Tensile and Electro-Mechanical Properties of Carbon Nanotube Film Twisted Yarn with Adjustable Diameter

2021-04-08ZHANGLinjie张琳婕WUQibing吴麒冰ZHANGGuangyang张广阳MAHuanXUFujun许福军

ZHANG Linjie(张琳婕), WU Qibing(吴麒冰), ZHANG Guangyang(张广阳), MA Huan(马 欢), XU Fujun(许福军)*

1 Key Laboratory of Textile Science & Technology, Ministry of Education, Donghua University, Shanghai 201620, China

2 College of Textiles, Donghua University, Shanghai 201620, China

Abstract: Carbon nanotube (CNT) yarns with adjustable diameters were manufactured by twisting CNT films with varied twists. Different from traditional CNT fibers, CNT yarns exhibited a larger diameter (423 μm) and a higher tensile force (1 988 cN). The results showed that CNT yarns with the twist angle of 35°exhibited the highest conductivity (886 S/cm) and the highest tensile strain (35%).

Key words: carbon nanotube (CNT) film; CNT yarn; surface morphology; tensile property; electrical and strain sensing property

Introduction

As a new type of smart yarns, carbon nanotube (CNT) yarns have received extensive attention for their multifunctional characteristics. However, the CNT yarns obtained by the CNT array drawing and twisting method showed limited mechanical and anti-abrasion properties due to their tiny diameters (10-50 μm)[1-3], hindering their applications in smart textiles. Therefore, improving mechanical and electrical properties of CNT yarns is essential for the wide application in various fields.

Some scholars tried to chemically modify CNT yarns by acid or other oxidizing agents to increase the interaction between the CNTs and thus enhance the tensile strength[4]. Furthermore, some researchers combined CNT yarns with polymer resin to obtain the strong interfacial bonding between CNTs[5]. However, chemical modification will destroy the framework structure of CNTs and seriously affect their properties, especially electrical and thermal properties. Moreover, some reagents used in chemical treatment will pollute the environment and even endanger the health of human beings[6-7]. The physical methods, such as compressing, twisting and yarn plying, are also adopted to improve electrical and strain sensing properties of CNT yarns. Shangetal.[8]made a stretchable CNT rope with a diameter of 43 μm by super-twisting. The elongation at break of stretchable CNT rope (about 250%) is an order of magnitude higher than that of the spun CNT-based yarns. However, the excessive twisting damaged the internal structure of CNTs, resulting in poor mechanical properties. Misak and Mall[9]conducted a systematic study on CNT ply yarns. Although the diameter of the plied yarn can be larger with the increase the number of strands[10-13], it is confirmed that the plied yarn cannot fully utilize the performance of single yarns in subsequent related studies[9, 14]. Therefore, exploring new methods of improving mechanical and electrical properties of CNT yarns is a necessary work.

In this study, the CNT films are twisted into CNT yarns with adjustable and uniform diameters. Then the surface morphology, tensile properties and strain sensing properties of CNT yarns with different twists and diameters are systematically characterized and analyzed.

1 Experiments

1.1 Materials and fabrication

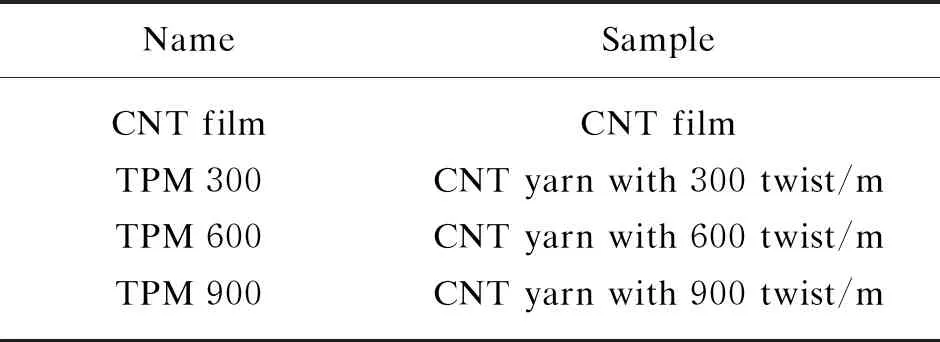

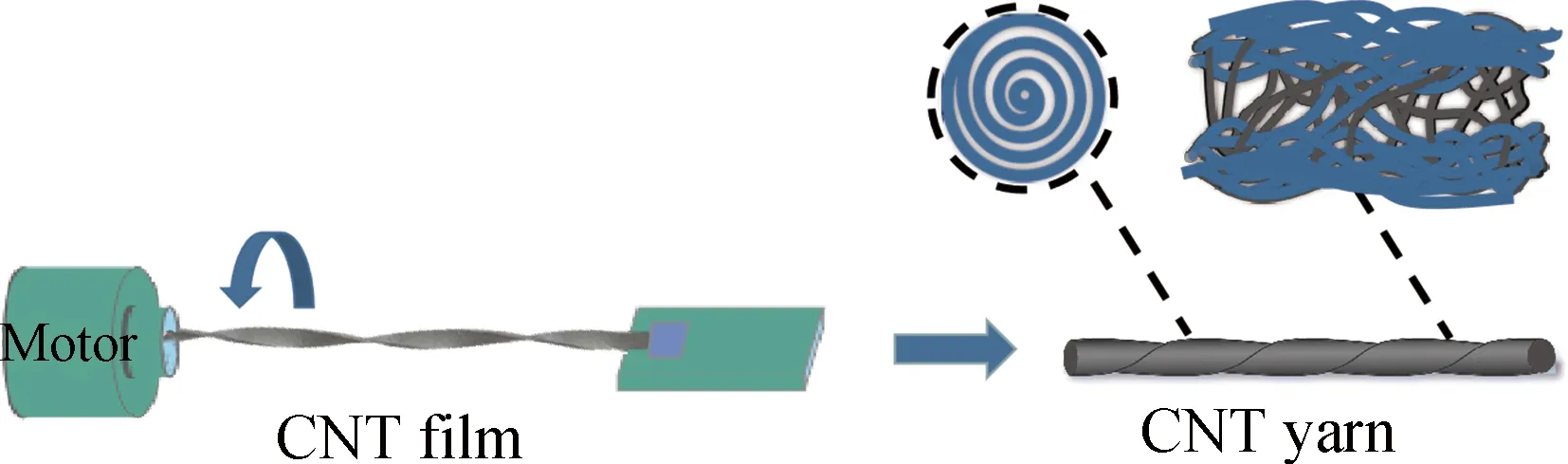

The CNT film is produced by the floating catalyst chemical vapor deposition (FCCVD) method and provided by the Suzhou Institute of Nano-Tech and Nanobionics Chinese Academy of Sciences, China. The density and the porosity of the CNT film are 0.189 g/cm3and 88.7%, respectively, while the thickness reaches about 18.9 μm. The CNT film was sliced into a strip with the width of 7 mm and then twisted into CNT yarns with various degrees (300, 600, and 900 twist/m) whose name is illustrated in Table 1. The twisted CNT yarns possess different characteristics. The schematic diagram of yarn twisting process is illustrated in Fig. 1.

Table 1 Name of CNT film twisted yarns

Fig. 1 Schematic diagram of twisting process for CNT yarn

1.2 Surface morphology

A polarized light microscope and a Nano Measurer software are used to observe the structure and the diameter of the yarns twisted by CNT film. Ten points are selected to calculate the average diameter of CNT yarns. The scanning electron microscope (SEM) is used to observe and characterize the cross-sectional morphology and the microstructure of CNT yarns after being stretched.

1.3 Testing

The tensile test is carried out with the Xusai XS(08)XG single fiber extensometer (Shanghai, China), the load cell is 30 N, the stretching gauge is 10 mm, and the stretching rate is 0.5 mm/min. During the stretching process, the resistance of the yarn is monitored in real time by the Agilent 34450A digital multimeter (Shanghai, China). In order to evaluate the sensitivity stability of the CNT yarn, the samples are repeatedly stretched with strains of 2% and 5% at a speed of 0.5 mm/min for 20 times.

2 Results and Discussion

2.1 Surface morphology

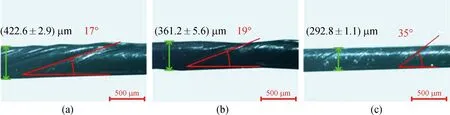

The CNT yarns with various diameters as shown in Fig. 2 are twisted from the CNT film with a width of 7 mm and twist numbers of 300, 600, and 900 twist/m. As the twist increases, the diameter of the CNT yarn decreases from 422.6 μm to 292.8 μm and the surface twist angle increases from 17°to 35°. After being twisted with the increasing twist angle, the CNT yarn shows smooth surface, a uniform diameter, and a compact spiral twisting structure.

Fig. 2 Surface morphologies of CNT yarns: (a) 300 twist/m; (b) 600 twist/m; (c) 900 twist/m

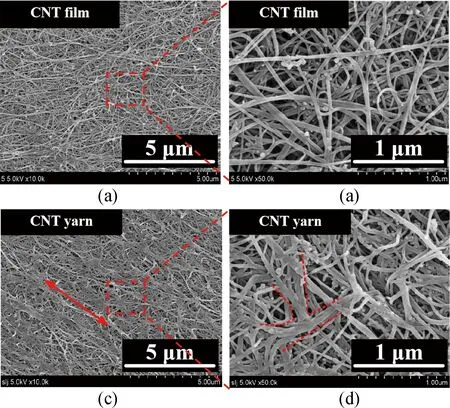

The microstructure of the CNT film before and after twisted into the CNT yarn at different magnifications is shown in Fig. 3.

Fig. 3 SEM images of surface morphologies: (a) and (b) CNT film; (c) and (d) CNT yarn with 900 twist/m

As for CNT film, the CNT bundles arrange disorderly with visible pores. However, as for the twisted yarn, the CNT bundles are more robust with less pores, which possess orientation due to the compaction effect of twist. Therefore, the compact structure and the improved orientation are primary reasons for the dramatic improvement of mechanical properties of the CNT yarn.

2.2 Tensile properties

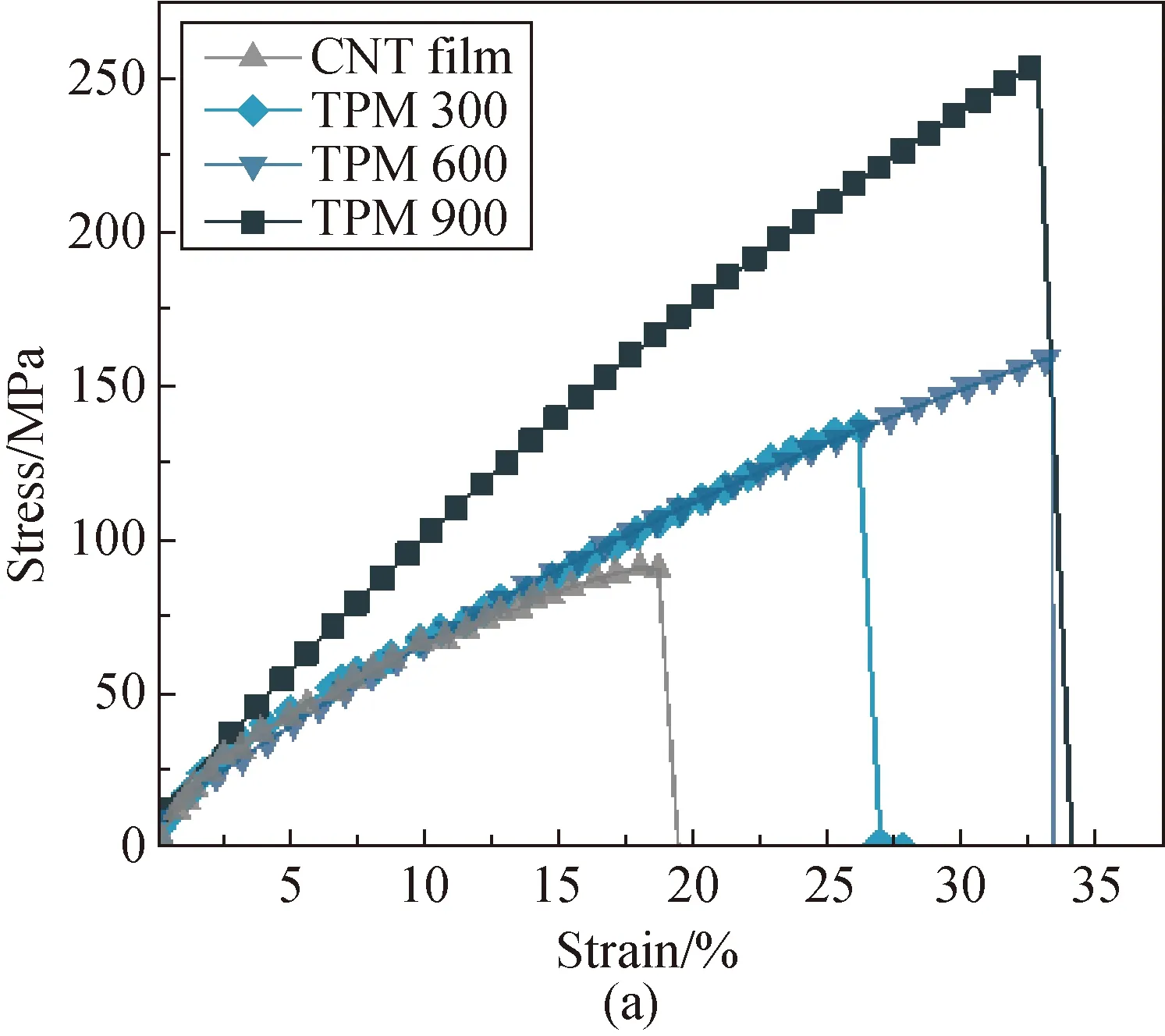

The tensile properties of CNT yarns with different twist numbers (300, 600, and 900 twist/m) are shown in Fig. 4. Figure 4(a) shows the stress-strain curves of CNT films and yarns. At a strain of 2.5%, the stresses of CNT films and CNT yarns increase linearly with no significant difference. Nevertheless, after the strain of 2.5%, the stress increase of the CNT films is slow and gent due to its loose structure for CNT bundles. The stress of twisted CNT yarns keeps growing linearly because of a stronger cohesive force and a higher degree of aligned axial orientation for CNT bundles, which is beneficial to the efficient improvement of CNT reinforcement. It is also verified by the surface morphology as shown in Fig. 3. As a result, with the twist increasing, the strength and the strain at break show rising trends as shown in Figs. 4(b) and (c). The strength and the strain at break of 900 twist/m CNT yarn are 265.9 MPa and 34.1%, respectively, which are 194.8% and 74.9% higher than those of the CNT film. The twisted CNT yarns (300, 600, and 900 twist/m) possess different tensile properties. When the twist number of the CNT yarn is 600 twist/m, the strength and the strain at break are 138.7 MPa and 28.4%, respectively. While the twist number of the CNT yarn adds to 600 twist/m, its strength and strain at break are 165.5 MPa and 33.9%, respectively. When the twist number adds to 900 twist/m, the strength and the strain at break are 265.9 MPa and 34.1%, respectively. The increase in strain at break is mainly due to the spiral structure of the yarn, which allows the CNT film to have a larger space for straightening and deformation during the stretching process. Similarly, because of the spiral structure of the yarn, the Young’s modulus gradually decreases with the twist angle increasing as shown in Fig. 4 (d).

Fig. 4 Mechanical properties of CNT film and CNT yarn: (a) stress-strain curve; (b) tensile strength;

The SEM images of cross-sections of CNT yarns are shown in Fig. 5. The cross-section of the CNT yarn with 300 twist/m is uneven with a tapered shape, indicating the loose structure and the weak interactions between the CNT bundles. Therefore, the tensile strength is relatively low as shown in Fig. 4. However, when the twist number is 600 twist/m and 900 twist/m, CNT yarns with compact and uniform structures show flat sections, indicating that CNT bundles are broken but not slipped during the tensile process[15]. The CNT film twisted yarn shows less defects and a compacter structure compared with CNT films, resulting in the improved tensile properties and a flat fracture mode.

2.3 Electrical and strain sensing properties

As shown in Fig. 6, CNT yarns with 300 twist/m and 600 twist/m show similar electrical conductivity to the CNT film. As the twist increases to 900 twist/m, the packing of CNT bundles becomes denser and the orientation of CNT bundles is more aligned, which is beneficial to the transfer of electrons. Therefore, the electrical conductivity of the CNT yarn with 900 twist/m can reach 886 S/cm. As shown in Fig. 6(b), CNT yarns with different twist numbers show similar resistance changing rates to CNT films during stretching, while the sensing strain ranges of the CNT yarn increase to 35% due to the twisting structure.

Fig. 5 SEM images of stretched section of CNT yarn: (a) 300 twist/m; (b) 600 twist/m; (c) 900 twist/m

The gauge factorFgcan be calculated by

(1)

whereR0is the original resistance,ΔRis the resistance change,L0is the original length, andΔLis the length change.

As shown in Fig. 6(c), the gauge factor of the CNT film is about 1.4. When the film is twisted into the yarn, the gauge factor of the CNT yarn with 600 twist/m decreases slightly to 1.3.

Fig. 6 Electrical strain sensing properties of CNT films and CNT yarns: (a) conductivity; (b) resistance changing rates; (c) gauge factors

2.4 Sensing performance under cyclic tensile load

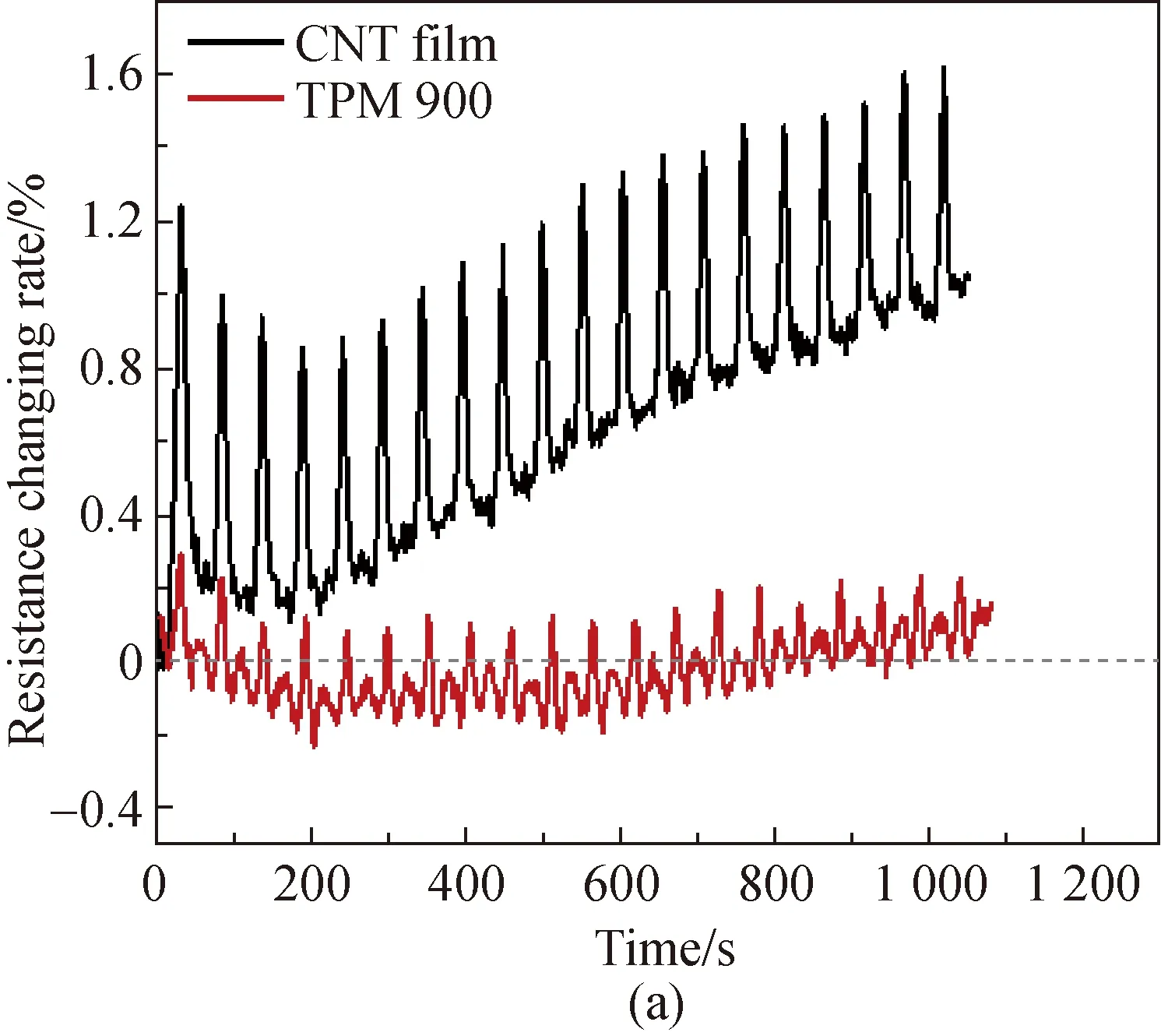

Figure 7 shows that the resistance changing rates of the CNT yarn with 900 twist/m which is stretched for 20 times at tensile strains of 2% and 5%. As shown in Figs. 7(a) and (b), when the CNT film is cyclically stretched at the strain of 2%, the resistance changing rate curves fluctuate and the peak increases from 1.24 to 1.62. However, the CNT yarn shows smaller resistance changing rate peaks but a more stable trend. It is because the structure is adjusted for incompact CNT films during 20 times stretching which is beneficial to the increment of the resistance changing rate. However, when the CNT film is cyclically stretched at the strain of 5%, its resistance changing rate decreases from 5.24 to 3.98, as shown in Figs. 7(c) and (d), due to the slippage of CNT bundles. In contrast, the CNT yarn still shows a similar resistance changing rate (2.44%) during the 20 times cyclic stretching, indicating better stability and repeatability of the strain sensing performance which are important for practical applications in the field of smart textiles and wearable electronics.

Fig. 7 Resistance changing rates of CNT yarn cyclically stretched for 20 times at different tensile strains:

3 Conclusions

In this study, CNT yarns with adjustable diameters and compact structures are fabricated by twisting CNT films. Compared with the CNT film, the strain at break and the strength of the CNT yarn was significantly improved. As the twist increased, the structure of the CNT yarn became more uniform and compacter with higher twist angles. The results showed that CNT yarns with 900 twist/m exhibited the highest strength (265.9 MPa), the highest tensile strain (34.1%) and the highest conductivity (886 S/cm), which were 194.8%, 74.9% and 25% higher than those of the CNT film. Furthermore, the CNT yarn showed better stability and repeatability in the strain sensing performance compared with the CNT film, which might be important for practical applications in the field of smart textiles and wearable electronics.

杂志排行

Journal of Donghua University(English Edition)的其它文章

- Polyacrylonitrile/Graphene-Based Coaxial Fiber-Shaped Supercapacitors

- Highly Stretchable and Transparent Hydrogel as a Strain Sensor

- Effect of Processing Parameters on Morphology and Mechanical Properties of Hollow Gel-Spun Lignin/Graphene Oxide/Poly (Vinyl Alcohol) Fibers

- Characteristic Analysis and Harmonic Feature Identification of Micro-Vibration on Flywheels

- Defect Detection Algorithm of Patterned Fabrics Based on Convolutional Neural Network

- Tufting Carpet Machine Information Model Based on Object Linking and Embedding for Process Control Unified Architecture