海登大道3555 号美国加利福尼亚州卡尔弗市

2021-03-04汤姆·邦纳

设计单位:埃里克·欧文·莫斯建筑师事务所

施工系统:数控铣木胶合梁和椽子,钢架,砌体

主要顾问:Englekirk Partners (结构),Moses and Associates(电气),Sullivan Partnership (机械管道),加州钢(结构钢),Structurlam产品 (重型木材),Spectrum Oak (CNC切割椽子),保护涂层和衬里 (玻璃纤维),Dandoy玻璃 (嵌装玻璃)

项目类型:办公楼、声场、视频制作及广播设施

建筑面积:25 000平方呎

时间:2006年-2007年

获奖:AIACC成就奖,2008年

摄影:汤姆·邦纳

Architect: Eric Owen Moss Architects

Construction Systems: CNC-milled wood glue-laminated beams and rafters, steel frame,and masonry

Key Consultants: Englekirk Partners (Structural), Moses and Associates (Electrical), Sullivan Partnership (Mech.& Plumbing), Cal State Steel (Structural Steel),Structurlam Products (Heavy Timber), Spectrum Oak (CNC-cut Rafters),Protective Coatings & Linings (Fiberglass), Dandoy Glass (Glazing)

Program: Office Building, Sound Stage, Video Production and Broadcast Facility

Building Area (Square Feet): 25 000sf

Year: 2006-2007

Awards: AIACC Achievement Award, 2008.

Photography: Tom Bonner

3555位于“连接点”(Conjunctive Points),是建筑师和开发商在加州卡尔弗市进行的一个城市规模合作的最新项目,旨在复兴该地区以前破旧的工业和仓库建筑。

最初的砖块结构建于20世纪50年代早期,当时是一个工业仓库,直接坐落在现在废弃的南太平洋铁路公司铁路用地附近。20世纪90年代后期,该建筑添加了一个二层砌体,被改造成了一个摄影棚,供即将进入该地区的电影制作公司使用。最近完成的第二期扩建工程,在现有制作设施之上增加了第三层,用作有线电视台总部的额外办公室和会议空间。

为了容纳第三层,沿着现有屋顶的边缘建造了一个钢梁的“地基”,以分担新楼层的额外荷载。钢柱和木柱从新框架向上延伸,支撑着上面新的起伏的屋顶。屋顶形状是由平均高度限制来确定的,以便允许项目体量按需分配。

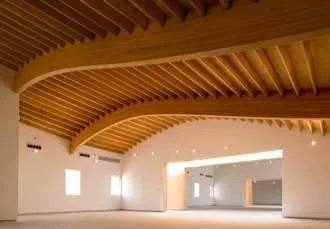

复杂的屋顶几何结构是由42英尺长的胶合木梁在12英尺的中心和2x椽在16”的中心里建造。每一根梁都被层压和铣削成独特的曲率,并在顶部表面有一个不断变化的斜面。CNC铣削的椽在安装时与梁保持垂直,并沿其长度旋转至垂直于屋顶表面的地方。每根椽的一侧都有一个曲线切口,两端都有用于悬挂的凹槽,并有一个磨铣的索引代码,用于屋顶系统内的识别和定位。

3555 is located in Conjunctive Points and is the most recent addition to the ongoing urban-scale collaboration in Culver City, California between architect and developer to revitalize an area of previously dilapidated industrial and warehouse buildings.

The original brick structure was built in the early 1950’s as an industrial warehouse located directly adjacent to a now abandoned Southern Pacific Railroad right-of-way.A masonry second floor was added in the late 1990’s as the building was converted into a sound stage for incoming film production companies in the area.A recently completed second expansion phase adds a third floor for additional office and conference space above the existing production facilities as a headquarters for a cable television station.

In order to accommodate a third floor, a “foundation” of steel beams was built along the perimeter of the existing roof to distribute the additional load of the new floor.Steel and wood columns extend upward from the new frame to support the new undulating roof above.The roof shape is determined by height limit averaging in order to allow the program volume to be distributed as needed.

The complex roof geometry is constructed with 42 foot long glue-laminated wood beams at 12 foot centers and 2x rafters at 16” centers.Each beam was laminated and milled to a unique curvature and has a continuously changing bevel on the top surface.CNC-milled rafters were installed perpendicular to the beams and rotated to be perpendicular to the roof surface along their length.Each rafter has a curve cut on one side, is notched on either end for hanging, and has a milled index code for identification and location within the roof system.

顶棚内视图 Interior view of ceiling

剖面透视图 Section perspective line drawing