Effects of admixture on properties of recycled aggregate mortar

2020-10-15MiRenjiePanGanghuaLiYang

Mi Renjie Pan Ganghua Li Yang

(1 School of Materials Science and Engineering, Southeast University, Nanjing 211189, China)(2 Jiangsu Key Lab of Construction Materials, Nanjing 211189, China)(3 Jiangsu Collaborative Innovation Center, Nanjing 211189, China)(4 Department of Architecture and Civil Engineering, City University of Hong Kong, Hong Kong 999077, China)

Abstract:Compared with strengthening the recycled fine aggregate (RFA) from construction and demolition waste, which is time-consuming and complex, adding admixture into the mixtures directly is more efficient and effective to expand the application of recycled aggregate mortar(RAM). The admixture (named as SSC), mixed with sodium hexametaphosphate, sodium ligninsulfonate and citric acid, was directly added into the RAM. First, the compositions and physical properties of the RFA and reference aggregate were studied, respectively. The properties of fresh and hardened mortars were then investigated. The results show that there is a clear difference between the RFA and reference aggregate, and the properties of RAM without SSC are not as good as those of normal mortar. However, the consistency value, water retention rate, compressive strength and setting time values of RAM increase by 5%,7%, 66% and 67%, and its consistency loss and density values decrease by 42% and 4% after the SSC is added into the RAM. Therefore, improving the properties of RAM through adding admixture is an effective and efficient approach to expanding its application.

Key words:construction and demolition waste; recycled fine aggregate; recycled aggregate mortar; admixture

Construction and demolition waste (CDW) has put a burden on the environment. Therefore, using the recycled fine aggregate (RFA) produced by the waste concrete in CDW to replace natural fine aggregate (NFA) can lower the pollution generated by CDW[1]. However, the RFA shows a high crush value, a high water absorption and a high powder content[23], so that the RFA cannot be widely used by mortar plants[46]due to its adverse impacts on the density[710]and consistency[7,1011]of fresh mortar, and on the setting time[9]and drying shrinkage[710,12]of hardened mortar. Therefore, many methods have been developed to enhance the properties of the mortar with RFA. For example, Pan et al.[23]increased the content of carbonated compounds in the RFA by calcium hydroxide pre-soaking. The results show that there is a significant improvement on the properties of aggregate, and on the flowability and compressive strength of the mortar. However, the processes of the above-mentioned strengthening method may require much time. Thus, these methods cannot be widely applied in actual projects.

Fortunately, adding admixture directly into the cement-based materials with RFA makes it possible to shorten the procedure. Meanwhile, admixture can improve the properties of cement-based materials. For example, sodium ligninsulfonate (SL) and sodium hexametaphosphate (SH) benefit the cement hydration because they can induce the dispersion of the cement particle by favouring mutual repulsion and hindering flocculation[1315]. Additionally, SH and citric acid (CA) are responsible for prolonging the setting time of mixtures by forming an adsorption layer on the surface of the cement particle, which can isolate the contact of water from cement minerals and hinder the release of the ions into the solution[1314, 1617].

However, it is still unclear whether admixture can improve the properties of recycled aggregate mortar (RAM). Therefore, in this study, SL, SH and CA were directly added into the RAM. The objective of this research is to investigate whether the used admixture can improve the properties of fresh and hardened RAMs. This study is significant because it can remind readers to add admixture directly to improve the properties of RAM rather than spending a lot of time to strengthen the properties of RFA for obtaining high-quality RAM. This can help mortar plants maximize the recycling of CDW and further mitigate the CDW pollution on the environment.

1 Materials and Experiments

1.1 Materials

1.1.1 Aggregate

River sand was used as the NFA, while the RFA was prepared by the CDW from housing in Zhenjiang in the 1980s. The CDW was offered by the Jiangsu Zhenjiang Research Institute of Building Science Group Co., Ltd. after be stored for 1 year. Afterwards, it was subjected to a primary crushing procedure for preparing the RFA and then put indoors for natural preservation. The fineness modulus of NFA and RFA are 2.7 and 2.8, respectively.

1.1.2 Cementitious materials

P·O 42.5 Portland cement which has properties that conform to the requirements of a Chinese specification[18]was provided by the Jiangsu Helin Cement Corporation. Its physical properties and chemical components were tested according to a Chinese specification[18]and the results are listed in Tabs.1 and 2, respectively. Additionally, the Zhenjiang Jianbi Power Plants provided the fly ash (FA) which is defined as level-2 based on the requirements of a Chinese specification[19]. The thickening powder, whose properties are given in Tab.3, was supplied by the Jiangsu Zhenjiang Research Institute of Building Science Group Co., Ltd.

Tab.1 Properties of P·O 42.5 Portland cement

Tab.2 Chemical composition of P·O 42.5 Portland cement %

Tab.3 Properties of thickening powder

1.1.3 Admixture

The SL, SH and CA were offered by the Shanghai Yunzhe New Material Technology Company, Tianjin Hengxing Chemical Reagent Manufacturing Company and Sinopharm Chemical Reagent Company, respectively. In this study, the SL, SH and CA were mixed at a ratio of 2: 6: 1[20]and then the mixed admixture was labeled as SSC. The SSC was added into the mortar mixtures at 0.5% of the binding materials.

1.2 Experiments

1.2.1 Preparation

According to the specific surface area method for mix proportion design[21], the specific surface area of aggregate should be decreased as much as possible to lower the consumption of cement. Thus, during the mix proportion design of RAMs, most researchers[2224]replaced NFA using the volume-replacement method since the density values of the RFAs in these studies were lower than those of the NFAs. However, in this study, the packing density of the NFA (1 520 kg/m3) is lower than that of the RFA (1 580 kg/m3). Thus, the authors decided to replace the NFA using the weight-replacement method to lower the specific surface area of the aggregate.

Mortar mixtures with a compressive strength grade of 10 MPa were prepared, and the mix proportions were designed based on the specific surface area method[21]and the requirements in a Chinese specification[25], and the results are listed in Tab.4. Three kinds of mixtures were prepared: 1) The mixtures with the NFA were used as the reference (REF); 2) The mixtures with the RFA at a replacement rate of 100% were labeled as the RAM; and 3) The mixtures with the RFA at a replacement rate of 100% and with SSC were labeled as RAM+SSC. The mortar mixtures were cast in some plastic molds, compacted using a vibrating table, covered with a plastic sheet and then cured in a laboratory. The specimens were demolded after 24 h and further cured in a water curing tank at (27±1)℃ for 27 d. After that, all the specimens were removed from the curing tank for various tests.

Tab.4 Mix proportions of mortars

1.2.2 Testing

The tests were divided into three groups and all the mean values of the properties for mortar specimens were obtained by three measurements. Firstly, two types of experiments were conducted to test the properties of fine aggregates: 1) The X-ray diffraction (XRD) patterns of the fine aggregates were collected using a D8 Advance instrument from Bruker AXS; and 2) The physical properties including crush value, water absorption rate, powder content, and packing density of the fine aggregates were obtained based on two Chinese standards[2627]. Secondly, four types of experiments were conducted to test the properties of the fresh mortars based on the Chinese specification[28]. The consistency and consistency loss after 2 h were obtained, while the water retention rate and apparent density were achieved based on the Chinese standard[29]. Thirdly, based on the Chinese standard[29], the experiments for the setting time and compressive strength at 28 d were conducted for the hardened mortars.

2 Results and Discussion

2.1 Aggregate

2.1.1 Composition

To investigate the composition of the fine aggregates, the XRD patterns are shown in Fig.1. As seen, quartz was detected in both the RFA and NFA, whereas CaCO3(CC) present in the form of calcite was only detected in the RFA. This is in agreement with Pan et al.’s work[2]. This is because the concrete members were subject to CO2attacks for approximately 30 years. Thus, most of Ca(OH)2in the cement paste has been transferred into CC due to the carbonation reaction[3031].

Fig.1 XRD patterns for fine aggregates

2.1.2 Physical properties

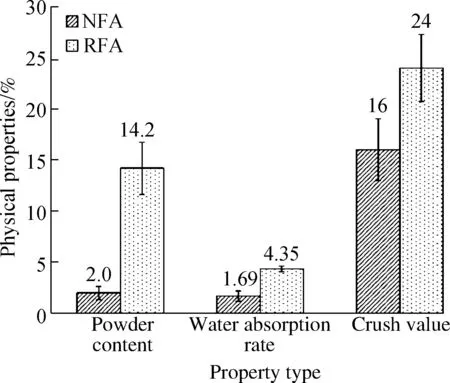

Fig.2 displays the physical properties of the fine aggregates. It is clear that the powder content of the RFA (14.2%) is higher than that of the NFA (2.0%) because the powders are attached to the aggregate during the crushing of CDW. In addition, the water absorption rate of the RFA is 2.66% higher than that of the NFA because more cracks exist in the RFA[2]. Moreover, the RFA shows a higher crush value, which can also be ascribed to the fact that the RFA has more micro-cracks compared with the NFA[2]. As a result, the RFA shows a lower strength, which increases its crush value.

2.2 Fresh mortar

2.2.1 Consistency

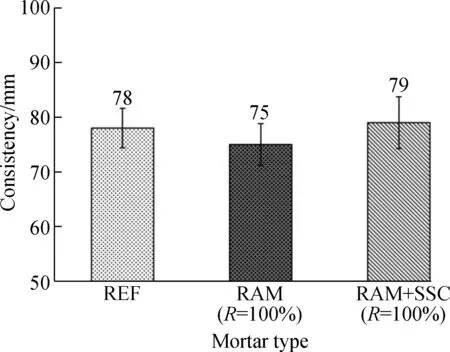

The consistency of fresh mortar is affected by three parameters: 1) The total amount of free water; 2) The rate between water and fine particle; and 3) The roughness of the aggregate surface[11]. Fig.3 displays the consistency values of the fresh mortars. It is evident that the consistency value of the RAM is lower than that of the REF by 3 mm, which is similar to the results obtained in a previous study[7]. This can be explained by two factors:1) The surface of the NFA is smoother than that of the RFA[2]; and 2) The micro powder content of the RFA is higher than that of the NFA (see Fig.2). Therefore, after all the NFAs are replaced by the RFAs, much free water is limited by the flocculate structures formed by micro powers because small particles can generate surface free energy[32].

Fig.2 Physical properties of fine aggregates

Fig.3 Consistency values of fresh mortars

Additionally, the consistency value of the RAM+SSC is higher than that of the RAM by 4 mm and similar to the value of the REF, which means that the SSC has some positive effects on the consistency of the RAM. This is because the amount of free water in the RAM+SSC is higher than that in the RAM because the SH and SL in the SSC can disperse the flocculate structures generated by micro powders[1315]. Thus, much free water is present in the RAM+SSC mixtures.

2.2.2 Water retention rate and consistency loss

Fig.4 depicts the water retention rates and consistency loss values of the fresh mortars. It is evident that the value of consistency loss of the RAM (50.0 mm) is higher than that of the REF (28.9 mm). A possible reason is that the water absorption rate of the RFA is higher than that of the NAF (see Fig.2). Interestingly, the water retention rate of the RAM (89.8%) is also higher than that of the REF (84.5%). This can also be attributed to the results of the water absorption rate.

Fig.4 Water retention rates and consistency loss values of fresh mortars

In terms of the RAM + SSC, their consistency loss value is similar to that of the REF. Due to the fact that the products generated by the complexation between the ingredients of the chemical admixture, the SH and CA in the SSC, and the Ca2+in the cement are hydrophilic[13, 16], much water can remain in the mixtures instead of flowing out.

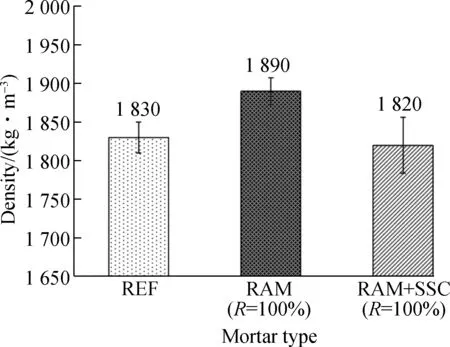

2.2.3 Density

Fig.5 presents the density values of the fresh mortars. It is evident that the density value of the RAM (1 890 kg/m3) is higher than that of the REF (1 830 kg/m3), which is in agreement with the result in Ref.[33]. This is because the water absorption rate of the RFA is higher than that of NFA (see Fig.2). As for the RAM+SSC, their density, which is similar to that of the REF, is lower than that of the RAM by 70 kg/m3as the water-binder ratio is reduced by 0.2 (see Tab.4).

Fig.5 Density values of fresh mortars

2.3 Hardened mortar

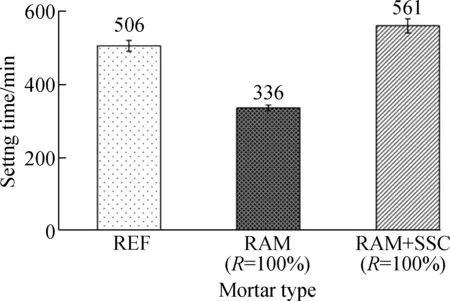

2.3.1 Setting time

The setting time results of the hardened mortars are shown in Fig.6. It is evident that the setting time of the RAM (336 min) is lower than that of the REF (506 min), which is in agreement with the result in Ref.[11]. This behavior might be related to the fact that the high water-retention capacity (see Fig.4) allows the material to hold a large amount of free water during the mortar preparation[2]. As expected, its setting time of RAM+SSC increases by 225 min because the SH and CA in the SSC can retard the hydration of the cement particle[1314, 1617].

Fig.6 Setting time results of hardened mortars

2.3.2 Compressive strength

Fig.7 depicts the compressive strengths and effective water-binder rates (w/beff) of the hardened mortars.w/beffvalue can be calculated as

(1)

wherem1,m2, andm3are the weights of total water, aggregate and binding materials; andPis the water absorption rate of the aggregate after 24 h.

Fig.7 Compressive strengths and effective water-binder rates of hardened mortars

It is evident that the compressive strength of the RAM is higher than that of the REF, which is in agreement with the results of some previous studies[3435]. This phenomenon can be explained as follows: 1) The amount of water in the RFA is higher than that in the NFA because the RFA shows a higher water absorption rate compared with the NFA (see Fig.2), and the water provides an internal curing environment[2, 34]. This facilitates the dense combination with the set cement interface, so that the intensity between the RFA and set cement is significantly increased; and 2) More micro powders are present in the RFA, and these powders serve as filler materials, which decreases the porosity of the mortar[35].

In terms of the RAM+SSC, its compressive strength value is higher than that of the RAM by 9.1 MPa.This phenomenon can be explained as follows:1) The water retention rate of the RAM+SSC is higher than that of the RAM; therefore, much more water is present in the RAM+SSC offering an internal curing environment. 2) The incorporation of SH and SL in the SSC can not only disperse the micro powders in the mixtures and then help the powders more effectively fill into the pores of the cement paste, but also decreases the amount of flocculate structures generated by micro powders and then loosens much free water for cement hydration.

3 Conclusions

1) The consistency value of fresh recycled aggregate mortar (RAM) is lower than that of the reference mortar by 3 mm, whereas the values of consistency loss, water retention rate and density of the RAM are higher than those of the reference mortar by 21.1 mm, 5.3% and 50 kg/m3, respectively. After the admixture is added into the RAM, the consistency value increased by 4 mm, and the consistency loss and density values decreased by 21.1 mm and 70 kg/m3, respectively.

2) The setting time of hardened RAM is lower than that of the reference mortar by 170 min, but the compressive strength value of the RAM is higher than that of the reference mortar by 2.7 MPa. After the admixture is added into the RAM, the setting time and compressive strength increase by 225 min and 9.1 MPa, respectively.

3) Therefore, adding SSC into RAM is an effective and efficient way to expand its application, and future research should pay more attention to the effect of the admixture on the durability of RAM.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Numerical investigation of liquid sloshing in FLNG membrane tanks with various bottom slopes

- Analysis of optimal referral reward programsfor innovative offerings

- Throughput optimization for multi-channel cooperative CR under reporting channel errors

- Modeling the special intersections for enhanced digital map

- Sweedler’s dual of Hopf algebras in

- Investigation of the environmental impacts of steel deck pavement based on life cycle assessment