A=ln ε·-nh。 (11)

将ln[sinh(ασ)]与1/T进行线性回归,如图6所示,求得的变形激活能Q和材料常数A的值分别为Q=133 767.196 J/mol,ln A=18.579 6。

将求得的各材料常数带入式(1),得到铝硅镀层22MnB5高强钢的本构模型为

σ=10.004 659 1×

arcsinh[exp(ln ε·-18.579 6+133 767.196/(8.314T)6.667 4)]。(12)

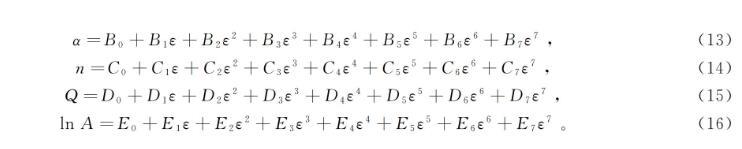

3.2考虑应变影响的本构模型

上述Arrhenius本构模型,采用了应变为0.2时的数据,并未考虑应变变化的影响,因此使用上述方法,分别求解不同应变时α,n,Q和ln A的值构建考虑应变影响的本构模型。以应变为自变量,各参数为因变量,进行多项式拟合,得到各参数与应变的多项式函数模型,采用应变为0.1,0.15,0.2,0.25,0.3,0.35,0.4和0.45(应变间隔0.05)时的数据求解各参数,并采用式(13)—式(16)所示的7阶多项式函数进行拟合,拟合曲线如图7所示,7阶多项式的系数列于表1。

α=B0+B1ε+B2ε2+B3ε3+B4ε4+B5ε5+B6ε6+B7ε7 , (13)

n=C0+C1ε+C2ε2+C3ε3+C4ε4+C5ε5+C6ε6+C7ε7,(14)

Q=D0+D1ε+D2ε2+D3ε3+D4ε4+D5ε5+D6ε6+D7ε7 ,(15)

ln A=E0+E1ε+E2ε2+E3ε3+E4ε4+E5ε5+E6ε6+E7ε7 。(16)

3.3本构模型精度分析

使用考虑应变影响的本构模型计算应力的预测值,并与等温拉伸试验得到的试验值进行对比,如图8 a)—c)所示,并将预测值与试验值进行线性回归,如图8 d)所示,线性拟合的相关系数R2为0.978,对比分析结果表明,构建的本构模型在整个应变范围具有较好的预测精度,能够较好地描述铝硅镀层22MnB5高强钢的高温本构关系。

4结语

针对铝硅镀层22MnB5高强钢应用越发广泛的现状,笔者采用双曲正弦型Arrhenius本构模型描述铝硅镀层22MnB5高强钢的高温流变行为,并构建了考虑应变影响的本构模型。根据研究结果,得出以下结论。

1)铝硅镀层22MnB5高强钢在高温拉伸过程中具有较宽的塑性变形区,并且其应力在塑性区较低,其高温拉伸性能及抗拉强度符合典型钢铁材料的高温变形行为,即相同应变速率时,随着温度的升高,真应力呈降低趋势;相同变形温度时,随着应变速率的升高,真应力呈上升趋势,在高温低应变速率条件下(900 ℃,0.1 s-1),峰值应力为381.25 MPa;在低温高应变速率条件下(750 ℃,10 s-1),峰值应力为134.24 MPa。

2)本文建立了考虑应变影响的铝硅镀层22MnB5高强钢的Arrhenius本构模型,模型预测值与等温拉伸试验值线性拟合的相关系数R2为0.978,表明模型在整个应变范围具有较好的预测精度,能够较好地描述铝硅镀层22MnB5高强钢的高温本构关系。该模型不仅丰富了铝硅镀层22MnB5高强钢本构关系的表征,而且其热变形条件是基于实际的热冲压成形工艺参数确定的,因此模型更加贴近高强钢实际热冲压成形工况。

本文从力学角度研究了铝硅镀层22MnB5高强钢的热变形行为并构建了模型,但未分析铝硅镀层22MnB5高强钢热变形过程微观组织的演变,后续还需通过对铝硅镀层22MnB5高强钢微观组织的分析,探索不同热变形条件对其微观组织演变的影响规律。

参考文献/References:

[1]张宜生,王子健,王梁.高强钢热冲压成形工艺及装备进展[J].塑性工程学报,2018,25(5):11-23.

ZHANG Yisheng,WANG Zijian,WANG Liang. Progress in hot stamping process and equipment for high strength steel sheet[J]. Journal of Plasticity Engineering,2018,25(5):11-23.

[2]孟炬, 朱彬, 张宜生, 等. 高强钢热冲压成形过程宏微观数值模拟综述[J]. 河北工业科技, 2015, 32(3): 272-276.

MENG Ju, ZHU Bin, ZHANG Yisheng, et al. Review on macro-and micro-modeling of high strength steel hot stamping process[J]. Hebei Journal of Industrial Science and Technology, 2015, 32(3): 272-276.

[3]BARCELLONA A,PALMERI D. Effect of plastic hot deformation on the hardness and continuous cooling transformations of 22MnB5 microalloyed Boron steel[J]. Metallurgical and Materials Transactions, 2009,40(5):1160-1174.

[4]MERKLEIN M,LECHLER J. Investigation of the thermo-mechanical properties of hot stamping steels[J]. Journal of Materials Processing Technology,2006,177(1/2/3):452-455.

[5]MIN Junying,LIN Jianpin,TIAN Haobin,et al.Investigation on uniaxial tensile instability of USIBOR1500 steel sheets at elevated temperature[J].Chinese Journal of Mechanical Engineering,2010,23(1):94-99.

[6]马宁,申国哲,张宗华,等.高强度钢板热冲压材料性能研究及在车身设计中的应用[J].机械工程学报,2011,47(8):60-65.

MA Ning,SHEN Guozhe,ZHANG Zonghua,et al.Material performance of hot-forming high strength steel and its application in vehicle body[J].Journal of Mechanical Engineering,2011,47(8):60-65.

[7]孙世清. 梁文瑞. 张楠. 9Cr5MoV钢的磁性分析与深冷处理[J]. 河北科技大学学报. 2013, 34(1): 75-78.

SUN Shiqing, LIANG Wenrui, ZHANG Nan. Magnetic analysis and deep cryogenic treatment of 9Cr5Mov steel[J]. Journal of Hebei University of Science and Technology, 2013, 34(1):75-78.

[8]胡平,史栋勇,盈亮,等.高强度钢板的热塑性成形极限[J].北京理工大学学报,2014,34(sup1):128-132.

HU Ping,SHI Dongyong,YING Liang,et al.Thermoplastic forming limit of high strength steel[J].Transactions of Beijing Institute of Technology,2014,34(sup1):128-132.

[9]GARCIA A L,CHASTEL Y,FERNANDEZ P J,et al. Experiments and simulation of the hot stamping of quenchable steels[J].Advanced Technology of Plasticity,2002,12(7):1135-1140.

[10]包軍,邢忠文,杨玉英,等.超高强度硼钢板热弯曲数值模拟[J].材料科学与工艺,2009,17(3):326-328.

BAO Jun,XING Zhongwen,YANG Yuying,et al.Numerical simulation of hot bending with ultra high strength boron steel[J]. Materials Science and Technology,2009,17(3):326-328.

[11]曹向茹,崔海亭,蒋静智.泡沫金属相变材料凝固传热过程的数值分析[J].河北工业科技﹐2011,28(1):1-4.

CAO Xiangru, CUI Haiting, JIANG Jingzhi. Numerical simulation on heat transfer of phase change in heat storage ball filled with metal foam[J]. Hebei Journal of Industrial Science and Technology, 2011, 28(1): 1-4.

[12]林建平,王立影,田浩彬,等.超高强度钢板热冲压成形研究与进展[J].热加工工艺,2008,37(21):140-144.

LIN Jianping,WANG Liying,TIAN Haobin,et al.Research and progress of hot stamping of ultrahigh strength steel[J].Hot Working Technology,2008,37(21):140-144.

[13]贺连芳,赵国群,李辉平,等.基于响应曲面方法的热冲压硼钢B1500HS淬火工艺参数优化[J].机械工程学报,2011,47(8):77-82.

HE Lianfang,ZHAO Guoqun,LI Huiping,et al.Optimization of quenching parameters for hot stamping boron steel B1500HS based on response surface methodology[J].Journal of Mechanical Engineering,2011,47(8):77-82.

[14]肖碧媛.22MnB5高强度钢热变形行为及冲压工艺仿真研究[D].长沙:湖南大学,2013.

XIAO Biyuan.Study on Hot Deformation Behavior and Hot Stamping Process Simulation of High Strength Steel 22MnB5[D]. Changsha:Hunan University,2013.

[15]曹淑芬,张立强,郭鹏程,等.22MnB5热变形行为研究及本构方程建立[J].中国机械工程,2014,25(9):1256-1261.

CAO Shufen,ZHANG Liqiang,GUO Pengcheng,et al.Study on hot deformation behavior and flow stress constitutive model of 22MnB5 at high temperature[J].China Mechanical Engineering,2014,25(9):1256-1261.

[16]王祥,陳炜,陈泷,等.高强度钢热冲压塑性本构关系建立及应用[J].热加工工艺,2015,44(3):107-110.

WANG Xiang,CHEN Wei,CHEN Long,et al. Establishment and application of constitutive relationship of high strength steel during hot stamping[J].Hot Working Technology,2015,44(3):107-110.

[17]童坤,韩先洪,崔振山.新型热冲压高强钢22MnB5(Nb&V)的热变形本构关系[J].塑性工程学报,2019,26(6):256-262.

TONG Kun,HAN Xianhong,CUI Zhenshan.Thermal deformation constitutive relationship of new type high strength hot stamping steel 22MnB5(Nb&V)[J].Journal of Plasticity Engineering,2019,26(6):256-262.

[18]左源,李琦,纪沙沙,等.22MnB5热成形钢铝硅镀层的制备工艺及抗氧化性能研究[J].热加工工艺,2019,48(8):145-148.

ZUO Yuan,LI Qi,JI Shasha,et al.Research on preparing process and oxidation resistance of aluminum silicon coating for 22MnB5 hot forming steel[J].Hot Working Technology,2019,48(8):145-148.

[19]刘浩,谭宁,金鑫焱.变形量对铝硅镀层热冲压用钢组织和性能的影响[J].金属热处理,2019,44(9):147-151.

LIU Hao,TAN Ning,JIN Xinyan. Effect of deformation on microstructure and mechanical properties of aluminum-silicon coating hot stamping steel[J].Heat Treatment of Metals,2019,44(9):147-151.

[20]王晗.铝硅镀层22MnB5激光焊接头组织与性能研究[D].长春:吉林大学,2020.

WANG Han.Study on Microstructures and Mechanical Properties of Al-Si Coating 22Mnb5 Laser Welded Joints[D]. Changchun:Jilin University,2020.

[21]李贤.对热浸Al-Si镀层22MnB5钢激光焊接及焊接接头的组织和性能的研究[D].武汉:武汉科技大学,2020.

LI Xian. Study on Microstructure and Properties of Hot-Dip Al-Si Coating 22MnB5 Steel Laser Welded Joint[D].Wuhan:Wuhan University of Science and Technology,2020.

[22]王伟,马世博,张双杰,等.20Cr2Ni4A钢高温变形行为及物理基参数本构模型[J].塑性工程学报,2018,25(6):147-153.

WANG Wei,MA Shibo,ZHANG Shuangjie,et al. Elevated temperature deformation behavior and physically-based parameter constitutive model of 20Cr2Ni4A steel[J]. Journal of Plasticity Engineering, 2018,25(6):147-153.

[23]CAI Jun,LEI Ying,WANG Kuaishe,et al.A comparative investigation on the capability of modified Zerilli-Armstrong and Arrhenius-Type constitutive models to describe flow behavior of BFe10-1-2 cupronickel alloy at elevated temperature[J]. Journal of Materials Engineering and Performance,2016,25(5):1952-1963.

[24]WU Mengwei,ZHANG Shuangjie,MA Shibo,et al. Hot deformation behavior of Q345 steel and its application in rapid shear connection[J]. Materials,2019,12(13):2186.

[25]ABBASI-BANI A,ZAREI-HANZAKI A,PISHBIN M H,et al. A comparative study on the capability of Johnson-Cook and Arrhenius type constitutive equations to describe the flow behavior of Mg-6Al-1Zn alloy[J]. Mechanics of Materials,2014,71:52-61.

[26]WANG Wei, MA Rui,LI Lianping, et al. Constitutive analysis and dynamic recrystallization behavior of as-cast 40CrNiMo alloy steel during isothermal compression[J]. Journal of Materials Research and Technology, 2020,9(2):1929-1940.

[27]王伟,王波,闫华军,等.基于等温压缩试验的20Cr2Ni4A钢Johnson-Cook本构模型及热加工图[J].热加工工艺,2020,49(13):103-108.

WANG Wei, WANG Bo, YAN Huajun, et al. Johnson-Cook constitutive model and hot processing map of 20Cr2Ni4A steel based on isothermal compression tests[J]. Hot Working Technology,2020,49(13):103-108.

[28]李輝平,赵国群,贺连芳,等.热冲压硼钢B1500HS高温本构方程的研究[J].机械工程学报,2012,48(8):21-27.

LI Huiping,ZHAO Guoqun,HE Lianfang,et al. Research on the constitutive relationship of hot stamping boron steel B1500HS at high temperature[J].Journal of Mechanical Engineering,2012,48(8):21-27.