A Veteran Potter

2021-01-09TextbyChenYongWangQiZhengYiWangYaliPhotosbyLiuZhongcan

Text by Chen Yong, Wang Qi, Zheng Yi & Wang Yali Photos by Liu Zhongcan

On an unknown mound deep in Wujiashan Mountain of Yingcheng in Central China, stands a nameless kiln. There is only a kiln, a small workshop, and an old man who’s been there for his whole life.The old man, a 69-year-old potter named Hu Guangrong, is the owner of the kiln. His family have been potters for four generations. Mr. Hu started learning the art of pottery from his grandfather and father when he was a child.

Sandwiched between the Qingming River and Fu River, Wujiashan Mountain boasts clean water and moist soil. With claylike soil rich in quartz plus ample firewood, the village has a long history as the birthplace of “kiln pottery” ranging from large wares like water jugs and pots to smaller items like teapots and salt shakers. The locally made potteries may not be exquisite, yet it is definitely durable and functioning.

In his workshop, Hu wears an apron and puts the well-prepared clay on the rotating wheel to form and shape it.

Gently supporting the mouth of the muddy product with his left hand, Hu’s right thumb separates from the other four fingers around the pot’s mouth, while skillfully and slowly he forms a circle out of the bulging rim, which gradually encircles the mouth.

It involves 27 steps such as sourcing clay, preparing clay, creating form, trimming, drying, glazing and the like before a piece of handmade pottery comes into being. Hu used to make a clay body in an average of 3 minutes before the age of 40. “At that time, I could do the job with my eyes closed without making any mistakes, but not any more, I am getting older and older...”

Trimming the clay molding 拉坯

应城伍家山深处的一个土丘上,隐藏着一个窑厂。说是窑厂,其实连招牌都没有。只有一口窑,一个棚,还有一个坚守的老人。

老人名叫胡光荣,今年69 岁,祖上四辈都是土陶制作手艺人,他从记事起,便跟祖父、父亲制作陶器。

伍家山背靠清明河、府河,水土洁净,黏土中富含石英砂,加上柴火充裕,历史上,这里就盛产“窑货”。大到水缸、大罐,小到茶壶、盐罐,说不上精美,但个个适用、耐用。

窑边工棚里,胡光荣系上布围裙,将和好的泥土,搭上拉坯的转盘,旋转做成一个个土陶壶身。

就着厚厚的泥脚,胡光荣用左手轻轻撑扶着壶口,右手拇指与四个指头分开,掐着口沿内外,慢慢将口沿捋出一圈鼓突的泥筋,口沿收紧。

Finished potteries after firing 陶器出窑

Entering his storage room, the neatly piled pottery attracted our attention. The big ones looked round and bulging, while the small ones seemed petite and exquisite. Their red earthen surfaces mirror the rays of sunlight. It is said that using the teapot made here can keep the tea cool and sweet, and the tea won’t become smelly overnight, even in the hot summer time. Some semi-finished products are kept on the other side of the room, which have been air-dried and ready to be fired in the kiln. The firing process in the kiln takes 6 to 10 hours, once every 10 days. The temperature of the kiln needs to be above 800℃, which he controls by experience.

When the kiln is being opened and the first batch of products sees the light, Ni Liping is always waiting outside. He is an online businessman in Yingcheng City, as well as a super fan of Hu.

In 2013, Ni Liping happened to learn of this unique potterymaking in Wushan Village. So he came to visit the village and got to know Hu. Since then he has frequented his kiln to purchase the earthenware, which he sold online through e-commerce platforms.

“This pottery is simple, natural, and traditional. With its traditional functions, it’s very popular among people interested in art, as well as health-minded circles at home and abroad.” Ni Liping said. “It is the best season now for drinking herbal tea. Drinking big leaf teas in these handmade pots is the best relaxation after a long day’s work.”

However, fewer and fewer locals can make pottery of this kind nowadays. “Young people are not keen on doing this anymore. I stick to it here for the time being. When I get older, I’ll ask one of my disciples to come back and take it over,” Hu said, with loneliness in his voice. “Really, pottery made of this clay-like earth can nourish one who is close to it.”

(Translation: Lu Qiongyao)

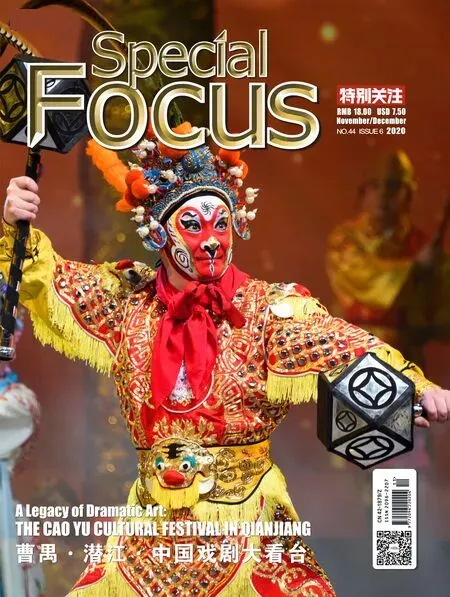

Hu Guangrong making pottery in his primitive workshop胡光荣在简陋的工棚内制作陶器

Controlling the fire temperature in the kiln窑前把控火候

取土、和泥、打型、拉坯、晾坯、上色……一件土陶器,要经过27 道工序,方能成型。40 岁以前,胡光荣平均3 分钟就能做好一把土陶壶的壶身。“那时,我可以拿布蒙上眼睛,纯凭手感做,现在不行,年纪大了……”

进入棚内储物间,一边堆放的是各种已烧好的陶器,大壶圆圆鼓鼓,小壶娇小玲珑,浓浓的土红色泛着光。夏天用这种壶泡茶,隔夜不馊,而且又凉又甜。另一边,是已晾晒好准备入窑烧制的半成品,10 天一个周期,一窑土陶器要烧6到10 小时,800℃以上的窑温,火候全凭经验把控。

每到开窑的日子,倪理平必然在窑外等候。他是胡光荣的“铁粉”,在应城做电商。

2013年,一次偶然的机会,倪理平知道了伍山村有烧窑制陶的绝活儿,于是慕名上门,从此两人相识。

他定期来收购胡光荣烧制的土陶制品,通过电商平台,网上“带货”。

“这些土陶制品朴拙纯厚,兼具养生功能,很受海内外文艺、养生圈子内人士喜欢。”倪理平说,到了饮用凉茶的季节,土陶壶、大叶茶是人们辛劳一日的最好慰藉。

如今,会烧制土陶的人越来越少了。“现在年轻人哪个还做这?我一个人暂时守着吧,守不动时,让在外打工的‘关门弟子’回来接手……”胡光荣的话语里,隐隐透着落寞,“其实,还是这种泥土制成的陶器养人啊。”