Water Management for Improvement of Rice Yield, Appearance Quality and Palatability with High Temperature During Ripening Period

2021-07-13YujiMatsueKatsuyaTakasakiJunAbe

Yuji Matsue, Katsuya Takasaki, Jun Abe

Research Paper

Water Management for Improvement of Rice Yield, Appearance Quality and Palatability with High Temperature During Ripening Period

Yuji Matsue1, Katsuya Takasaki2, Jun Abe3

(Global Innovation Center, Kyushu University, Minami-ku, Fukuoka 815-8540, Japan; AGL Co, Ltd, Aso, Kumamoto 869-2225, Japan; Faculty of Agriculture, Tokai University, Higashi-ku, Kumamoto 862-8652, Japan)

To clarify the optimal water management in large-scale fields under high temperatures at the ripening period, effective water managements during this period for improvement of yield, appearance quality and palatability were investigated. Compared with intermittent irrigation and flooded irrigation, the soil temperature with saturated irrigation remained low throughout the day, and the decrease rate of the bleeding rate of hills was the lowest. These results suggested that the saturated irrigation maintained root activity. For the three irrigation types, the number of spikelets per m2and 1000-grain weight were similar, however, saturated irrigation resulted in significantly higher rice yield due to improvement in the percentage of ripened grains. The saturated irrigation produced a high percentage of perfect rice grains and thicker brown rice grain, furthermore, the palatability of cooked rice was excellent because protein content and hardness/adhesion ratio were both low. Thus, under high-temperature ripening conditions, soil temperature was lowered and root activity was maintained when applying saturated irrigation after heading time. The results indicated that saturated irrigation is an effective countermeasure against high-temperature ripening damage.

appearance quality; root activity; high-temperature ripening damage; palatability; saturated irrigation; soil temperature; water management; rice yield; intermittent irrigation; flooded irrigation

Rice (L.) is one of the world’s most important food crops and is a staple food in Japan. Decreased yield (Kim et al, 1996; Morita, 2011) and deterioration of appearance quality (Terashima et al, 2001; Nakamura et al, 2003; Wakamatsu et al, 2007; Sakanashi et al, 2008; Morita, 2011) and palatability (Matsue, 2012) due to abnormally high temperatures during the ripening period have become serious problems for rice farmers in Japan (MAFF, 2006). The palatability described here is overall eating-quality by sensory test. Heat damage has occurred frequently over the past 20 years. The damage consists of a decrease in percentage of ripened grains thus lowering yield. In terms of appearance quality, there have been frequent occurrences of milky white rice kernel, white backed rice, white belly rice, cracked rice and immaturegrains. Regarding palatability, the overall eating-quality of cooked rice is inferior due to decreased stickiness and increased hardness. The IPCC (Intergovernmental Panel on Climate Change, 2018) also warns that the temperature will rise by 1.5 ºC during 2030–2052 if global warming continues at its current rate. Therefore, it is urgent to establish cultivation management techniques to avoid or overcome damage from high-temperature at ripening.

In Japan, yield, appearance quality and palatability are the main objectives of rice breeding and cultivation.Because of increasing sale competition among the rice producing area, the palatability has become strong key to appeal the individual rice to the consumers. However, rice palatability is currently over-emphasized, which leads to encouraging of rice production with low protein content. For this reason, insufficient nitrogen fertilization is also emphasized, resulting in low yield and poor appearance quality and palatability due to plant nitrogen deficiency. Thus, there has been no progress in developing technology for quality improvement combined with increasing yield under high temperature during the ripening period. In general, as the protein content of brown rice increases, the cooked rice becomes harder and less sticky, resulting in lower palatability. However, protein content of about 7% in brown rice does not lead to reduced palatability (Matsue, 2012). In addition, even if the protein content of brown rice is controlled to less than 7%, palatability is not always excellent (Kondo and Nozoe, 1993).

Progress in rice production simultaneously aims at threetraits: appearance quality and palatability improvement, and yield increase. Reports on cultivation management techniques for countermeasures against high-temperatureripening damage have been comprehensively summarized by the Hokuriku branch of the Crop Science Society of Japan and Hokuriku branch of Japanese Society of Breeding (2007) and Morita (2011). The available countermeasures include growing healthy seedlings, sparse planting, late transplanting, improving nitrogen fertilization methods, continuous irrigation during ripening period, proper harvesting and breeding heat-tolerant varieties. Concerning nitrogen fertilization methods, nitrogen topdressing methods have been improved in response to sink-source balancing and climate change.

Additionally, water management during the growing season strongly influences the growth of rice plants, and in particular is closely related to rice yield and quality. For this reason, water management is positioned as an important growth control technique along with fertilization. Water management during the ripening period is a very important operational management for yield and quality. It has been reported that intermittent irrigation and flow irrigation during the ripening period reduce the occurrence of milky white rice kernels and cracked rice kernels (Nakamura et al, 2003; Sakanashi et al, 2008; Morita, 2011). However, flow irrigation is difficult because it requires a large amount of irrigation water (Tomosho and Yamashita, 2009; Nishida et al, 2016) under the current situation of an increase in large-scale paddy fields and large-scale rice cultivation. Irrigation water of low temperatureis not always available (Sakata et al, 2012). Furthermore, intermittent irrigation is not possible in areas where timely access to irrigation water is difficult.

Although there have been many studies on the relationship between water management and yield and appearance quality, little is known about water management and palatability during the ripening period. Furthermore, there have been no reports on the relationship between saturated irrigation and palatability. Therefore, this study investigated the effects of water management under high-temperature conditions in the paddy rice ripening period on yield, appearance quality and palatability in order to increase yield, and improve appearance quality and palatability.

Results

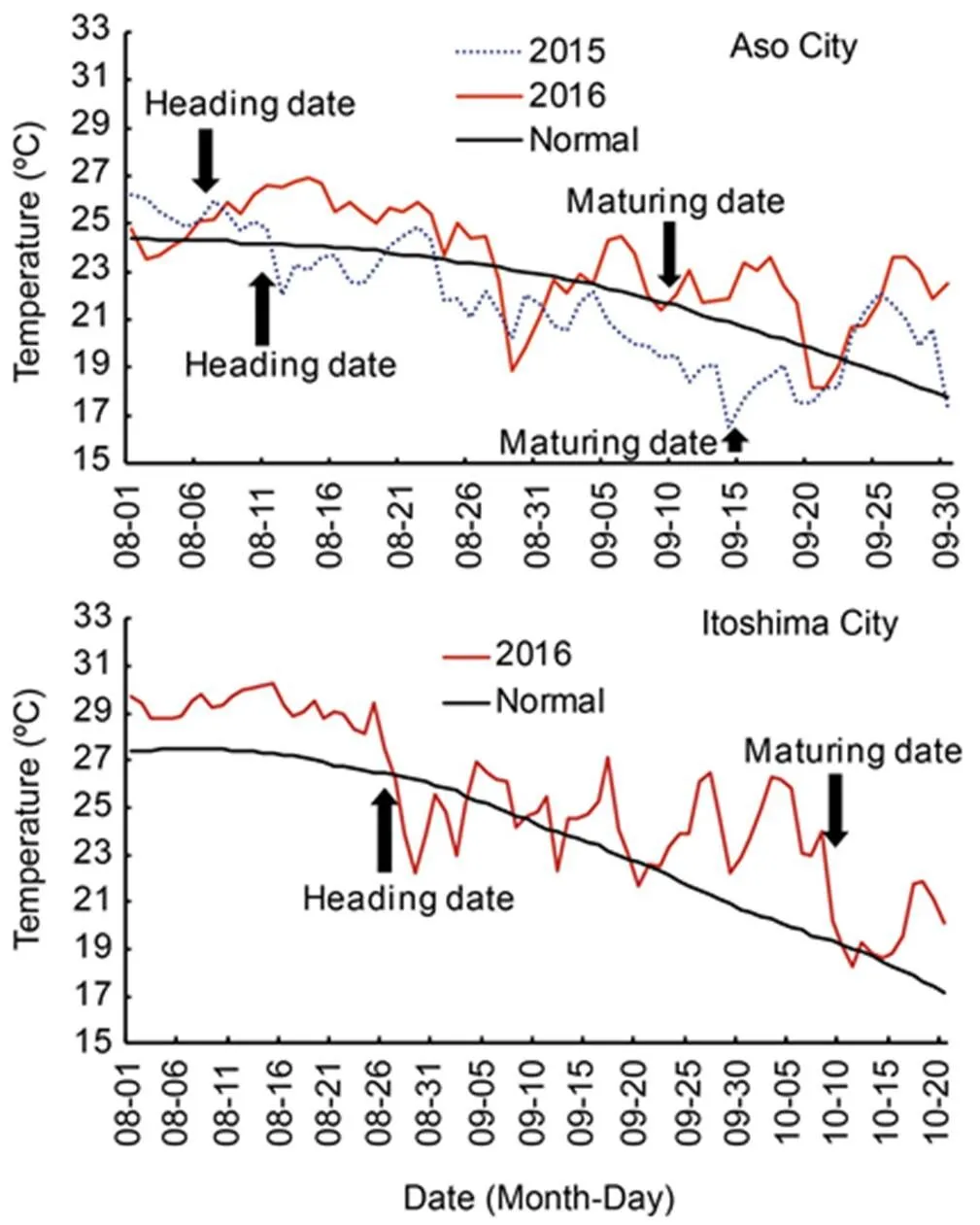

Changes in average temperature during ripening period

The changes in average temperature during the ripening period are shown in Fig. 1. In Aso, the heading and maturing dates were 10August and 21September in 2015, and 6 August and 15 September in 2016. In Itoshima in 2016, they were 27 August and 10October. In 2015, the average temperature during the ripening period in Aso was 21.4 ºC, which was 1.2ºC lower than normal. In 2016, the average temperatures during the ripening period in Aso and Itoshima were 23.7 ºC and 24.3 ºC, respectively, which were 1.0 ºC and 1.4 ºC higher than normal.

Fig. 1. Changes in average temperature during ripening period.

Normal, Average temperature from 1981 to 2010.

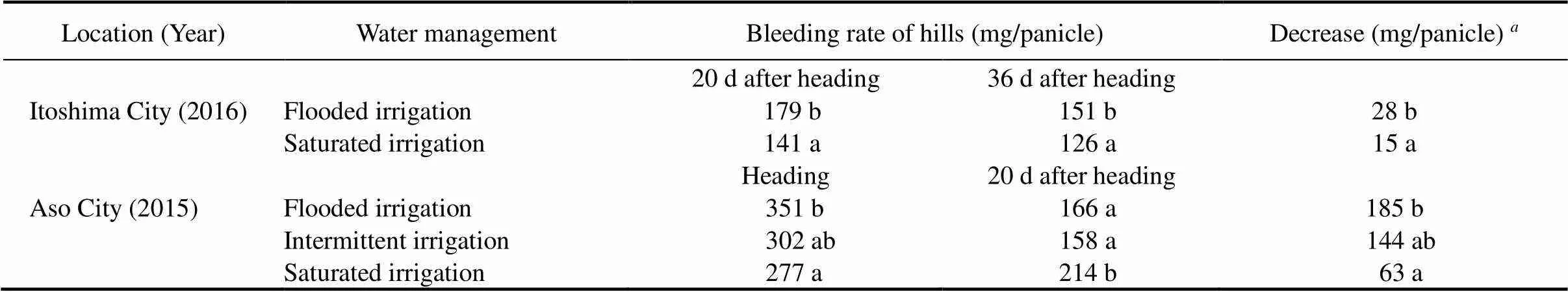

Diurnal changes of soil temperature and bleeding rate of hills

Diurnal changes of soil temperature for each water management are shown in Fig. 2. In both 2015 and 2016, soil temperatures for saturated irrigation were lower all day than those for flooded and intermittent irrigations. In particular, soil temperatures in Aso and Itoshima at night (19:00pm–6:00 am) for saturated irrigation, which greatly affect the extent of grain filling and brown rice quality, were lower than those for intermittent and flooded irrigations. The soil temperatures at night for saturated irrigation in Aso were about 0.8ºC lower in 2015 and 2.0 ºC lower in2016 than those for flooded irrigation. During the ripening period, the bleeding rate of hills tended to be lower for saturated irrigation than those for intermittent and flooded irrigations (Table 1), probably because there was no water on the soil surface. However, the degree of decrease in the bleeding rate of hills during the ripening period was the smallest for saturated irrigation by 15–63 mg/panicle.

Yield and yield components

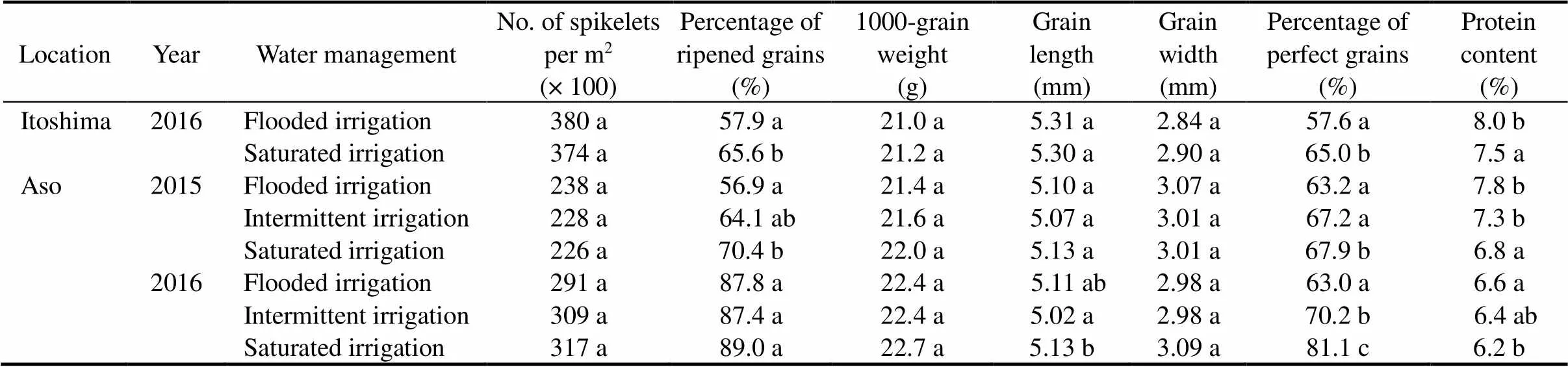

The yields were higher for saturated irrigation than for intermittent and flooded irrigations in both Aso and Itoshima (Fig. 3). Yields for saturated irrigation relative to yields for flooded irrigation were 117% in Aso in 2015 and 106% and 113% in Itoshima and Aso in 2016, respectively. Yields for saturated irrigation relative to yields for intermittent irrigation were 108% and 107% in 2015 and 2016 in Aso, respectively. The yield in Aso in 2015 was remarkably lower than that in 2016 due to frequentoccurrence of rice blast caused by low temperatures and lack of solar radiation during growth. Regarding yield components, although there were no significant differences in the number of spikelets per m2and 1000-grain weight caused by the three types of water management, the percentage of ripened grains was higher for saturated irrigation than those for intermittent and flooded irrigationsin both years (Table 2).

Fig. 2. Diurnal changes of soil temperature by field water management after heading.

Measurement date of the soil temperature: Aso City is 10 d after heading, and Itoshima City is 20 d after heading.

Table 1. Bleeding rate of hills according to water management.

The difference between 20 d after heading and 36 d after heading is indicated in Itoshima City, and the difference between heading and 20 d after heading is indicated in Aso City.

Means withthe same lowercase letters are not significantly different at 5% level according to the Tukey-Kramer.

Fig. 3. Grain yield under different water managements during ripening period.

The numerical values on the vertical bar indicate yield rate with the flooded irrigation as 100. Means with the same lowercase letters are not significantly different at 5% level according to the Tukey-Kramer. Values are Mean ± SD (= 3).

Grain shape of brown rice

The length and width of brown rice were not significantlyaffected by water management type (Table 2). However, the thickness of brown rice, which greatly affects grain quality, was significantly greater for saturated irrigation than intermittent and flooded irrigations by 0.03–0.08 mm(Fig. 4).

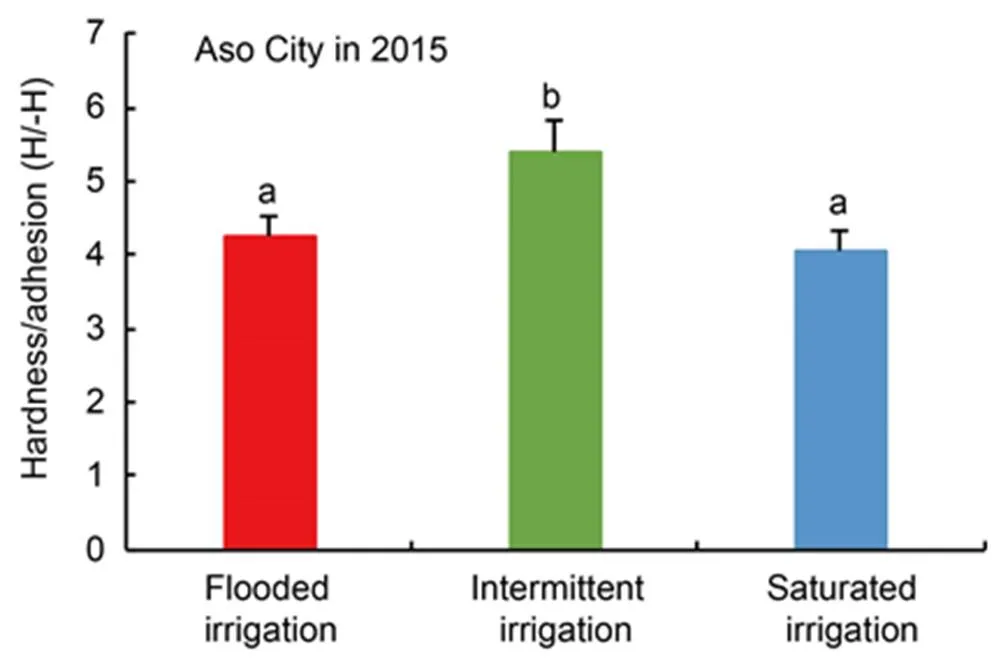

Percentage of perfect rice grains and physicochemical properties

The percentage of perfect ricegrains, as an indicator of appearance quality, produced with saturated irrigation ranged from 65.0% to 81.1%, which was significantly higher than those with intermittent and flooded irrigations (Table 2). The protein content of brown rice produced with saturated irrigation was in the range of 6.2%–7.5%, significantly lower than those with intermittent and flooded irrigations (Table 2). The hardness/ adhesion (H/-H) ratio of cooked rice for saturated irrigation was 4.04, which was significantly lower than that for intermittent irrigation (Fig. 5).

Fig. 4. Grain thickness of brown rice under different water managements during ripening period.

Means with the same lowercase letters are not significantly different at 5% level according to the Tukey-Kramer. Values are Mean ± SD (= 3).

Fig. 5. Hardness/adhesion (H/-H) ratio of rice grains under different water managements during ripening period.

Means with the same lowercase letter are not significantly different at 5% level according to the Tukey- Kramer. Values are Mean ± SD (= 3).

Palatability

The values of overall eating-quality of cooked rice produced with saturated irrigation were positive compared with a check cultivar Hinohikari(Table 3). Generally speaking, the overall eating-quality of cooked rice produced with saturated irrigation was superior to those produced with intermittent and flooded irrigations in both 2015 and 2016. Also, the appearance, aroma and taste of cooked rice produced with saturated irrigation tended to be superior to those with intermittent and flooded irrigations. Thus, the overall eating-quality of cooked rice produced with flooded irrigation tended to be the worst due to the poor appearance and aroma.

Table 2. Yield component and grain quality of brown rice according to water management.

Means with the same lowercase letters are not significantly different at 5% level according to the Tukey-Kramer.

Table 3. Palatability values of cooked rice according to water management.

Means with the same lowercase letters are not significantly different at 5% level according to the Tukey-Kramer.

DISCUSSION

The most important point for producing rice with excellent characteristics of yield, appearance quality and palatability is to achieve good ripening following heading. However, in Japan, damages such as yield decrease, low appearance quality and deterioration of palatability caused by abnormally high temperatures during the ripening period are becoming serious problems for rice farmers. In addition, IPCC (2007) is warning of the negative effects on crop production due to global warming.

As a countermeasure against high-temperature damage during the ripening period, it is extremely important to improve root activity through water management. By supplying sufficient oxygen to the roots and lowering the temperatures of the hill base and the soil, the water absorption of the roots is increased and ripening is not interrupted (Tsuno, 1973). Against this background, this study analyzed the effects of different water managements during grain filling on yield, appearance quality and palatability in a large-scale field, with a focus on root activity maintenance due to soil temperature decrease.

Soil temperature

The diurnal soil temperature was lower for saturated irrigation than for intermittent and flood irrigations. The reason was that the heat of vaporization was taken from the soil surface, which was constantly wet for saturated irrigation compared to intermittent and flooded irrigations. These results of controlling the soil temperature rise with saturated irrigation under high temperature conditions are in agreement with the results of Fujihara et al (2013). Furthermore, the difference in soil temperature in Itoshima due to water management was not larger than that in Aso because the soil in Itoshima contained a large amount of sand. Sandy soil that contains a large amount of water has low thermal conductivity and thermal capacity (Inaba, 1989), so it is likely that differences in soil temperature due to water management type were small. The reason for the highest soil temperature in the flooded irrigation is considered to be that the amplitude of the diurnal change in the flooded water temperature is smaller than air temperature and that the water temperature rises significantly due to the heat fromsun radiant.

Bleeding rate of hills

Compared with the intermittent and flooded irrigations, saturated irrigation showed a smaller decrease in the bleeding rate of hills during the ripening period. The bleeding rate is an effective indicator trait for root activity (Shimotashiro, 2009; Morita and Abe, 2015). Fujihara et al (2013) pointed out that the saturated irrigation results in an oxidative soil environment because redox potential is higher than for flooded irrigation. Thus, saturated irrigation maintains root activity by lowering soil temperature and supplying sufficient oxygen to roots. In addition, Morita and Abe (2015) found that the bleeding rate of hills is affected by the soil water content: the higher the water content, the greater the bleeding rate. Therefore, the small value of the bleeding rate of hills for saturated irrigation was likely due to the lower soil water content compared to intermittent and flooded irrigations.

Yield

The yield was significantly higher for saturated irrigation compared to intermittent and flooded irrigations due to the increase in percentage of ripened grains, even though the number of spikelets per m2and the 1000-grain weight were similar. The percentage of ripened grains during the ripening period is closely related to the root activity (Tsuno, 1973; Shimotashiro et al, 2009; Morita and Abe, 2015). Therefore, the increase in the percentage of ripened grains for saturated irrigation was probably due to maintenance of root activity during the ripening period caused by the decrease in soil temperature. The reasons for the low percentage of ripened grains in Itoshima in 2016 and Aso in 2015 are as follows. Tanaka (2011) reported that the optimum number of spikelets per m2is 30 000‒32 000 for a target yield (570 to 600 g/m2) of Hinohikari. However, in Itoshima, the number of spikelets per m2was 37 400‒38 000, which exceeds the optimum number for Hinohikari. Therefore, it was considered that the decline in percentage of ripened grains was due to excessive number of spikelets per m2. In Aso, as mentioned above, this was due to an outbreak of rice blast and lack of solar radiation during the ripening period.

Appearance quality and grain shape of brown rice

The percentage of perfect rice grains was higher for saturated irrigation than for intermittent and flooded irrigations. This result supports the report of Fujihara (2013) that saturated irrigation tends to result in a higher percentage of perfect rice grains and superior appearance quality compared to flooded irrigation. The occurrence of milky white rice and grain fissuring is reduced by lowering soil temperature (Arai and Ito, 2001; Nakamura et al, 2003; Nagahata et al, 2005). Thus, we considered that the high percentage of perfect rice grains for saturated irrigation was due to the reduction in occurrence of immature grains (e.g. milky white rice) as a result of the improved ripening rate caused by the lower soil temperature.

In this study, the water managements affected the thickness but not the length and width of brown rice, and the thickness was increased by saturated irrigation. High night temperature is one ofthe environmental factors known to affect the length, width and thickness of brown rice (Morita et al, 2002). The thickening of brown rice by saturated irrigation is likely due to improved percentage of ripened grains caused by the lower soil temperature.

Palatability

Overall eating-quality (palatability) of cooked rice for saturated irrigation was excellent with a tendency for appearance, taste and aroma to be superior compared to those for intermittent and flooded irrigations. Generally, rice with good palatability has low protein content and low H/-H ratio, which is an indicator trait of texture. Additionally, palatability, protein content and H/-H ratio are closely related to grain thickness, with thicker grain associated with better palatability, lower protein content and lower H/-H ratio (Matsue et al, 2001). Therefore, the excellent palatability for saturated irrigation resulted from the decreased protein content and improved texture due to the increase in starch accumulation with the thickening of brown rice.

In summary, under high temperature conditions during the ripening period, soil temperature was lowered and the root activity maintained by the saturated irrigation after heading. As a result, yield was increased and appearance quality and palatability were excellent due to the higher percentage of ripened grains and the thickening of brown rice. Thus, saturated irrigation is an effective countermeasure against damage by high temperature at ripening.

METHODS

Cultivation management and experimental design

The experiment was conducted in experimental fields of Itoshima City (33º33′ N, 130º12′ E) and Aso City (32º58′ N, 131º03′ E), Japan in 2015 and 2016. Two highly palatablerice cultivars, Koshihikari and Hinohikari, were used. The cultivation management in both locations is described in Table 4. Three to four seedlings per hill were transplanted by a rice transplanting machine. Both experimental rice fields were 6000 m2in size. These field experiments were composed of three (Aso) or two (Itoshima) water managements. The area of each watermanagement was2000 m2in Aso and 3000 m2in Itoshima, with three replications in a randomized block design. The heading date was the day when 50% of the total number of productive culms headed. The maturitydate was the day when more than 80% of the total number of panicles had turned yellow.

Table 4. Cultivation management.

Weather observation

The average temperatures at the two locations were measured by the Weather System (Climatec Inc., Tokyo). The normal values of the average temperatures at the two locations were based on data from the Japan Meteorological Agency. Normal values were calculated based on the average of observations for 30 years of 1981–2010.

Water management

Three water management conditions were applied: saturated, intermittent and flooded irrigations.Proper water management during the treatment period was maintained using a tensiometer. Saturated irrigation involved no water on the surface of the soil, but sufficient water was contained in the soil and pF value in soil was 1 (Fig. S1). In this case, standing water in the soil footprints can be seen here and there. pF is a numerical value that expresses how strongly water is retained by soil. The strength of water retention in the soil is calculated from the height of a water column (cm), and is expressed logarithmically. When soil is sufficiently moist, pF values are low, if soil is dry, pF values are high. Intermittent irrigation (pF 0.3‒0.8) involved pouring water every 3–4 d. Flooded irrigation was water flooding to a depth of 5–6 cm. The treatment period was for 25 d following heading time. Water management after the treatment period was performed using intermittent irrigation. The times of surface drainage for the three water managements were 30 dafter heading in Aso and 35 d after heading in Itoshima.

Soil temperature and bleeding rate of hills

The soil temperature of each water management was the average value of three points at 5 cm underground using a Wireless Thermo Recorder (RTR-502, T&D Corporation, Tokyo, Japan). The water depth during the measurement of soil temperature in the intermittent irrigation was about 1.5 cm.Bleeding rate of hills was measured according to the method of Morita and Abe (1999). That is, absorbent cotton that had been weighed in advance was used to absorb the amount of water bleeding from a cut hill, the weight of the absorbent cotton was then measured and the increased weight was the bleeding rate of hills. The cutting height of the hill was about 10 cm from the ground surface. Water absorption time from the cut hills was 1 h during 10:00–11:00 am. The bleeding rate of hills in each water management was indicated by the average value of three positions with five hills measured per point.

Yield and yield components

At the time of harvesting, yield was determined from the sampling area (7 m2) of three positions for each water management and adjusted to grain moisture content of 15%. Using 10 randomly selected individuals in the harvested area, the number of spikelets per panicle, 1000-grain weight and percentage of ripened grains were measured. The number of spikelets per m2was calculated by multiplying the number of spikelets per panicle by the number of panicles per m2. Yield and yield components were the average values measured at three places for each water management. Brown rice grainswith thickness of more than 1.85 mm were used for calculating yield, 1000-grain weight and percentage of ripened grains.

Grain shape, appearance quality and physicochemical properties

Grain shape of brown rice (length, width and thickness) was measured using a grain shape tester (Kett Electric Laboratory, Tokyo, Japan). Percentage of perfect rice grains was measured with a Grain Quality Inspector RGQI 20A (Satake Co., Ltd., Hiroshima, Japan). Protein content of brown rice was measured with an Infratec1241 Grain Analyser (Foss Japan Co., Ltd., Tokyo, Japan) and values were adjusted to moisture content of 15%. The hardness/adhesion (H/-H) ratio of cooked rice was measured with a Tensipreser My Boy2 (Taketomo Electric Inc., Tokyo, Japan).

Sensory test

The palatability evaluation of cooked rice was evaluated by the methodof Matsue (1992). The check cultivar for the sensory tests was Hinohikari produced in Fukuoka Prefecture, Japan. The following five sensory attributes were evaluated by 20 panel members from Kyushu University in Japan: overall eating-quality, appearance, stickiness, taste and hardness. Five sensory attributes were classified into seven stages compared with a check cultivar: -3 (very poor), -2 (poor), -1 (slightly poor), 0 (no difference), +1 (good), +2 (very good) and +3 (excellent) for overall eating-quality, appearance and taste; -3 (very weak) to+3 (very strong) for stickiness; and -3 (very soft) to+3 (very hard) for hardness.

Statistical analysis

Analysis of variance (ANOVA) was used in conjunction with Tukey-Kramer to test for significant differences. All statistical analysis was performed with the Statcel Statistical Analysis System (Statcel-the Useful Addin Forms on Excel-3rd ed., 2012, OMS Publishing Ltd., Tokyo, Japan).

Acknowledgements

This study was supported by the grants from the Project of the National Agriculture and Food Research Organization Bio-oriented Technology Research Advancement Institution in Japan (the Special Scheme to Create Dynamism in Agriculture, Forestry and Fisheries through Deploying Highly Advanced Technology) (Grant No. shoNavi1000). We thank Mr. Isokazu Ita for appropriate field management in this experiment.

SUPPLEMENTAL DATA

The following material is available in the online version of this article at http://www.sciencedirect.com/journal/rice-science; http://www.ricescience.org.

Fig. S1. Field water management after heading time.

Arai Y, Ito H. 2001. Effect of flow irrigation on high temperature ripening in paddy field rice., 44: 89‒90. (in Japanese)

Fujihara Y, Toriyama K, Fuji H. 2013. Effects of saturated irrigation on soil environment and rice quality., 81: 273‒276. (in Japanese)

Hokuriku branch of the Crop Science Society of Japan, Hokuriku branch of Japanese Society of Breeding. 2007. Rice Resistant to Heat Damage. Tokyo, Japan: Yokendo Ltd: 1‒147. (in Japanese)

Inaba H. 1989. Thermophysical properties of soils., 3: 31‒39. (in Japanese with English abstract)

IPCC. 2007. Climate change 2007:Impacts, adaptation and vulnerability.[2020-04-20]. http://www.ipcc.ch/activity/uncertaintyguidancenote.pdf.

IPCC. 2013. Climate change 2013: The physical science basis. Summary for policy makers. [2020-04-20]. http://www.ipcc.ch.

IPCC. 2018. Global warming of 1.5 ºC. [2020-04-20]. http://www.ipcc.ch/report/sr15/.

Kim H Y, Horie T, Nakagawa H, Wada K. 1996. Effects of elevated CO2concentration and high temperature on growth and yield of rice:II. The effect on yield and its component of Akihikari rice., 65: 644‒651. (in Japanese with English abstract)

Kondo M, Nozoe T. 1993. Relationship between rice grain composition and eating quality., 46: 53‒54. (in Japanese)

MAFF. 2006. To overcome high temperature damage in rice. [2020-04-18]. https://www.maff.go.jp/j/kanbo/kihyo03/gityo/g_kiko_hendo/suito_kouon/. (in Japanese)

Matsue Y. 1992. On a sensory test of cooked rice in which 10 cultivars were evaluated by 13 panel members.,43:1027‒1032. (in Japanese)

Matsue Y. 2012. Rice Palatability Science from the Viewpoint of Crop Production. Tokyo, Japan: Yokendo Ltd: 1‒141. (in Japanese)

Matsue Y, Sato H, Uchimura Y. 2001. The palatability and physicochemical properties of milled rice for each grain-thickness group.,4: 71‒76.

Morita S. 2008. Prospect for developing measures to prevent high-temperature damage to rice grain ripening., 77: 1–12. (in Japanese with English abstract)

Morita S. 2011. High Temperature Damage in Rice and Its Measures.Tokyo, Japan: Nosan Gyoson Bunka Kyokai Corporation: 1‒143.

Morita S, Abe J. 1999. How to measure and to evaluate bleeding sap rate., 8: 117‒119.(in Japanese)

Morita S, Abe J. 2015. Grasping root system activity., 24: 79‒88. (in Japanese with English abstract)

Morita S, Shiratsuchi H, Takanashi J, Fujita K. 2002. Effect of high temperature on ripening in rice plants: Comparison of the effects of high night temperatures and high day temperatures.,71: 102‒109. (in Japanese with English abstract)

Nagahata H, Nakamura K, Ino M, Kuroda K, Hashimoto Y. 2005. The cultivation management to make the occurrence of the milky white kernel and the cracked rice reduce under the high temperature during the ripening period., 26: 1‒10.(in Japanese with English abstract)

Nakamura K, Hashimoto Y, Nagahata H. 2003. Effect of water management during ripening period on the occurrence of crackedgrain and milky-white grain., 38: 18‒20. (in Japanese)

Nishida K, Ninomiya Y, Uo T, Yoshida S, Shiozawa S. 2016. Relationship between irrigation conditions and distribution of paddy water temperature under continuous irrigation with running water., 84(3): 391‒401. (in Japanese with English abstract)

Sakanashi J, Ide S, Ueno I. 2008. Improvement of crop managementto decrease the incidence of white-immature kernels of a medium-maturing rice () cultivar ‘Hinohikari’ induced by high temperature during ripening period, 1., 15: 1‒5. (in Japanese with English abstract)

Sakata S, Tomosho T, Uchimura M. 2012. The relationship between the ripening of rice grains during hot summer weather conditions and water temperature in irrigation canals and paddy fields in southeastern Miyagi, Japan., 68: 87‒92.

Shimotashiro T, Goiduka N, Sasaki O, Matsumoto S. 2009. Relationship between root activity and ripening of rice plants grown in south west-warm region in Japan., 78: 465–470. (in Japanese with English abstract)

Tanaka K. 2011. Studies on growth prediction, diagnosis and quality improvement in rice plants under high temperature conditions.,32: 1‒68. (in Japanese with English abstract)

Terashima K, Saito Y, Sakai N, Watanabe T, Ogata T, Akita S. 2001. Effects of high air temperature in summer of 1999 on ripening and grain quality of rice., 70: 449–458. (in Japanese with English abstract)

Tomosho T, Yamashita T. 2009. Problems and future directions of agricultural water management as measures against grain damage under high temperatures during ripening of rice.,209:131‒138. (in Japanese with English abstract)

Tsuno Y. 1973. Rice Plants Science. Tokyo, Japan: Nosan Gyoson Bunka Kyokai Corporation: 1‒212. (in Japanese)

Wakamatsu K, Sasaki O, Uezono I, Tanaka A. 2007. Effects of high air temperature during the ripening period on the grain quality of rice in warm regions of Japan., 76: 71–78. (in Japanese with English abstract)

29 May 2020;

14 September 2020

Copyright © 2021, China National Rice Research Institute. Hosting by Elsevier B V

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/)

Peer review under responsibility of China National Rice Research Institute

http://dx.doi.org/10.1016/j.rsci.2021.05.011

Yuji Matsue (matsue@farm.kyushu-u.ac.jp)

(Managing Editor: Wu Yawen)

杂志排行

Rice Science的其它文章

- Genome-Wide Association Study of Nitrogen Use Efficiency and Agronomic Traits in Upland Rice

- Development of Chromosome Segment Substitution Lines and Genetic Dissection of Grain Size Related Locus in Rice

- Effect of Milling and Parboiling Processes on Arsenic Species Distribution in Rice Grains

- iTRAQ-Based Proteomics Investigation of Critical Response Proteins in Embryo and Coleoptile During Rice Anaerobic Germination

- A New Approach to Select Doubled Haploid Rice Lines under Salinity Stress Using Indirect Selection Index

- OsbZIP09, a Unique OsbZIP Transcription Factor of Rice, Promotes Rather Than Suppresses Seed Germination by Attenuating Abscisic Acid Pathway