极近距离煤层上覆采空区下大断面切眼掘进技术研究

2021-09-10万磊孙茂如郭辉

万磊 孙茂如 郭辉

摘 要:随着煤炭开采深度不断增加,很多矿区在工作面布置上都存在近距离煤层采空区下回采的问题。由于上覆工作面回采后采空区内垮落不充分,矿山压力分布规律性不强,且采空区下巷道掘进期间,受二次扰动影响易造成顶板裂隙发育,对上覆采空区形成漏风通道,容易引发采空区内有毒有害气体外溢和采空区内遗煤自燃事故,极近距离煤层采空区下大断面巷道掘进问题尤为突出。本论文以新集二矿2201采区首个采空区下工作面切眼掘进为研究背景,制定了极近距离煤层上覆采空区下大断面巷道掘进施工方案,取得了成功并形成了类似条件下的安全掘进综合技术措施,为后续指导极近距离煤层上覆采空区下开采拓展了思路。

關键字:极近距离煤层;采空区下;大断面;巷道掘进

中图分类号:TD822 文献标识码:A 文章编号:1003-5168(2021)21-0067-04

Research on Tunneling Technique for the Cut-hole with the Large Section under Goaf in Extremely Close Coal Seams

WAN Lei SUN Maoru GUO Hui

(The Second Coal Mine of Xinji, China Coal Xinji Energy Co., Ltd, Huainan Anhui 232180)

Abstract: With the increasing of coal mining depth, many mining areas have the problem of mining under goaf in t extremely close coal seams. Because of the overlying after mining face goaf caving inadequate, the mine pressure distribution regularity is not strong, and under the goaf roadway drivage, affected by the secondary disturbance of the roof fracture, the overlying goaf air leakage passage formation, which is easy to cause the toxic or harmful gases within the mined-out area and traces of mined-out area in coal spontaneous combustion accident, the drivage problem with large section roadway under goaf in extremely close to the coal seams is particularly prominent. The research background of this pa per is the cut hole under goaf in 2201 mining area of xinji no.2 mine. The construction plan of the large section roadway under the extremely close coal seams is formulated. The comprehensive technical measures for safe tunneling under similar conditions have been developed successfully. The train of thought is expanded for the follow-up guidance of mining under goaf of the extremely close coal seams.

Keywords: extremely close coal seams; under goaf; large section; roadway excavation

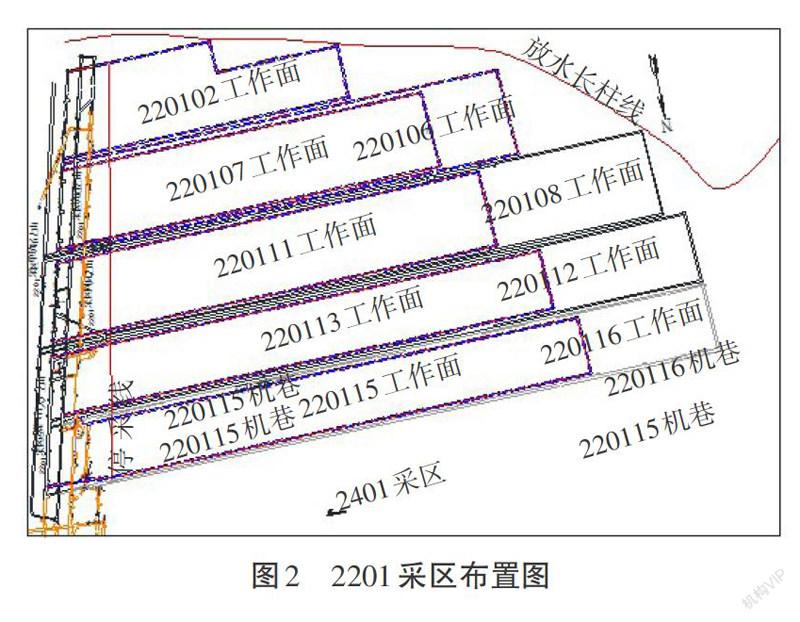

新集二矿1煤组资源量约10 632.6万t,保有储量约6 393.5万t,可采储量约3 327.7万t,其安全开采经济效益显著、社会效益长远。新集二矿1煤组由1上煤和1煤组成,其煤质为1/3焦煤,其中1上煤厚度为3.3~3.8 m,平均厚度约3.6 m;1煤层厚度为2.6~3.6 m,平均厚度约3.0 m;两次层夹矸为泥岩,厚度约为0.8~1.2 m,平均厚度约为1.0 m。受副井罐笼空间限制,最大可提升ZZ9200-24/50型液压支架,其能力不能满足1煤组一次采全高要求,因此,矿井针对1煤组开采时采取分层开采方式,即先开采1上煤工作面,待采空区冒落稳定后再开采1煤工作面。

由于上覆工作面回采后采空区内垮落不充分,矿山压力分布规律性不强,且岩体受采动影响裂隙较发育,极易形成漏风通道,对工作面围面及回采都将带来很大的影响。虽然有些学者已对近距离煤层下行开采条件下的采场覆岩应力演化[1-2]、工作面开采技术[3]、巷道掘进支护方案[4-6]等方面进行了深入研究,但对无法采取锚网支护的采空区极近距离煤层大断面切眼掘进支护工艺还没有过多研究。

本文结合新集二矿极近距离煤层开采条件,制定了上覆采空区下极近距离煤层大断面巷道掘进支护方案和防治采空区遗煤自然发火措施,实现了首个极近距离煤层采空区下大断面切眼安全施工,并保证了工作面支架顺利安装及回采,对类似条件下资源安全开采具有借鉴指导意义。