Surface Modification of Electrospun Poly(L-lactide)/Poly(ɛ-caprolactone) Fibrous Membranes by Plasma Treatment and Gelatin Immobilization

2021-09-07SHITongna史同娜SHIZhenjiang施镇江ZHUBingjie朱冰洁WUWenhua吴文华

SHI Tongna(史同娜), SHI Zhenjiang(施镇江), ZHU Bingjie(朱冰洁), WU Wenhua(吴文华)

National Demonstration Center for Experimental Materials Science and Engineering Education, Donghua University, Shanghai 201620, China

Abstract: Biopolymer fibers have great potential for technical applications in biomaterials. The surface properties of fibers are of importance in these applications. In this study, electrospun poly(L-lactide) (PLLA)/poly(ɛ-caprolactone) (PCL) membranes were modified by cold plasma treatment and coating gelatin to improve the surface hydrophilic properties. The morphologies of the fibers were observed by scanning electron microscopy (SEM). Atomic force microscopy (AFM) was employed to show the surface characteristics of the fibers. The chemical feature of the fibrous membrane surfaces was examined by X-ray photoelectron spectroscopy (XPS). The surface wettability of the fibrous membrane was also characterized by water contact angle measurements. All these results show that plasma treatment can have profound effects on the surface properties of fibrous membranes by changing their surface physical and chemical features. Gelatin-PLLA/PCL membrane has great potential in applications of tissue engineering scaffolds.

Key words: surface property; modification; electrospun fiber; plasma treatment; chemical feature; morphology; wettability

Introduction

Tissue engineering is rapidly growing into an increasingly important field in regenerative medicine. One of the significant challenges for tissue engineering is to design and fabricate suitable biodegradable scaffolds that are suitable for cell adhesion, growth, proliferation and differentiation, and can guide process of tissue formation[1-2]. Polymer-based nanofibers are considered as a potential material applied in filtration, tissue engineering, and fuel cell[3]. Electrospinning is a well-established process for fabrication of polymeric nanofibers used in scaffolds with high surface areas, large volume-to-mass ratios, and high porosities[4-6]. Recently, polylactone-type biodegradable polymers, such as poly(L-lactide) (PLLA), poly(ɛ-caprolactone) (PCL) and their copolymer poly(L-lactide-co-ɛ-caprolactone) (PLLACL), have been extensively studied as scaffold materials[7-11], since polylactone-type biodegradable polymers possess good mechanical properties, non-toxicity, and adjustable degradation rates. However, the poor hydrophilicity of the polymers affects cells to attach and grow on them when the polymers are used as scaffold materials.

Plasma treatment is a very promising and frequently used technique for the chemical and physical modification to increase hydrophilicity, which is suitable for most of the materials, especially polymers and polymer fibers[12-13]. Typical plasma treatments with oxygen, ammonia or air can generate carboxyl groups or amine groups on the surface[14-16]. In addition, a variety of extracellular matrix (ECM) protein components, such as gelatin, collagen, laminin and fibronectin, have been immobilized onto the plasma-treated surface to enhance cellular adhesion and proliferation[17-18]. Gelatin is a mixture of proteins which is obtained by hydrolysis of collagen, and it is widely used in tissue engineering due to its biocompatibility, biodegradability and easy availability[19-22]. Gelatin is nonimmunogenic compared with its precursor and can promote cell adhesion, migration, differentiation and proliferation[23-24].

In this study, the PLLA/PCL (mass ratio was 70∶30) membrane was prepared by electrospinning. However, being synthetic biomaterials, PLLA/PCL membrane is not a good substrate for cell adhesion because of the hydrophobic surface and lacking of functional groups. Thus, Helium (He) plasma treatment was used to modify the electrospun PLLA/PCL membrane, and gelatin was coated onto the He-plasma-treated PLLA/PCL membrane. The fibrous membranes before and after modification were characterized by scanning electron microscopy (SEM), atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS) and water contact angle measurements.

1 Experiments

1.1 Materials preparation

PLLA (Mn=150 000) and PCL (Mn=50 000) were obtained from Sigma-Aldrich Company, Shanghai, China. The polymer solution concentration of 3% (mass percentage) was prepared by dissolving the polymers (the mass ratio of PLLA to PCL was 70∶30) in chloroform. The solution was spun from a 10 mL syringe with a needle of 0.7 mm in diameter. Upon applying a high voltage (10 kV), a fluid jet was ejected from the capillary. As the jet accelerated towards a grounded collector, the solvent evaporated and sub-micron fibers were deposited on an aluminium foil. The distance between the needle and the grounded collector was 20 cm. The PLLA/PCL membrane was dried in a vacuum oven at 37 ℃ for 24 h to remove the residual solvent.

1.2 Surface modification

Plasmas were excited with a capacitively coupled 13.56 MHz radio frequency generator capable of delivering a continuously varying power output from 0 to 500 W. The base pressure of the plasma chamber was down to 0 Pa, and the He gas was fed to the chamber until the pressure reached the working pressure of 20 Pa. The electrospun PLLA/PCL fibers were treated at 45 W with He plasma for 2 min. The plasma treated sample was further exposed to the air for 10 min before coating gelatin.

Anchorage of gelatin was performed by immersing the He-plasma-treated PLLA/PCL sample in 10% (mass percentage) gelatin solution for 12 h at 37 ℃. Then the gelatin-PLLA/PCL sample was washed by distilled water for three times and dried overnight in a vacuum oven. And then it was stored in a desiccator for 12 h at 37 ℃.

1.3 Morphology observation by SEM

The original and surface-modified fibrous membranes were characterized by a JSM-5600LV SEM (JEOL, Japan). Prior to SEM examination, a conductive thin gold film was deposited on the specimen surface.

1.4 Surface structure tested by AFM

All AFM images were obtained in ambient atmosphere at room temperature with a Nanoscope Ⅳ(Veeco, USA) microscope. The scanning was carried out in contact mode AFM. Each fiber sample was mounted to double-sided tape on magnetic AFM sample stubs.

1.5 Elemental analysis by XPS

Changes of the chemical bond environment of the treated samples were examined using the ESCALAB 200R XPS system (V.G Scientific Co., U.K.). Al Kα line (300 W) was used as a source of excitation. The XPS measurements used an Al Kα X-ray source with an optimum energy resolution 0.47 eV. The pressure in the analysis chamber was maintained at 5×10-6Pa.

1.6 Water contact angle measurement

The contact angle between water droplets and the surface was measured using a contact anglemeter (Dataphysics Co., Germany) at room temperature. The water droplets made of 3 μL distilled water were dropped at six different spots on each sample, and the average value was adopted.

2 Results and Discussion

2.1 Surface morphologies of original and modified PLLA/PCL membranes

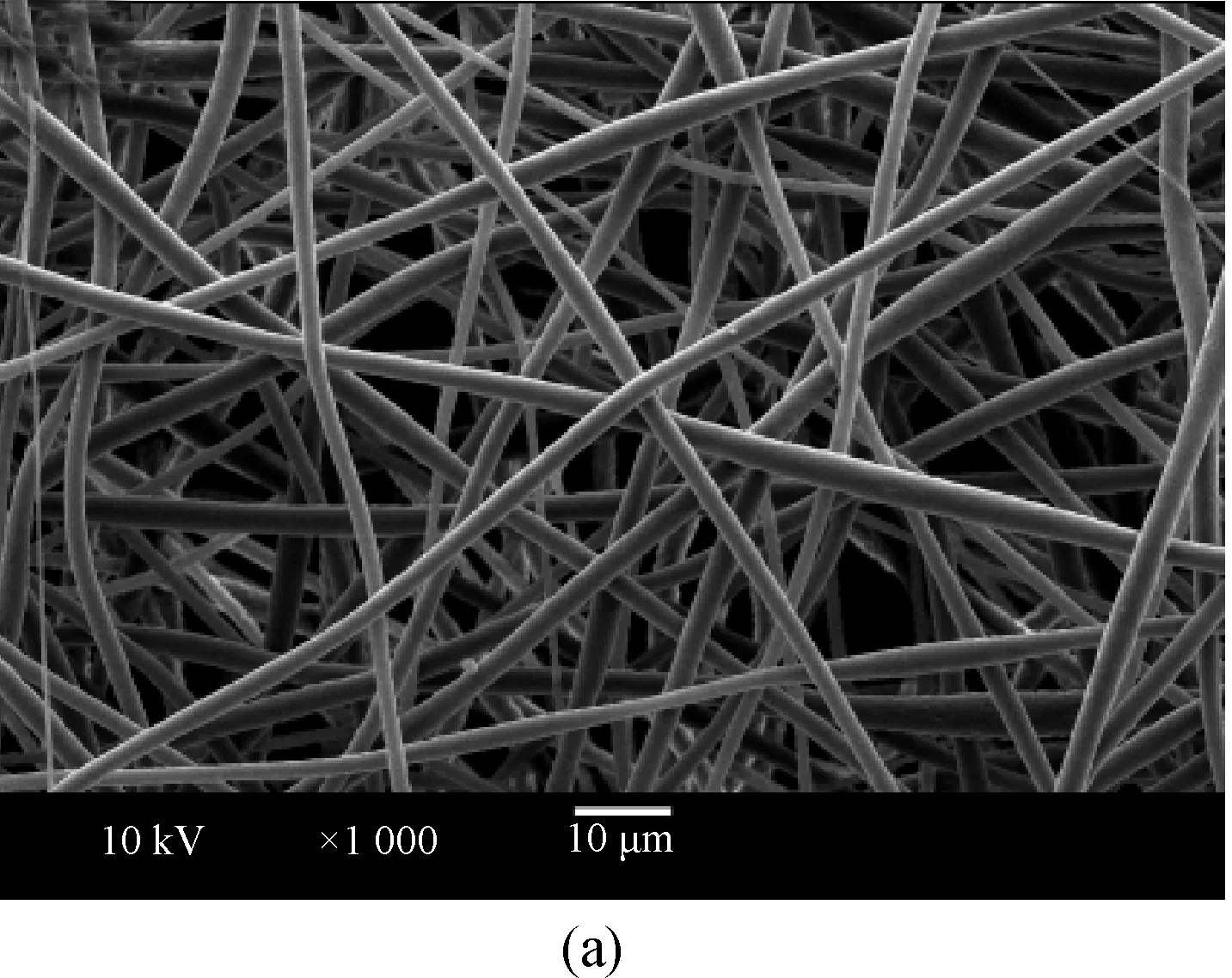

Surface morphology of various PLLA/PCL membranes was observed by SEM technique as shown in Fig. 1. In Figs. 1(a) - (b), it can be seen that the fiber surfaces of original PLLA/PCL film are smooth. However, He-plasma-treated sample presents the formation of groove-like structures on the fiber surfaces as exhibited in Figs. 1(c) - (d). The surface roughness of the fibers is greatly increased by He plasma treatment compared with the surface roughness of untreated ones. This can be attributed to the etching effect of the He plasma treatment. As shown in Figs. 1(e)-(f), distribution of gelatin is much even on the surface of fibers after the PLLA/PCL film is pretreated by He plasma, and the gelatin exhibits as mesh-like structures because of the rough surface of the He-plasma-treated film and subsequent gelatin anchoring process.

Fig.1 SEM observation of surface morphology of various fibrous membranes: (a) original PLLA/PCL membrane (×1 000); (b) original PLLA/PCL membrane (×5 000); (c) He-plasma-treated PLLA/PCL membrane (×1 000); (d) He-plasma-treated PLLA/PCL membrane (×5 000); (e) gelatin-PLLA/PCL membrane (×1 000); (f) gelatin-PLLA/PCL membrane (×5 000)

2.2 Surface roughness of original and modified PLLA/PCL fibers

Topographical examination by AFM indicates the changes in the surface morphology of electrospun PLLA/PCL fibers before and after modification, as shown in Fig. 2. The AFM image in Fig. 2(a) illustrates that the original fiber with diameter ranging from 500 nm to 1 000 nm has relative smooth surface. The image also reveals that the diameter is uneven along an individual fiber. The sample treated by He plasma at 45 W for 2 min in Fig. 2(b) presents nanosize pores and aggregates on the fiber surface, and also there are some protruding particles like dots on the surface. In Fig. 2(c), gelatin distributing on the surface of He-plasma-treated sample results in the formation of groove-like structures on the fiber surface. All these AFM results show the changes on the surface roughness in detail and are consistent with the SEM analysis in Fig. 1.

Fig. 2 AFM images of original and modified PLLA/PCL fibers:(a) original PLLA/PCL fiber; (b) He-plasma-treated PLLA/PCL fiber; (c) gelatin-PLLA/PCL fiber

2.3 Surface composition of untreated and treated PLLA/PCL fibrous membranes

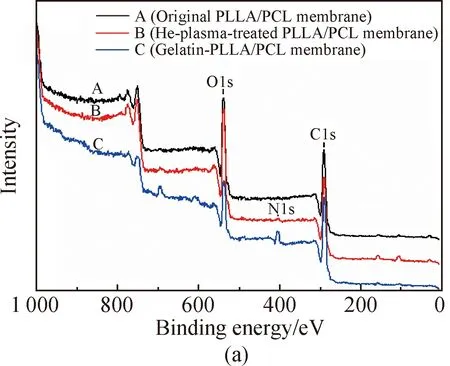

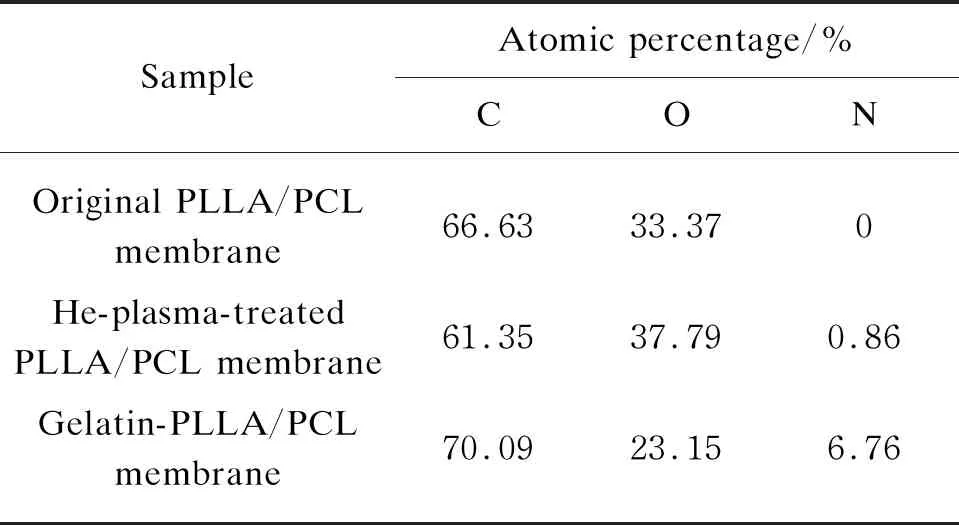

To confirm changes of surface compositions and introduction of additional functional groups, XPS analysis was carried out. XPS is the leading analytical technique for characterizing various chemical/physical forms of elements in surface structures. XPS is especially attractive since additional chemical information can be derived from the line positions of the corresponding peaks[25-26]. Figure 3 shows survey scan spectra and C1s spectra of pristine PLLA/PCL membrane, He-plasma-treated PLLA/PCL membrane and gelatin-PLLA/PCL membrane.

As can be seen from Fig. 3(a), all XPS spectra have two separated peaks which correspond to C1s (about 285 eV) and O1s (about 532 eV). A distinct N1s peak at 420 eV in the He-plasma-treated PLLA/PCL membrane indicated that a very small amount of nitrogen was introduced on the surface after the plasma-treated sample exposing to air. And the N1s peak in the gelatin-PLLA/PCL membrane spectrum indicated that gelatin had been successfully introduced onto the fiber surface. In addition, all the peaks on the spectra moved to lower-binding energy from curve A to curve C in Fig. 3(a).

Fig.3 XPS survey scan spectra and C1s spectra of various PLLA/PCL membranes: (a) full spectra; (b) C1s spectra

Table 1 Surface composition of various samples measured by XPS

2.4 Water contact angle analysis for untreated and treated PLLA/PCL membranes

The effect of plasma treatment and coating gelatin on the hydrophilicity of the PLLA/PCL membrane was shown in Fig. 4. As seen in Fig. 4, the water contact angle of the original PLLA/PCL membrane is found to be about 133°. After He plasma treatment, it appears that the water contact angles of the surface decease from 130° to 0° in 40 s. This can be attributed to the polar groups of the fibers and the rough surfaces. It is evident that He plasma treatment considerably reduces the water contact angle on the membrane surface. He plasma treatment is an effective method to introduce oxygen containing groups (such as carboxyl and hydroxyl groups) onto polymer surfaces. This simple method was used in this work to improve the hydrophilicity and introduce carboxyl groups onto the PLLA/PCL membrane surface for the possibility of gelatin grafting in aqueous solution. After gelatin was attached to the He-plasma-treated surface, the water contact angles dropped rapidly from 105° to 0° in 12 s, which further indicated the carboxyl groups generated on the plasma-treated surface conjugated with gelatin.

Fig. 4 Water contact angles of (a) original PLLA/PCL membrane; (b) He-plasma-treated PLLA/PCL membrane; (c) gelatin-PLLA/PCL membrane

3 Conclusions

This study has explored the effects of plasma treatment and gelatin coated on PLLA/PCL membranes. It has shown that plasma treatment can have profound effects on the surface properties of fibrous membrane by changing their surface physical and chemical features. Furthermore, gelatin was successfully anchored on the surface of electrospun PLLA/PCL membrane by He plasma treatment, as evident from a detailed physical and chemical characterization of gelatin-PLLA/PCL membrane. And the surface hydrophilicity of modified fibrous membrane has been greatly improved. The modification of electrospun fibers surface by plasma pretreatment and bound gelatin has great potential in applications such as biomaterials, sensors and medical devices, which is expected to carry out cell culture research in the next step.

猜你喜欢

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Hardware-in-the-Loop Simulation of Vibration Control of Stay Cables with Damper Based on dSPACE System

- Effect of Two Kinds of Similarity Factors on Principal Component Analysis Fault Detection in Air Conditioning Systems

- One Class of the Least Congruences on Completely Regular Semigroups

- Abundant Exact Solutions for Differential-Difference Equations Arising in Toda Mechanics

- Linear Dynamical System over Finite Distributive Lattice

- Optimal Reactive Power Compensation of Distribution Network to Prevent Reactive Power Reverse